Patents

Literature

43results about How to "Improve textile performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special twistless roving impregnating compound for grinding wheel mesh

According to the invention, a various impregnating compound composition component complex formulation technology is adopted to improve different performance requirements of a product, a film forming agent adopts a complex formulation technology of a polyurethane film forming agent, an epoxy film forming agent and a polyester film forming agent, the polyurethane film forming agent is utilized to improve the abrasion resistance of a glass fiber, the epoxy film forming agent is utilized to improve the permeability of a phenolic resin of the grinding wheel mesh, and the polyester film forming agent is used to adjust the hardness of the glass fiber; a lubricant adopts a various lubricant complex formulation technology to improve the wire drawing and weaving performances of glass; and a coupling agent adopts a various coupling agent complex formulation technology to improve binding force of the impregnating compound with the glass fiber.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

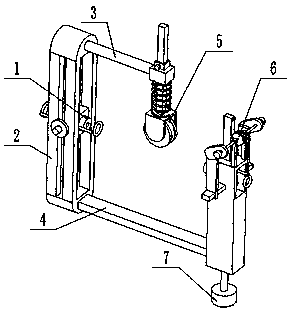

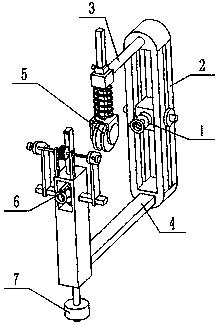

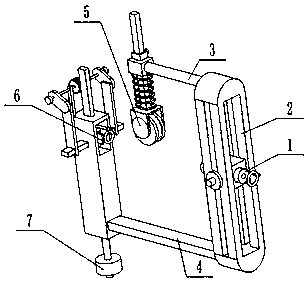

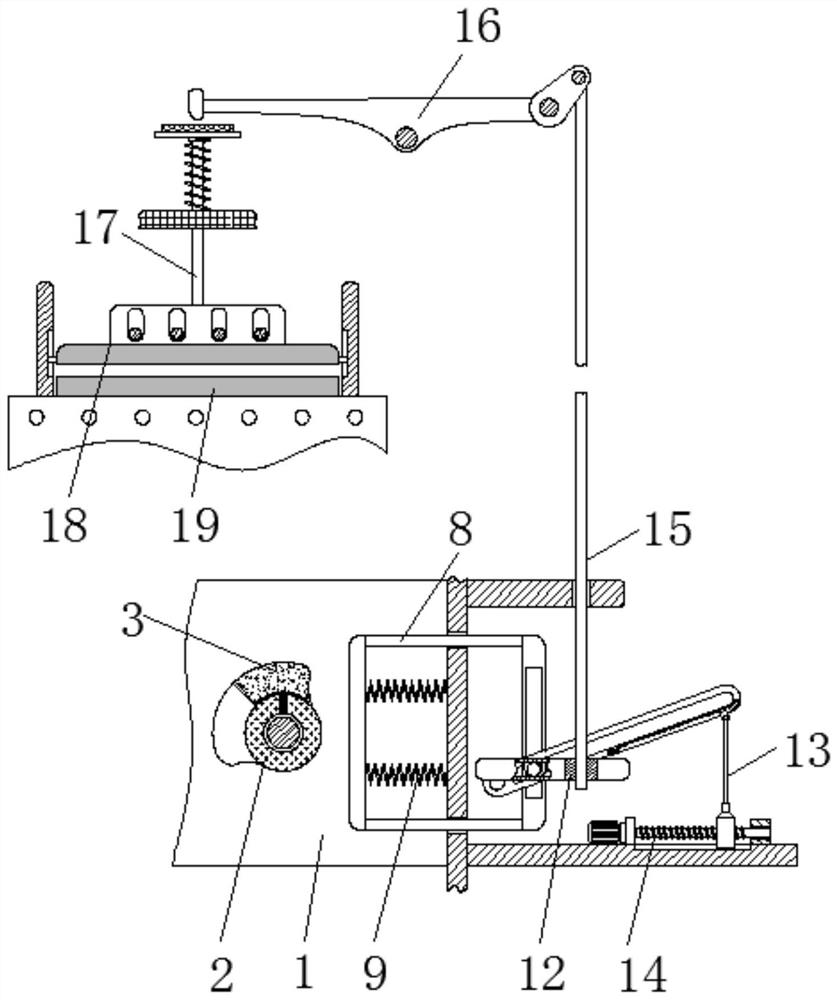

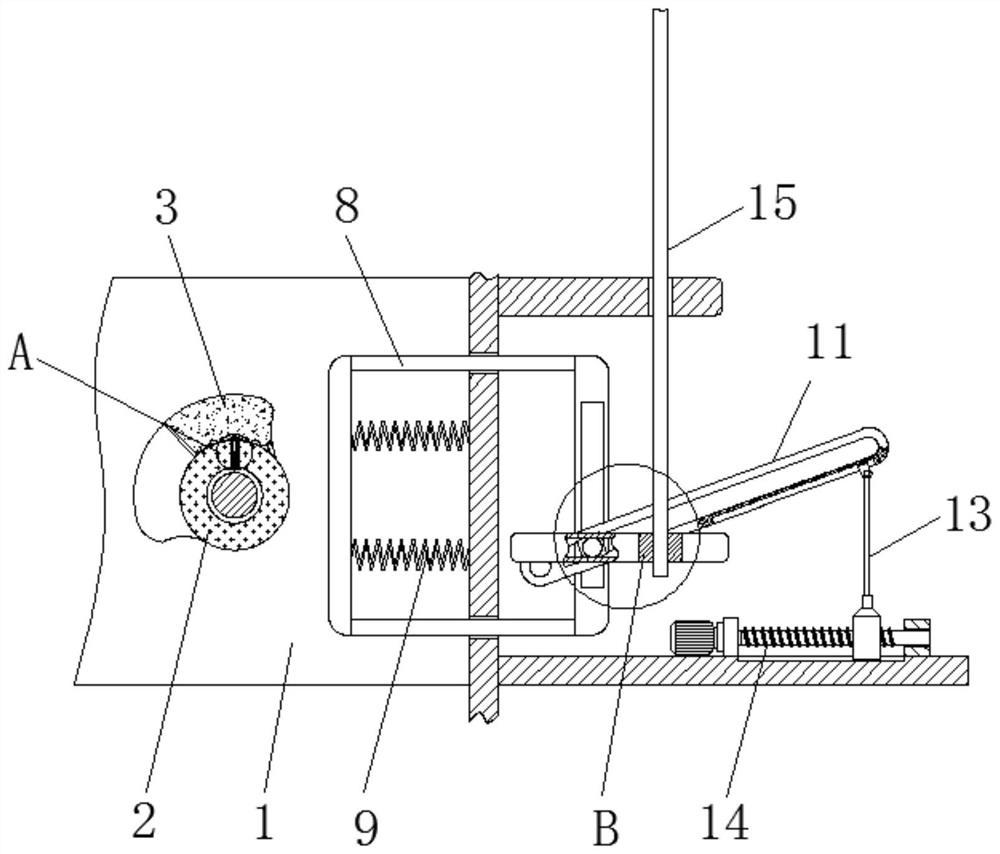

Yarn inlet and guiding device for textile machine

InactiveCN108455376AAvoid disconnectionEasy to disconnectFilament handlingFibre cleaning/openingYarnEngineering

The invention relates to the field of textile processing equipment, in particular to a yarn inlet and guiding device for a textile machine. The yarn inlet and guiding device for the textile machine comprises a yarn guiding pipe mechanism, a mounting frame, a cylinder connection rod, a rectangular connection rod, a yarn guiding wheel mechanism, a dust removing brush assembly and a dust collecting pipe assembly; a through rectangular groove I is formed in the front and back side faces of the mounting frame; the left side face and the right side face of the mounting frame are each provided with one rectangular groove II; the rectangular groove I and the two rectangular grooves II communicate with each other; the yarn guiding pipe mechanism is connected to the inner sides of the rectangular groove I and the two rectangular grooves II of the mounting frame; the upper end of the rear side face of the mounting frame is fixedly connected with the cylinder connection rod; and the rear end of the cylinder connection rod is fixedly connected with the yarn guiding wheel mechanism. The yarn guiding pipe mechanism inside the yarn inlet and guiding device is used for guiding yarns and properly adjusting the guiding height and direction of the yarns, and requirements of different textile machines are met conveniently.

Owner:佛山市冠康隆纺织有限公司

Biological enzyme degumming method for cotton stalk bark fibre

InactiveCN101215717AAvoid damageEmission reductionBiochemical fibre treatmentVegetable materialFiberWastewater

The invention discloses a method for bio-enzymatic degumming of cotton stalk bark fiber, which belongs to the technical field of natural plant fiber degumming. The main points of the technical proposal comprises following steps: first peeling cotton stalk bark from cotton stalks, second, putting the cotton stalk bark in acidic enzyme liquid whose PH value is 4-6.0 under the temperature of 20-60 DEG C to process for 1-8 hours, third, putting the cotton stalk bark in acidic enzyme liquid whose PH value is 7-10.0 under the temperature of 30-70 DEG C to process for 1-6 hours, and finishing degumming process. The invention adopts bio-enzymatic degumming, which can not only reduce the damage of fiber in the process of chemical degumming, the loss of the fiber reduces over 10 %, simultaneously, the invention can increase weaving performance of the fiber, and enzyme liquid can be used repeatedly, discharging and handling capacity of waste water are reduced, and environmental pollution is reduced.

