Cost-saving household garbage incineration slag recycling water treatment process

A technology for domestic waste incineration and water treatment, which is applied in multi-stage water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can save costs, facilitate daily application and reduce power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

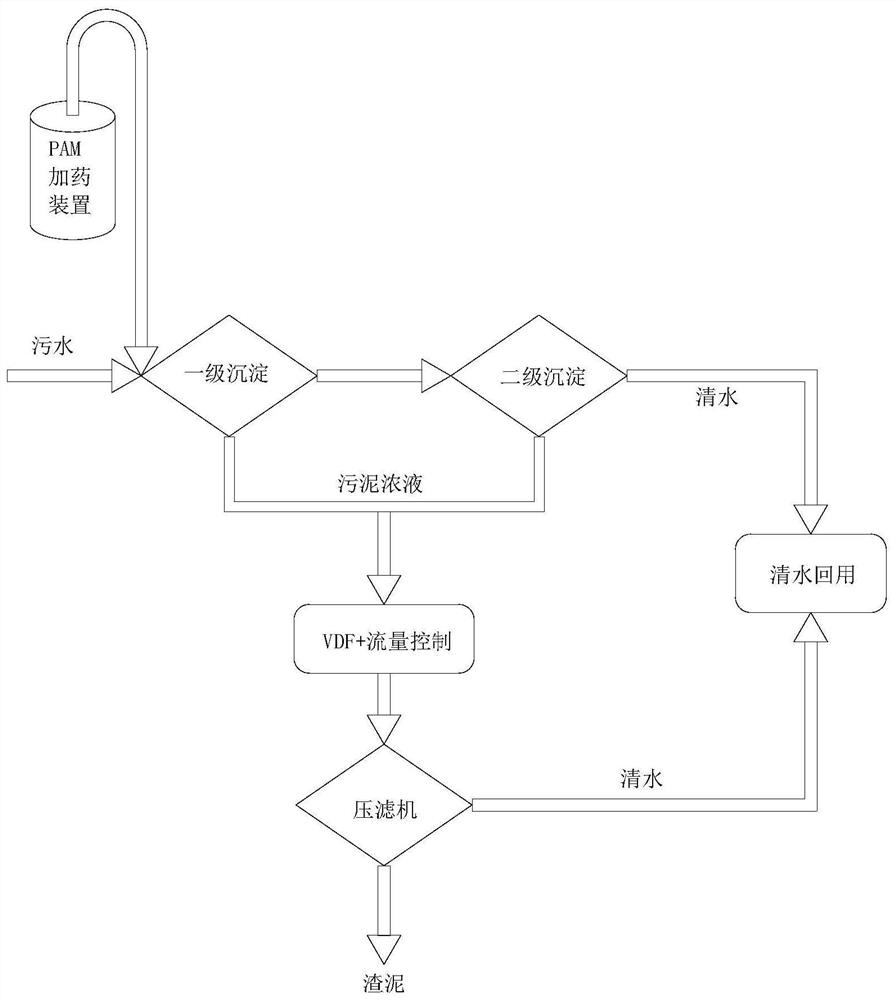

[0037] like Figure 1-3 As shown, the present invention provides a cost-saving trend of domestic waste incinerator slag recovery, which saves cost of domestic waste incinerator slag recycled water treatment processes, including the following steps:

[0038] Step 1, dosing the slag water, specifically:

[0039] A1, incorporating the sewage pipes in the processing system and the pharmaceutical port of the PAM dielectric apparatus into the primary sedimentation tank, controlling the PAM dosing device to put PAM in a ratio of 2 ppm;

[0040] A2, adequately reflected in PAM and sewage, improve the precipitation effect of the overall sewage, achieve the function of reducing the volume of the filter machine, can reduce the electric energy required for the filter machine, enhance the environmental protection of the system;

[0041] Step 2, the first-level sedimentation tank is initially treated, specifically:

[0042] B1, after the hydration is thoroughly mixed, precipitate in the primary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com