Catalytic conversion method for preparing lower olefins and aromatics

A technology of low-carbon olefins and aromatics, applied in the field of catalytic conversion, can solve the problems of low yield of propylene and aromatics, underutilization of low-carbon olefins potential content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

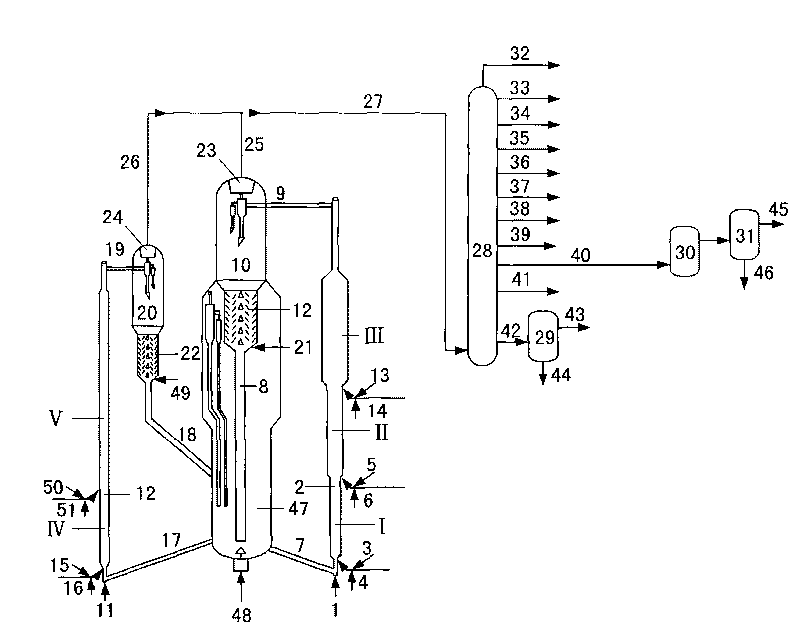

Embodiment approach 1

[0049] The preferred technical solution of this embodiment comprises the following steps:

[0050] (1) The difficult-to-crack raw oil enters the bottom of the first riser reactor and contacts with the thermally regenerated catalytic cracking catalyst. -1 -800h -1 , the reaction pressure is 0.10MPa-1.0MPa (absolute pressure), the weight ratio of catalytic cracking catalyst and raw material is 30-150, and the weight ratio of water vapor and raw material is 0.05-1.0 to carry out the cracking reaction;

[0051] (2) The reaction effluent is not separated from the oil agent, and is mixed with the easily cracked raw material oil. -1 -100h -1 , the reaction pressure is 0.10MPa-1.0MPa (absolute pressure), the weight ratio of catalytic cracking catalyst to raw material is 2-30, and the weight ratio of water vapor to raw material is 0.05-1.0 to carry out the cracking reaction;

[0052] (3) The reaction effluent is mixed with one or more of optional difficult-to-crack raw material oil,...