Owner:刘俊巧

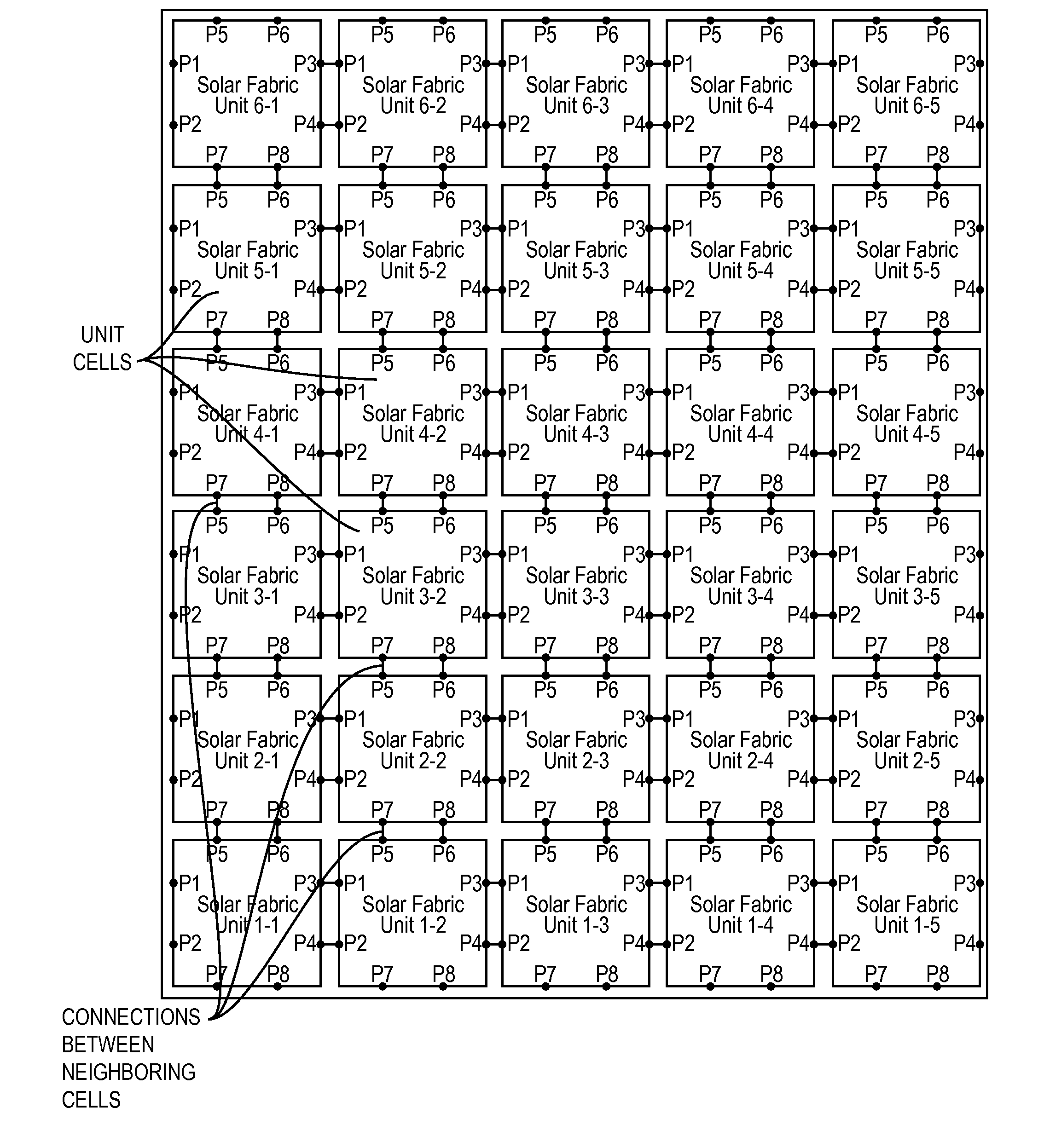

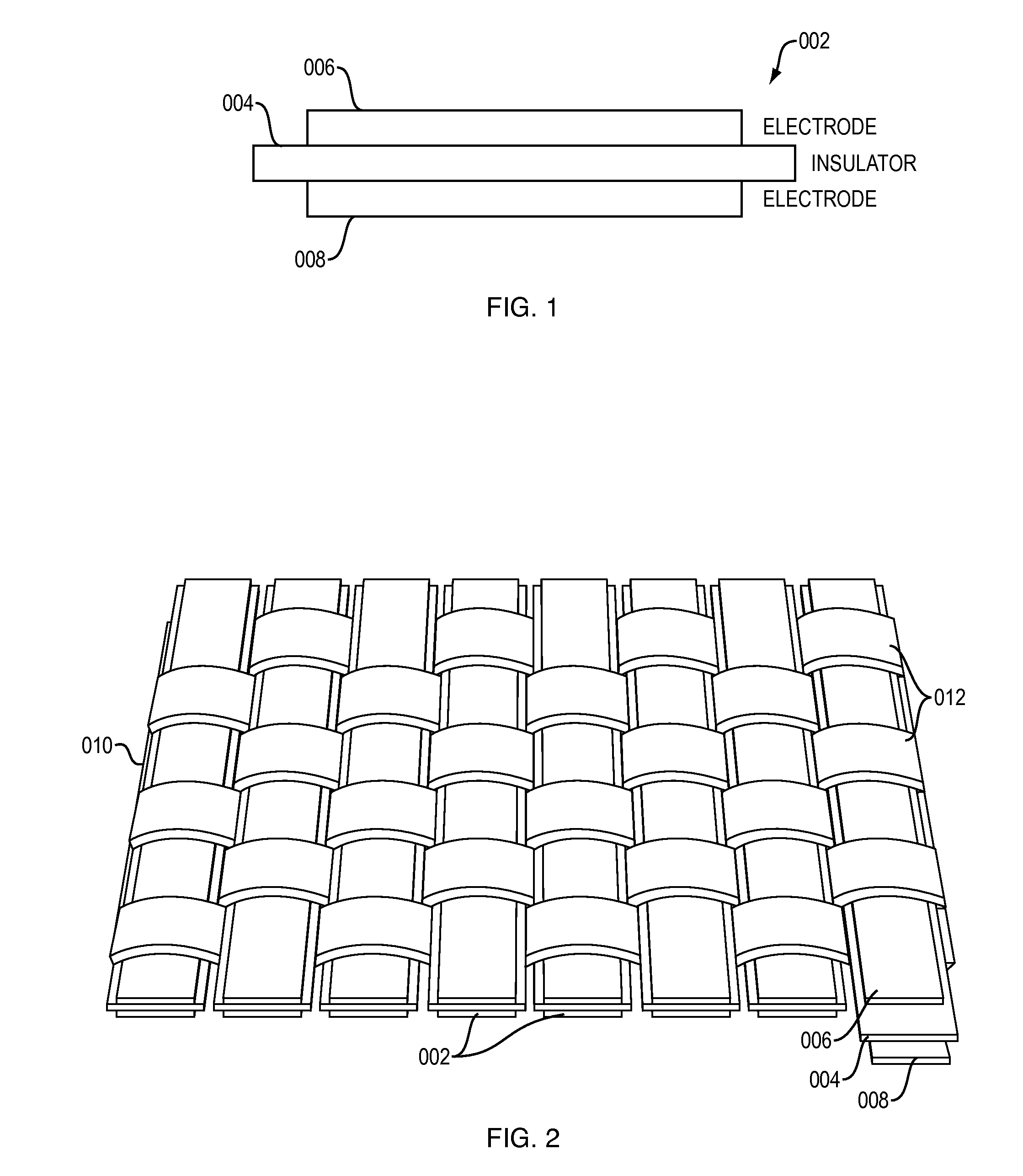

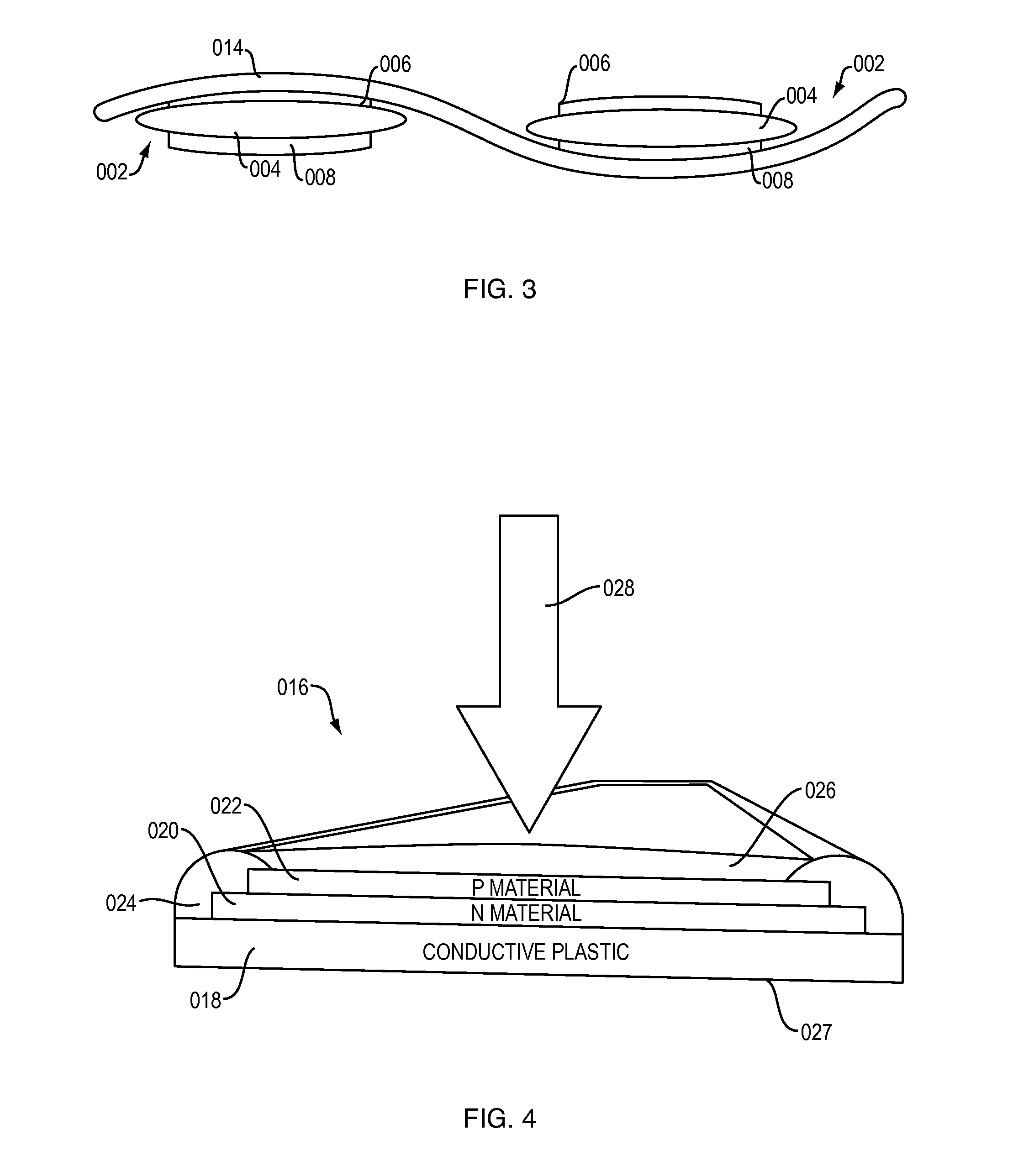

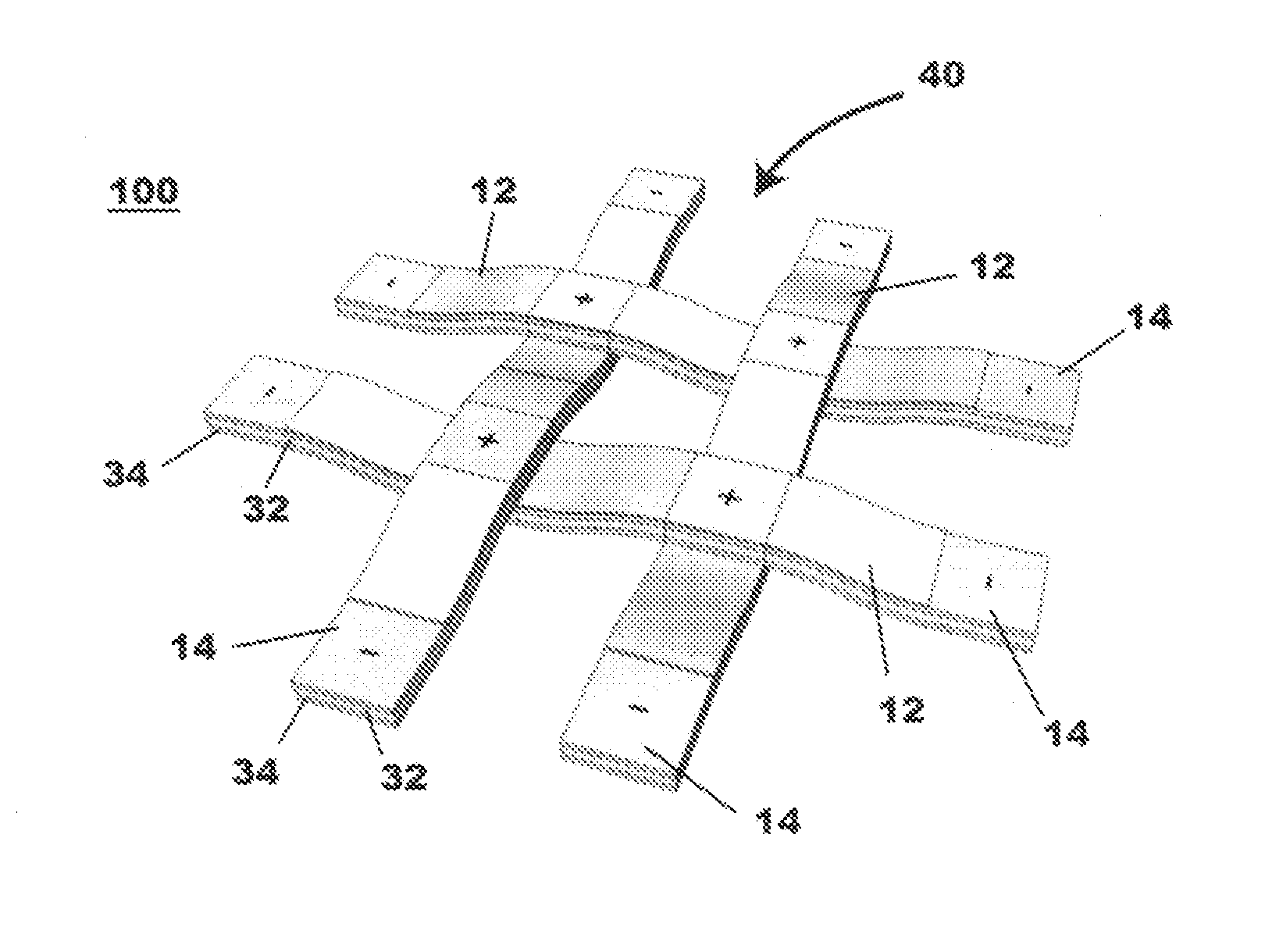

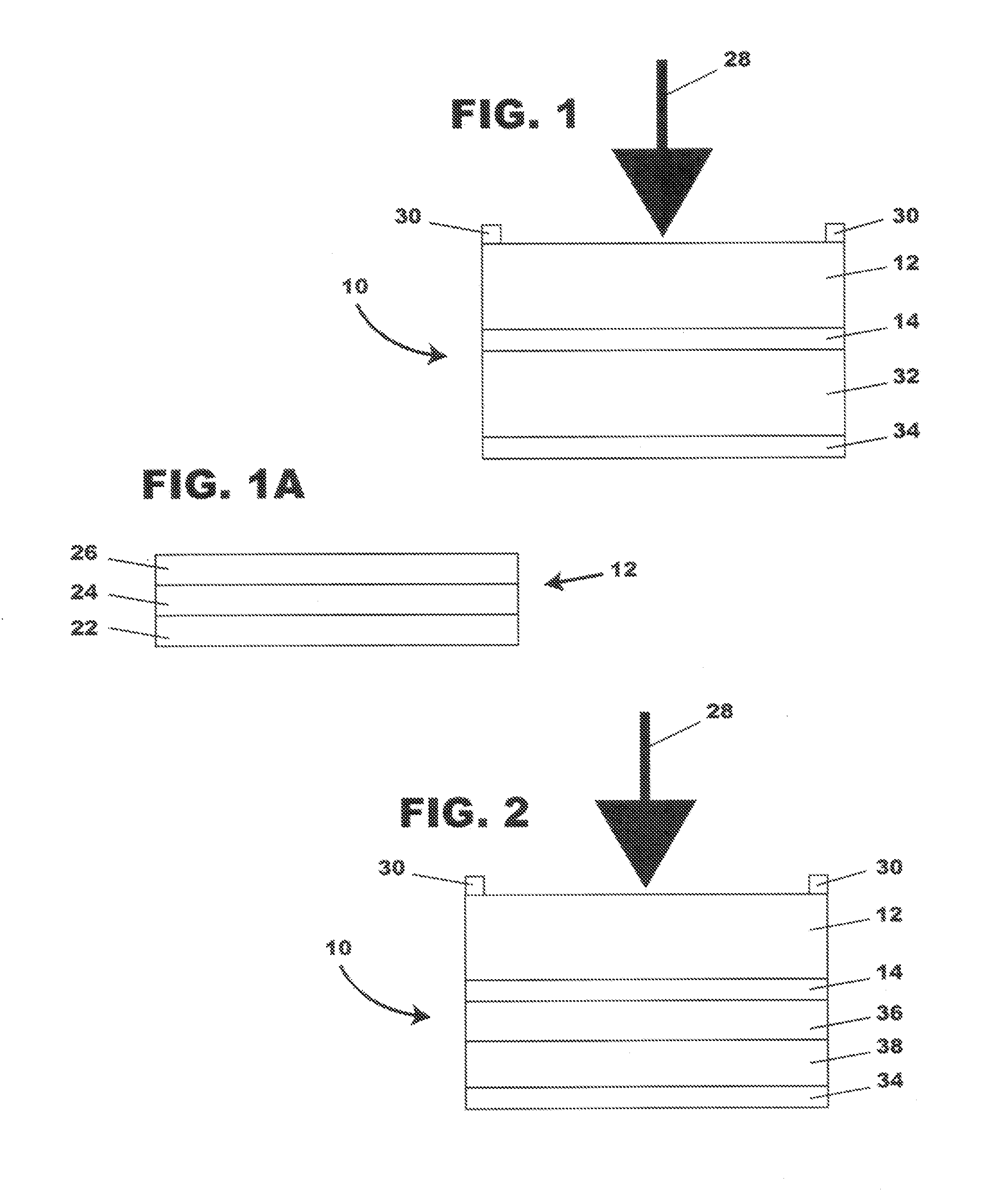

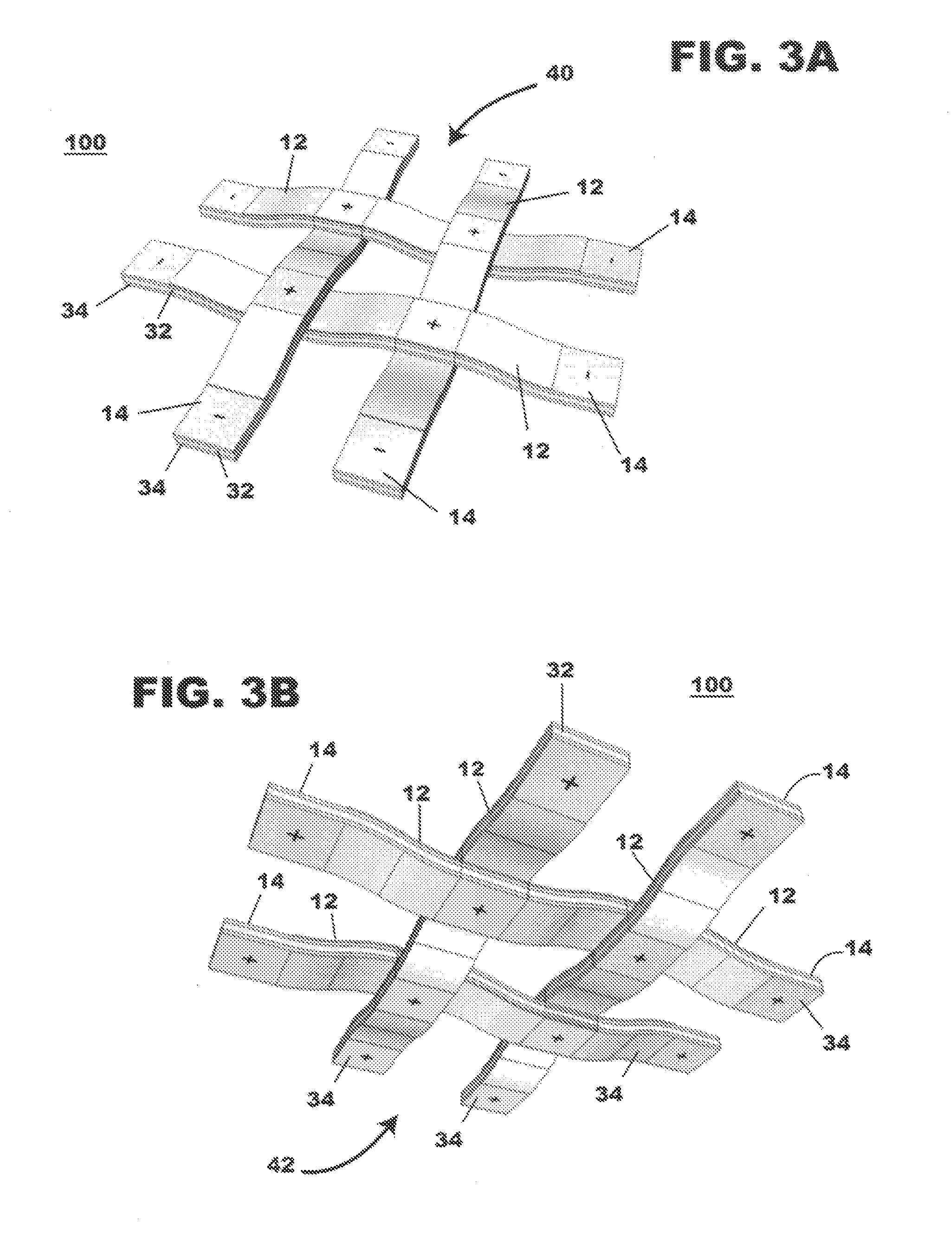

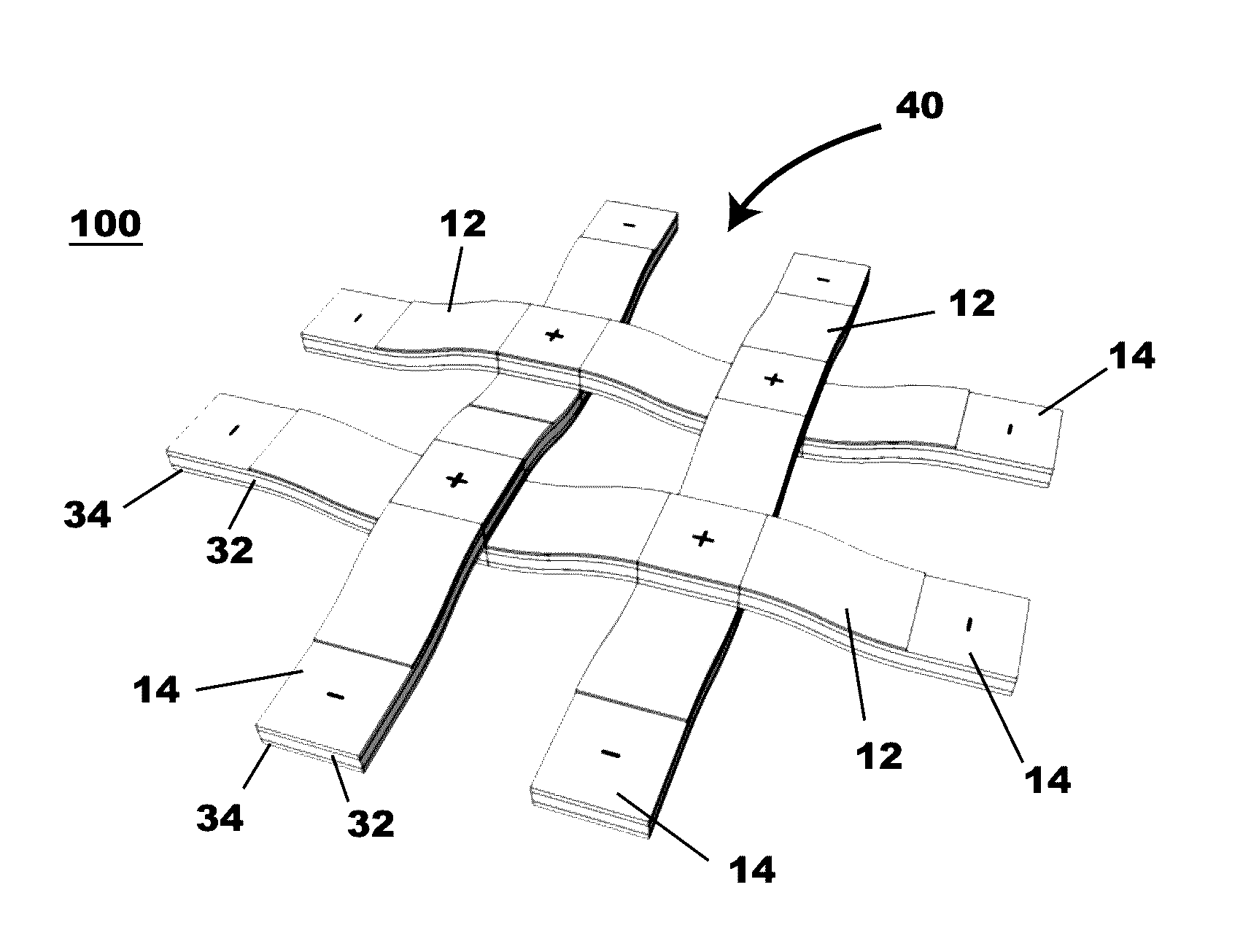

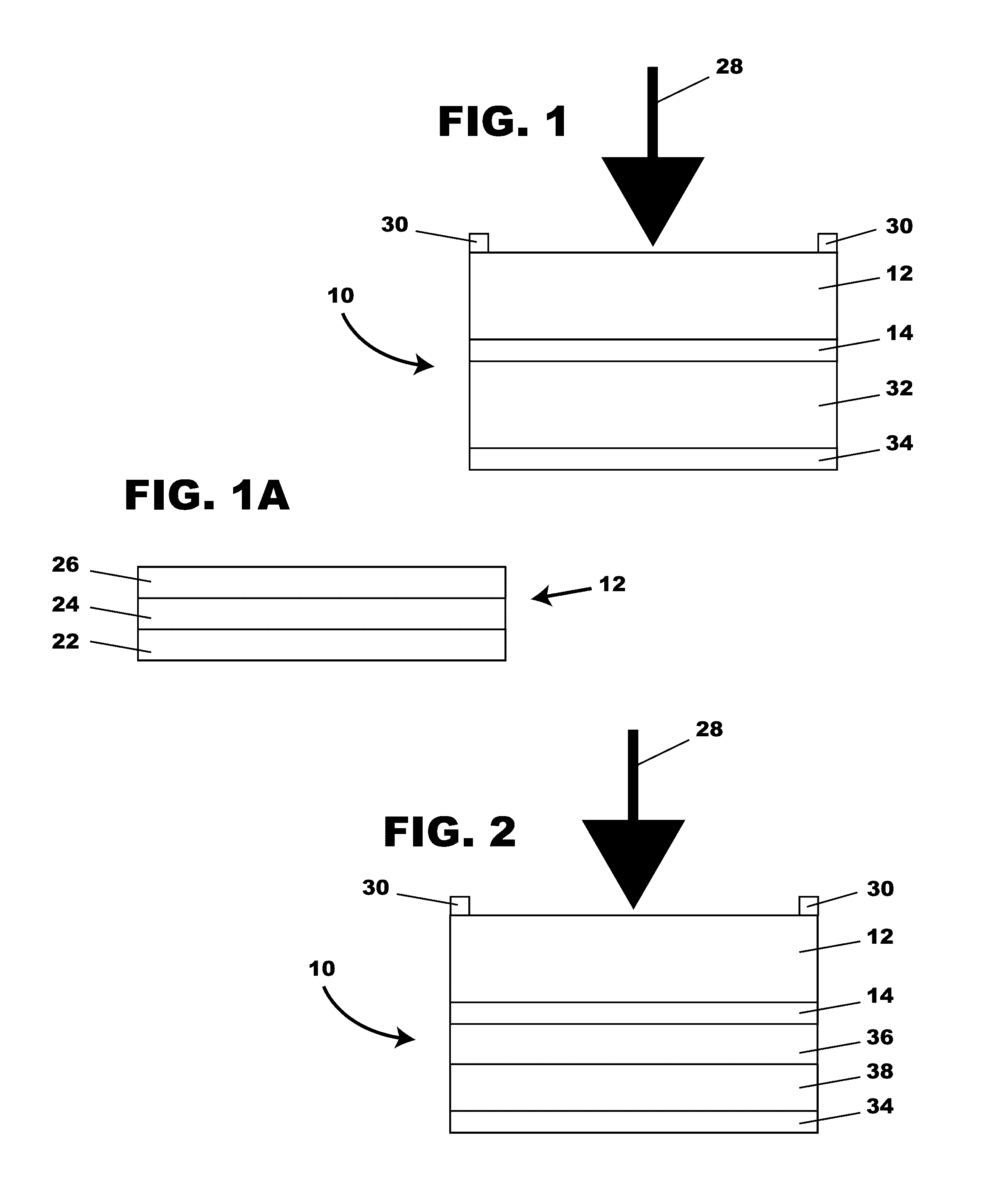

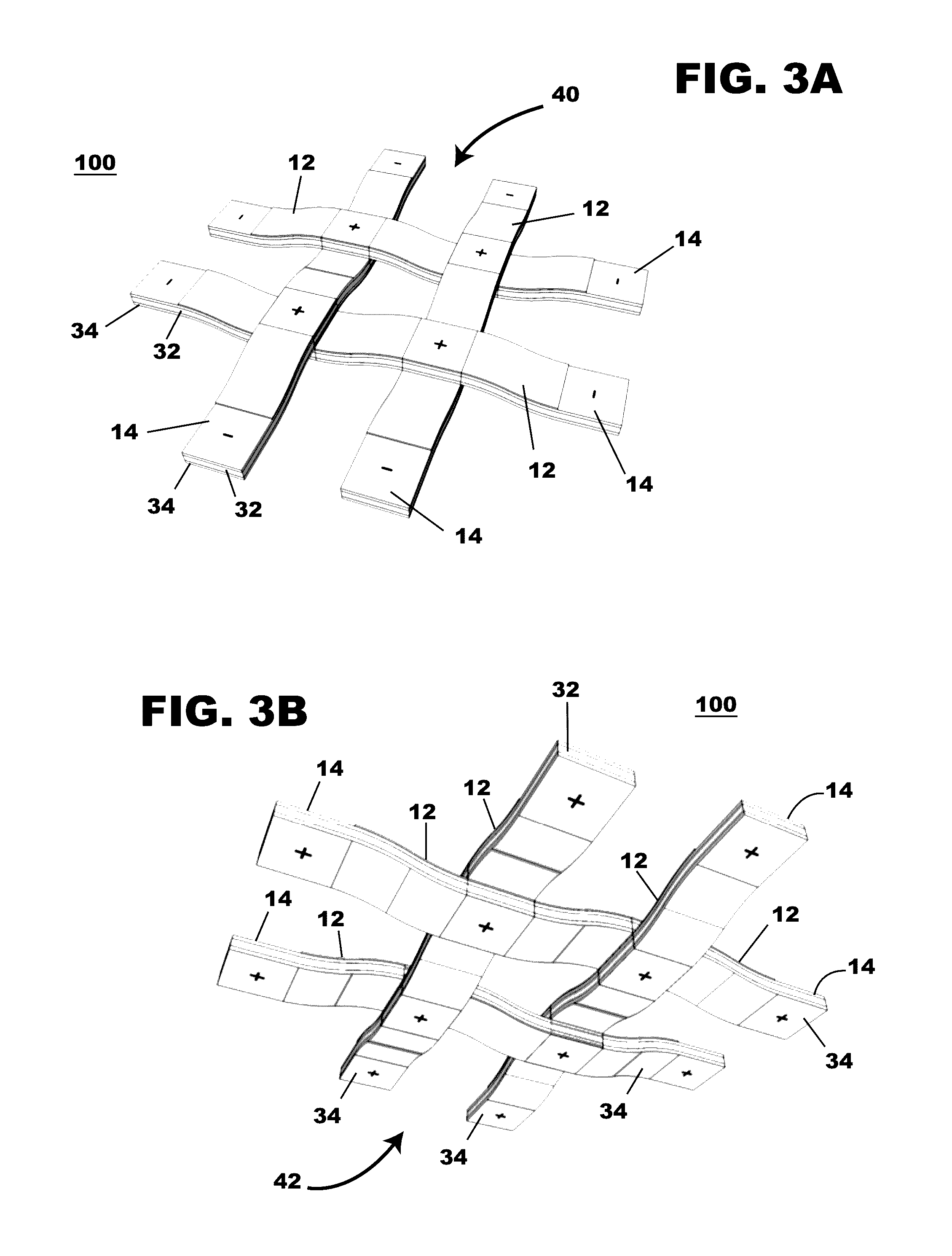

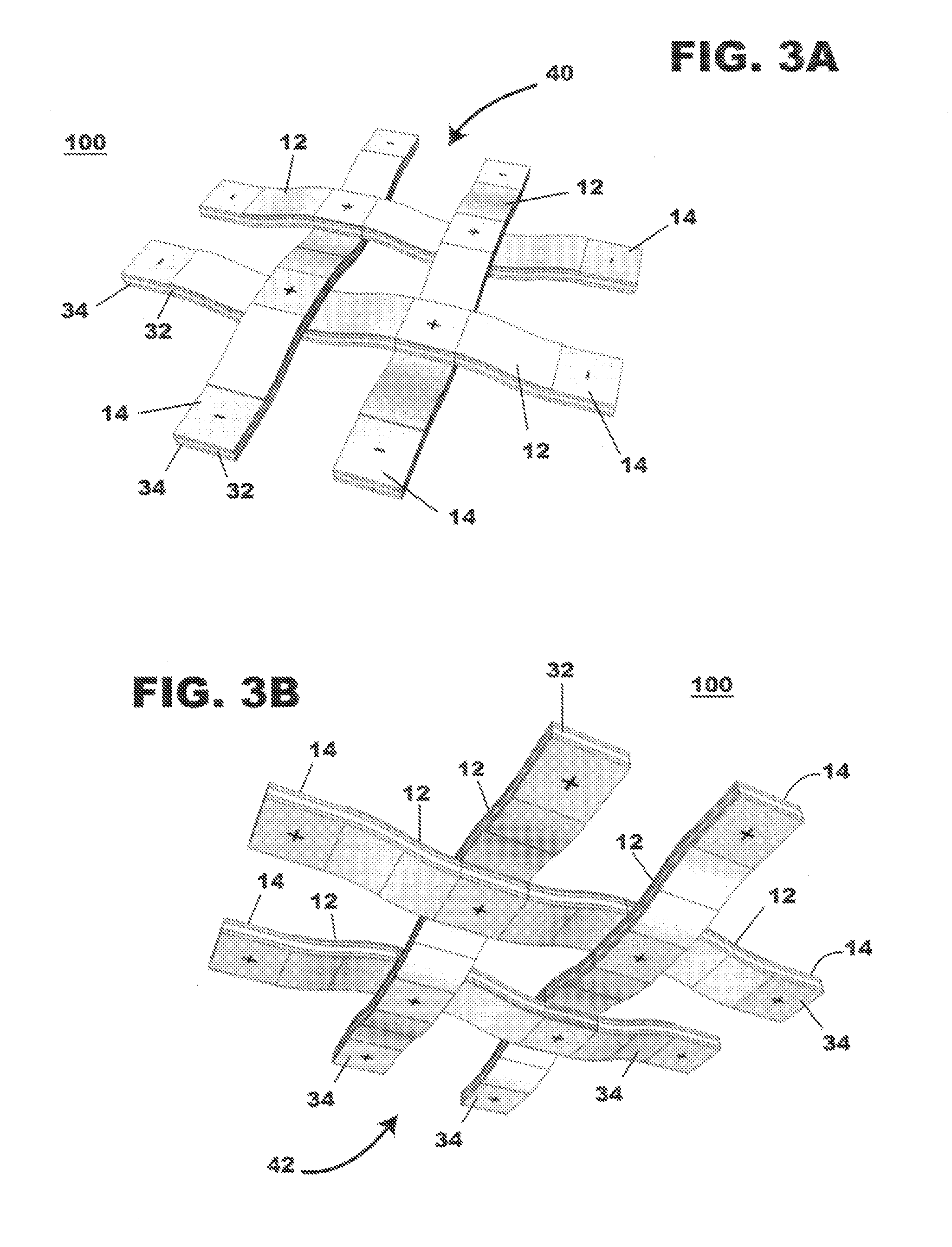

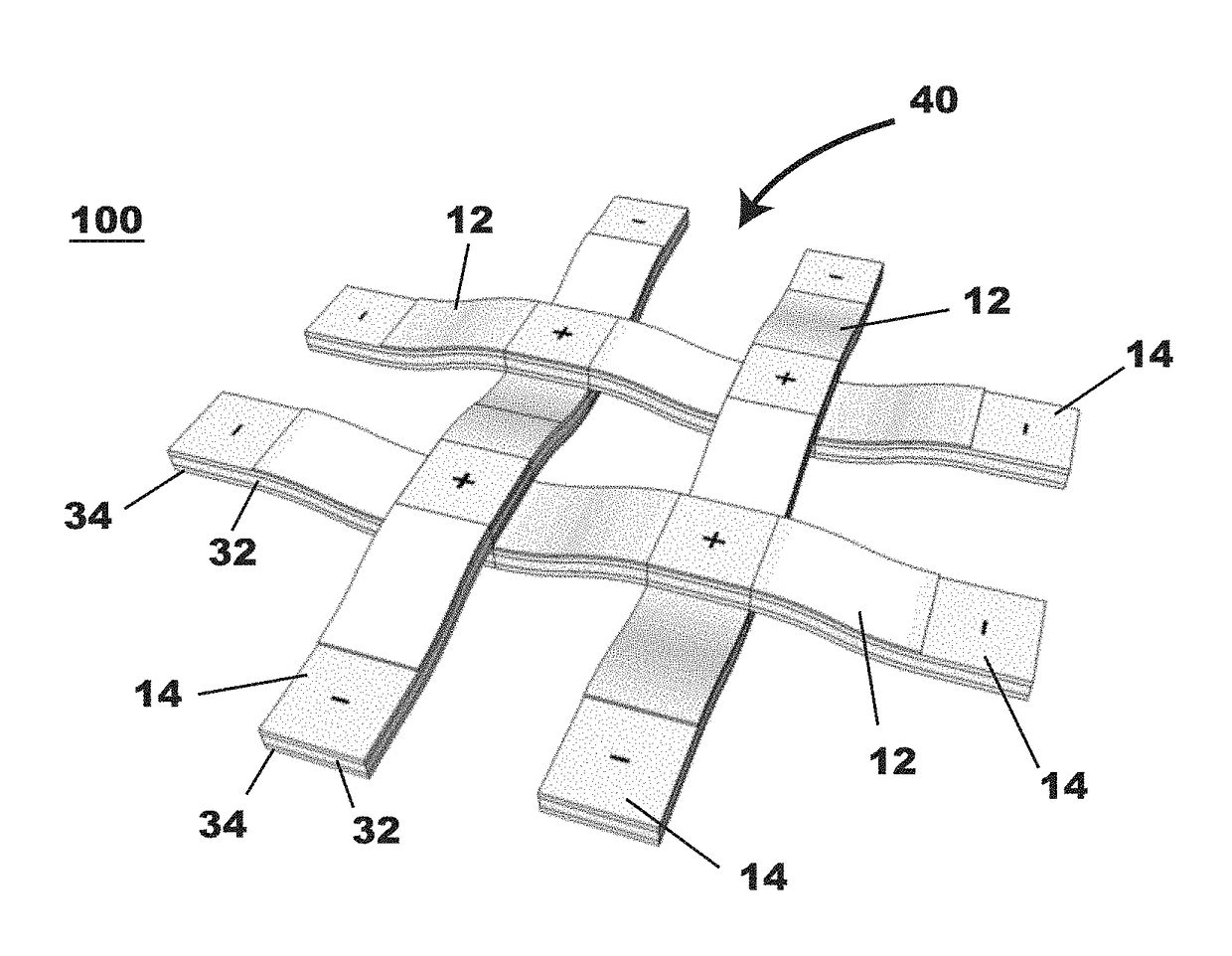

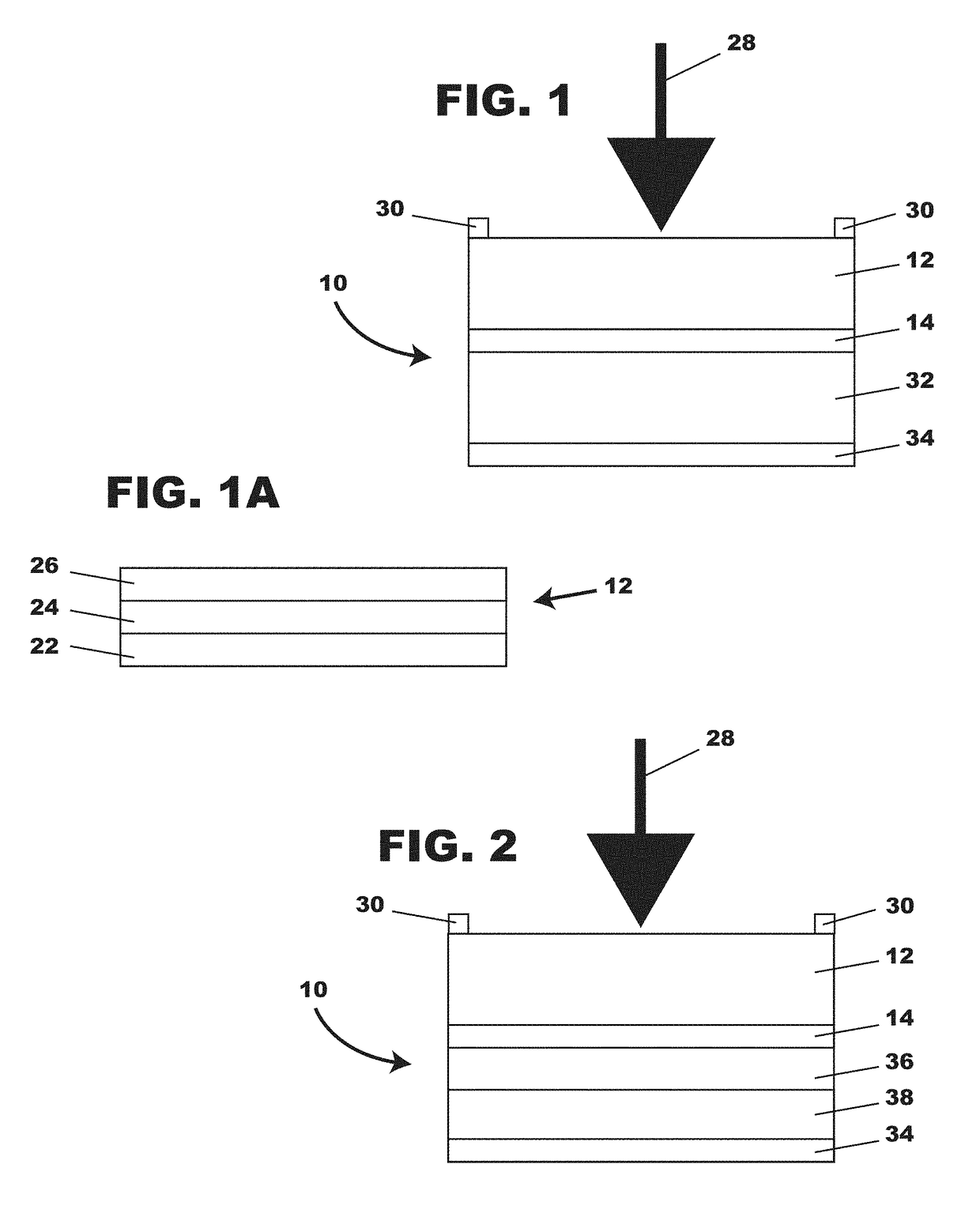

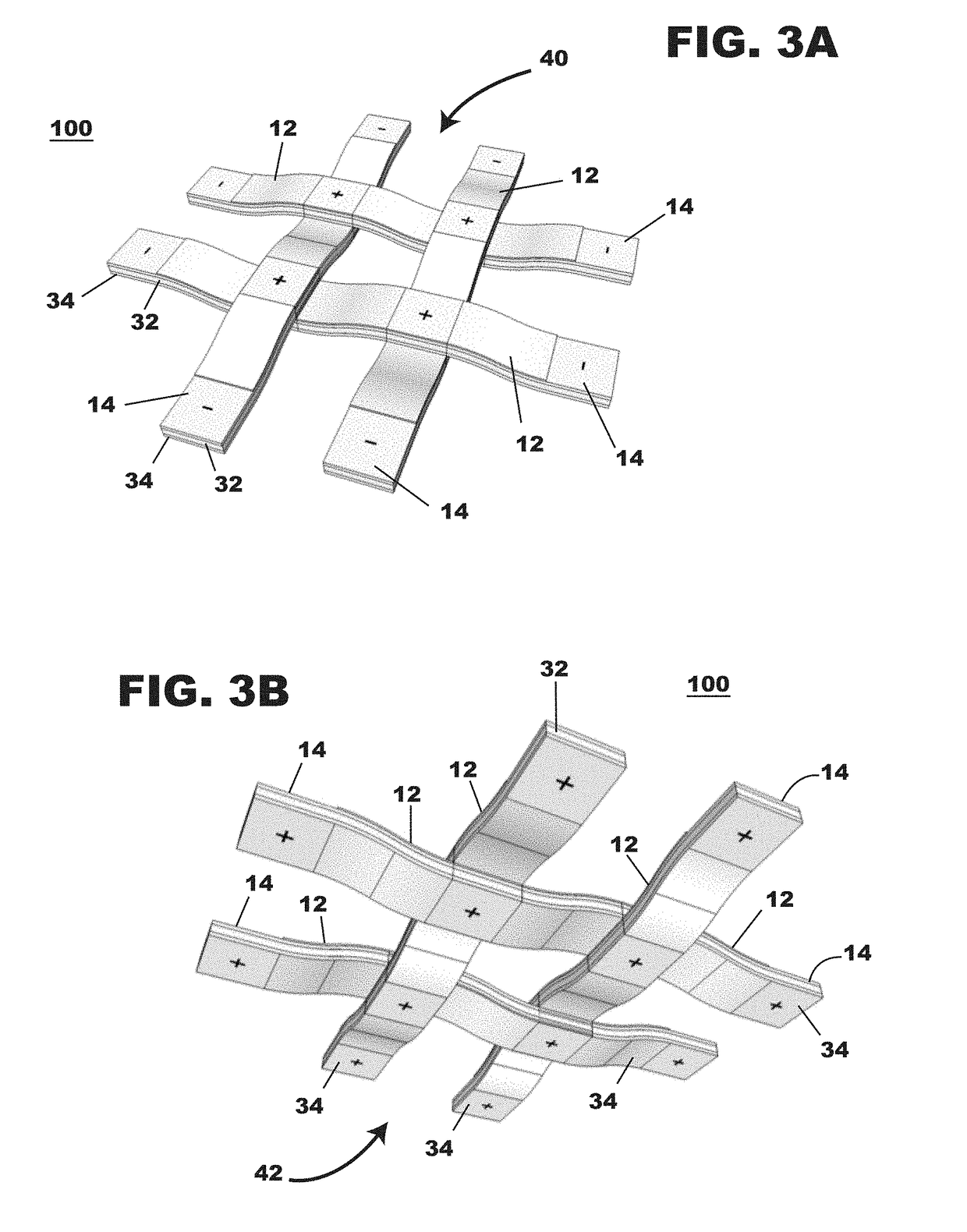

