Preparation method of polymer-based conductive microporous foam composite material

A composite material and microcellular foam technology, applied in the field of polymer foam materials, can solve the problems of large cell diameter, poor mechanical properties and electrical conductivity of foam materials, etc., and achieve small cell diameter, high cell density, and mechanical properties. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

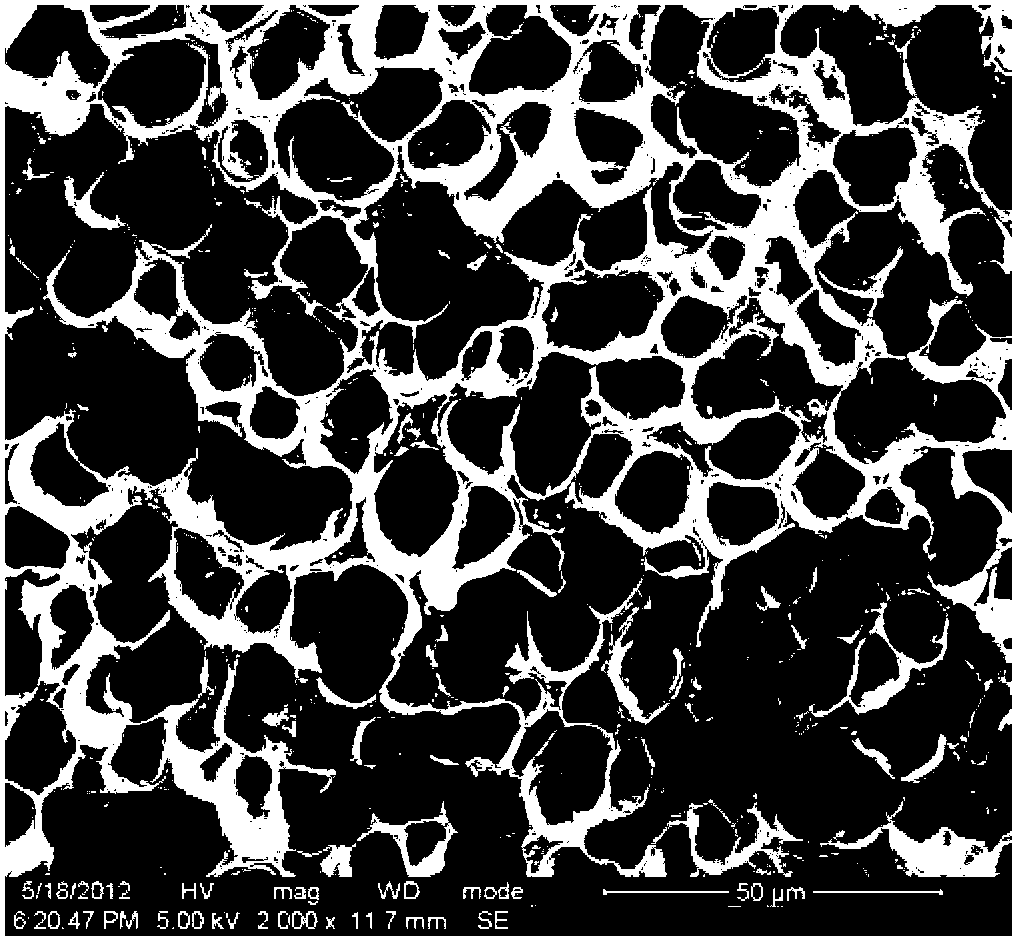

Image

Examples

Embodiment 1

[0027] In this embodiment, polylactic acid (PLA) and hydroxylated multi-walled carbon nanotubes (MWNTs) are used as raw materials. Polylactic acid is produced by NatureWorks Corporation of the United States, model 2002D, which is a semi-crystalline polymer, and the mass content of D-polylactic acid is 4.25%. Density is 1.24 g / cm 3 , Hydroxylated multi-walled carbon nanotubes are produced by Chengdu Organic Chemistry Co., Ltd., Chinese Academy of Sciences, model: TNMH5, purity greater than 95%, -OH mass content is 1.76%, outer diameter: 20-30 nm, length about 30 μm.

