Method for extracting cannabidiol by using subcritical water extraction technology

A cannabidiol and subcritical water technology, applied in the chemical industry, can solve the problems of difficulty in realizing industrialized scale-up production, long reaction time, low efficiency, etc., and achieves avoiding oxidative denaturation and residual pollution of poor solvents, short reaction period and high efficiency The effect of extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

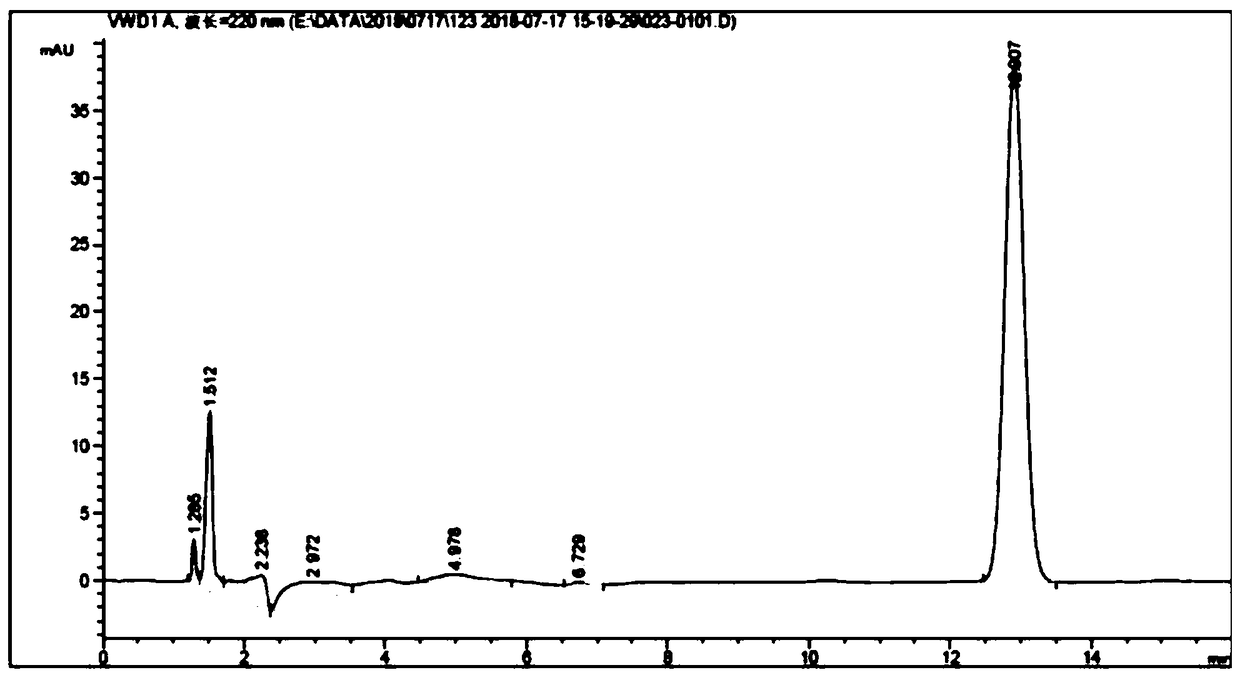

Embodiment 1

[0046] After sifting 10Kg of the mosaic leaves of the marijuana plant in the flowering stage, spread them flat in an oven for drying treatment at a temperature of 100-130°C for 2-3 hours until the water content of the hemp mosaic leaves is less than 6%. Then add it into the pulverizer and grind it until the particle size is 10-20 mesh. The dried and pulverized marijuana flowers and leaves are divided into filter bags, placed in the closed extraction tank of the subcritical water extraction device, and pure water is added at a material-to-liquid ratio of 1:10 (W / V), and extracted at a temperature of 374 ° C. Extract under the subcritical state with a pressure of 21.7MPa for 30 minutes, repeat the extraction three times, filter to separate the waste residue and the aqueous solution, and combine the extracts. The extracted solution obtained above was heated under reduced pressure, and the excess pure water was evaporated to dryness to obtain a concentrated solution of cannabidiol...

