Preparation method of freeze-dried modified sepiolite mineral loaded Pd monatomic catalyst

A catalyst and drying technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the complex preparation and processing technology, selectivity and stability of single-atom catalyst carrier Poor performance, low atom utilization rate, etc., to achieve the effect of improving atom utilization rate, good tolerance, and fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

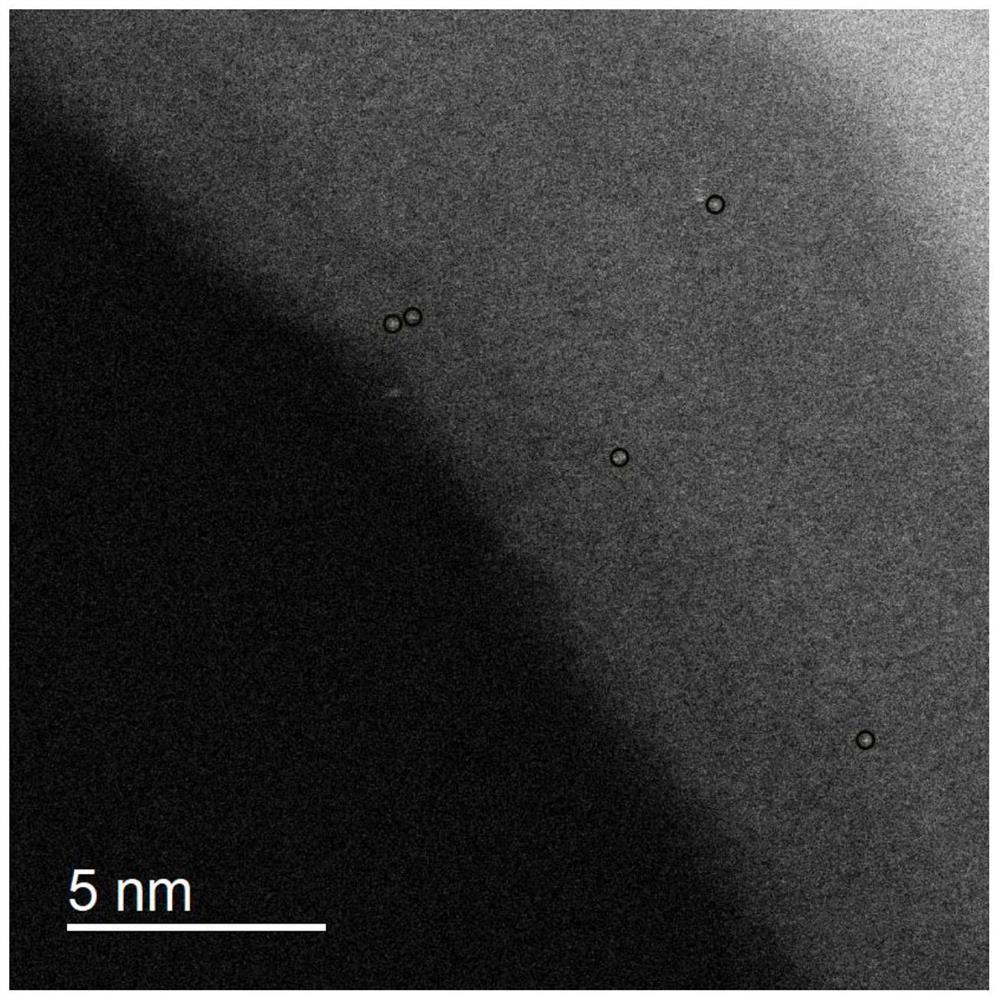

[0034] Weigh 600 mg of sepiolite nanofiber powder (100 mesh) and immerse in 100 ml of deionized water, centrifuge the mixture after ultrasonication for 2 h and discard the supernatant; place the centrifuged solid in a refrigerator at -18°C for 24 h, then place It was transferred to a vacuum freeze dryer, and was freeze-dried at -50°C for 48 hours in a vacuum state. After drying, it was transferred to a vacuum dryer for use; 0.025 mmol of palladium chloride was added to 100 ml of 0.5 mmol / L chloride The sodium solution was stirred for 4 hours, and then 500 mg of treated sepiolite nanofiber powder was added, and then the mixture was transferred to a water bath at 80°C under condensing reflux and continued to stir at a speed of 700 rpm / min for 1 hour, then aged at room temperature for 2 hours, Afterwards, the mixed solution was suction-filtered, washed, and dried at 80° C. for 12 hours to obtain a precursor. Put the precursor into a quartz boat, put it into a tube atmosphere furn...

