Method and device for preparing low carbon olefine and arene

A technology for low-carbon olefins and aromatics, applied in the field of catalytic conversion, can solve the problems of low propylene yield, inability to produce low-carbon olefins and aromatics at the same time, moving reforming catalysts, and complex regeneration process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

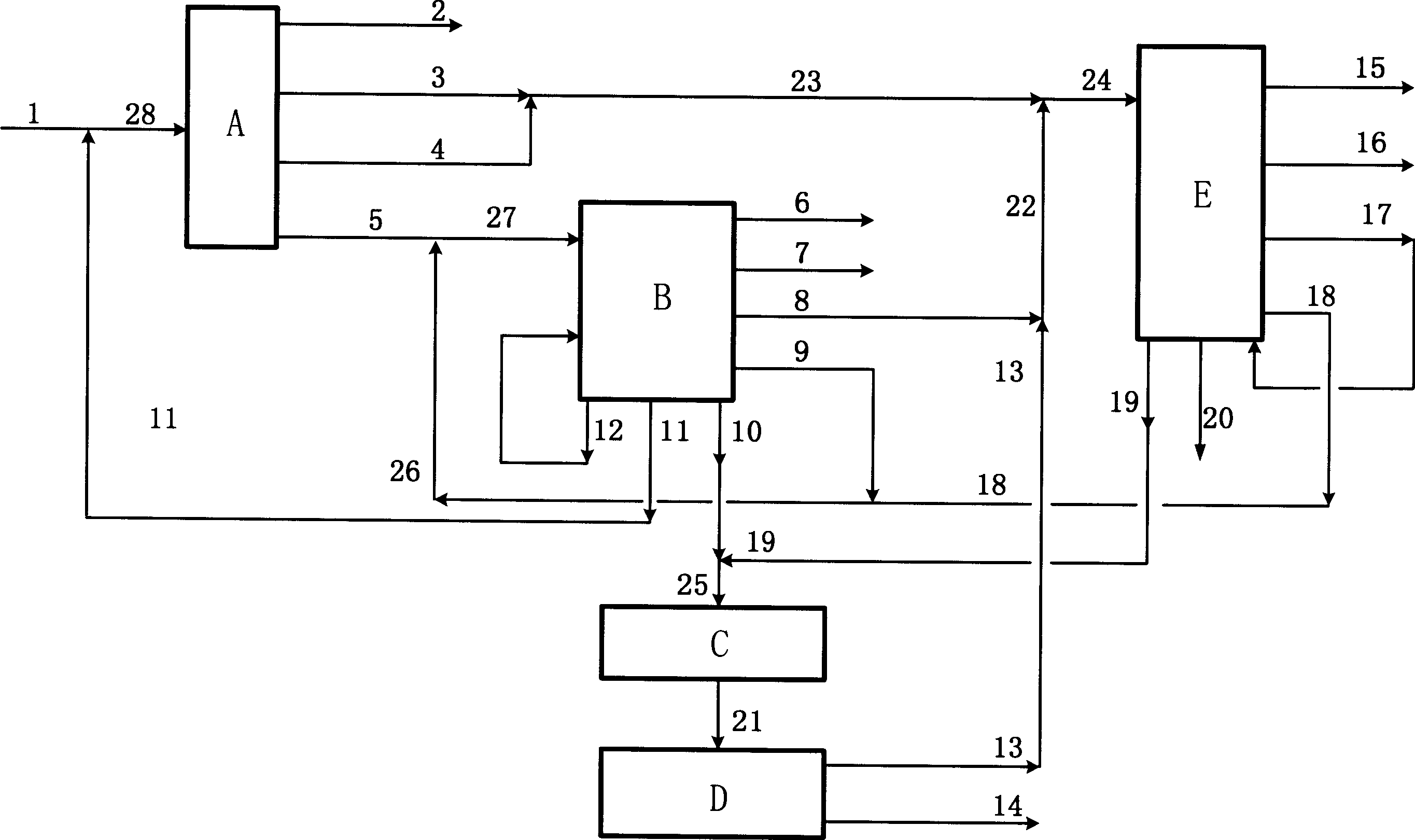

