Preparing method for oil-based hydroxyapatite colloidal crystals

An oil-based hydroxyapatite and colloidal technology, which is applied in the direction of liquid crystal materials, chemical instruments and methods, phosphorus compounds, etc., to achieve the effects of easy-to-obtain, low-cost, and easy-to-implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Add 24 mL of 0.83 mol / L calcium nitrate aqueous solution and 48 mL of ethanol, 0.038 mol of oleic acid and 0.025 mol of ethylenediamine into a three-necked flask and mix, and stir to obtain a uniform solution; under stirring conditions, add 0.5 mol / L trisodium phosphate Add 24mL of aqueous solution to the above solution slowly dropwise, and continue to stir for 10min after the addition is complete;

[0032] 2) heating the mixed liquid obtained in step 1) to 80° C. for 6 hours, and then naturally cooling to room temperature to obtain a reaction liquid;

[0033] 3) Use a high-speed centrifuge to centrifuge the reaction solution obtained in step 2) to obtain a precipitate, and use absolute ethanol and cyclohexane to alternately centrifuge and wash 3 times to remove electrolytes and excess fatty acids in the system to obtain oil-soluble hydroxyapatite nanoparticles ;

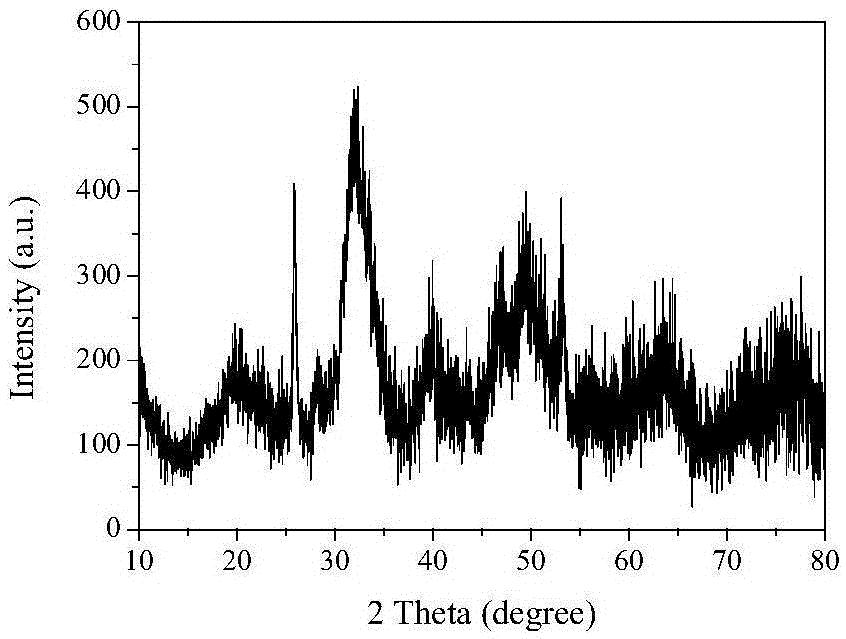

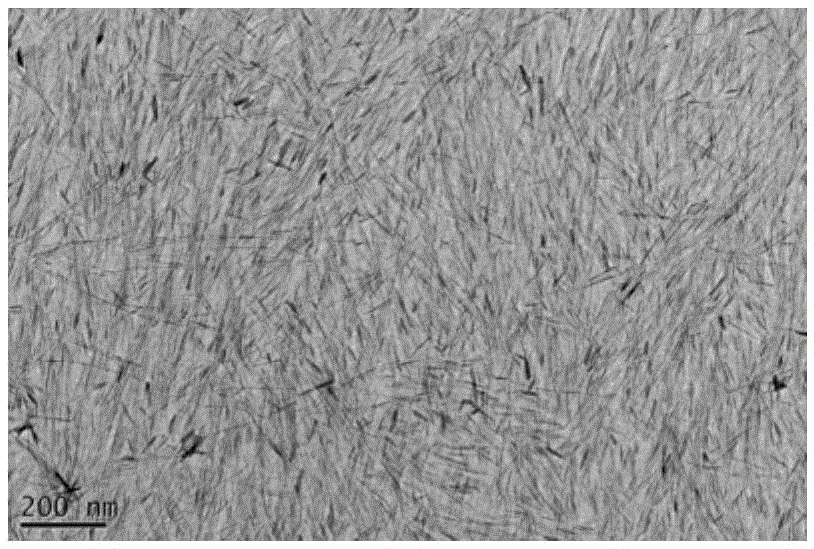

[0034] The X-ray diffraction pattern of oil-soluble hydroxyapatite nanoparticles is shown in figure 1...

Embodiment 2

[0038] 1) Add 24 mL of 0.83 mol / L calcium chloride aqueous solution and 48 mL of ethanol, 0.038 mol of oleic acid and 0.025 mol of ethylenediamine into a three-necked flask and mix, and stir to obtain a uniform solution; Slowly add 24mL potassium aqueous solution to the above solution dropwise, and continue stirring for 10 minutes after the addition is complete;

[0039] 2) heating the mixed liquid obtained in step 1) to 80° C. for 3 hours, and then naturally cooling to room temperature to obtain a reaction liquid;

[0040] 3) Using a high-speed centrifuge to centrifuge the reaction solution obtained in step 2) to obtain a precipitate, and use absolute ethanol and toluene to alternately centrifuge and wash 3 times to remove electrolytes and excess fatty acids in the system to obtain oil-soluble hydroxyapatite nanoparticles;

[0041] Figure 5 It is the macrophotograph of the dispersion liquid of prepared oil-soluble hydroxyapatite nanoparticles, the particle mass concentratio...

Embodiment 3

[0045] 1) Add 24 mL of 0.83 mol / L calcium acetate aqueous solution and 48 mL of ethanol, 0.038 mol of oleic acid and 0.025 mol of ethylenediamine into a three-necked flask and mix, and stir to obtain a uniform solution; under stirring conditions, add 0.5 mol / L triammonium phosphate Add 24mL of aqueous solution to the above solution slowly dropwise, and continue to stir for 10min after the addition is complete;

[0046] 2) heating the mixed solution obtained in step 1) to 50° C. for 12 hours, and then naturally cooling to room temperature to obtain a reaction solution;

[0047] 3) Using a high-speed centrifuge to centrifuge the reaction solution obtained in step 2) to obtain a precipitate, and use absolute ethanol and styrene to alternately centrifuge and wash 3 times to remove electrolytes and excess fatty acids in the system to obtain oil-soluble hydroxyapatite nanoparticles;

[0048] Figure 7 It is the macrophotograph of the dispersion liquid of prepared oil-soluble hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com