Method for preparing biodiesel from hemp plant oil

A biodiesel and vegetable oil technology, applied in biofuel, petroleum industry, fatty acid esterification, etc., can solve the problems of high production cost, complex composition, complex process, etc., to reduce product cost, simplify reaction conditions, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

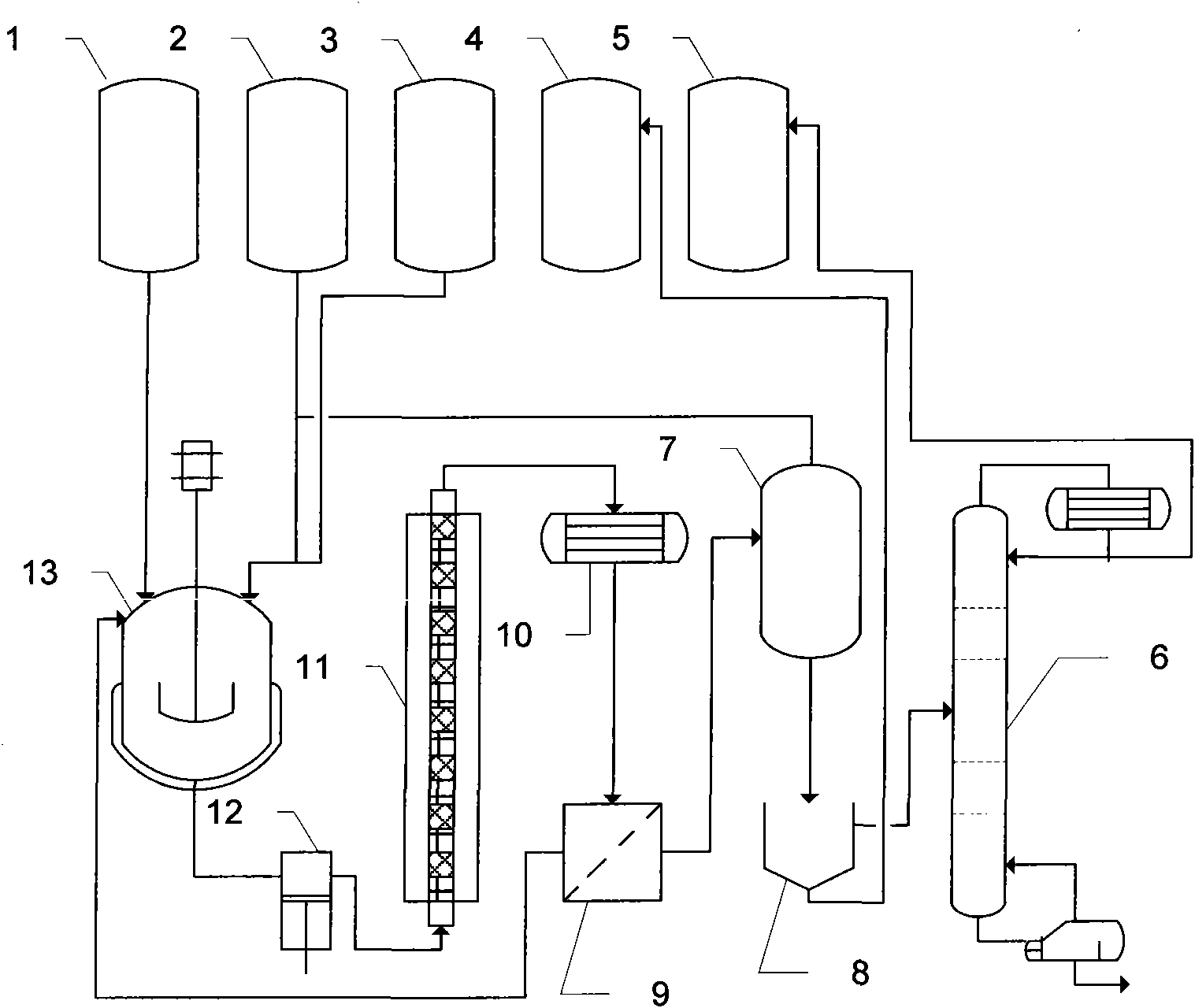

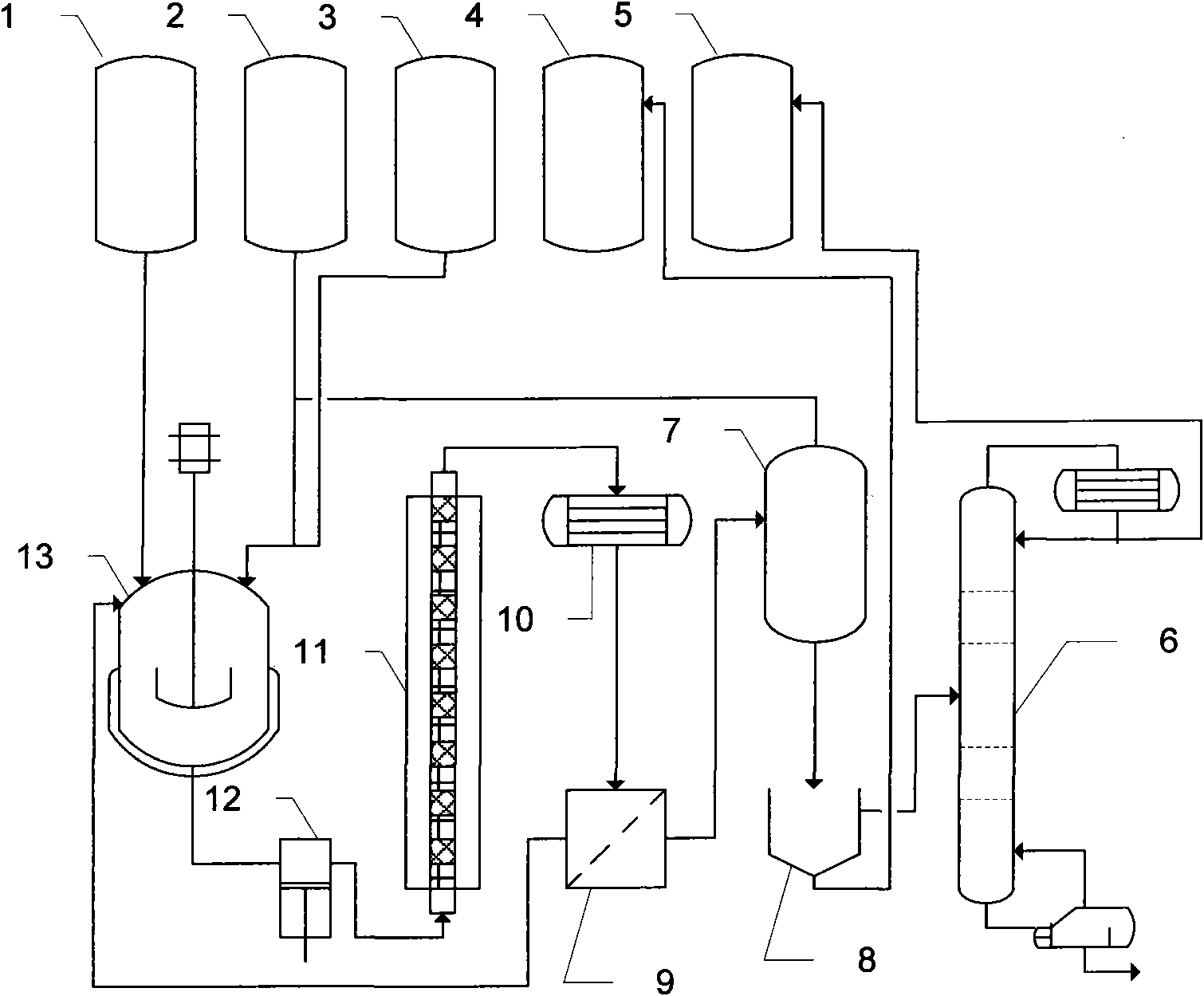

Method used

Image

Examples

Embodiment 1

[0037] Linseed oil is used as raw material, the molar ratio of methanol to linseed oil is 9:1, the molar ratio of tert-butanol:linseed oil is 6:1, CaO is used as catalyst, and the amount of catalyst is 2.5% of the mass of linseed oil. After mixing well in the stirring mixer, the liquid phases are completely miscible. Then use a plunger pump to pump the material into the tubular reactor, the tube length is 1.5m, the tube diameter is Φ20×1mm, and the material is stainless steel. The reaction conditions are 12MPa, 250°C, and the reaction time is 50 minutes. After the material is discharged through the pressure reducing valve, it enters the cooler for cooling, and the product passes through the filter to recover the solid alkali catalyst, and then undergoes flash evaporation, static stratification and rectification to obtain biodiesel product, and the mass yield of biodiesel is 95.4%.

Embodiment 2

