Immobilized enzyme based protein enzymolysis method

An immobilized enzyme and protein enzyme technology, applied in the field of protein enzymatic hydrolysis and protein enzymatic hydrolysis based on immobilized enzyme, can solve the problems of enrichment of protein samples to be tested, affecting the efficiency and accuracy of enzymatic hydrolysis, and improve the detection rate. , the effect of improving efficiency and fast sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

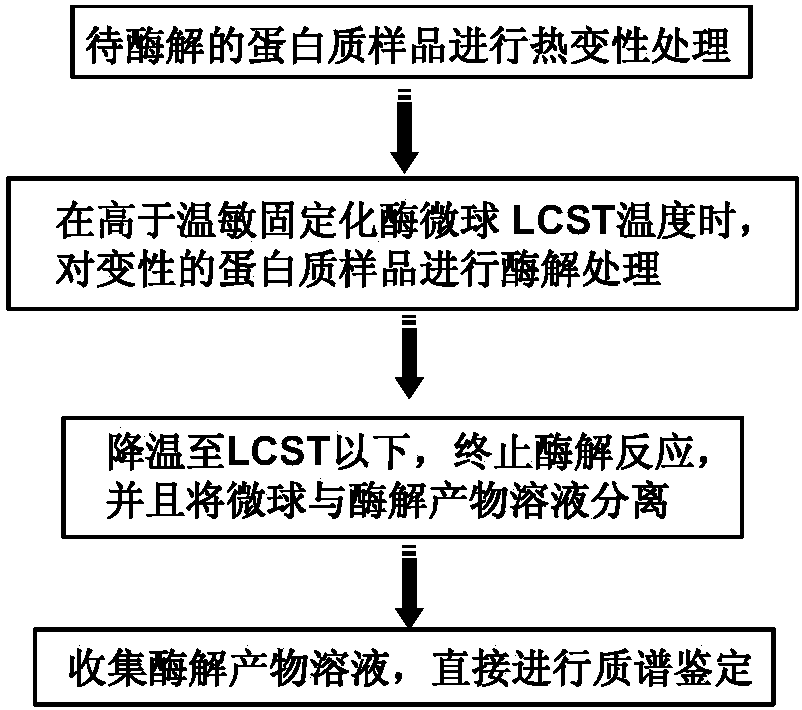

[0109] A protein enzymatic hydrolysis method based on immobilized enzymes, the specific operation steps are as follows:

[0110] (1) Preparation of thermosensitive immobilized trypsin microspheres

[0111] (a) Preparation of carrier material

[0112] The carrier material is formed by copolymerization of N-isopropylacrylamide and acrylic acid at a mass ratio of 9:1. The specific preparation method is:

