Peeling and degumming process for hemp plants

A plant and degumming technology, applied in textiles and papermaking, fiber treatment, biochemical fiber treatment, etc., can solve the problems of restricting the development of hemp spinning industry, manpower, and high cost, so as to reduce water resource consumption and environmental pollution, reduce hemp Effects of fiber loss and labor saving for scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

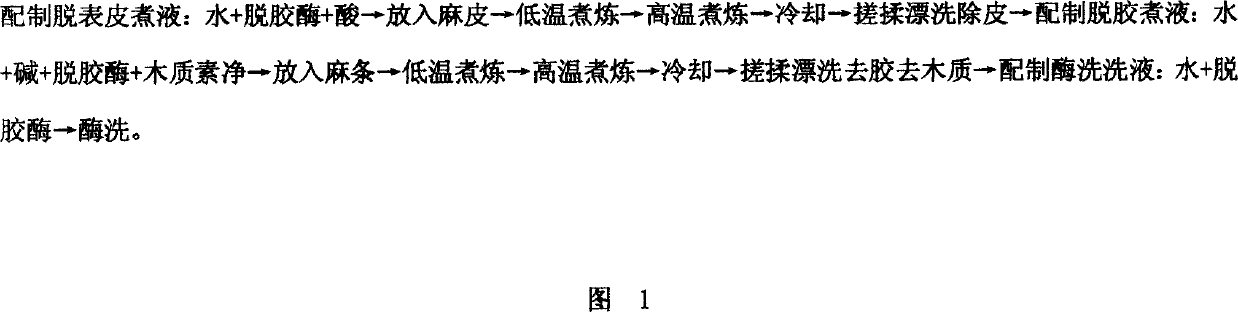

Method used

Image

Examples

Embodiment 1

[0017] Get the degumming enzyme T28, T66, T85 strains produced by the Hemp Research Institute of the Chinese Academy of Agricultural Sciences to cultivate the degumming enzyme, and prepare an acidic compound enzyme at 25%, 50%, and 25%, and then make an aqueous solution with an enzyme concentration of 0.6% , then add oxalic acid to make the pH of the solution = about 5, pour it into the cooking pot, put the ramie bark peeled off from the hemp stalk into the cooking pot, open the steam valve to supply steam to the cooking pot, and use it as a pot When the medium temperature rises to 50°C, turn off the steam to keep the temperature in the pot basically constant for 1 hour, then turn on the steam to raise the temperature to 100°C, then turn off the steam to keep the temperature in the pot basically constant for 1 hour, then turn off Steam, cool to normal temperature, pull out the hemp skin from the pot, rinse with water, rub while flushing, remove the hemp skin; get the degumming ...

Embodiment 2

[0019] Get the degumming enzyme T28, T66, T85 bacterial classification that Chinese Academy of Agricultural Sciences Institute of Hemp produces and cultivate degumming enzyme, and be mixed with acidic compound enzyme by 30%, 30%, 40%, after being made into enzyme concentration is adjusted to 1%. Add sulfuric acid to the aqueous solution to make the pH of the solution about 3, pour it into the cooking pot, put the ramie bark peeled off from the hemp stalk into the cooking pot, open the steam valve to supply steam to the cooking pot, when When the temperature in the pot rises to 70°C, turn off the steam to keep the temperature in the pot basically constant for 2 hours, then turn on the steam to raise the temperature to 120°C, turn off the steam to keep the temperature in the pot basically constant for 1.5 hours, Turn off the steam, cool to normal temperature, remove the hemp skin from the pot, rinse with water, rub while washing to remove the hemp skin; take the degumming enzyme ...

Embodiment 3

[0021] Get the degumming enzyme T28, T66, T85 bacterial classification that Chinese Academy of Agricultural Sciences Institute of Hemp produces and cultivate degumming enzyme, and be mixed with acidic compound enzyme by 30%, 30%, 40%, after being made into enzyme concentration is adjusted to 1%. Add sulfuric acid to the aqueous solution to make the pH of the solution about 3, pour it into the cooking pot, put the tung hemp bark peeled off from the hemp stalk into the cooking pot, open the steam valve to supply steam to the cooking pot, When the temperature in the pot rises to 70°C, turn off the steam to keep the temperature in the pot basically constant for 2 hours, then turn on the steam to raise the temperature to 120°C, then turn off the steam to keep the temperature in the pot basically constant for 2 hours , turn off the steam, cool to normal temperature, remove the hemp skin from the pot, rinse with water, rub while flushing, remove the hemp skin; take the degumming enzym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com