Photovoltaic textiles

InactiveUS20140338721A1Increase electrical contact areaReduce contact resistancePV power plantsPhotovoltaic energy generationElectrical and Electronics engineeringPhotovoltaics

Textile systems and components for establishing electrical characteristics of textiles. The textiles incorporate charge carrying components, such as photovoltaic components, in contact with highly conductive bus conduits to improve electrical properties without compromising physical characteristics of the textiles. Structure, geometries, and methods are provided for textile constructs, including photovoltaic textile constructs.

Owner:PARENT DONALD G +1

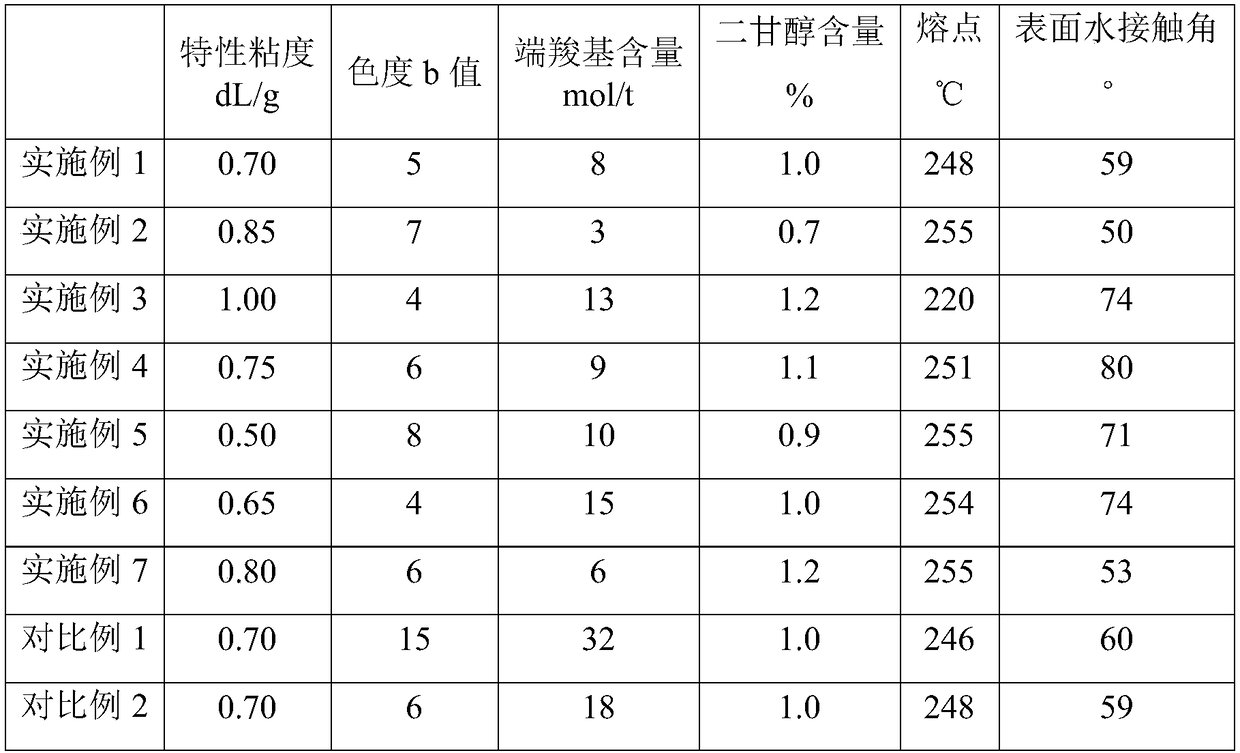

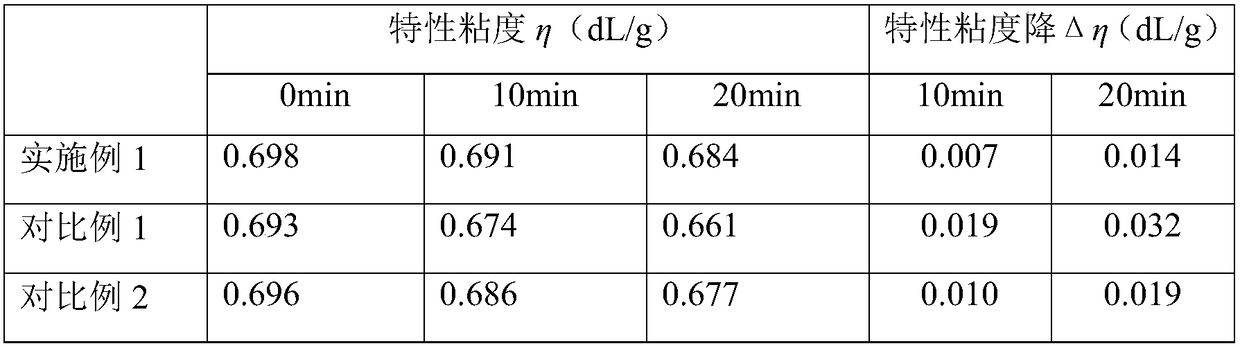

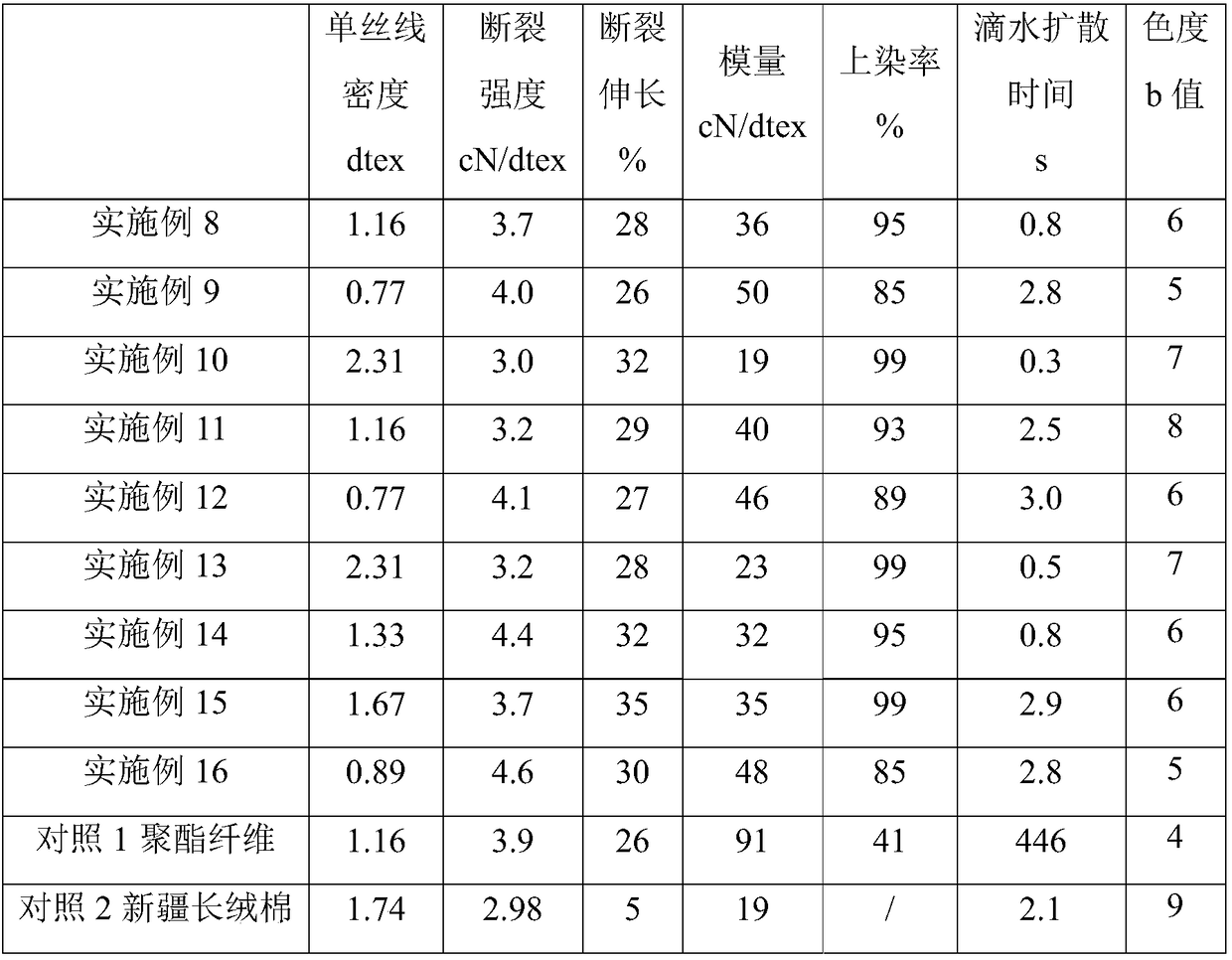

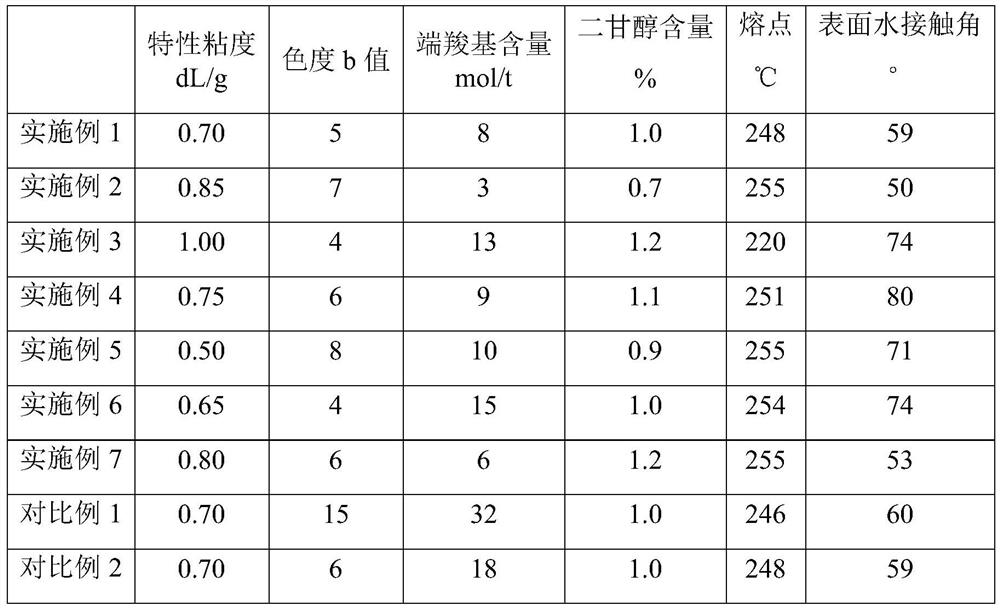

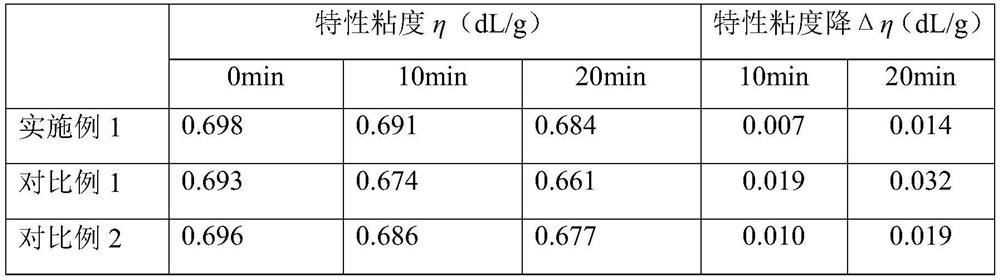

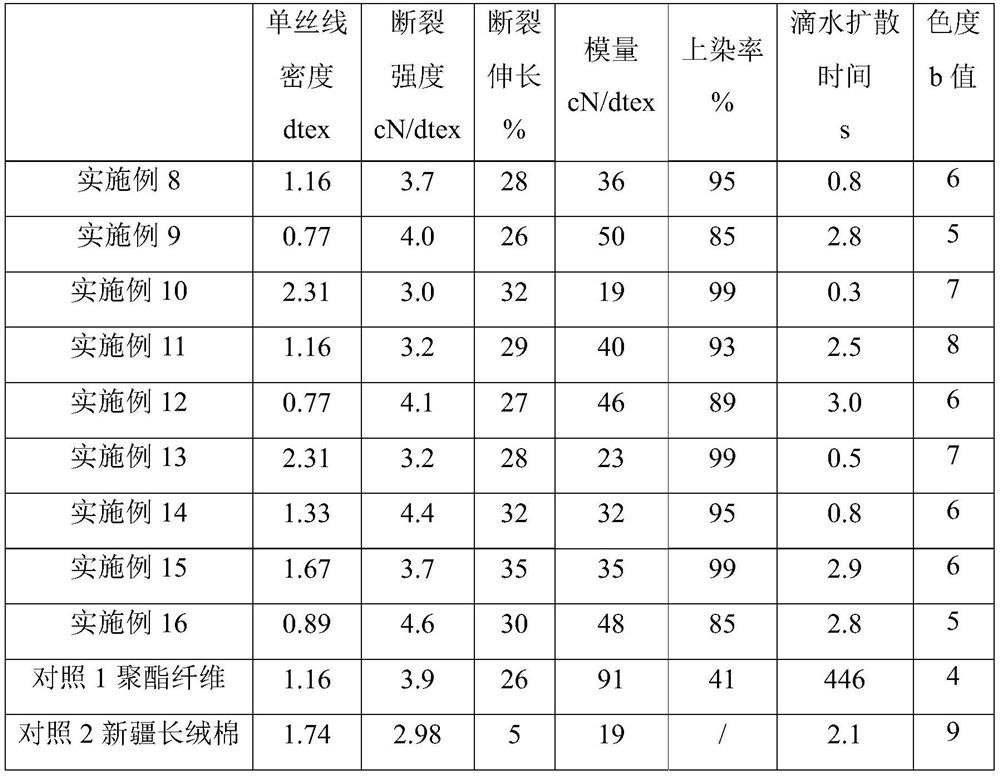

Hydrophilic polyester fiber and preparation method thereof

ActiveCN108193303AViscosity drop becomes smallerGood moisture absorptionSpinnerette packsMonocomponent copolyesters artificial filamentChemistryMetal alkoxide