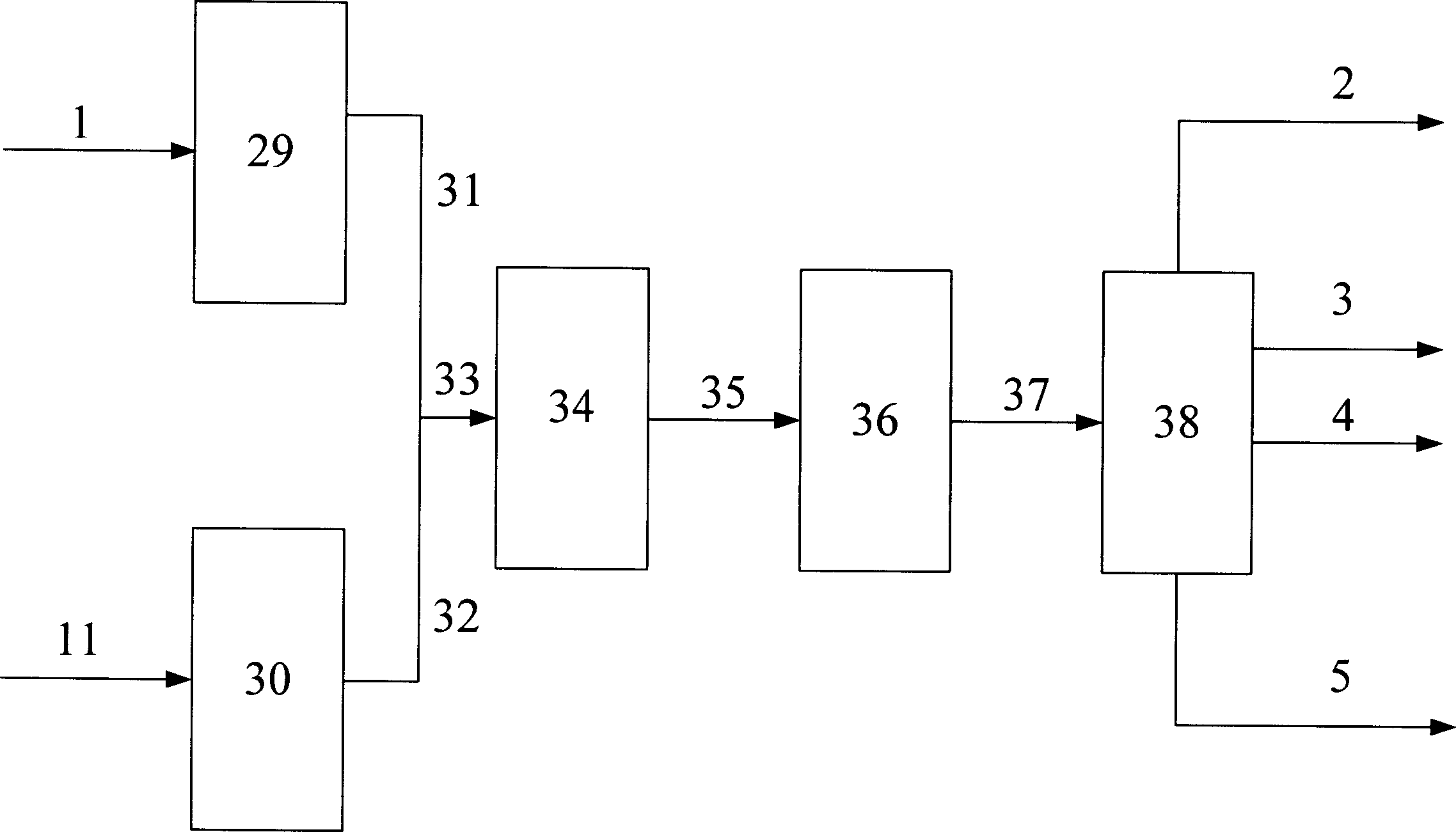

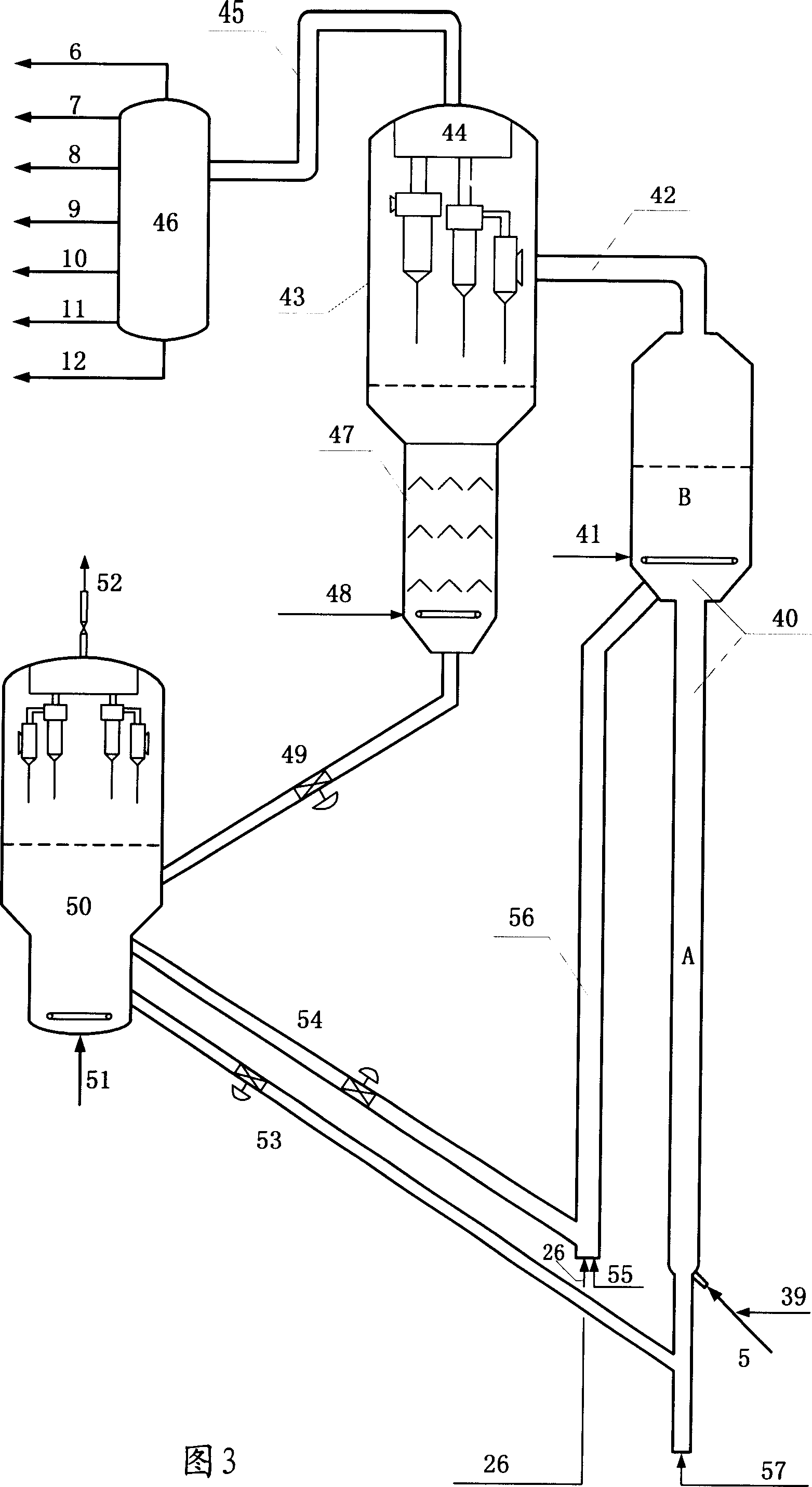

[0100] This example follows figure 1 The process of catalytic cracking is tested, the reactor of catalytic cracking is a medium-sized riser + fluidized bed, and the tests of hydrotreating, steam cracking, selective hydrogenation and solvent extraction are all carried out on the corresponding medium-sized test equipment.

[0101] The operating conditions and product distribution are shown in Table 2. It can be seen from Table 2 that the yields of propylene and ethylene are as high as 40.65% by weight and 20.64% by weight respectively, and the yields of toluene and C8 aromatics are 4.34% by weight and 5.18% by weight respectively.

[0102] Raw oil properties

[0103] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com