Micro-nano fiber ion exchange resin deiodinating agent and preparation method thereof

A technology of ion exchange resin and micro-nano fiber, which is applied in the field of chemical industry, can solve the problems of poor selectivity and small adsorption capacity, and achieve the effects of many adsorption sites, short mass transfer distance, and increased specific surface area and pore size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

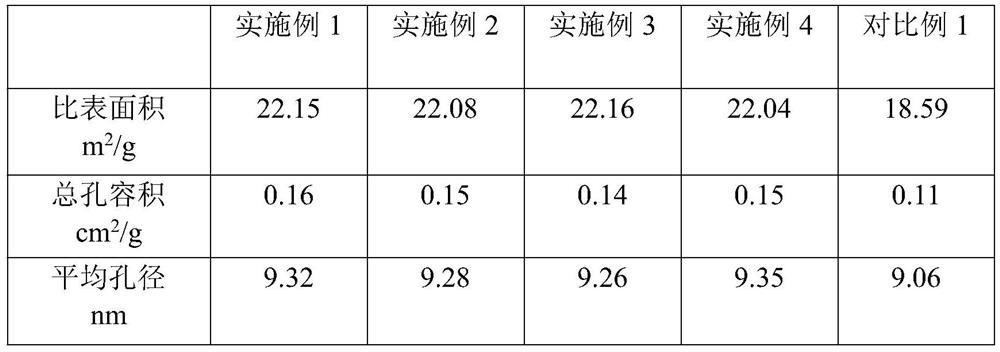

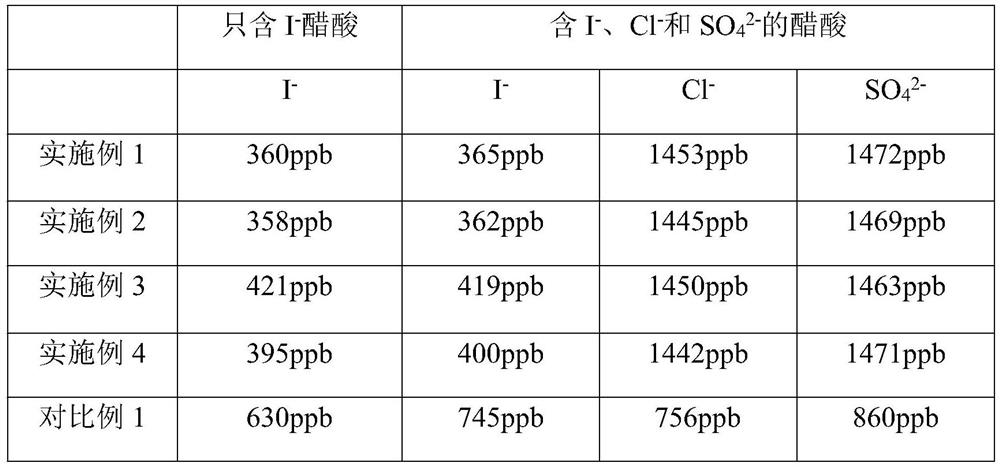

Examples

Embodiment 1

[0021] Step 1: Take 2.5g of polylactic acid and 0.5g of polyvinyl alcohol and mix them evenly, dissolve them in a mixture of 16.7ml of chloroform and 8.3ml of dimethyl sulfoxide, ultrasonicate for 40min, then transfer the solution to a syringe, and spin The fiber is spun horizontally under certain conditions on the device; after spinning, the sample is dried in an oven at 60°C for 6 hours.

[0022] Step 2: Soak 2.4g of the fiber prepared in Step 1 in nitric acid solution for 3 hours, then wash it with deionized water until the washing solution is neutral, then put the washed fiber into a polyethylene sealed bag and discharge the air Infuse nitrogen gas, cool and irradiate with electron beams. After irradiation, place the sample in a mixed solution of 36ml trioctyl / decyl tertiary amine and 36ml silane coupling agent KH-560, and place it in a water bath at 50°C after vacuuming After standing for 3 hours, the samples were alternately washed with methanol and deionized water for 3...

Embodiment 2

[0026] Step 1: Mix 2.7g of polylactic acid and 0.38g of polyvinyl alcohol and dissolve in a mixture of 16.8ml of chloroform and 5.6ml of dimethyl sulfoxide, sonicate for 46min, then transfer the solution to a syringe, and spin The fiber is spun horizontally under certain conditions on the device; after spinning, the sample is dried in an oven at 70°C for 8 hours.

[0027] Step 2: Soak 2.46g of the fiber prepared in Step 1 in nitric acid solution for 2 hours, then wash it with deionized water until the washing solution is neutral, then put the washed fiber into a polyethylene sealed bag and discharge the air Infuse nitrogen gas, cool and irradiate with electron beam. After irradiation, place the sample in a mixed solution of 24.6ml trioctyl / decyl tertiary amine and 36.9ml silane coupling agent KH-560. After standing in the pot for 2 hours, the sample was alternately washed with methanol and deionized water for 3 times, and then dried in a vacuum oven at 70°C for 10 hours to obt...

Embodiment 3

[0031] Step 1: Take 2.6g of polylactic acid and 0.51g of polyvinyl alcohol and mix them evenly, dissolve them in a mixture of 15.5ml of chloroform and 6.2ml of dimethyl sulfoxide, ultrasonicate for 42min, then transfer the solution to a syringe, and spin The fiber is spun horizontally under certain conditions on the device; after spinning, the sample is dried in an oven at 65°C for 7 hours.

[0032] Step 2: Soak 2.49g of the fiber prepared in Step 1 in nitric acid solution for 2 hours, then wash it with deionized water until the washing solution is neutral, then put the washed fiber into a polyethylene sealed bag and discharge the air Infuse nitrogen gas, cool and irradiate with electron beam. After irradiation, place the sample in a mixed solution of 30.1ml trioctyl / decyl tertiary amine and 42.1ml silane coupling agent KH-560, vacuumize and place in a water bath at 48°C Stand in the pot for 2 hours; then wash the sample with methanol and deionized water alternately for 3 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com