The invention belongs to the technical field of textile fibers, and particularly relates to a hydrophilic polyester fiber and a preparation method thereof, wherein the hydrophilic polyester fiber is obtained by carrying out melt spinning on a hydrophilic polyester, and the hydrophilic polyester is obtained by polymerizing a ethylene glycol terephthalate oligomer and polyether diol under the actionof a titanium metal alkoxide, a polyhydroxy compound and a phosphorus compound / hindered phenol compound / acetate complex. According to the present invention, the hydrophilic polyester fiber has characteristics of yellowing resistance, reduced viscosity reduction during molding processing, good moisture absorption performance, good normal pressure dyeing performance, no heavy metal pollution, softhand feeling and excellent hue.

Owner:CHINA TEXTILE ACADEMYTIANJINSCI & TECH DEV CO LTD +1

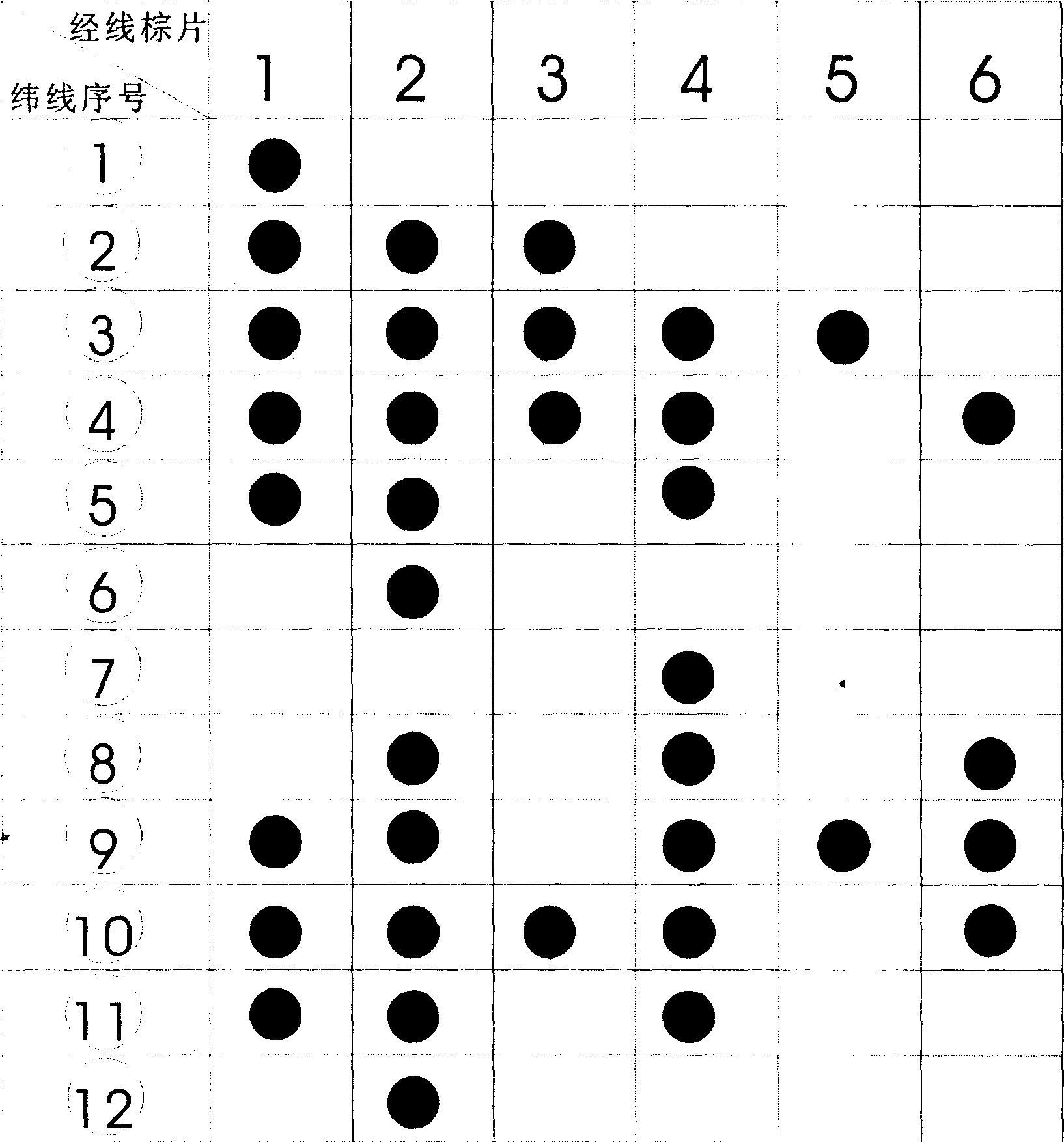

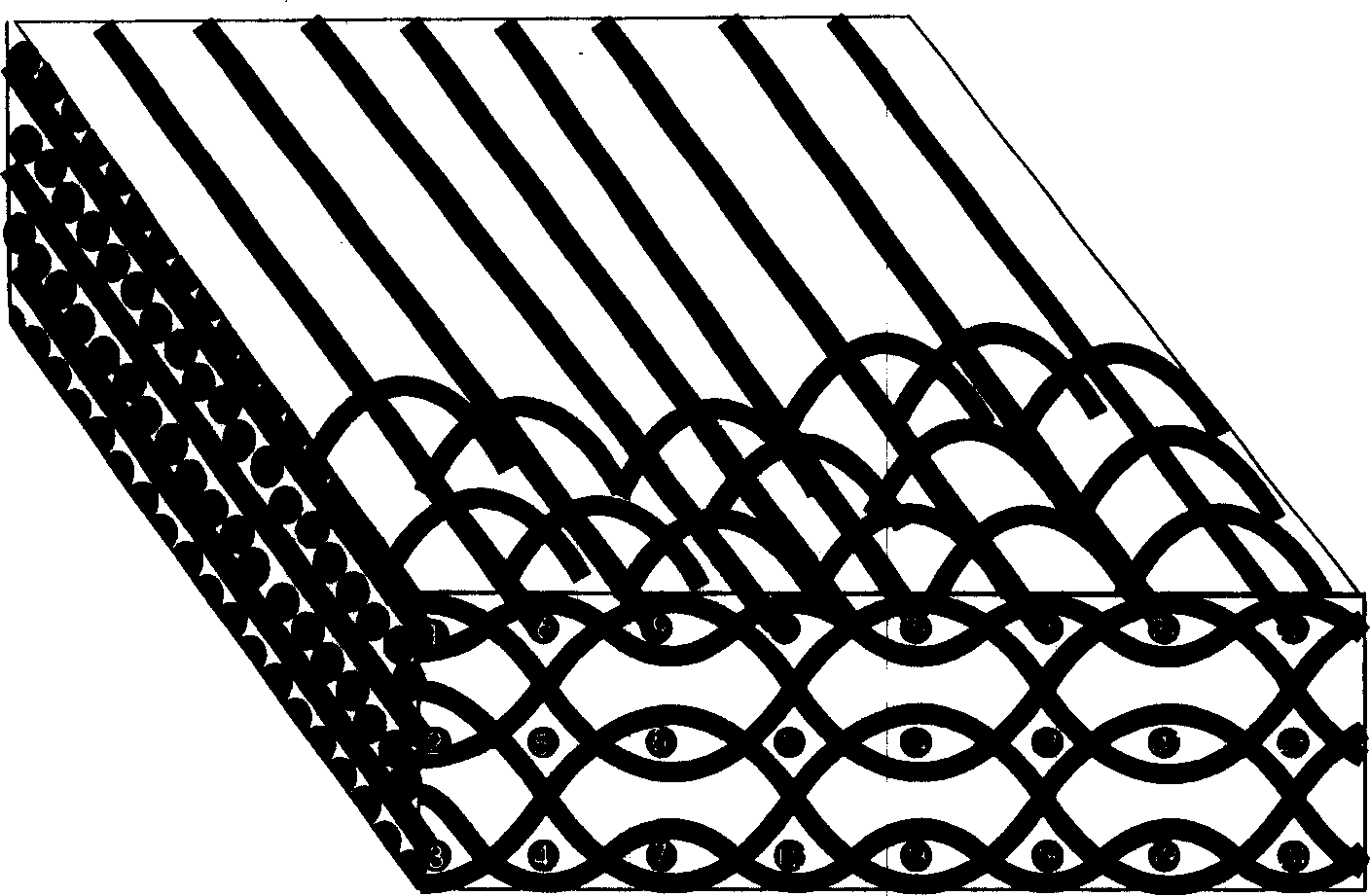

Brake band woven by blend-spinning fiber

InactiveCN1837430AReasonable fiber ratioImprove textile performanceBraking membersWoven fabricsYarnEngineering

This invention relates to a brake strap of blended fibrage, which belongs to braking material field of mechanical apparatus. The present brake strap comprises the following defects: environmental contamination, harm to human's health, bad frictional behavior, rough manufacturing technique, bad textile performance, low product density, small strong force, fissility, easy attrition, no adaptability to modernization equipment. In order to settle these problems, the invention provides a brake strap of blended fibrage with multilayer, and its characters are following: including stock straps and adhesive material, many core-spun single yarn of blended fibrage, which contains a wire, twisted into twine and braided into said stock straps, selecting thermoplastic phenolic resin as adhesive material, osmosizing fully into braided brake strap with multilayer. The invention comprises the following merits: good textile performance, various fibre mixing fully, homogeneous wire distribution, dense textile texture, high product density, burliness, strong force, good flexible performance, logical friction coefficient, good abradability and heat-durability, flexibility and diversification, satisfying the need of power transmission, deceleration and braking of various mechanical equipment, safe reliability, no environmental contamination and harm to human's health in the process of production and application.

Owner:陈钜源

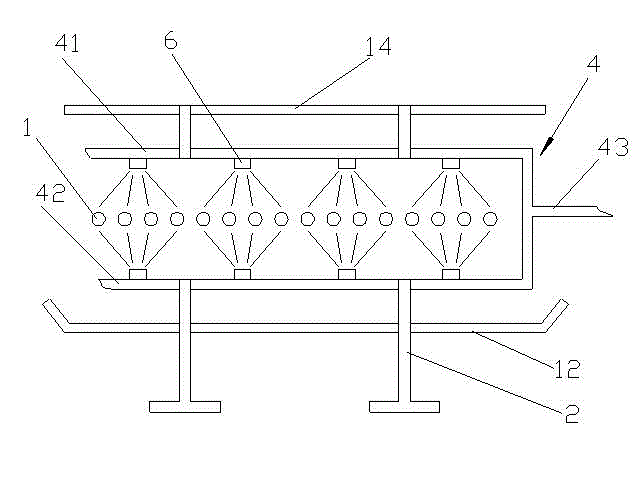

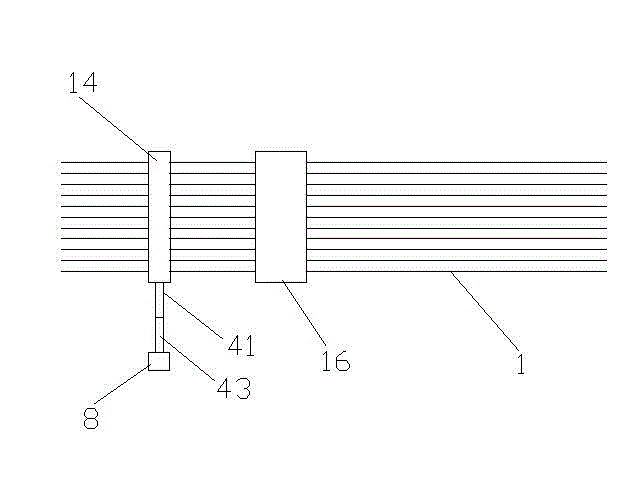

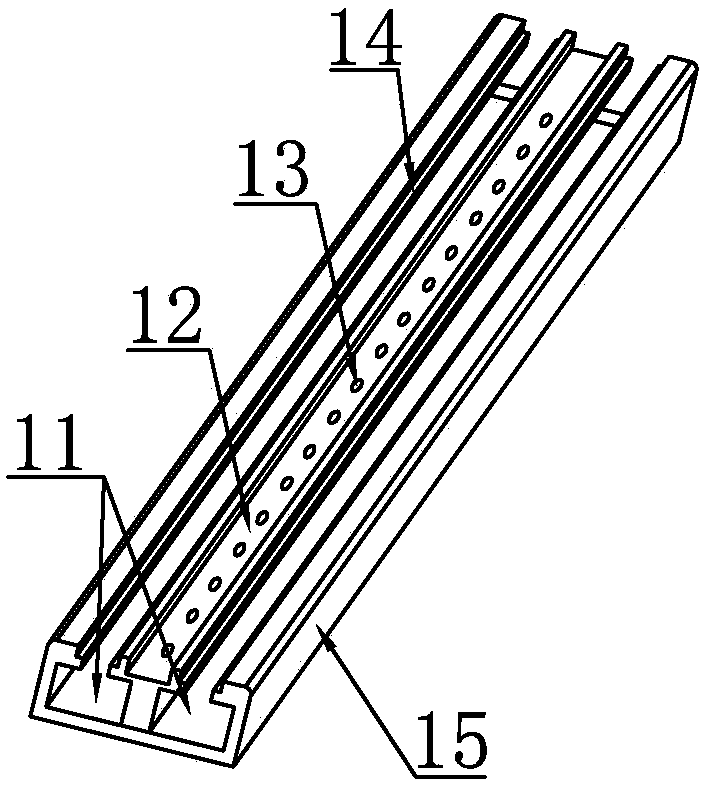

Comprehensive warp lubricating device

InactiveCN102912540AImprove toughnessImprove textile performanceAuxillary apparatusSpray nozzleBlock structure

The invention relates to a comprehensive warp lubricating device which comprises a bracket which extends longitudinally, an oil transporting pipe which is arranged on the bracket and extends horizontally, and a plurality of oil spraying nozzles which are arranged on the oil transporting pipe, wherein the oil transporting pipe is connected with an oil supplying device. The comprehensive warp lubricating device is characterized in that the oil transporting pipe comprises an upper oil transporting pipe and a lower oil transporting pipe; the oil spraying nozzles on the upper oil spraying pipe face downwards; the oil spraying nozzles on the lower oil transporting pipe face upwards; the comprehensive warp lubricating device adopts a opposite spraying manner in the vertical direction, so that the condition that each warp can absorb lubricating oil by 360 degrees can be ensured, and no lubricating dead angle exists; compared with the conventional one-way spraying device, the comprehensive warp lubricating device is relatively uniform in sparing, and conductive to improving the routing and spinning performances of the warps; an oil blocking structure and an oil collecting structure are respectively arranged above and below the integrity of all the oil spraying nozzles, so that the lubricating oil can be prevented from being sprayed to areas outside the warps, the pollution is prevented, and the cleaning is convenient; and a drying oven also can be arranged on one side of the integrity of the upper oil transporting pipe and the lower oil transporting pipe, so that wet parts (carrying the lubricating oil) of the warps can be dried in real time, and the conglutination of the warps can be prevented.