[0039] Castor oil is used as raw material, the molar ratio of methanol to castor oil is 6:1, the molar ratio of tetrahydrofuran to castor oil is 12:1, SrO is used as a catalyst, and the catalyst dosage is 2.0% of the mass of castor oil. Mix evenly in a stirring mixer, and then use a plunger pump to pump the material into the tubular reactor, the tube length is 1.5m, the tube diameter is Φ20×1mm, and the material is stainless steel. The reaction conditions are 10 MPa, 220° C., and the reaction time is 40 minutes. After the material is discharged through the pressure reducing valve, it enters the cooler for cooling, and the product passes through the filter to recover the solid alkali catalyst, and then undergoes flash evaporation, static stratification and rectification to obtain biodiesel product, and the mass yield of biodiesel is 96.4%.

Embodiment 3

[0041] Linseed oil is used as raw material, the molar ratio of methanol to linseed oil is 12:1, the molar ratio of tert-butanol to linseed oil is 12:1, calcium methoxide is used as a catalyst, and the amount of the catalyst is 2.0% of the mass of the linseed oil. After mixing well in the stirring mixer, the liquid phases are completely miscible. Then use a plunger pump to pump the material into the tubular reactor, the tube length is 1.5m, the tube diameter is Φ20×1mm, and the material is stainless steel. The reaction conditions are 10 MPa, 240° C., and the reaction time is 60 minutes. After the material is discharged through the pressure reducing valve, it enters the cooler for cooling, and the product passes through the filter to recover the solid alkali catalyst, and then undergoes flash evaporation, static stratification and rectification to obtain biodiesel product, and the mass yield of biodiesel is 95.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com