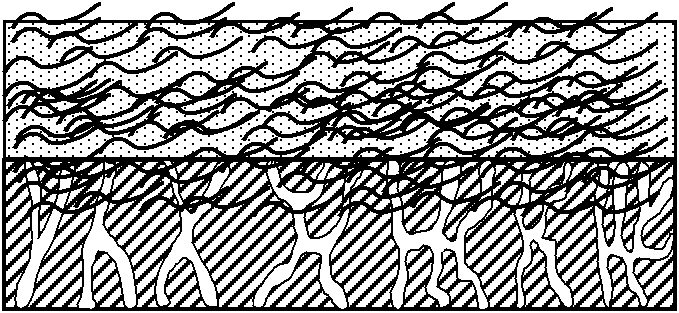

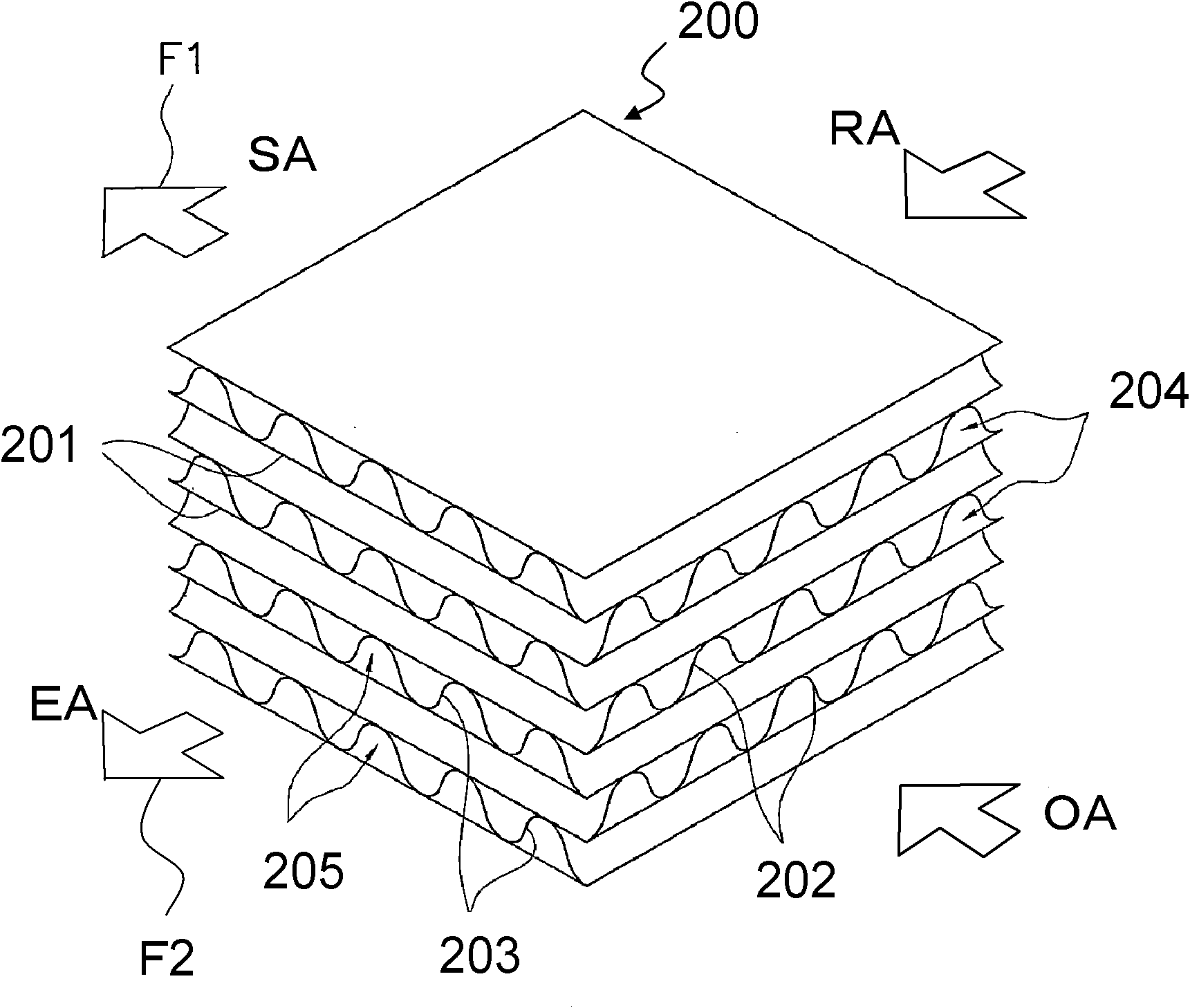

Hydrophilic and hydrophobic compound steam permeation film as well as preparation method and application thereof

A water vapor, composite technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low latent heat exchange efficiency, increased air resistance, low water resistance, etc., to achieve good permeability and The effect of gas selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Add 4g of polyvinyl alcohol and 0.12g of lithium chloride to 120g of pure water, stir at 90-100°C for 1 hour to prepare a polyvinyl alcohol solution, and let the above solution stand for 24-36 hours to obtain A coating solution for a hydrophilic membrane.

Embodiment 2

[0067] Add 2 g of polyvinyl alcohol and 0.10 g of lithium chloride to 100 g of pure water, stir at 90 to 100° C. for 1.5 hours, and prepare a polyvinyl alcohol solution. The above solution was left to stand for 24 hours to obtain a coating solution for forming a hydrophilic film.

Embodiment 3

[0069] 150 g of pure water was added with 15 g of polyvinyl alcohol and 0.15 g of lithium chloride, and stirred at 100° C. for 2 hours to prepare a polyvinyl alcohol solution. The above solution was left to stand for 3 days to obtain a coating solution for forming a hydrophilic film.

[0070] 2. Select sodium polyacrylate as the main component of the hydrophilic membrane

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com