Glass ceramic and preparation method thereof, glass protection layer, glass cover plate and electronic device

A technology of glass-ceramic and glass cover, which is applied to glass protective layer, glass cover and electronic devices, glass-ceramic and its preparation field, can solve the problem of surface microhardness reduction, difficult impact resistance and other problems of ultra-thin glass products. Anti-drop performance, poor chemical tempering effect, etc., to achieve the effect of high surface microhardness, low cost, and excellent tempering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

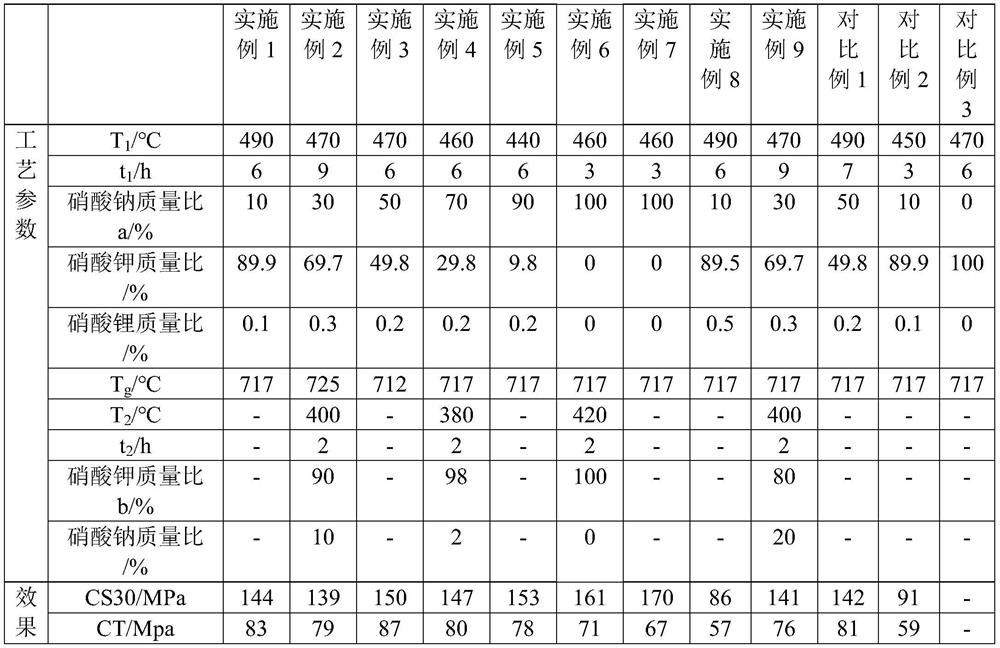

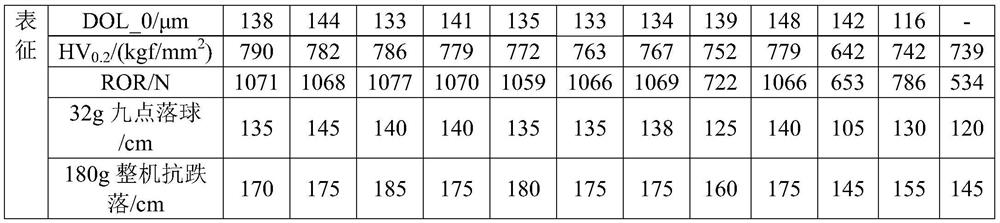

[0039] The invention provides a method for preparing glass ceramics, comprising the steps of:

[0040] Carrying out crystallization treatment on the precursor glass to prepare a glass-ceramics prefabricated part;

[0041] Mixing the glass-ceramic preform with the first molten salt for the first chemical toughening;

[0042] Wherein, the first molten salt comprises at least one of sodium nitrate, potassium nitrate and lithium nitrate;

[0043] The mass proportion of sodium nitrate in the first molten salt is a; the temperature of the first chemical tempering is T 1 ℃, the time of the first chemical toughening is t 1 hour; the glass transition point temperature of the glass-ceramic preform is T g ℃;

[0044] 10%≤a1 +T 1 =(0.75T g -80a)~(0.83T g -100a); or

[0045] 50%≤a≤100%, 10t 1 +T 1 =(0.75T g -50a)~(0.83T g -80a).

[0046]The inventors found that when the tempering process in the first step meets the above conditions, the glass-ceramics can maintain a high ion e...

Embodiment 1

[0076] The present embodiment provides a kind of preparation method of glass ceramics, specifically as follows:

[0077] (1) In terms of weight percentage, the raw materials of the precursor glass are mixed according to the following composition: 69.24% SiO 2 , 8.45% Al 2 o 3 , 12.08% Li 2 O, 2.33% Na 2 O, 4.31% ZrO 2 , and a P of 3.59% 2 o 5 , B 2 o 3 Mixture with MgO.

[0078] (2) Crystallization treatment: first treat at 570°C for 4h, then at 740°C for 1h, the heating rate is 2°C / min, the glass transition point temperature T of the glass-ceramics preform g It is 717°C.

[0079] (3) The first chemical tempering: Mix the glass-ceramic prefabricated parts prepared above with the first molten salt, use Suzhou Xinfu tempering furnace for tempering treatment, and use a contact thermometer for temperature correction, at 490°C The first chemical toughening treatment was carried out for 6 hours; wherein, in terms of mass ratio, the composition of the first molten salt was...

Embodiment 2

[0082] The present embodiment provides a kind of preparation method of glass ceramics, specifically as follows:

[0083] (1) In terms of weight percentage, the raw materials of the precursor glass are mixed according to the following composition: 73.23% SiO 2 , 6.62% Al 2 o 3 , 8.86% Li 2 O, 1.69% Na 2 O, 6.71% ZrO 2 , and a P of 2.89% 2 o 5 , B 2 o 3 Mixture with MgO.

[0084] (2) Crystallization treatment: first treat at 590°C for 6h, then at 670°C for 4h, then at 750°C for 1h, the heating rate is 10°C / min, the glass transition point temperature T of the glass-ceramic preform g It is 725°C.

[0085](3) The first chemical tempering: Mix the glass-ceramic prefabricated parts prepared above with the first molten salt, use Suzhou Xinfu tempering furnace for tempering treatment, and use a contact thermometer for temperature correction, at 470°C The first chemical tempering treatment was carried out for 9 hours to prepare a glass intermediate; wherein, in terms of mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com