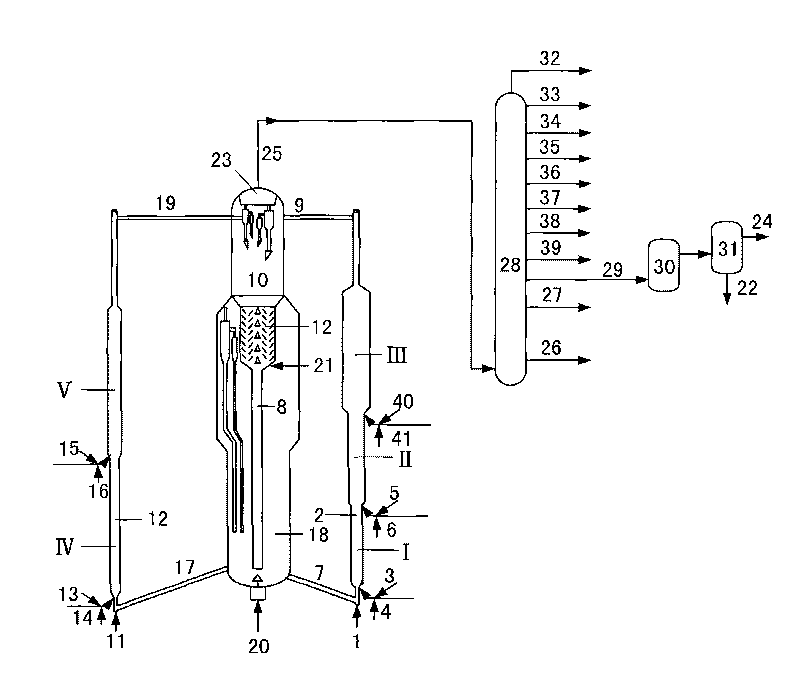

Embodiment approach 2

[0058] The preferred technical solution of this embodiment comprises the following steps:

[0059] (1) The difficult-to-crack raw oil enters the bottom of the first riser reactor and contacts with the thermally regenerated catalytic cracking catalyst. -1 -800h -1 , the reaction pressure is 0.10MPa-1.0MPa (absolute pressure), the weight ratio of catalytic cracking catalyst and raw material is 30-150, and the weight ratio of water vapor and raw material is 0.05-1.0 to carry out the cracking reaction;

[0060] (2) The reaction effluent is not separated from the oil agent, and is mixed with the easily cracked raw material oil. -1 -100h -1 , the reaction pressure is 0.10MPa-1.0MPa (absolute pressure), the weight ratio of catalytic cracking catalyst to raw material is 2-30, and the weight ratio of water vapor to raw material is 0.05-1.0 to carry out the cracking reaction;

[0061] (3) The reaction effluent is mixed with one or more of optional difficult-to-crack raw material oil,...

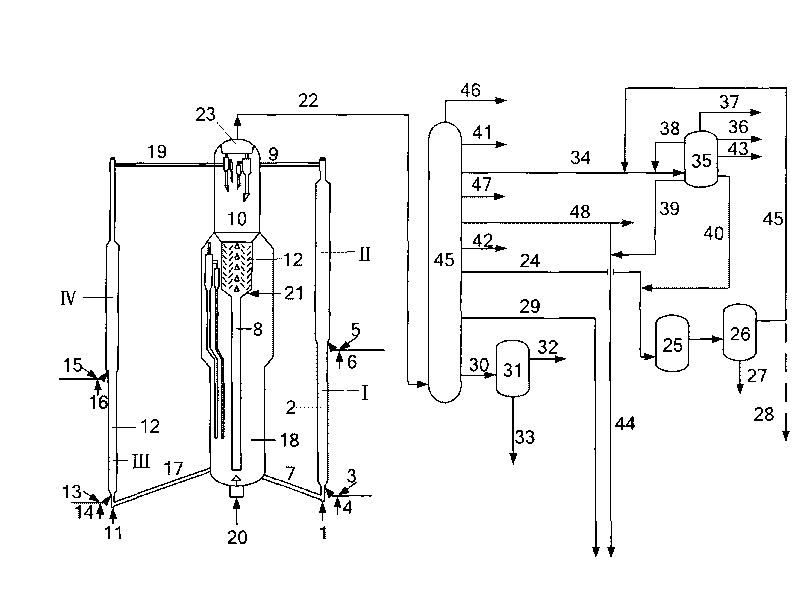

Embodiment approach 3

[0067] The preferred technical solution of this embodiment comprises the following steps:

[0068] (1) The difficult-to-crack raw oil enters the bottom of the first riser reactor and contacts with the thermally regenerated catalytic cracking catalyst. -1 -800h -1 , the reaction pressure is 0.10MPa-1.0MPa (absolute pressure), the weight ratio of catalytic cracking catalyst and raw material is 30-150, and the weight ratio of water vapor and raw material is 0.05-1.0 to carry out the cracking reaction;

[0069] (2) The reaction effluent is not separated from the oil agent, and is mixed with the easily cracked raw material oil. -1 -100h1-1 , the reaction pressure is 0.10MPa-1.0MPa (absolute pressure), the weight ratio of catalytic cracking catalyst to raw material is 2-30, and the weight ratio of water vapor to raw material is 0.05-1.0 to carry out the cracking reaction;

[0070] (3) The reaction effluent is mixed with one or more of optional difficult-to-crack raw material oil, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com