A kind of soil improver using waste rubber powder as main raw material and preparation method thereof

A technology of soil improver and waste rubber powder, which is applied in the field of soil improver and its preparation, can solve problems such as soil pollution, achieve the effects of improving soil nutrient content, promoting ion exchange efficiency, and improving soil pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

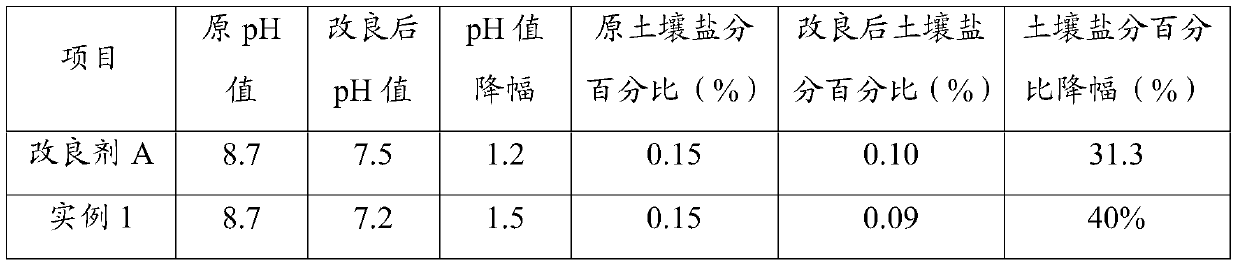

Examples

Embodiment 1

[0024] 1. The raw materials of each component of the soil conditioner are: 315g of waste rubber powder, 150g of desulfurized gypsum, 10g of weathered coal, 15g of kaolin, 5g of activated carbon, 15g of straw, and 1g of organic fertilizer.

[0025] 2. Processing method of soil conditioner:

[0026] (1) After crushing straw and organic fertilizer respectively, pass through a 40-mesh sieve; after pulverizing the waste rubber powder by normal temperature crushing method, pass through a 80-mesh sieve;

[0027] (2) Put the pulverized rubber powder particles, straw, organic fertilizer and other raw materials mentioned above into a mixer and mix evenly, then put them into a granulator for granulation to obtain a granular soil conditioner.

[0028] 3. Application of soil conditioner:

[0029] (1) Select the green belt on the side of the road where snow melting agent has been used in Shanghai Pudong New Area, and level the soil of the green belt, especially the obvious concave and conv...

Embodiment 2

[0034] 1. Raw materials of each component of the soil conditioner: waste rubber powder 300g, desulfurized gypsum 150g, weathered coal 15g, kaolin 10g, activated carbon 5g, straw 15g, organic fertilizer 1g.

[0035] 2. Processing method of soil conditioner:

[0036] (1) After crushing the straw and organic fertilizer respectively, pass through a 60-mesh sieve; after crushing the waste rubber powder by normal temperature crushing method, pass through a 60-mesh sieve;

[0037] (2) Put the pulverized rubber powder particles, straw, organic fertilizer and other raw materials mentioned above into a blender and mix evenly, then put them into a granulator for granulation to obtain a granular soil conditioner.

[0038] 3. Application of soil conditioner:

[0039] (1) Select the same green belt (different locations) on the side of the road where deicing agent has been used, and level the soil of the green belt, especially the obvious concave and convex parts of the improved area;

[0...

Embodiment 3

[0044]1. Raw materials of each component of the soil conditioner: waste rubber powder 275g, desulfurized gypsum 175g, weathered coal 5g, kaolin 20g, activated carbon 5g, straw 15g, organic fertilizer 0.5g.

[0045] 2. Processing method of soil conditioner:

[0046] (1) After crushing the straw and organic fertilizer respectively, pass through a 40-mesh sieve; after crushing the waste rubber powder by normal temperature crushing method, pass through a 70-mesh sieve;

[0047] (2) Put the pulverized rubber powder particles, straw, organic fertilizer and other raw materials mentioned above into a blender and mix evenly, then put them into a granulator for granulation to obtain a granular soil conditioner.

[0048] 3. Application of soil conditioner:

[0049] (1) Select the same green belt (different locations) on the side of the road where deicing agent has been used, and level the soil of the green belt, especially the obvious concave and convex parts of the improved area;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com