Embodiment 2

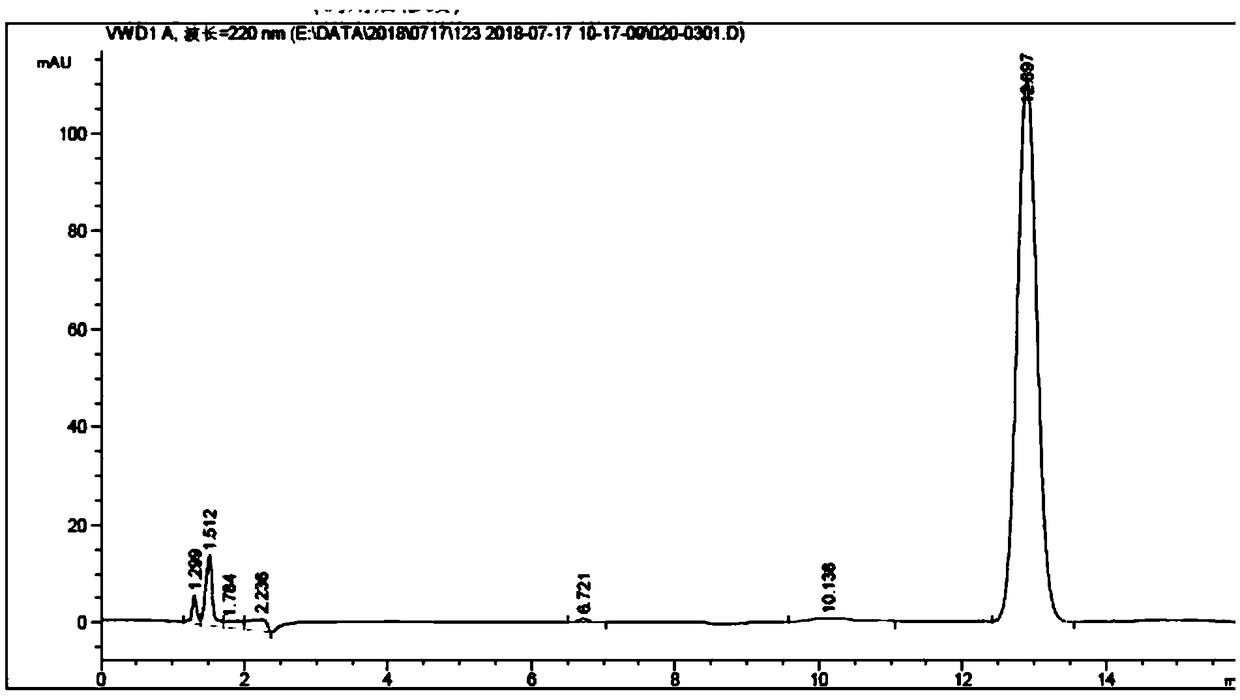

[0048] After screening 100Kg of the mosaic leaves of cannabis plants in the stage of flowering, spread them flat in an oven for drying treatment at a temperature of 100-130°C for 3-3.5 hours until the water content of the cannabis flowers and leaves is less than 6%. Then add it into the pulverizer and grind it until the particle size is 10-20 mesh. The dried and pulverized marijuana flowers and leaves are divided into filter bags, placed in the closed extraction tank of the subcritical water extraction device, and pure water is added at a material-to-liquid ratio of 1:10 (W / V), and extracted at a temperature of 374 ° C. Extract under the subcritical state with a pressure of 21.7MPa for 40 minutes, repeat the extraction three times, filter to separate the waste residue and the aqueous solution, and combine the extracts. The extract obtained above was heated under reduced pressure, and the excess pure water was evaporated to dryness to obtain a concentrated solution of cannabidi...

Embodiment 3

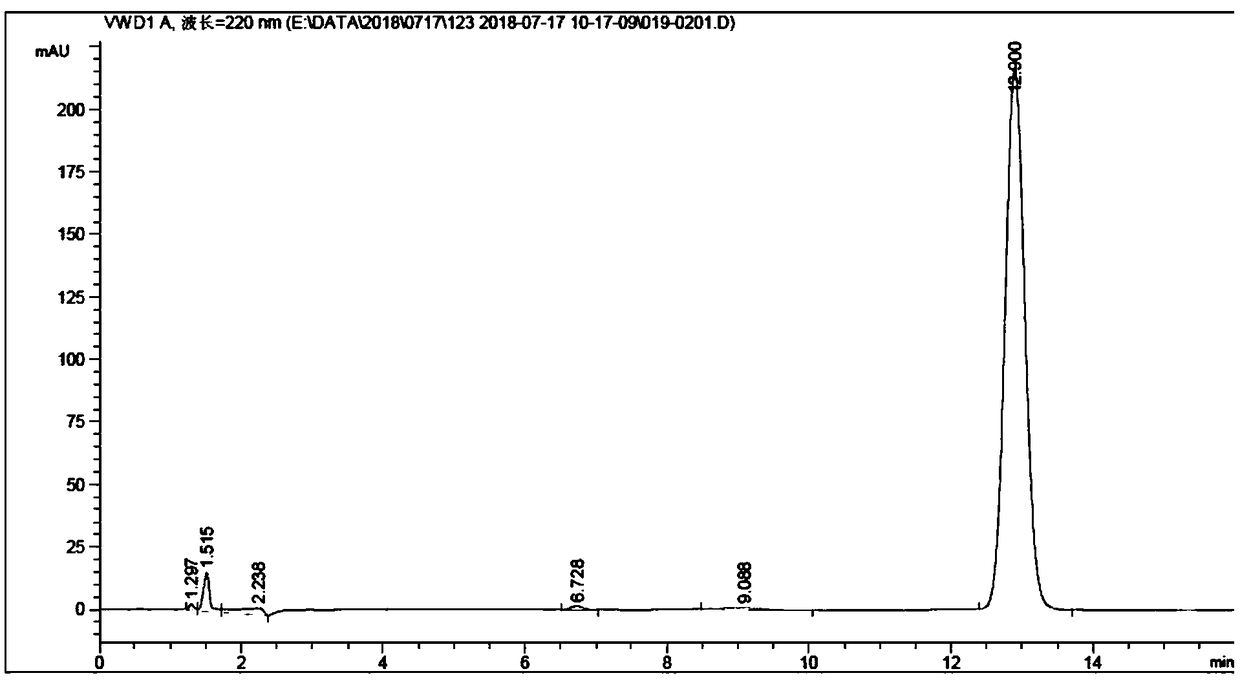

[0050] After sifting 10Kg of the mosaic leaves of the cannabis plant in the flowering stage, spread them flat in an oven for drying treatment at a temperature of 100-130°C for 2.5-3 hours until the water content of the cannabis flowers and leaves is less than 6%. Then add it into the pulverizer and grind it until the particle size is 10-20 mesh. Put the dried and pulverized marijuana flowers and leaves in a closed container, add 95% ethanol according to the ratio of material to liquid 1:10 (W / V), soak and extract 3 times, each time for 2-3 hours, filter to separate the waste residue from the aqueous solution , combined extracts. Heat the extract obtained above under reduced pressure, evaporate the excess pure water to dryness and volatilize, and obtain a concentrated solution of cannabidiol; the content of CBD in the paste is 25.0%. Add the concentrated solution of cannabidiol to pure After diluting with water, use a chromatographic column to carry out gradient elution on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com