Owner:WUJIANG KESHIDA TEXTILE

Photovoltaic textiles

ActiveUS20150372249A1Improves solar textile performanceEliminates shadowing limitationPV power plantsSolid-state devicesPhotovoltaicsTextile

A tape structure and related circuit configurations for textile systems to establish electrical characteristics of textiles. The textiles incorporate charge carrying components, such as photovoltaic components, in contact with conductive layers in a single tape structure to improve electrical properties without compromising physical characteristics of the textiles. The textiles include photovoltaic tapes, each having an optically transparent layer, a photovoltaic layer, a first electrically conducting layer, a second electrically conducting layer and an insulating substrate located between the first electrically conducting layer and the second electrically conducting layer.

Owner:PARENT DONALD G

Preparation method of impregnating agent for high silicic acid glass fiber

The invention discloses a preparation method of an impregnating agent for high silicic acid glass fiber. The impregnating agent comprises the following components in parts by weight: 0.2 to 0.6 part of coupling agent, 5 to 15 parts of reinforcing agent, 2 to 7 parts of film forming agent, 0.5 to 1.5 parts of lubricant, 0.3 to 0.5 part of antifoaming agent, 0.01 to 0.07 part of pH adjuster, 0.5 to 1.1 parts of protective agent, and 70 to 95 parts of deionized water. The preparation method comprises the following steps: adding part of deionized water into the reactor, adding a coupling agent and a pH adjuster, stirring to obtain a mixed solution (A); adding deionized water into unsaturated polyester resin in a stirring pot, adding diluted water soluble epoxy emulsion into the stirring pot, stirring, then mixing the mixture with the mixed solution (A) to obtain a mixed solution (B); adding diluted lubricant into the mixed solution (B), evenly mixing to obtain a mixed solution (C); adding an antifoaming agent and a protective agent into the mixed solution (C), stirring, and finally adding the residual deionized water.

Owner:四川威玻股份有限公司

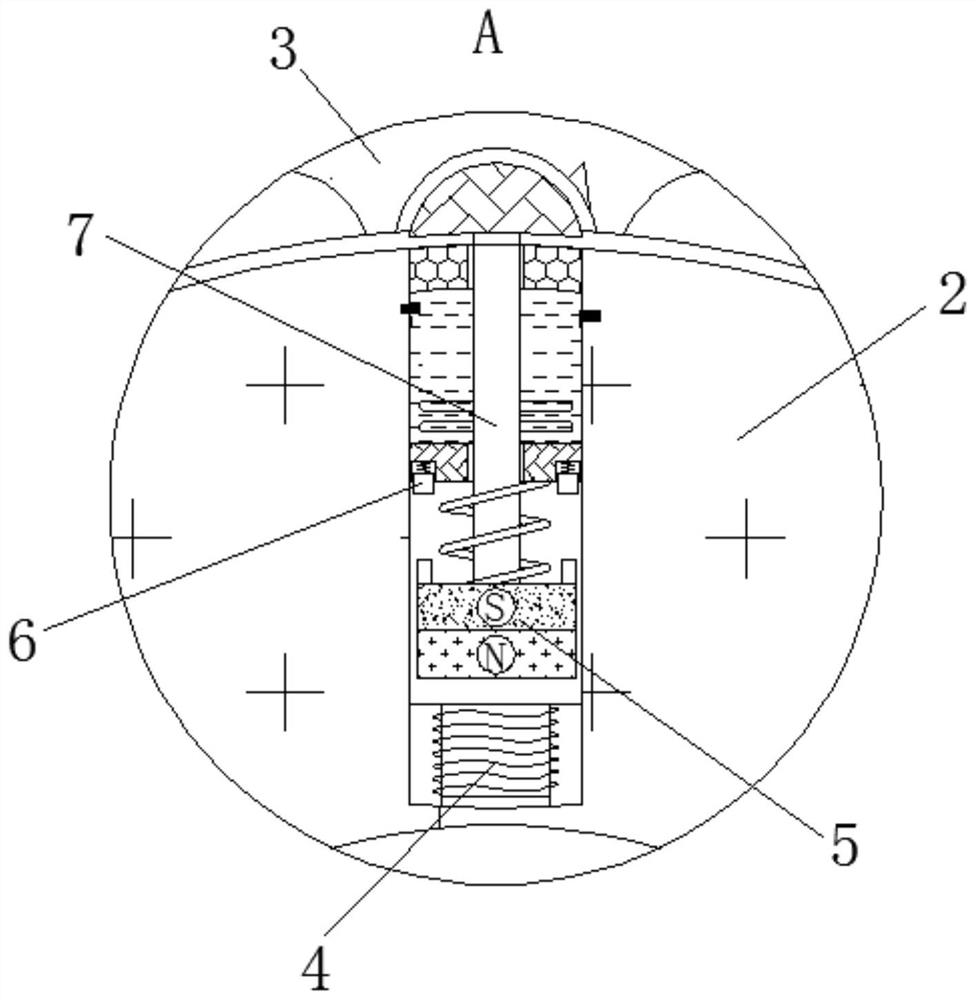

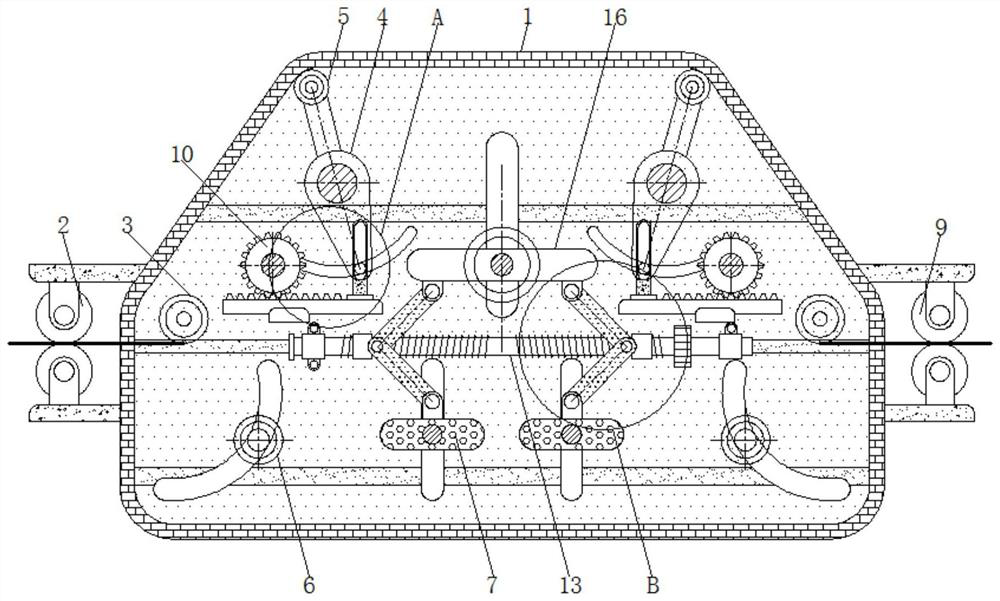

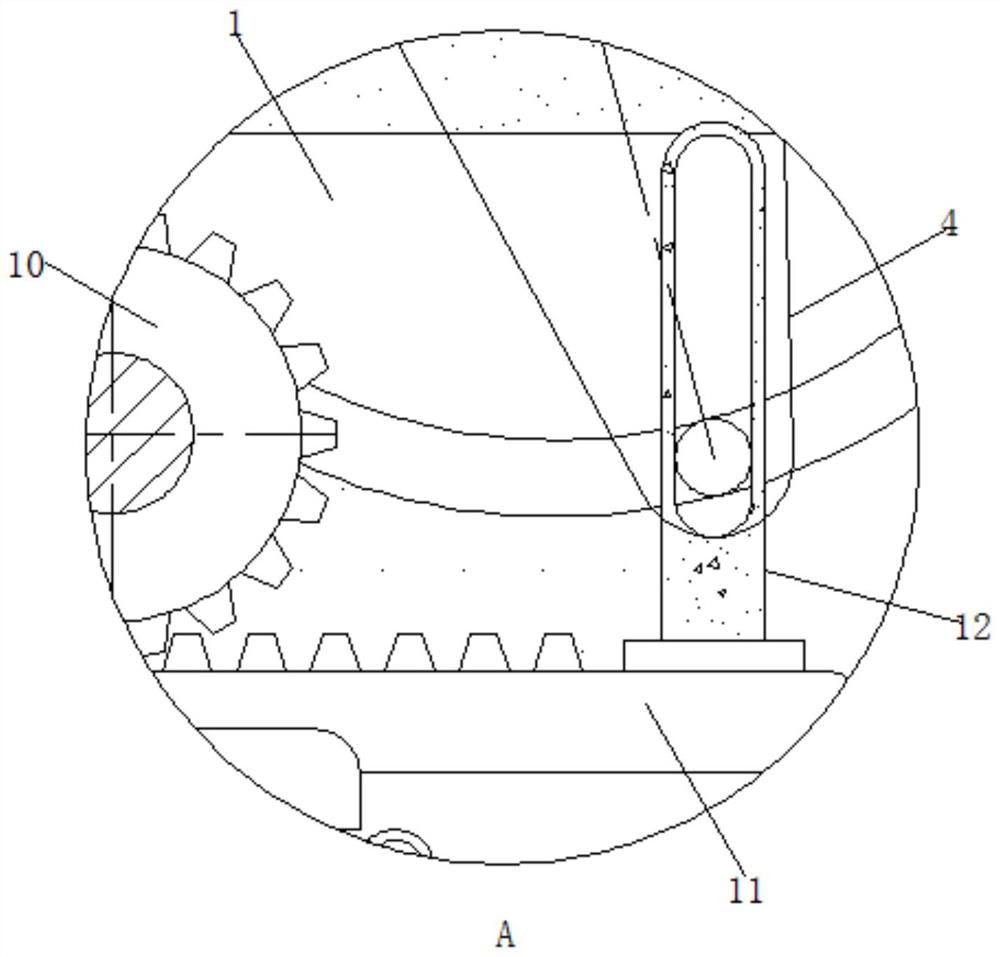

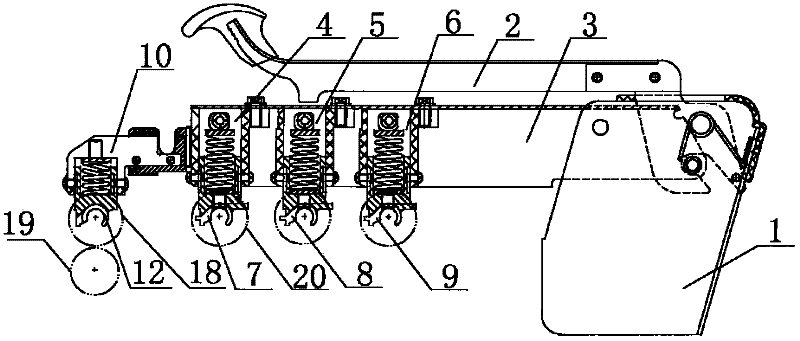

Pressure-adjustable yarn gripper for air-jet loom based on intelligent manufacturing principle

The invention relates to the technical field of textile equipment, and discloses a pressure-adjustable yarn gripper for an air-jet loom based on the intelligent manufacturing principle. The pressure-adjustable yarn gripper comprises a machine frame, a cam is movably connected into the machine frame, a movable protruding block is movably connected to the exterior of the cam, an electromagnet is fixedly connected into the cam, a permanent magnet block is movably connected to the exterior of the electromagnet, and an electric contact block is movably connected to the exterior of the permanent magnet block. Through cooperative use of a pressure rod, a limiting sliding block, a sliding rod, a lifting rod, an adjusting rod and a threaded rod, the effect of increasing the yarn clamping pressure in the yarn clamping process is achieved, so that the yarn gripper meets the requirement for fabrics with small warp and weft density or small warp and weft cross weaving friction force, the use rangeof the yarn gripper is effectively widened, and the use effect of the yarn gripper is effectively improved; and loosening of the finished fabrics due to insufficient weft tension caused by insufficient clamping force is effectively avoided, so that the quality of the woven finished fabrics is effectively guaranteed, the textile effect is effectively improved, untwisting or retracting of yarns is effectively prevented, and the production efficiency is guaranteed.

Owner:嘉兴市恒丰纺织股份有限公司

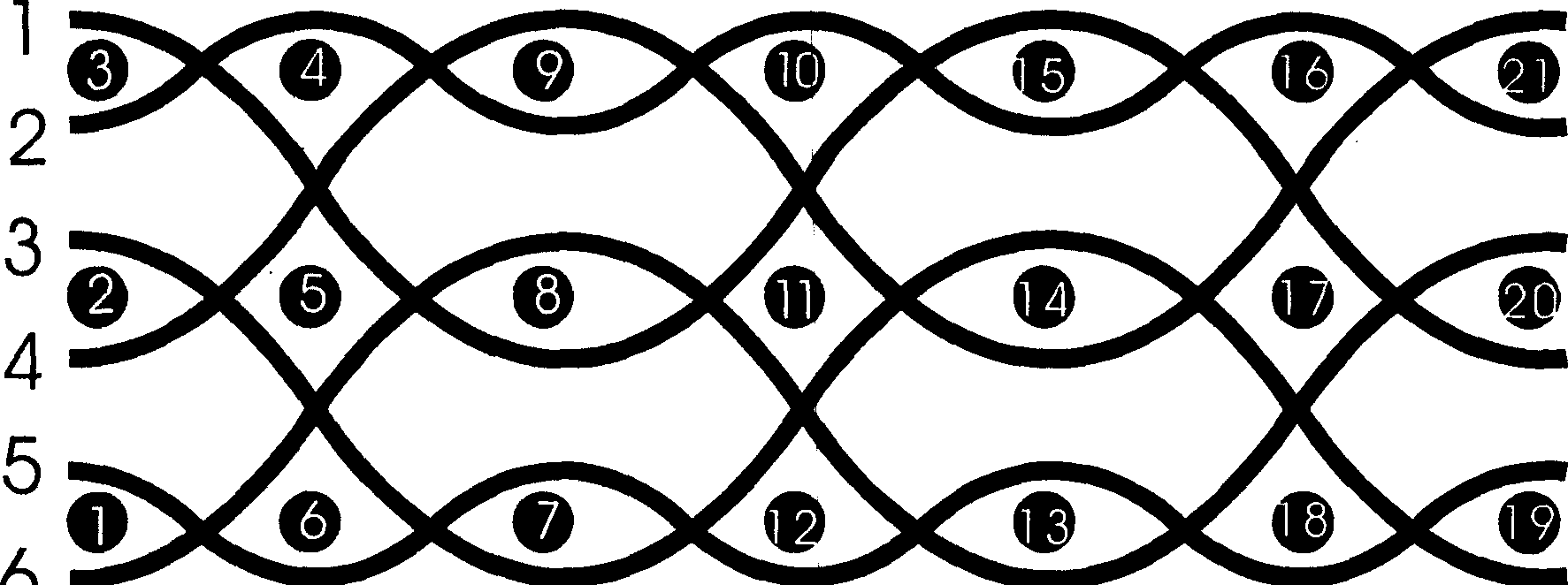

Photovoltaic textiles

ActiveUS20160359452A1Improves solar textile performanceEliminates shadowing limitationSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerElectrically conductive

A solar textile formed of a weave of a first tape structure and a second tape structure. In one embodiment, the ratio of the number of the first tape structure to the second tape structure is three to one. The first tape structure includes a photovoltaic (PV) conversion layer and an electrically conductive substrate. The second tape structure includes a PV conversion layer, a first electrically conductive layer, a non-conducting insulation layer and a second electrically conductive layer. The first tape structure and the second tape structure are in contact with one another so that the electrically conductive substrate of the first tape structure is in contact with the PV conversion layer of the second tape structure.

Owner:PARENT DONALD G

Water-soluble resin

The invention relates to water-soluble resin, which is synthesized from the composition comprising the following components by the weight percentage: 5% to 15% of maleic anhydride, 15% to 30% of diethylene glycol, 25% to 35% of oxalic acid, 15% to 25% of diethanol amine and 5% to 20% of acetic acid, wherein the component of diethanol amine is preferably 20% to 23%. The resin is prepared through the following steps: pumping nitrogen into a reaction kettle for protection; heating slowly; stirring, heating up and heat-insulating; and cooling and further heat-insulating. The water-soluble resin can be adopted as the composition of the domestic enhanced glass fiber sizing agent so as to improve the textile performance of the glass fiber, improve the monofilament tension and enhance the toughness, thereby meeting the requirements for the subsequent production.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Method of processing textile products utilizing decomposable emulsifiers

InactiveUS6110231AImprove performanceImprove textile performanceLiquid surface applicatorsFibre typesWater bathsPolymer chemistry

A method of applying a surface coating to an intermediate textile product to enhance the performance of the textile product in a downstream manufacturing process. The method includes the steps of preparing an application composition having a process-enhancing material, an acid-decomposable emulsifier and an acid; emulsifying the application composition in a water bath to improve the surface activity of the process-enhancing material; exposing the intermediate textile product to the water bath containing the application composition; and decomposing the emulsifier into non-surface active substances simultaneously with the step of applying the application composition to the intermediate textile product to thereby permit the process-enhancing material to exhaust onto the textile product.

