A kind of ion exchange method

A technology of ion exchange and ion exchange column, which is applied in the field of ion exchange of solid substances containing exchangeable groups by ion exchange column, can solve the problems that the process cannot be completed at one time, large industrial waste water, etc., and reduce the cost of washing and regeneration frequency, reduce the frequency of clogging, and prolong the effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

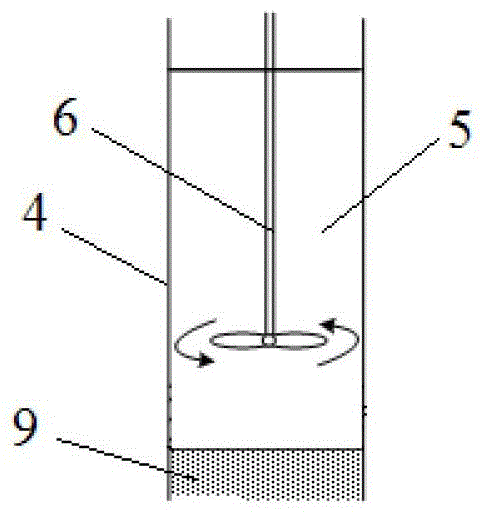

[0069] (1) 240 mL of ammonium-type styrene-based strongly acidic magnetic ion-exchange resin (commercially purchased from Nankai University Chemical Plant, with iron particles as the magnetic core, the content of which is 10% by weight, was loaded into a reactor with an inner diameter of 40 mm, The volume average particle diameter of the ion exchange resin was 720 μm, and the total exchange capacity was 1.8 mmol / mL), and an ion exchange column was obtained.

[0070] Three layers (6 per layer) of inductance coils are evenly arranged along the height direction of the ion exchange column. The inner diameter of each inductance coil is 40mm, the outer diameter is 65mm, the height is 70mm, and the number of turns is 370. The 6 inductance coils in each layer The coils are evenly arranged along the outer circumference of the ion exchange column, wherein the axis of the inductance coil is perpendicular to the axis of the ion exchange column, and the inductance coil is connected to a thr...

Embodiment 2

[0083] Adopt the same method as embodiment 1 to carry out ion exchange, the difference is that a glass tube (inner diameter is 10mm, length is 20mm, outer diameter is 12mm, and this glass tube is the same as ion exchange column) is arranged above the ion exchange resin bed layer. shaft, the distance between the lower end surface of the glass tube and the upper surface of the ion exchange resin bed is 5mm), and air is introduced into the glass tube through the gas channel at a gas inlet speed of 30mL / min, and then the slurry containing molecular sieve Pumped into the ion exchange column for ion exchange.

[0084] The sodium oxide content of each obtained molecular sieve sample is listed in Table 1. After the ion exchange, no deposited ion exchange resin was observed on the upper surface of the ion exchange resin bed in the ion exchange column, and the mass change rate of the solid matter in the ion exchange column before and after ion exchange was 4.9%.

Embodiment 3

[0086] Ion exchange was carried out in the same manner as in Example 1, except that 1 g of NaCl was added to the dispersion as an ion exchange initiator.

[0087] The sodium oxide content of each obtained molecular sieve sample is listed in Table 1. After the ion exchange, the thickness of the molecular sieve deposited on the upper surface of the ion exchange resin bed in the ion exchange column was 1mm, and the mass change rate of the solid matter in the ion exchange column before and after ion exchange was 5.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com