Thermosensitive warm-keeping fabric microcapsule finishing agent and preparation method and application thereof

A technology for microcapsule finishing and fabrics, applied in textiles and papermaking, fiber processing, plant fibers, etc., can solve problems such as rare research, and achieve the effects of enhancing metabolism, improving immunity, and improving obesity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of temperature-sensitive warm-keeping health-care fabric finishing agent

[0031] (1) Add 10g wormwood essential oil, 10g capsicum essential oil, 10g gum arabic to 500g deionized water, stir at 60°C at high speed to obtain an O / W emulsion;

[0032] (2) Take 10g of temperature-sensitive material and adjust the pH to 4 with 5% citric acid;

[0033] (3) Slowly add the temperature-sensitive material to the O / W emulsion and mix at a rate of 10 drops / min, add 2g of TG enzyme, and cure at room temperature for 6 hours;

[0034] (4) Stand still, filter, wash, and vacuum dry at 60°C.

[0035] How to apply the finishing agent:

[0036] Prepare 8% microcapsule working solution, add 3% acrylate supersoft adhesive, dip and roll the cotton fabric, the liquid retention rate is 75%, and set it at 150°C for 40s.

Embodiment 2

[0038] A kind of preparation method of temperature-sensitive warm-keeping health-care fabric finishing agent

[0039] (1) Take 10g wormwood essential oil, 10g capsicum essential oil, 5g gum arabic and add it to 400g deionized water, stir at 60°C at high speed to obtain O / W emulsion;

[0040] (2) Take 5g of temperature-sensitive material and adjust the pH to 4 with 5% citric acid;

[0041] (3) Slowly add the temperature-sensitive material to the O / W emulsion and mix at a rate of 10 drops / min, add 1.5g of TG enzyme, and cure at room temperature for 6 hours;

[0042] (4) Stand still, filter, wash, and vacuum dry at 60°C.

[0043] How to apply the finishing agent:

[0044] Prepare 5% microcapsule working solution, add 2% acrylate supersoft adhesive, soak and roll the cotton fabric, the liquid retention rate is 75%, and set at 150°C for 40s.

Embodiment 3

[0046] A kind of preparation method of temperature-sensitive warm-keeping health-care fabric finishing agent

[0047] (1) Add 10g wormwood essential oil, 10g capsicum essential oil, and 10g carboxymethylcellulose into 500g deionized water, stir at 60°C at high speed to obtain an O / W emulsion;

[0048] (2) Take 10g of temperature-sensitive material and adjust the pH to 4 with 5% citric acid;

[0049] (3) Slowly add the temperature-sensitive material to the O / W emulsion and mix at a rate of 10 drops / min, add 2g of glutaraldehyde, and cure at room temperature for 6 hours;

[0050] (4) Stand still, filter, wash, and vacuum dry at 60°C.

[0051] How to apply the finishing agent:

[0052] Configure 8% microcapsule working solution, add 3% polyurethane super soft adhesive, dip and roll the wool fabric, the liquid retention rate is 70%, and set it at 150°C for 40s.

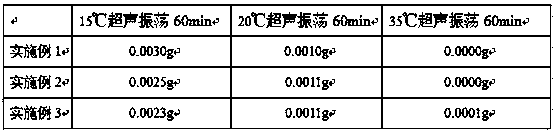

[0053] The fabrics obtained in Example 1, Example 2, and Example 3 were respectively taken three parts with a mass o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com