Manufacturing process method of all-solid-state lithium ion battery

A lithium-ion battery and manufacturing process technology, applied in the direction of electrolyte battery manufacturing, sustainable manufacturing/processing, secondary batteries, etc., can solve the problems of high energy consumption in drying, low flash point, and low battery safety, and achieve The effect of changing the growth direction, reducing the cost of use, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

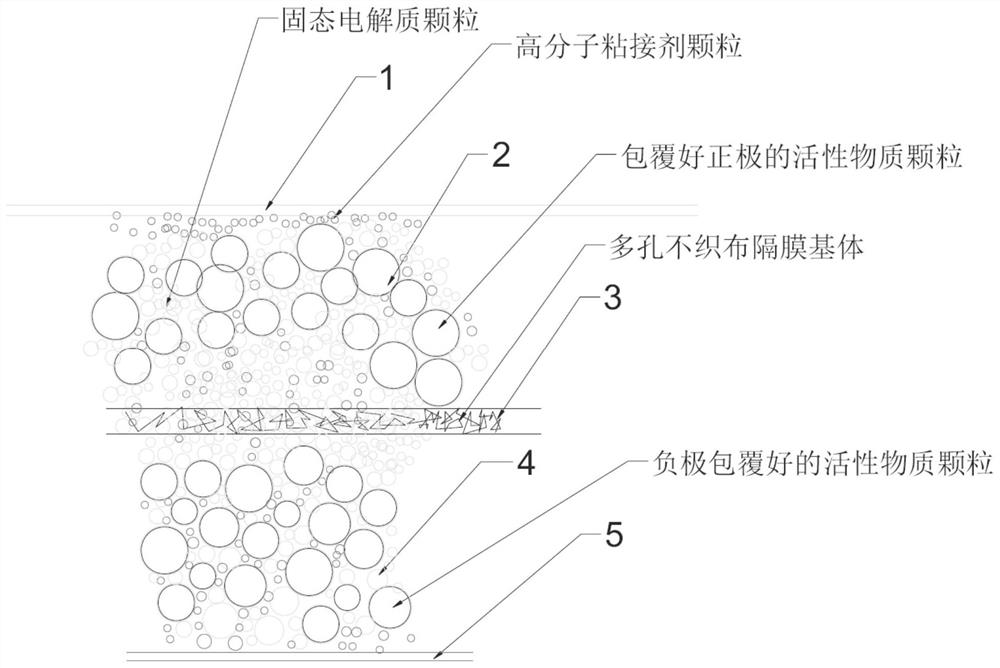

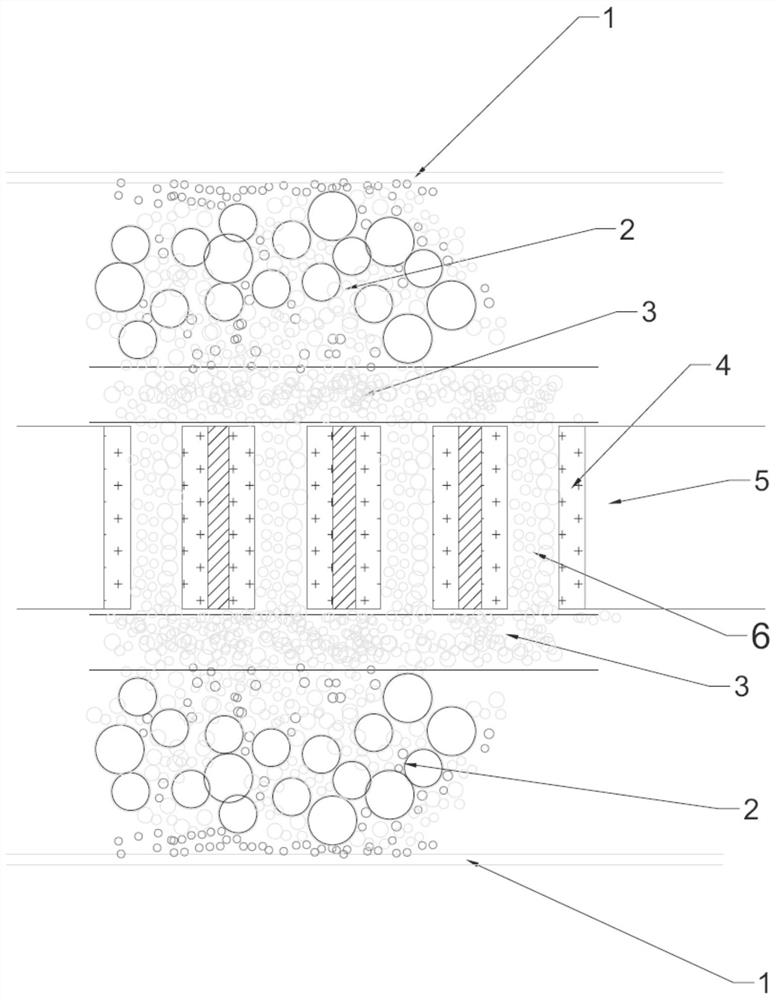

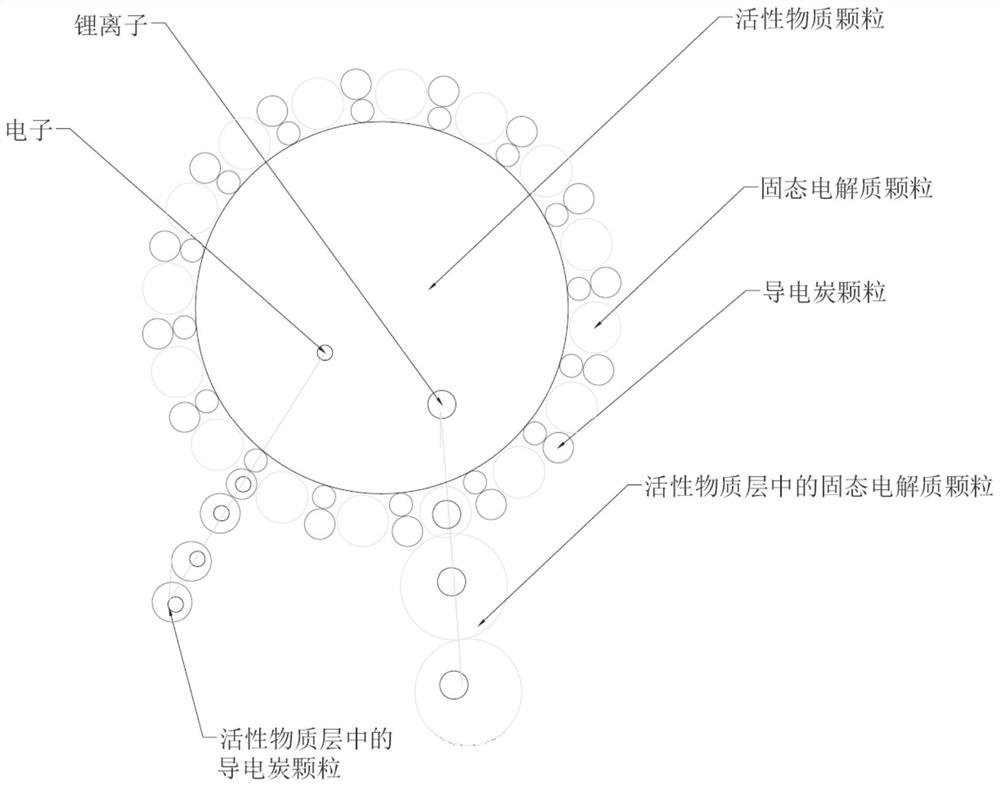

[0023] Such as figure 1 As shown, the positive electrode active material layer includes positive electrode active material (ternary material NCM, NCA and other high-energy positive electrode materials) particles, the size of which is in the order of microns, D50 is 5-20 microns, and its surface has been coated with small particles of carbon black (diameter 30-200 nanometers) and small particles of solid electrolyte particles (30-200 nanometers), carbon black 150-200 nanometers or carbon nanotube fibers, etc. PVDF and solid electrolyte particles have a particle size D50 of 2-9 microns.

