Preparation method of high-crystallinity and high-silica-alumina-ratio modified Y-type molecular sieve

A technology with high silicon-aluminum ratio and high crystallinity, applied in crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, separation methods, etc., can solve the problem of difficult balance between silicon-aluminum ratio secondary pore volume and crystallinity, etc. problems, to achieve the effect of excellent hydrophobicity, mild treatment conditions and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

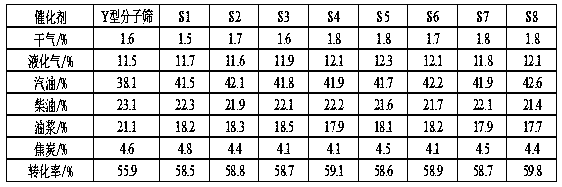

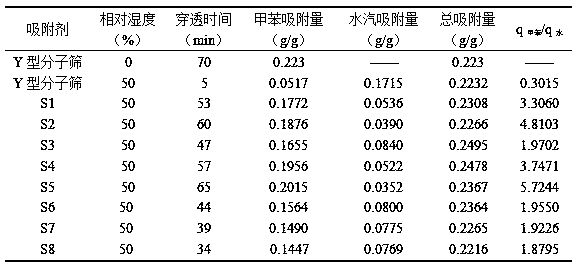

Embodiment 1

[0026] Add Y-type molecular sieve to NH with a pH value of 8.2 at a mass ratio of 1:12 3 ·H 2 O-NH 4 In the Cl buffer system, sealed and stirred at 25°C for 300min, then filtered, and washed with deionized water 1 times the mass of the buffer system to obtain a filter cake; In the acetic acid-ammonium acetate buffer system, it was sealed and stirred at 55°C for 720min, then filtered, washed with deionized water 1 times the mass of the buffer system, finally dried at 100°C for 12h, and roasted at 500°C for 6h to obtain the modified Y Type molecular sieve, number S1, its properties are shown in Table 1.

Embodiment 2

[0028] Add Y-type molecular sieve to Na with a pH value of 12 by mass ratio 1:3 2 CO 3 -NaHCO 3 In the buffer system, seal and stir at 45°C for 50 minutes, then filter, wash with deionized water 3 times the mass of the buffer system to obtain a filter cake; add the above filter cake to nitric acid with a pH value of 2.5 at a mass ratio of 1:35 - In the ammonium nitrate buffer system, stir at 95°C for 350 minutes, then filter, wash with deionized water 3 times the mass of the buffer system, dry at 120°C for 6 hours, and roast at 600°C for 3 hours to obtain the modified Y type Molecular sieve, number S2, its properties are shown in Table 1.

Embodiment 3

[0030] Add Y-type molecular sieve to NaOH-Na with a pH value of 11 at a mass ratio of 1:6 2 HPO 4 In the buffer system, seal and stir at 35°C for 150 minutes, then filter, wash with deionized water twice the mass of the buffer system to obtain a filter cake; add the above filter cake to sulfuric acid with a pH value of 5.5 at a mass ratio of 1:25 -Aluminum sulfate system buffer system, sealed and stirred at 75°C for 580min, then filtered, washed with deionized water 2.5 times the mass of the buffer system, finally dried at 110°C for 8h, and roasted at 550°C for 4h to obtain modification Y-type molecular sieve, number S3, its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com