Zinc phosphorus aluminum silicate glass with high strain point, fast ion exchange function and weak-acid resistance

A silicate glass, ion exchange technology, applied in the field of glass materials, can solve the problems of affecting yield, reducing glass chemical stability, reducing glass transmittance, etc., and achieving the effect of reducing stress relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

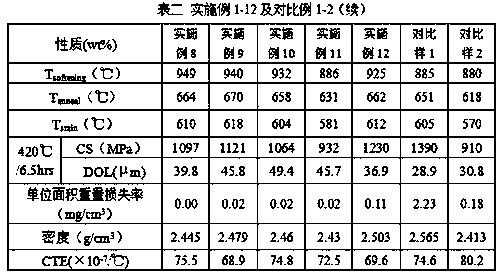

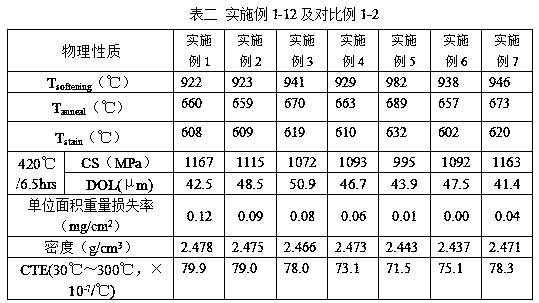

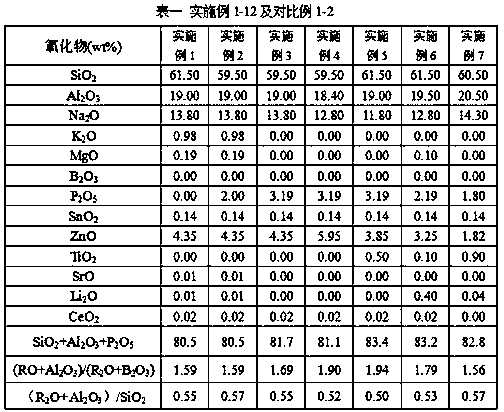

Embodiment 1-12 and comparative example 1-2

[0031] 1. Test sample preparation

[0032] Sample preparation of Embodiment 1-12 and Comparative Example 1-2: Weigh according to the purity and moisture content of raw materials such as quartz sand, alumina, sodium carbonate, etc., and uniformly mix to obtain uniform ingredients; then mix the ingredients from the plastic bottle Transfer to about 800ml platinum crucible, put the platinum crucible into the silicon-molybdenum rod high-temperature furnace, gradually raise the temperature to 1650°C, hold the temperature for 4-8 hours, accelerate the discharge of glass bubbles and homogenize and eliminate the glass by stirring. After melting, pour the molten liquid into a heat-resistant stainless steel mold for molding, then take out the glass block and move it into a box-type annealing furnace for heat treatment at 630°C for about 2 hours, and then lower it to 570°C at a rate of less than 1°C / min , and then naturally cooled to room temperature. The glass blocks were cut and ground...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com