Oil-bearing solid waste resource utilization device and method

A solid waste and recycling technology, applied in the application field, can solve the problems of polluting water bodies, polluting air, polluting soil, etc., and achieve the effects of improving combustion quality and efficiency, increasing fluidization air temperature, and reducing smoke exhaust loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

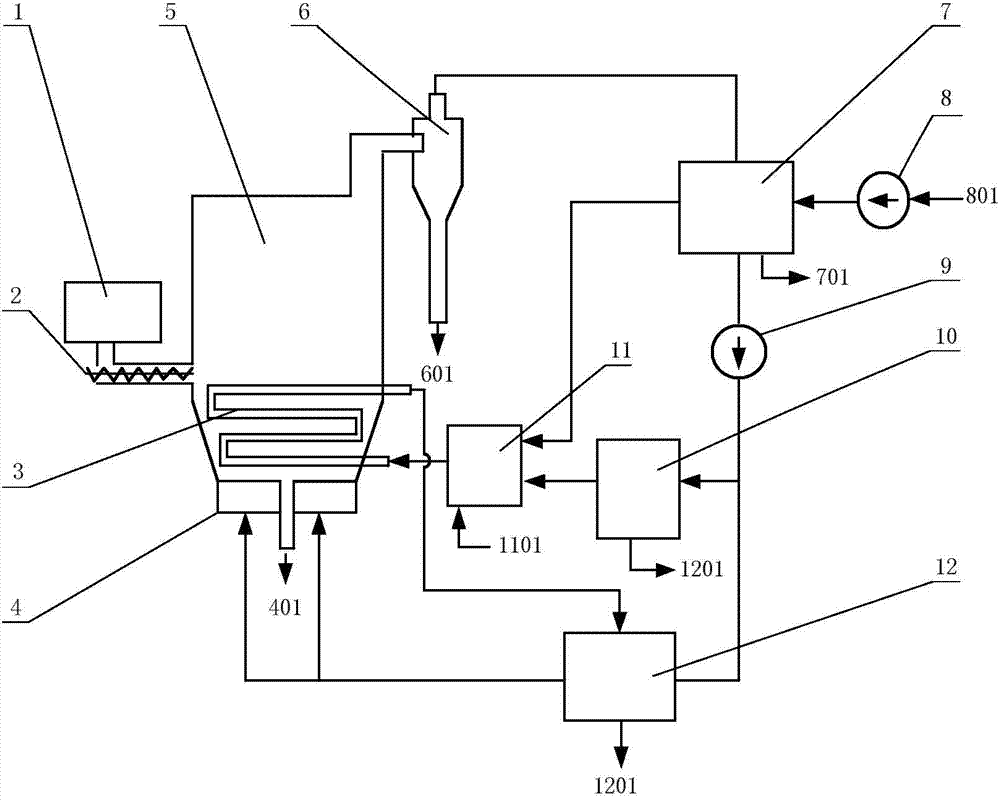

[0041] see figure 1 , the resource utilization device of oily solid waste provided by the present invention, the device includes a silo 1, a feeding device 2, a buried pipe heat exchanger 3, an air chamber 4, a fluidized bed pyrolysis reaction distiller 5, and a dust removal device 6 , air preheater 7, condenser 10, burner 11, fluidized air preheater 10, booster fan 8 and booster fan 9.

[0042] The lower part of the feed bin 1 is connected to the upper part of the inlet of the feeding device 2, and the feeding outlet of the feeding device 2 is connected to the feed port of the fluidized bed pyrolysis reaction still 5, and the fluidized bed pyrolysis reaction still 5. A buried tube heat exchanger 3 is arranged at the bottom, and an air chamber 4 is arranged at the bottom. A slag discharge outlet 401 is arranged in the middle of the air chamber; The top is connected to the top 7 of the air preheater through a pipe, and the dust discharge port 601 is provided at the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com