A sulfonated polystyrene@mesoporous silica microsphere with egg yolk-shell structure and its preparation method

A technology of mesoporous silica and polystyrene microspheres, applied in chemical instruments and methods, chemical/physical processes, cation exchange materials, etc., can solve problems such as unsatisfactory effects, increased production costs, and low exchange capacity , to achieve the effect of mild conditions, cheap raw materials and high ion exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

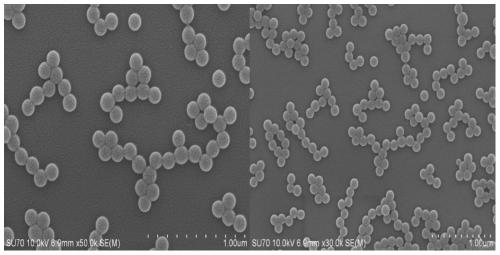

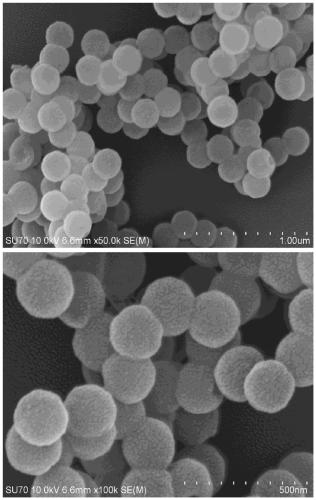

[0033] 1) Under the protection of nitrogen, add 0.6g PVP and 50mL deionized water to the container equipped with stirring magnet and condensing reflux device, stir, then continue to add 6.5mL St, heat up to 75°C, keep the temperature for 10min, add The aqueous solution dissolved with 0.15g KPS was reacted for 24 hours, and the product was centrifuged several times with absolute ethanol and deionized water, purified, and vacuum-dried to obtain monodisperse polystyrene microspheres as a milky white solid powder, which was set aside.

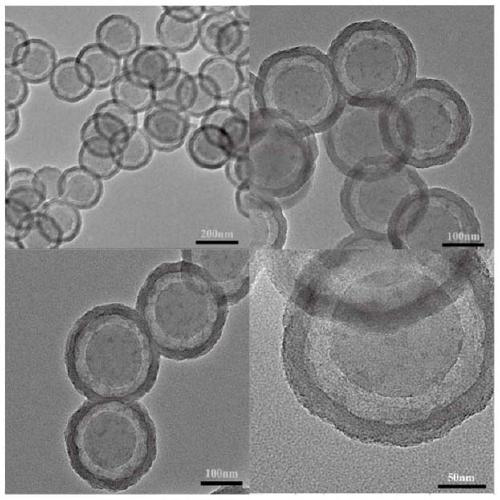

[0034]2) Add 0.2g of the above-mentioned monodisperse polystyrene microsphere milky white solid powder, 60mL of deionized water, 20mL of ethanol, 0.2g of CTAB, and 0.7mL of ammonia water into a three-neck flask, stir at 50°C for 30min, then add 0.5g of TEOS and stir for 2h , then add an aqueous phase solution containing 0.08g CTAB and 0.2mL ammonia water, stir for 30min, dissolve 480μL BTME in 2mL ethanol solution, then add to the above reaction sys...

Embodiment 2

[0037] 1) Under the protection of nitrogen, add 0.4g PVP and 70mL deionized water into the container equipped with stirring magnet and condensing reflux device, stir, then continue to add 5mL St, heat up to 70°C, keep the temperature for 12min, add the dissolved The aqueous solution of 0.2g KPS was reacted for 20h, and the product was centrifuged several times with absolute ethanol and deionized water, purified, and dried in vacuum to obtain monodisperse polystyrene microspheres, which were milky white solid powders, which were ready for use.

[0038] 2) Add 0.3g of the above-mentioned monodisperse polystyrene microsphere milky white solid powder, 40mL of deionized water, 30mL of ethanol, 0.1g of CTAB, and 0.9mL of ammonia water into a three-neck flask, stir at 40°C for 45min, then add 0.8g of TEOS and stir for 1h , then add an aqueous phase solution containing 0.05g CTAB and 0.4mL ammonia water, stir for 15min, dissolve 360μL BTME in 0.5mL ethanol solution, then add to the abo...

Embodiment 3

[0041] 1) Under the protection of nitrogen, add 0.8g of PVP and 30mL of deionized water into the container equipped with stirring magnet and condensing reflux device, stir, then continue to add 8mL of St, heat up to 80°C, keep the temperature for 8min, add the dissolved The aqueous solution of 0.1 g KPS was reacted for 26 hours, and the product was centrifuged several times with absolute ethanol and deionized water, purified, and vacuum-dried to obtain monodisperse polystyrene microspheres as a milky white solid powder, which was set aside.

[0042] 2) Add 0.1g of the above monodisperse polystyrene microsphere milky white solid powder, 80mL of deionized water, 10mL of ethanol, 0.3g of CTAB, and 0.5mL of ammonia water into a three-neck flask, stir at 60°C for 15min, then add 0.2g of TEOS and stir for 4h , then add an aqueous phase solution containing 0.11g CTAB and 0.1mL ammonia water, stir for 45min, dissolve 600μL BTME in 3.5mL ethanol solution, then add to the above reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com