Embodiment 2

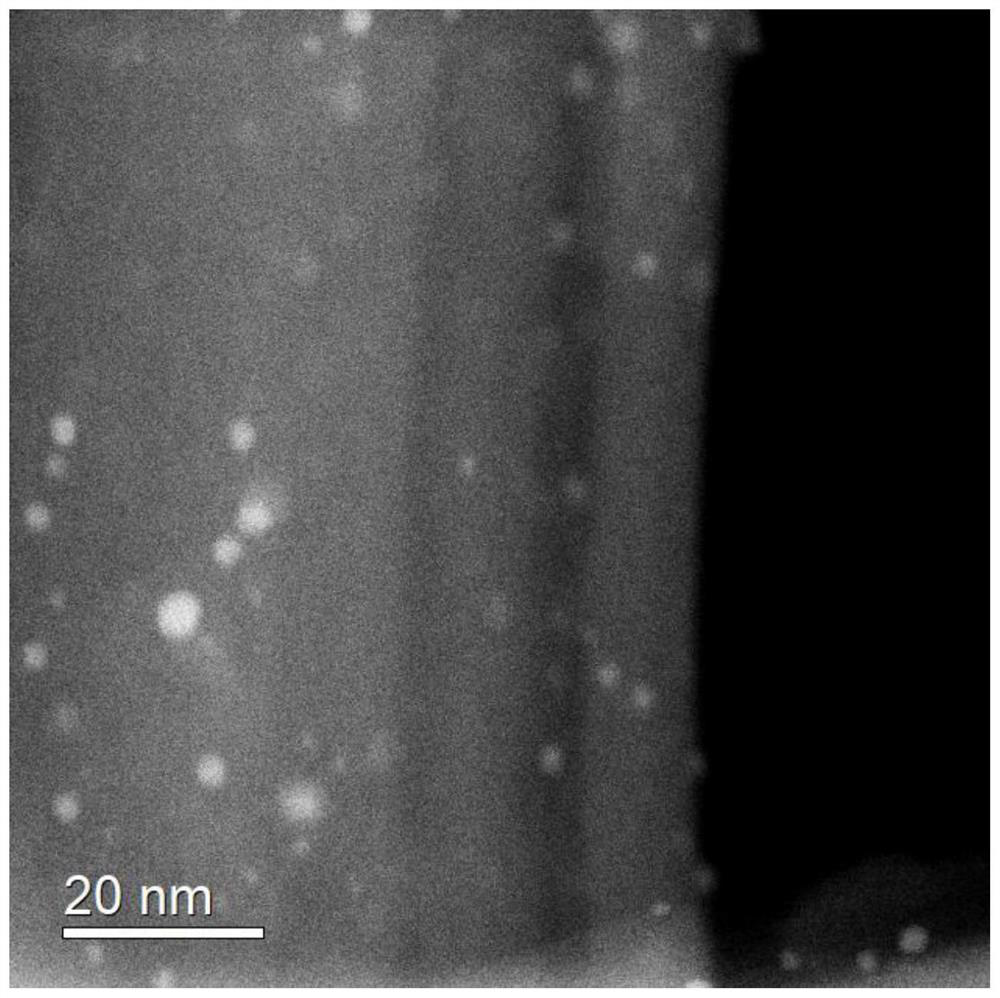

[0037] Other steps are the same as in Example 1, except that "0.025mmol palladium chloride is added to 100ml 0.5mmol / L sodium chloride solution" is replaced by "0.1mmol palladium chloride is added to 100ml 2mmol / L sodium chloride solution".

[0038] The single-atom Pd / sepiolite nanofiber catalyst with higher loading was obtained, indicating that the sepiolite channel has a good confinement effect, and increasing the concentration of palladium chloride solution will not make Pd grow into Pd particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com