Owner:BOEHME FILATEX +1

Ramie degumming method suitable for close-fitting fabric

InactiveCN106498506AImprove oil absorption capacityReduce hardnessVegetable materialBreaking strengthUltrasound - action

The invention discloses a ramie degumming method suitable for a close-fitting fabric. The method comprises the following steps: adding vegetable oil before the traditional enzyme treatment, and pretreating fiber bundles, wherein a small amount of the added vegetable oil can infiltrate into the fiber interior and fiber surface so as to achieve a certain protective effect on the fiber structure, and the condition that the strength of the ramie is greatly damaged by subsequent ultrasonic treatment is avoided; adding pelelith, namely treating the fiber surface by referring to a stone wash process, wherein the particle size of the pelelith is controlled to 2-5mm so as to prevent the pelelith of large particle size from causing great damage to the fibers under the ultrasonic action, and if the particle size is too small, the grinding effect on the fiber surface is not obvious. In conclusion, the ramie degumming method disclosed by the invention is actually a degumming method of integrating biological enzyme degumming, ultrasonic treatment and stone wash treatment, the degummed ramie fibers have good degumming effects, and the indexes of the fibers such as breaking strength, whiteness and the like meet the textile requirements of the close-fitting fabric.

Owner:长兴锦桥纺织有限公司

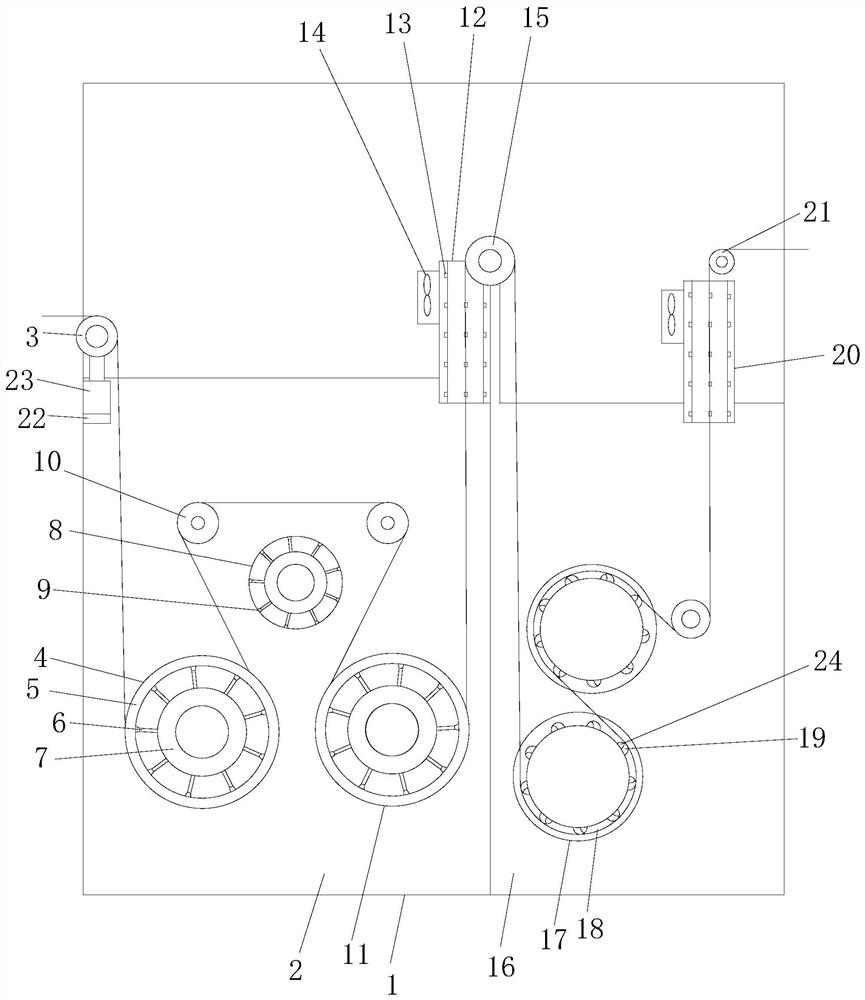

Textile yarn dedusting and sizing device

PendingCN112359515AImprove sizing effectImprove textile performanceLiquid/gas/vapor removalTextile treatment machine arrangementsTextile yarnWater spray

The invention discloses a textile yarn dedusting and sizing device. The textile yarn dedusting and sizing device comprises a rack, a cleaning box, a yarn inlet wheel, a first cleaning roller, a yarn guide annular groove, a water spraying hole, a water spraying pump, a second cleaning roller, a cleaning spraying head, an auxiliary yarn guiding wheel, a third cleaning roller, a first hot air dryingchannel, hot air spraying holes, an air heater, a yarn transition wheel, a sizing groove, a first sizing wheel, a yarn sizing annular groove, a stirring paddle plate, a second hot air drying channel and a discharging guide wheel. According to the textile yarn dedusting and sizing device provided by the invention, the sizing device can clean and dedust yarns to improve the cleanliness of the surfaces of the yarns, and the yarns are uniformly sized in multiple directions, so that the sizing effect of the yarns is improved, and the textile performance of the yarns is improved.

Owner:HAIYAN SHENHE TEXTILE DEV

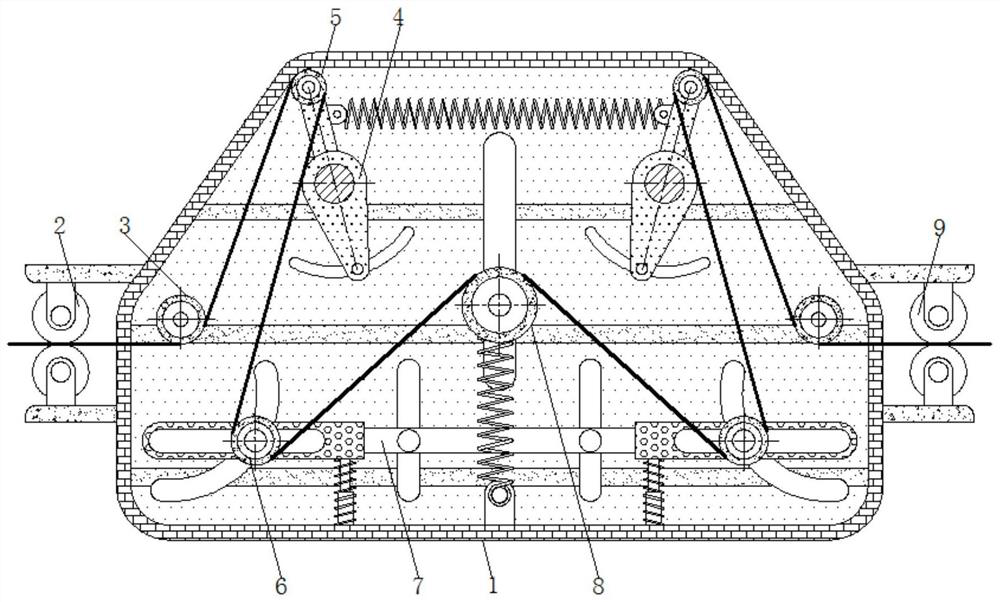

Doubling thread traction tightness adjusting mechanism for knitting machine

InactiveCN114592275AGuaranteed uptimeChange the tensionWeft knittingWarp knittingGear wheelEngineering

The invention relates to the technical field of knitting machines, and discloses a doubling thread traction tightness adjusting mechanism for a knitting machine, which comprises a shell, a thread inlet roller is arranged on the surface of the shell, a fixed wheel is arranged in the shell, a turntable is movably connected in the shell, a first moving wheel is arranged on the surface of the turntable, and a second moving wheel is arranged on the surface of the turntable. The doubling thread traction tightness adjusting mechanism for the knitting machine has the advantages that the driving gear and the toothed plate are used in a matched mode, the toothed plate and the push rod are used in a matched mode, and the rotating disc and the first moving wheel are used in a matched mode; the distance between the first moving wheel and the fixed wheel can be adjusted, the tension on the surface of a doubling thread can be changed, the tension adjusting effect on the surface of the doubling thread is good, normal operation of the knitting machine can be effectively guaranteed, and the spinning effect of fabric can be improved.

