Ion exchange resin, and preparation method and application thereof

An ion exchange resin, ion exchange group technology, applied in ion exchange, cation exchange, anion exchange and other directions, can solve the problems of slow ion exchange speed, small specific surface area, large running resistance, etc. The effect of increasing specific surface area and high fluid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

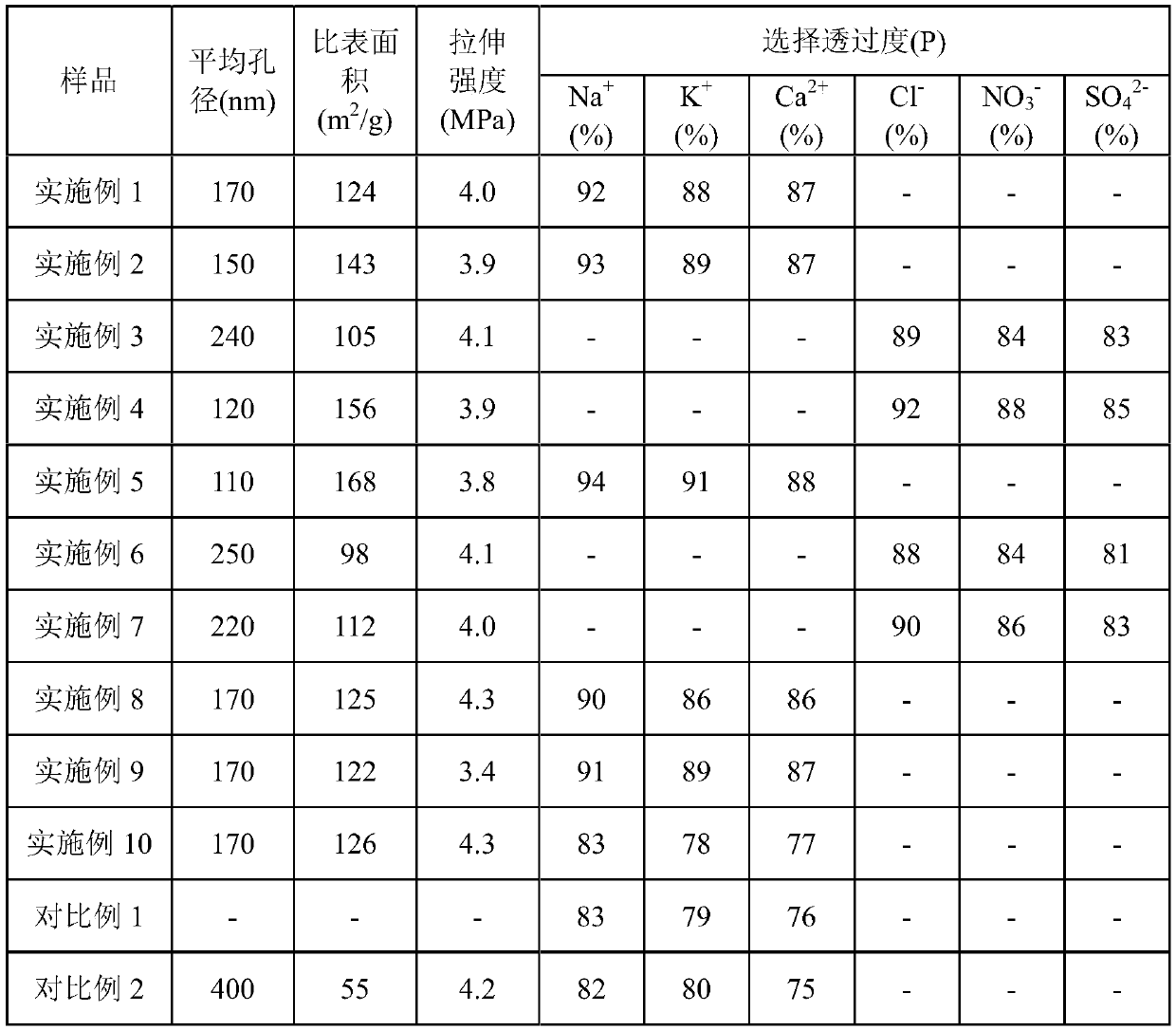

Examples

Embodiment 1

[0051] This embodiment provides a kind of cation exchange resin and preparation method thereof

[0052] Wherein, the fiber average diameter of the cation exchange resin is 200nm.

[0053] The preparation method of present embodiment ion exchange resin is as follows:

[0054] (1) Copolymerize styrene and butadiene to obtain a copolymer, wherein butadiene is 5wt% of the styrene mass; add the copolymer and benzophenone to DMAc, stir for 5h, and prepare a mass fraction of 10wt % spinning solution, wherein, benzophenone is 2wt% of copolymer quality;

[0055] (2) Electrospinning the spinning solution obtained in step (1) to obtain an electrospun fiber membrane, wherein the electrospinning voltage is 20kV, the spinning distance is 20cm, the spinning speed is 1mL / h, and the spinning temperature is 23°C , with a relative humidity of 40%, to obtain an electrospun fiber membrane;

[0056] (3) irradiating the electrospun fiber membrane obtained in step (2) under ultraviolet light for 1...

Embodiment 2

[0058] This embodiment provides a kind of cation exchange resin and preparation method thereof

[0059] Wherein, the fiber average diameter of the cation exchange resin is 180nm.

[0060] The preparation method of present embodiment ion exchange resin is as follows:

[0061] (1) Styrene and butadiene are copolymerized to obtain a copolymer, wherein butadiene is 7wt% of the styrene mass; the copolymer and benzophenone are added in butanone, stirred for 6h, and the mass fraction is prepared as The spinning solution of 12wt%, wherein, benzophenone is 2wt% of copolymer quality;

[0062] (2) Electrospinning the spinning solution obtained in step (1) to obtain an electrospinning fiber membrane, wherein the electrospinning voltage is 15kV, the spinning distance is 23cm, the spinning speed is 1.5mL / h, and the spinning temperature is 25 ℃, relative humidity 45%, to obtain the electrospun fiber membrane;

[0063] (3) irradiating the electrospun fiber membrane obtained in step (2) und...

Embodiment 3

[0065] This embodiment provides a kind of anion exchange resin and preparation method thereof

[0066] Wherein, the average fiber diameter of the anion exchange resin is 230nm.

[0067] The preparation method of present embodiment ion exchange resin is as follows:

[0068] (1) Styrene and butadiene are copolymerized to obtain a copolymer, wherein butadiene is 8wt% of the styrene mass; the copolymer and benzophenone are added in butanone, stirred for 8h, and the mass fraction is prepared as The spinning solution of 15wt%, wherein, benzophenone is 2wt% of copolymer quality;

[0069] (2) Electrospinning the spinning solution obtained in step (1) to obtain an electrospinning fiber membrane, wherein the electrospinning voltage is 22kV, the spinning distance is 17cm, the spinning speed is 2mL / h, and the spinning temperature is 40°C , with a relative humidity of 37%, to obtain an electrospun fiber membrane;

[0070] (3) The electrospun fiber membrane obtained in step (2) was irrad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com