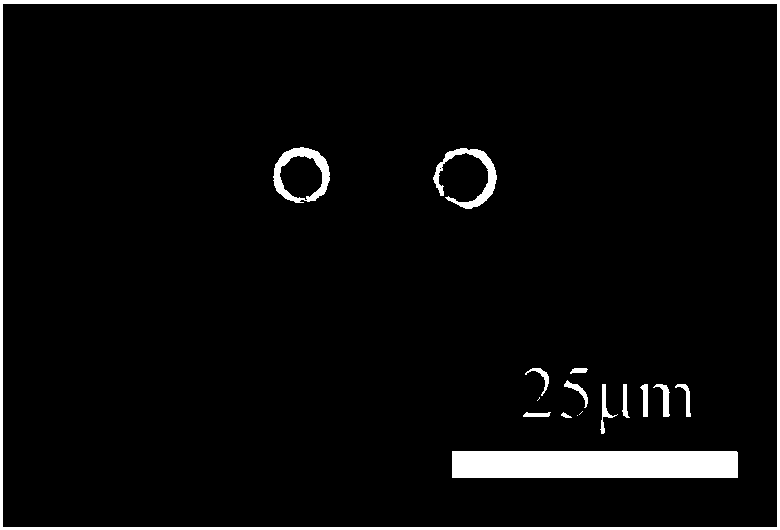

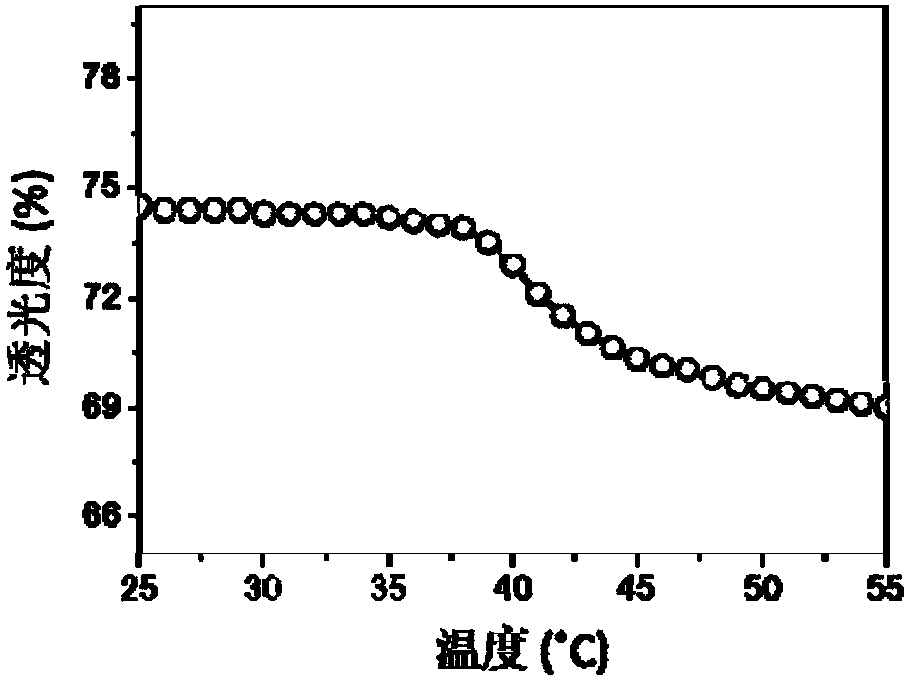

[0113] Preparation of copolymerized microspheres by rapid membrane emulsification method: Add acrylic acid, N-isopropylacrylamide, initiator, and crosslinking agent to deionized water, N-isopropylacrylamide, initiator, crosslinking agent, and deionized water The mass ratio is 10:0.2:1.5:500, stirred until the solid is completely dissolved, and prepared into an aqueous phase; mix Span-80 and cyclohexane at a mass ratio of 1:20, stir at room temperature until Span-80 is completely dissolved, Prepare the oil phase; mix the oil phase and the water phase at a volume ratio of 1:5, s...

Embodiment 2

[0124] A kind of protein enzymolysis method based on immobilized enzyme, its specific operation steps are as follows:

[0125] (1) Preparation of thermosensitive immobilized trypsin microspheres

[0126] (a) Preparation of carrier material

[0127] The carrier material is formed by copolymerization of N-isopropylacrylamide and methacrylic acid at a mass ratio of 1:1. The specific preparation method is:

[0128] Copolymerized microspheres were prepared by soap-free emulsion polymerization: the monomer N-isopropylacrylamide, methacrylic acid and cross-linking agent were dissolved in 200mL deionized water and put into a 250mL four-necked flask, N-isopropylacrylamide The mass ratio of acrylamide, cross-linking agent and deionized water is 100:0.1:20000. Nitrogen gas is introduced and mechanical stirring is carried out. After 15 minutes of stabilization, the initiator is added, and the temperature is raised to 80°C, and the reaction is continued for 6 hours. After the reaction, t...

Embodiment 3

[0135] A kind of protein enzymolysis method based on immobilized enzyme, its specific operation steps are as follows:

[0136] (1) Preparation of thermosensitive immobilized chymotrypsin microspheres

[0137] (a) Preparation of carrier material

[0138] The carrier material is formed by copolymerization of N-isopropylacrylamide and acrylic acid at a mass ratio of 20:1. The specific preparation method is:

[0139] Copolymerized microspheres were prepared by precipitation polymerization: acrylic acid, N-isopropylacrylamide, initiator and crosslinking agent solvent were dissolved in 80mL aqueous solution, and the concentration of N-isopropylacrylamide was 7g / L; N in the solution - The mass ratio of isopropylacrylamide, initiator and crosslinking agent is 10:1:0.5; nitrogen is passed through the solution for 30 minutes, and then the above solution is heated to 70°C in an oil bath or water bath for 8 hours of reaction; After the end, the temperature of the reaction solution was l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com