[0028] Process conditions and steps are as follows:

[0029] (1) Dissolve 5 g of polylactic acid in 50 ml of dichloromethane solvent, and at the same time disperse 208 mg of carbon nanotubes in 20 ml of dichloromethane by ultrasonic vibration, and then pour the carbon nanotube dispersion into the polylactic acid solution Afterwards, carry out ultrasonic oscillation, and after the carbon nanotubes are uniformly di...

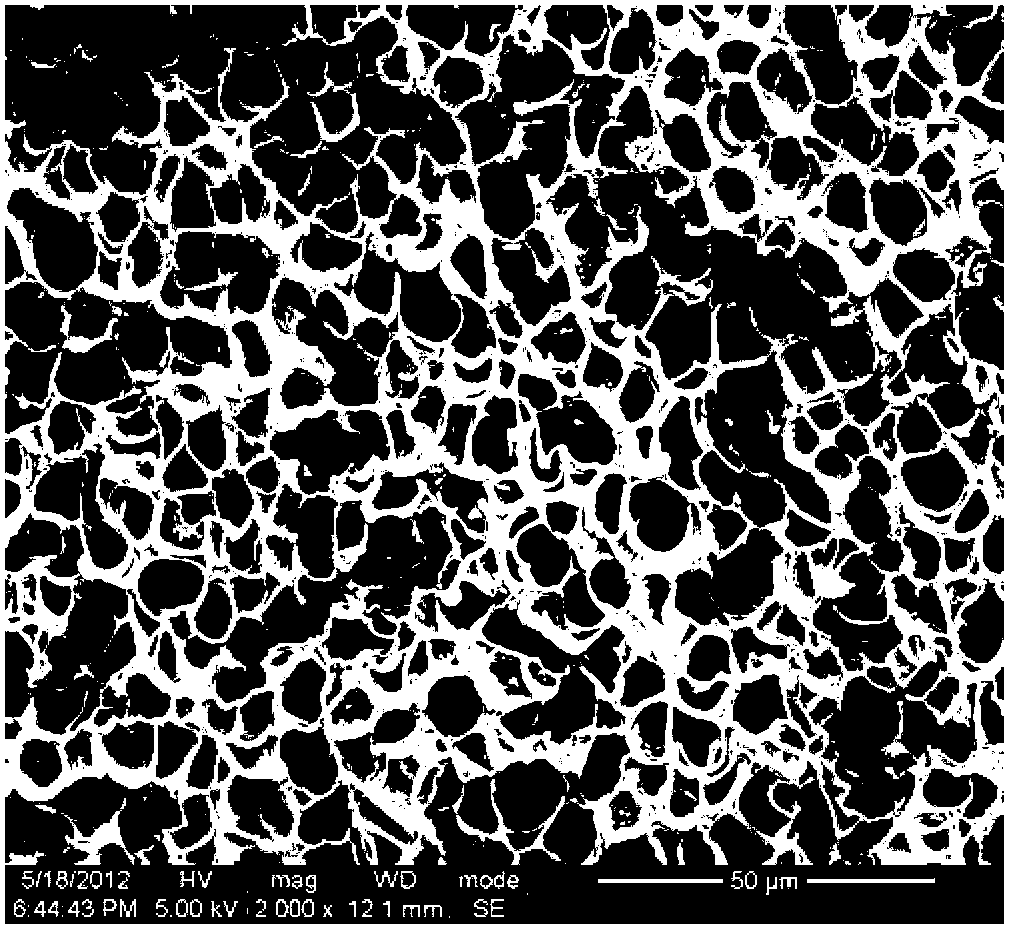

Embodiment 2

[0035] Present embodiment raw material is identical with embodiment 1

[0036] Process conditions and steps are as follows:

[0037] (1) Same as step (1) of embodiment 1;

[0038] (2) Same as step (2) of embodiment 1;

[0039](3) Put the green body obtained in step (2) into a foaming high-pressure reactor, and pass through supercritical CO 2 , the pressure in the reactor is controlled at 24 MPa, the temperature is controlled at 115 ℃, so that the supercritical CO 2 Dissolved into the composite sheet body, when supercritical CO 2 After reaching the saturated state in the composite sheet blank, the pressure in the reactor is released to normal pressure at a pressure relief rate of about 30 MPa / s, and a conductive polymer-based microcellular foam is obtained after cooling and setting composite material.