[0024] First heat and melt PVDF in a kneading equipment, the temperature control range is 100-250 degrees Celsius (°C), and then add small particles of carbon black, solid electrolyte, and active substances for kneading, and the proportion of active substances accounts for 70%-98%. PVDF accounts for 1.5%-15%, conductive agent 1%-2%, and solid electrolyte particles 2%-10%; then, knead in a mixer...

Embodiment 2

[0032] The positive electrode active material layer includes positive electrode active material (ternary material NCM, NCA and other high-energy positive electrode materials) particles, the size of which is in the order of microns, D50 is 5-20 microns, and its surface has been coated with small particles of carbon black (diameter 30-200 Nano) and small particles of solid electrolyte particles (30-200 nanometers), carbon black 150-200 nanometers or carbon nanotube fibers, etc. PVDF and solid electrolyte particles have a particle size D50 of 2-9 microns.

[0033] First heat and melt PVDF in a kneading equipment, the temperature control range is 100-250°C, then add small particles of carbon black, solid electrolyte, and active substances for kneading, the proportion of active substances accounts for 70%-98%, and PVDF accounts for 1.5% %-15%, conductive agent 1%-2%, solid electrolyte particles 2%-10%; then, knead in a mixer to form a uniform plastic colloidal state, and roll into s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com