Cement-based self-leveling mortar and preparation process thereof

A self-leveling mortar and cement-based technology, which is applied in the field of dry-mixed mortar, can solve the problems of easy generation of dust and surface peeling, etc., and achieve the effect of improving water retention, not easy to lose water, and good water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0028] Example of Soybean Flour Preparation

[0029] Take the dried soybeans, put the soybeans into water with a mass ratio of 1:3 to the soybeans, soak the soybeans for 24 hours, remove the soybeans after soaking, add water with a volume of 1:1 to the soybeans, and add The soybeans soaked in water are crushed, and the mixture of the crushed soybeans and water is filtered with gauze, and the obtained filtrate is soybean liquid, and the soybean liquid is vacuum-concentrated to 20% to obtain a concentrated solution, which is sprayed Dry to get soybean powder.

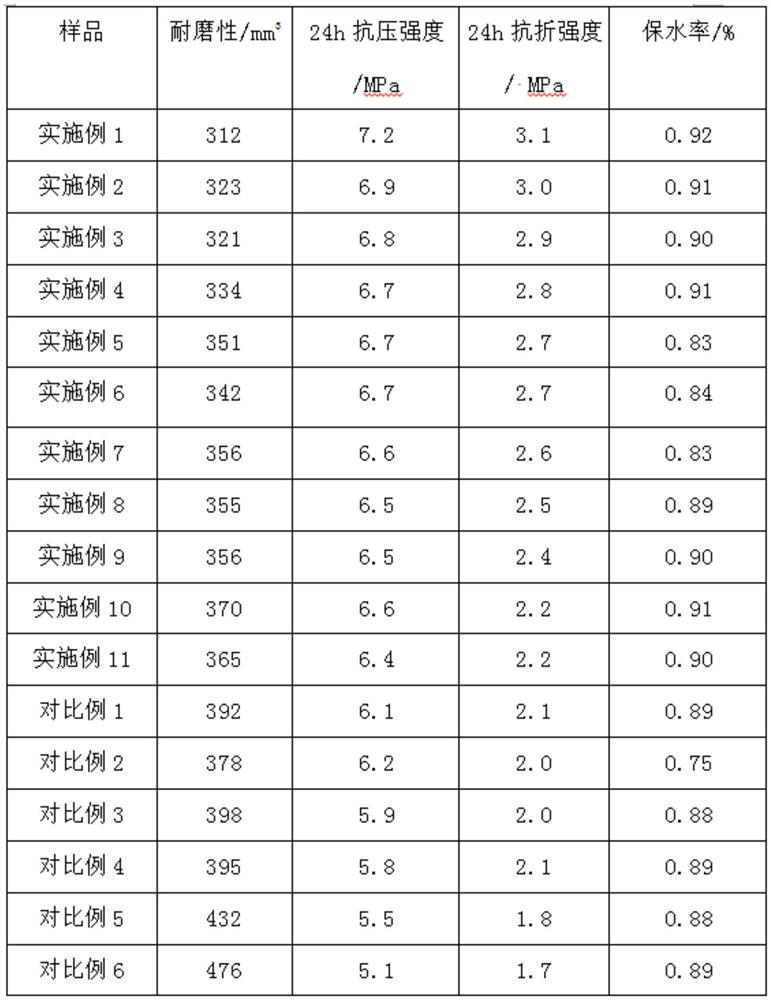

Embodiment 1

[0035] A cement-based self-leveling mortar, the preparation process of which is as follows: 200 kg of Portland cement, 20 kg of desulfurized gypsum, 50 kg of sulphoaluminate cement, 0.55 kg of ethyl cellulose, 0.445kg of carboxymethyl cellulose, 0.8kg of water reducer, 0.5kg of defoamer, 0.2kg of coagulant accelerator, 0.5kg of retarder, 400kg of graded sand, 93.87kg of fly ash , 27.85kg of silicon powder, 9.28kg of talcum powder, 30kg of aliphatic epoxy resin and 20kg of soybean powder, and mix them evenly to obtain a cement-based self-leveling mortar.

Embodiment 2

[0037] A cement-based self-leveling mortar, the preparation process of which is as follows: 250 kg of Portland cement, 40 kg of desulfurized gypsum, 80 kg of sulphoaluminate cement, 0.12 kg of ethyl cellulose, 1.08kg of carboxymethyl cellulose, 1.4kg of water reducer, 0.8kg of defoamer, 0.35kg of coagulant accelerator, 0.9kg of retarder, 500kg of graded sand, 110kg of fly ash , 35kg of silica fume, 10kg of talc powder, 40kg of aliphatic epoxy resin and 40kg of soybean powder, and mix evenly to obtain cement-based self-leveling mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com