[0040] Volume resistivity: In order to reduce the contact resistance, after applying silver glue on both ends of the conductive cell, Tonghui TH2684 high-precision insulati...

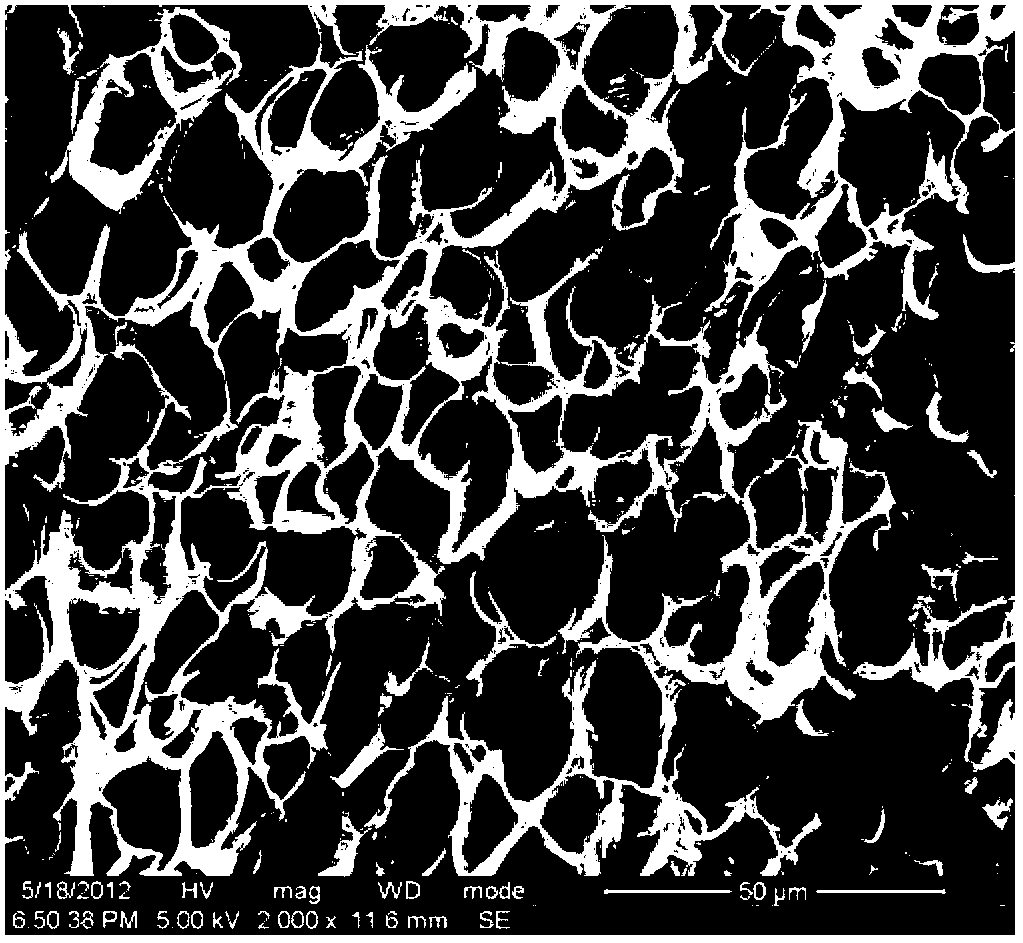

Embodiment 3

[0043] Present embodiment raw material is identical with embodiment 1

[0044] Process conditions and steps are as follows:

[0045] (1) Dissolve 5 g of polylactic acid in 50 ml of dichloromethane solvent, while ultrasonically dispersing 102 mg of carbon nanotubes in 20 ml of dichloromethane, and then pour the carbon nanotube dispersion into the polylactic acid solution Afterwards, carry out ultrasonic oscillation, and after the carbon nanotubes are uniformly dispersed, pour the dispersion liquid into a glass petri dish with a cover to volatilize the solvent. PLA / MWCNTs composite material with a mass fraction of 2%;

[0046] (2) Same as step (2) of embodiment 1;

[0047] (3) Same as step (3) of Example 1.

[0048] Volume resistivity: In order to reduce the contact resistance, after applying silver glue on both ends of the conductive cell, Tonghui TH2684 high-precision insulation resistance tester is used to test the resistance, and the volume resistivity of the conductive f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com