A Cementing Slurry Preservative Applicable to Sour Oil and Gas Reservoirs

A technology for cementing cement slurry and preservatives, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of high cost, cumbersomeness, and many restrictive conditions, and achieves strong H2S corrosion ability, good compatibility, The effect of slowing down the corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

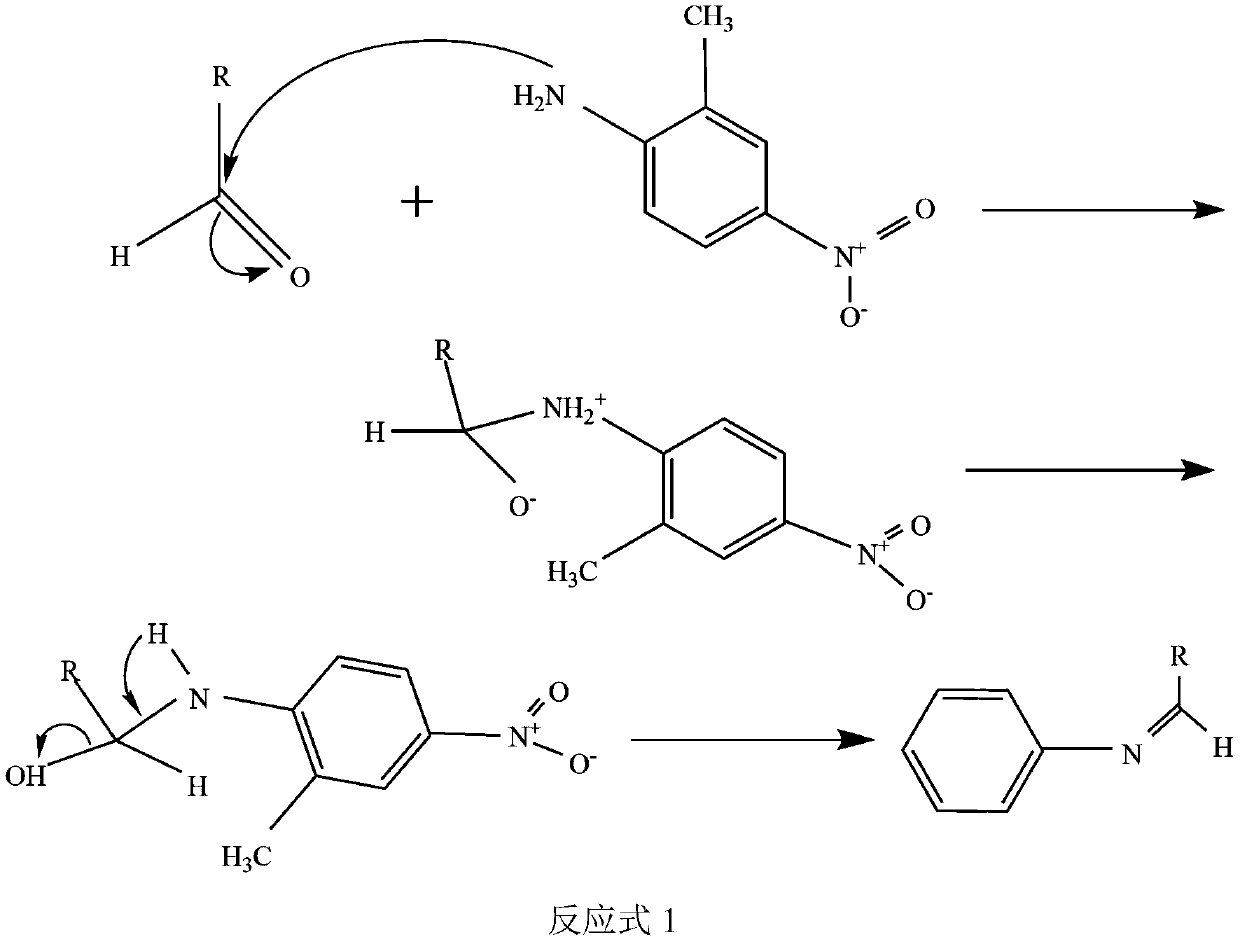

Method used

Image

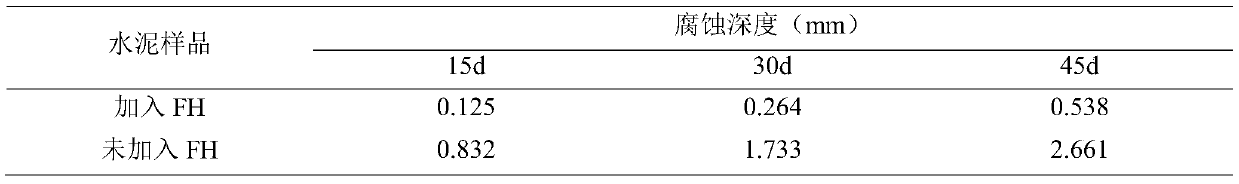

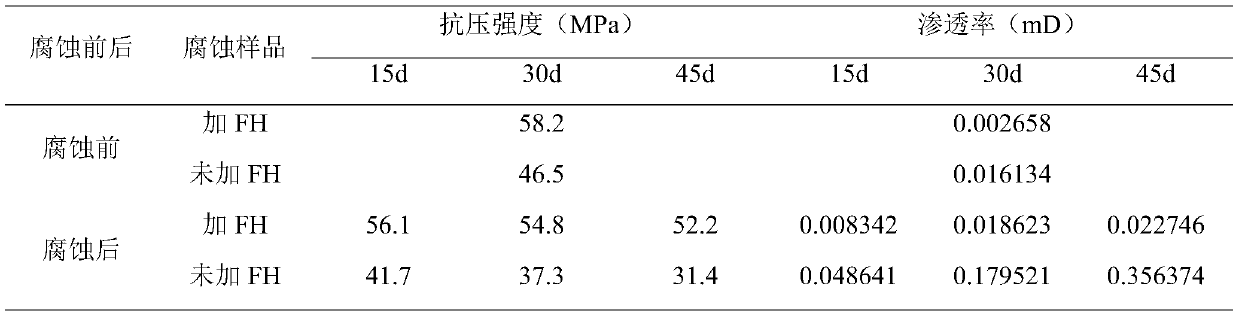

Examples

Embodiment 1

[0027] Parameter conditions for preservative preparation:

[0028] Raw material F: 16g

[0029] Raw material U 1 :U 2 :U 3 =4:3:3

[0030] Polyvinyl alcohol: 2.2g

[0031] Mass percentage of hydrochloric acid: 10%

[0032] NaOH mass percentage: 10%

[0033] Electronic stirrer speed: 350r / min

[0034] Adjust the temperature in the constant temperature water bath to 40°C. After the temperature stabilizes, turn on the electronic stirrer, add 16g of F as raw material, and 2.2g of polyvinyl alcohol, and then add 10% NaOH to adjust the pH of the solution to 8. Then add the first batch of 4g of U, raise the temperature to 75°C, keep this temperature and react for 30 minutes. After reacting for 30 minutes, adjust the pH value of the reaction solution to 5 with 10% HCl solution, and keep the temperature for 15 minutes. After 15 minutes of heat preservation, adjust the pH value of the reaction solution to 5.5 with 10% HCl solution, add a second batch of 3g of U, keep the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com