Owner:唐意凤

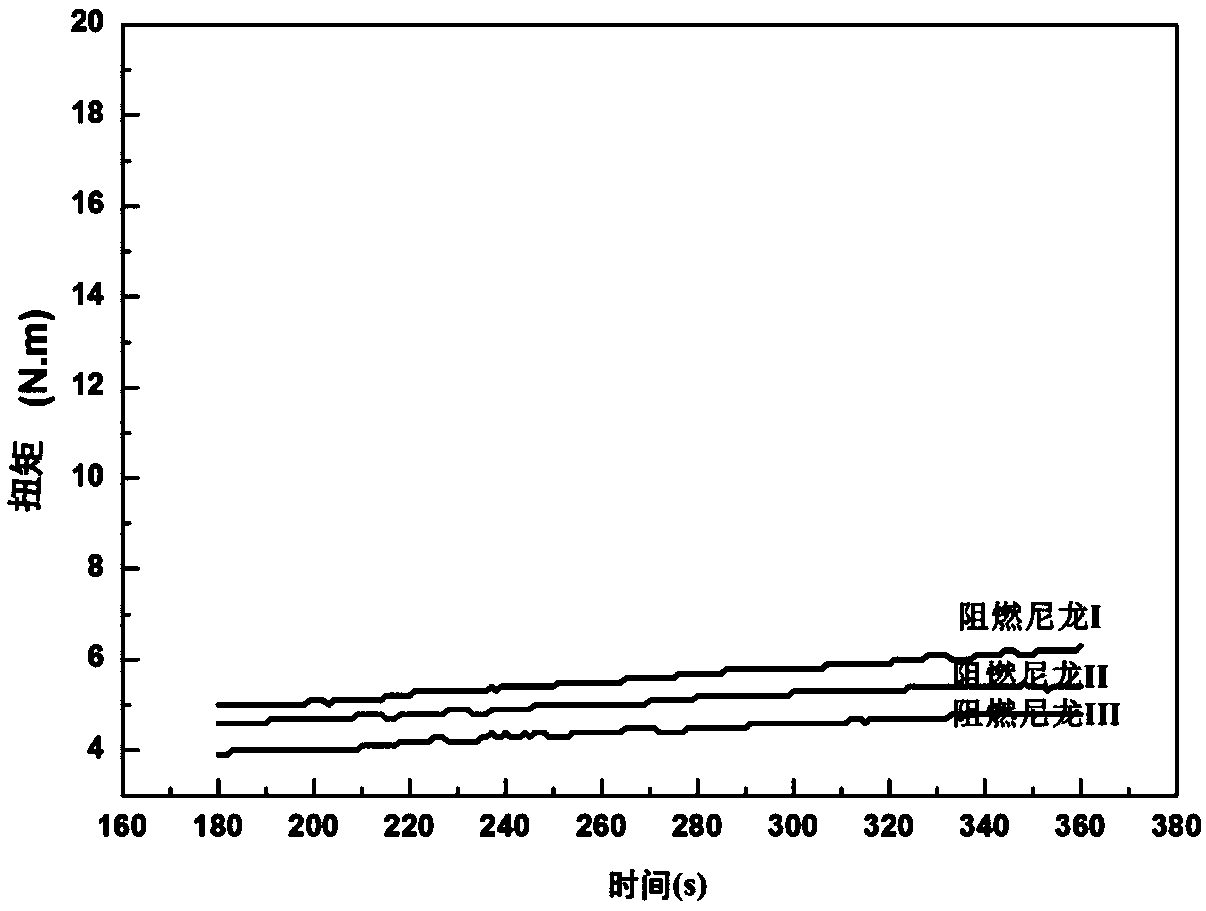

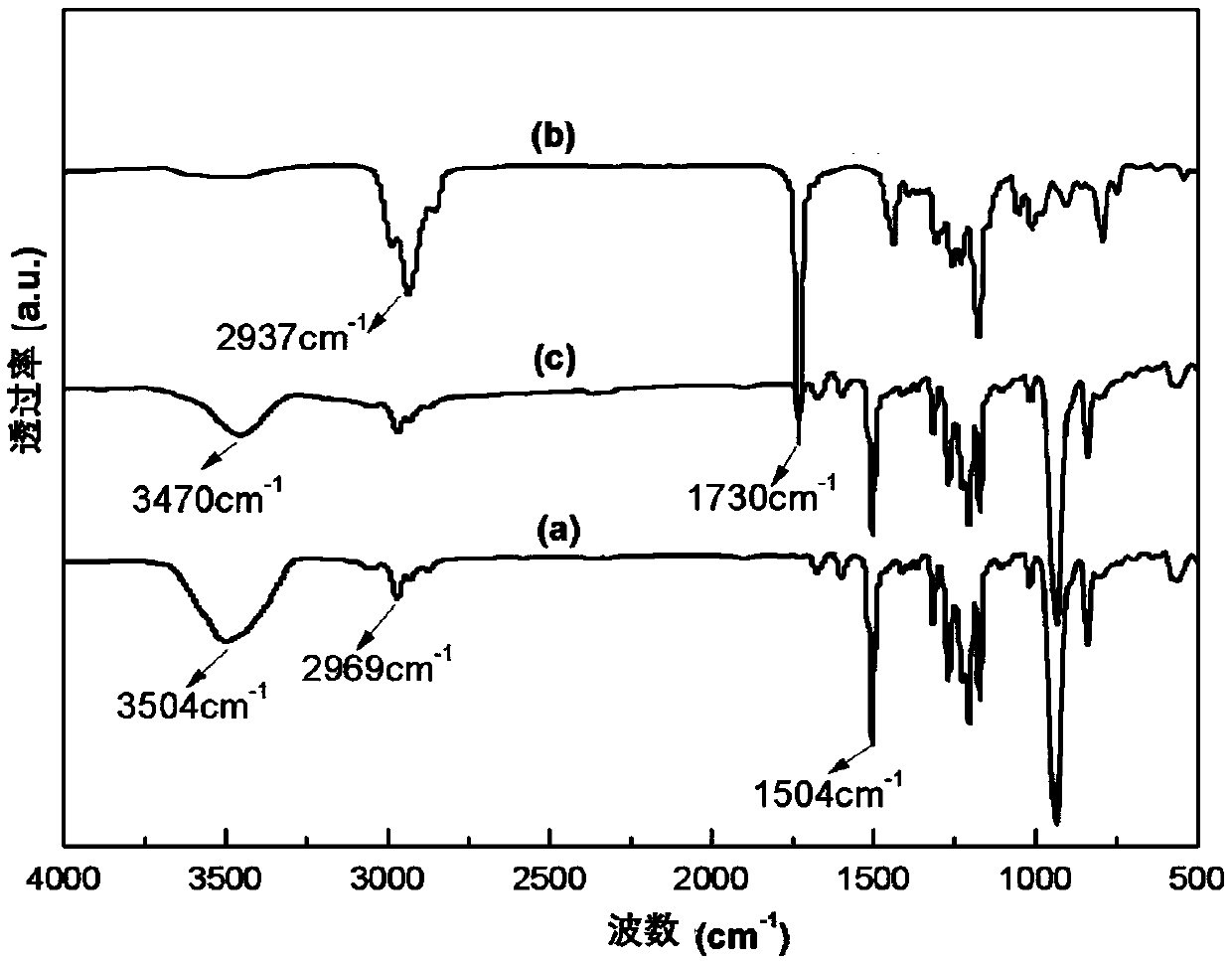

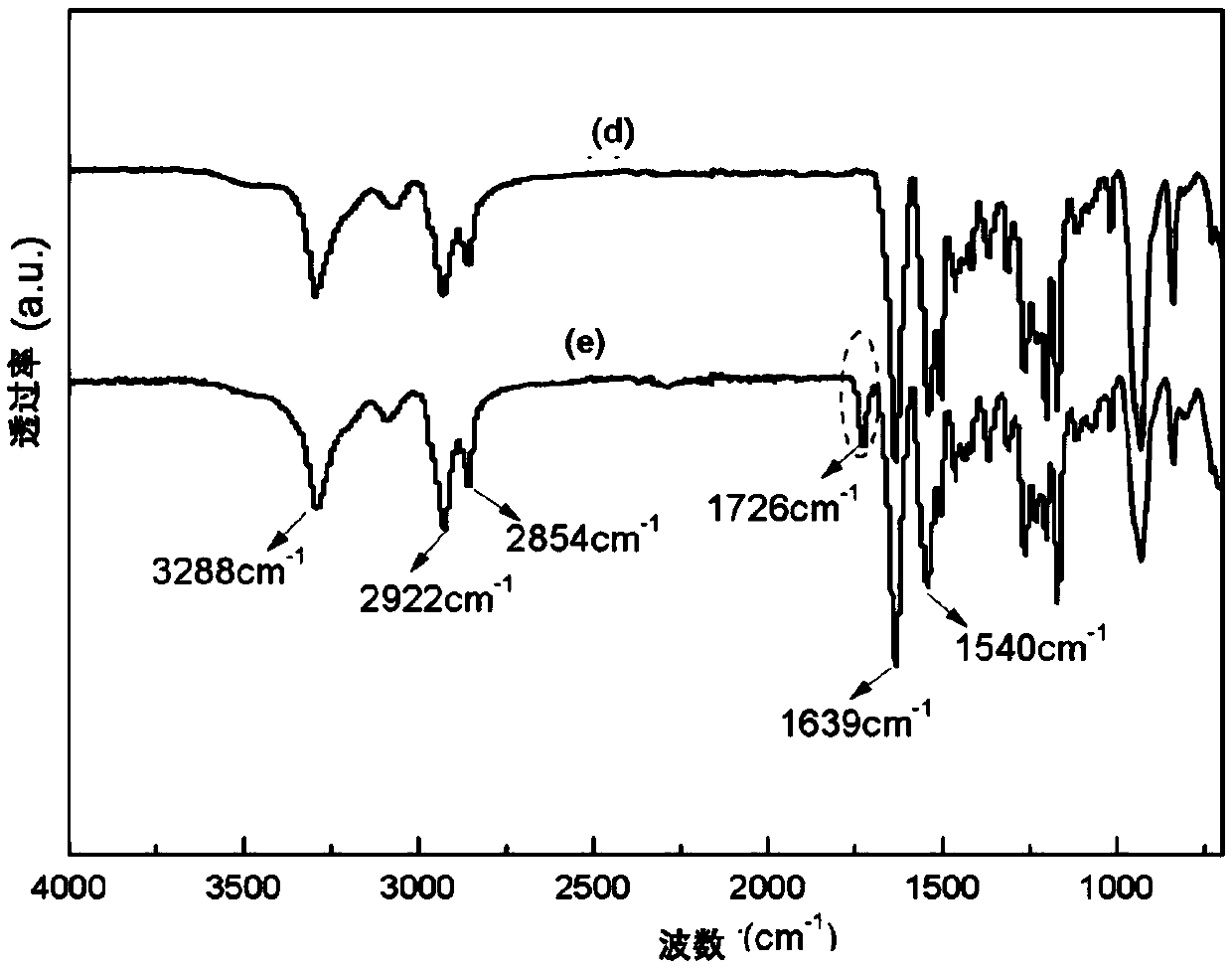

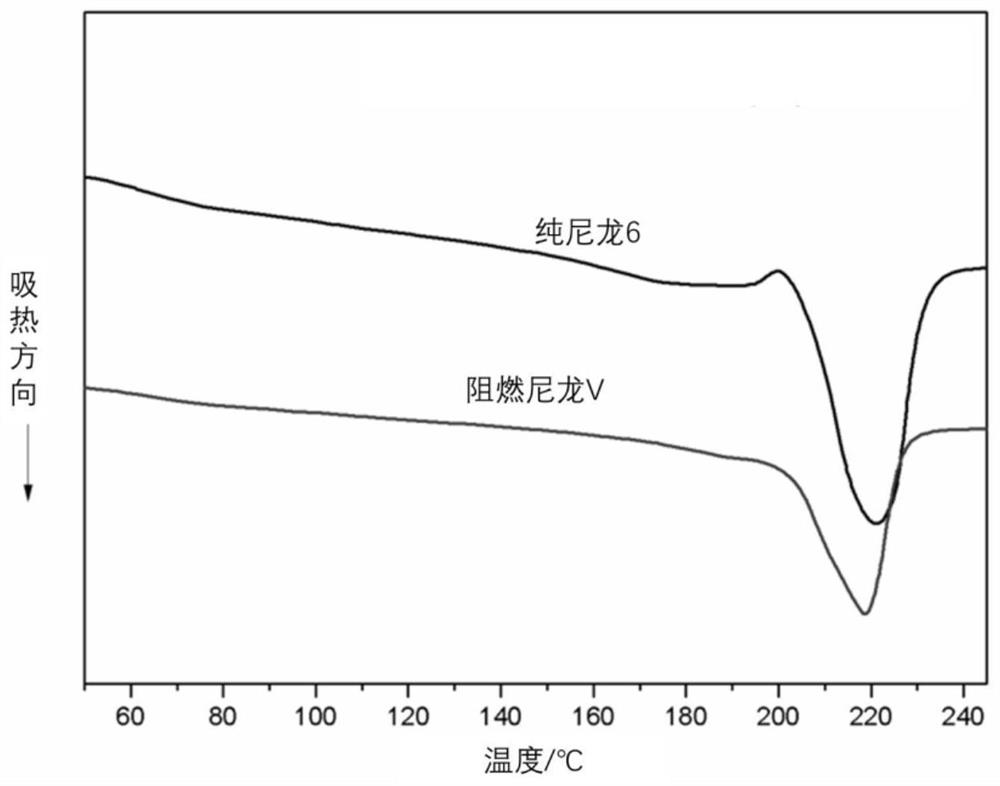

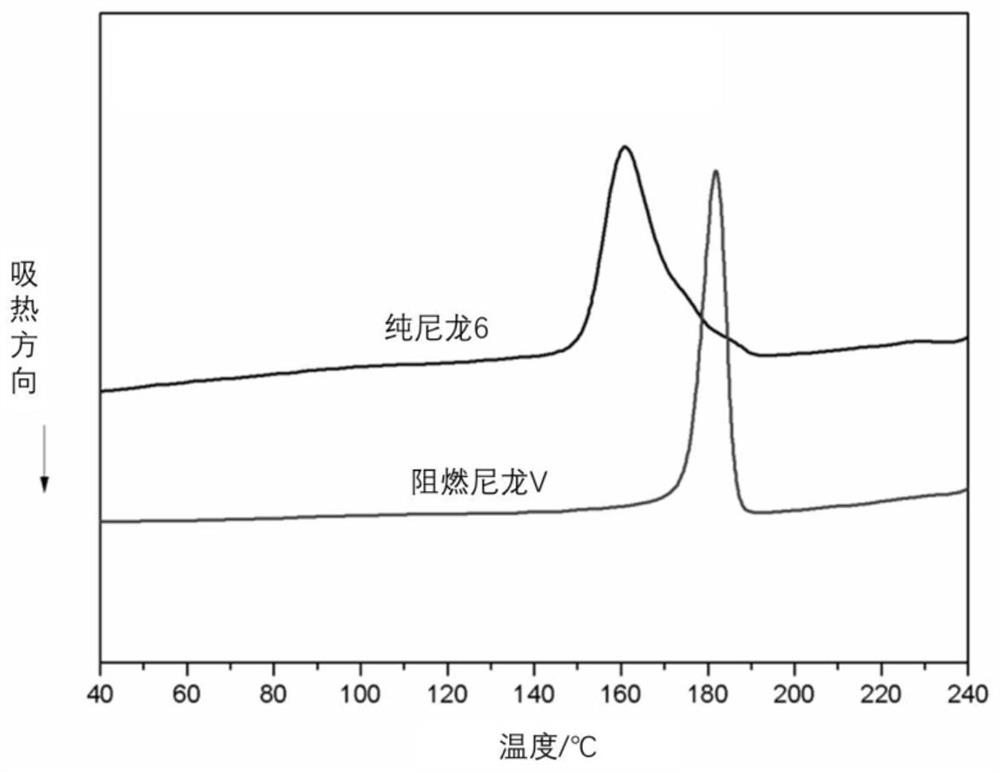

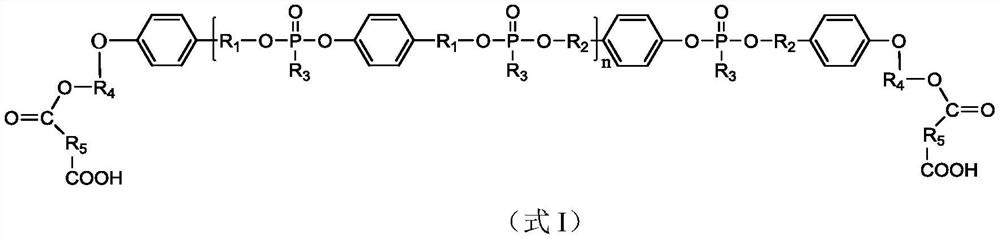

Phosphorus-containing copolymerized nylon as well as preparation method and application thereof

The invention provides phosphorus-containing copolymerized nylon as well as a preparation method and application thereof. Nylon and polyphosphonate are melted and mixed and subjected to an exchange reaction in the presence of an accelerant to prepare phosphorus-containing nylon. Macromolecular phosphine-containing components are introduced in the polymerization process of nylon, the compatibilityof the system is improved to the maximum extent, the problems easily occurring in blending modification are reduced, the using amount of a flame retardant is reduced, the flame retardant performance and spinnability of nylon can be remarkably improved, and the method is simple in process, easy for large-scale production and more suitable for being applied to the fields of spinning fibers, wires and cables and 3D printing.

Owner:JINCHUANGJING NEW MATERIAL TECH SHANGHAI

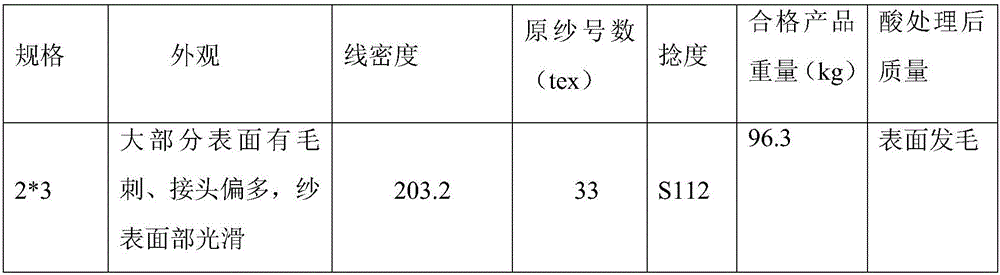

Technology for heavy quantitatively producing high-grade weaved yarns by using card slivers by Zheng spinner blowing-carding combined carding machine

InactiveCN102634877AImprove textile performanceDoes not affect carding qualityContinuous processingFiberYarn

The invention provides a technology for heavy quantitatively producing high-grade weaved yarns by using card slivers by a Zheng spinner blowing-carding combined carding machine and relates to the technical field of production technology of the high-grade weaved yarns. The production technology comprises the following steps in turn: preparing cotton; opening picking; carding cotton; combing; drawing; roving; spinning; post-processing; and checking end products, wherein the processes of preparing cotton and opening picking are finished by adopting Zheng spinner blowing-carding; the processes comprise the steps of grabbing cotton back and forth, removing impurities by a metal probe, automatically mixing cotton, opening picking in a double-shaft flowing form, opening original cotton, removing impurities and mixing; the process of carding cotton comprises the steps of mixing cotton, beating and opening cotton, feeding cotton in middle, scutching by using a sawtooth roller, coagulating cotton, conveying cotton, feeding cotton and carding cotton by using a carding machine; and the process of carding cotton is mainly used for finishing carding, removing impurities, uniformly mixing and twisting into strips. The Zheng spinner blowing-carding production technology is changed by the technology provided by the invention, the weaving effect of middle / high-grade yarn and high branch yarn is increased; the quality of fiber carding is not influenced after the fixed weight is increased; the production efficiency is increased; and the problem of insufficient card sliver supply is solved.

Owner:NANTONG HUAQIANG CLOTH IND

Functional ramie fiber fabric and preparation method

InactiveCN109338562AImprove textile performanceImprove performanceFilament/thread formingWoven fabricsPolyesterRamie

The invention relates to a functional ramie fiber fabric and a preparation method. The functional ramie fiber fabric comprises following components including ramie fiber, polyester fibers, natural bamboo fiber and colored cotton fiber, wherein the polyester fibers are sheath-core composite polyester fibers, each sheath-core composite polyester fiber comprises a sheath layer and a core layer, eachcore layer has a circular cross section and is covered with the corresponding sheath layer, each sheath layer comprises PET polyester and first polyester masterbatches, and each core layer comprises PET polyester and second polyester masterbatches; the first polyester masterbatches are obtained by mixing and granulating first powder and polyester slices, and the second polyester masterbatches areobtained by mixing and granulating second powder and the polyester slices.

Owner:东莞青柳新材料有限公司

A kind of hydrophilic polyester fiber and preparation method thereof

ActiveCN108193303BGood hueImprove spinnabilitySpinnerette packsMonocomponent copolyesters artificial filamentTextile fiberPolyester

The invention belongs to the technical field of textile fibers, and in particular relates to a hydrophilic polyester fiber and a preparation method thereof. The hydrophilic polyester fiber is obtained by melt spinning of hydrophilic polyester, and the hydrophilic polyester is composed of ethylene terephthalate oligomer, polyether glycol in titanium metal alkoxide, polyol It is obtained by polymerization under the action of phosphorus compound / sterically hindered phenol compound / acetate complex. The hydrophilic polyester fiber described in the present invention is not easy to yellow, has small viscosity drop during molding process, has good hygroscopic performance and normal pressure dyeing performance, and also has the characteristics of no heavy metal pollution, soft hand feeling and excellent hue.

Owner:CHINA TEXTILE ACADEMYTIANJINSCI & TECH DEV CO LTD +1

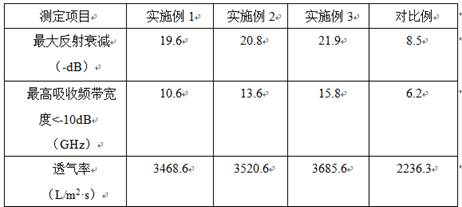

Preparation method of a wave-absorbing and radiation-proof composite textile material

InactiveCN110578195BGood flexibilityImprove spinnabilityShielding materialsInorganic material artificial filamentsCarbide siliconCarbon fibers

The invention relates to a preparation method of a wave-absorbing radiation-proof composite textile material and belongs to the technical field of textile materials. According to the preparation method, the radiation-proof composite textile material is prepared by adding polyacrylonitrile-based carbon fibers and silicon carbide fibers, the polyacrylonitrile-based carbon fibers and the silicon carbide fibers both belong to structural wave-absorbing materials and are manufactured into structural parts bearing compression, bending and shearing loads, the silicon carbide fibers and the polyacrylonitrile-based carbon fibers are orthogonal to form a circuit simulation structure, the silicon carbide fiber and the carbon fibers which are orthogonally arranged form a planar conductive network, induction current is produced under the action of incident electromagnetic waves, electromagnetic wave energy is converted into heat energy through ohmic loss and eddy current loss so as to be lost, and the attenuation of the electromagnetic waves is enhanced. In addition, a wave-absorbing screen formed by orthogonally arranged silicon carbide fibers can play a role of a reflecting screen, the electromagnetic waves reflected from the surface of the wave-absorbing screen and the electromagnetic waves reflected from a polycrystal iron fiber reflecting layer can generate a phase cancellation effect,and the radiation-proof capacity of the wave-absorbing radiation-proof composite textile material is improved.

Owner:深圳市盛鸿医疗科技有限公司

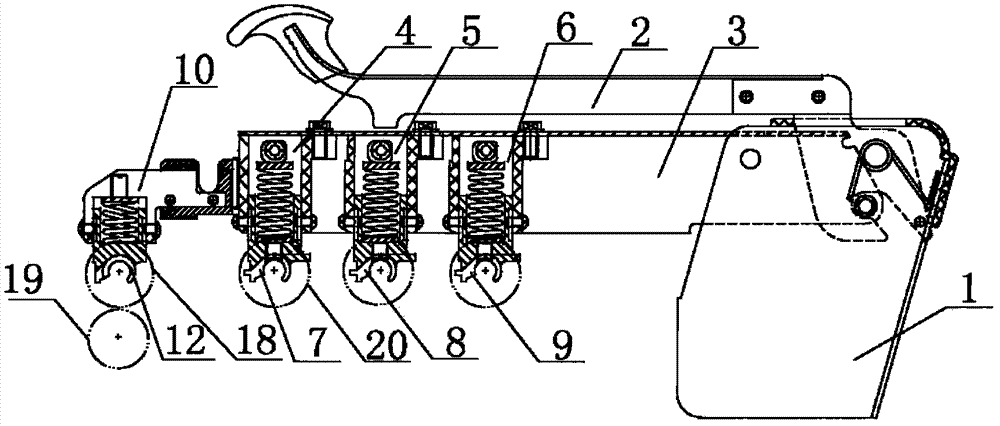

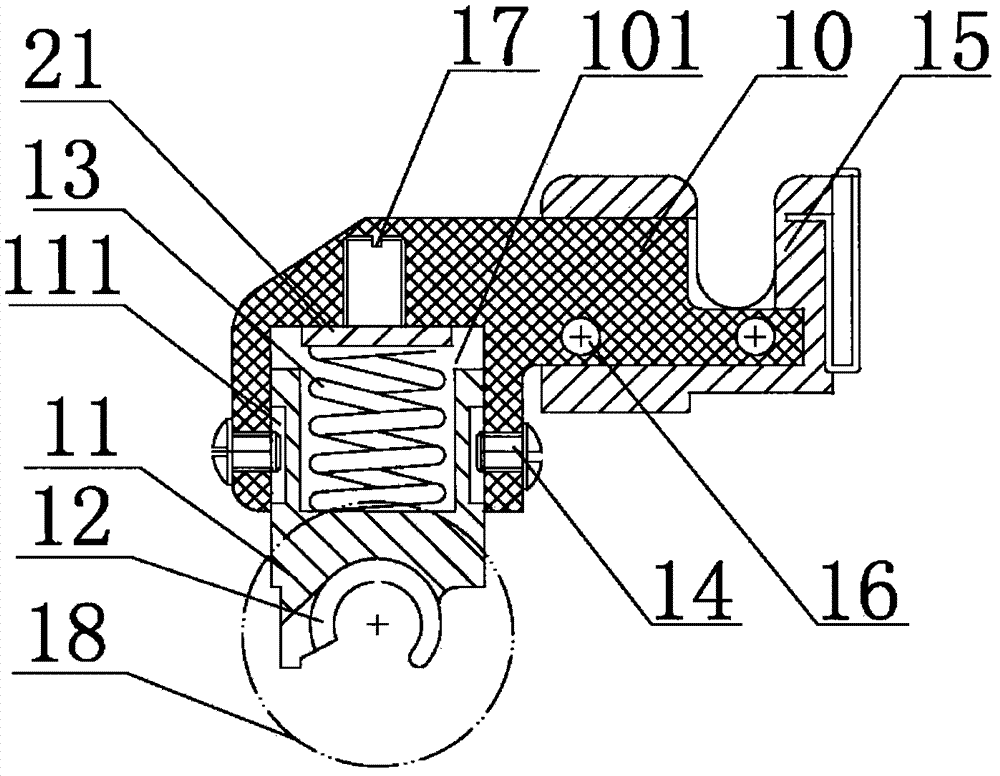

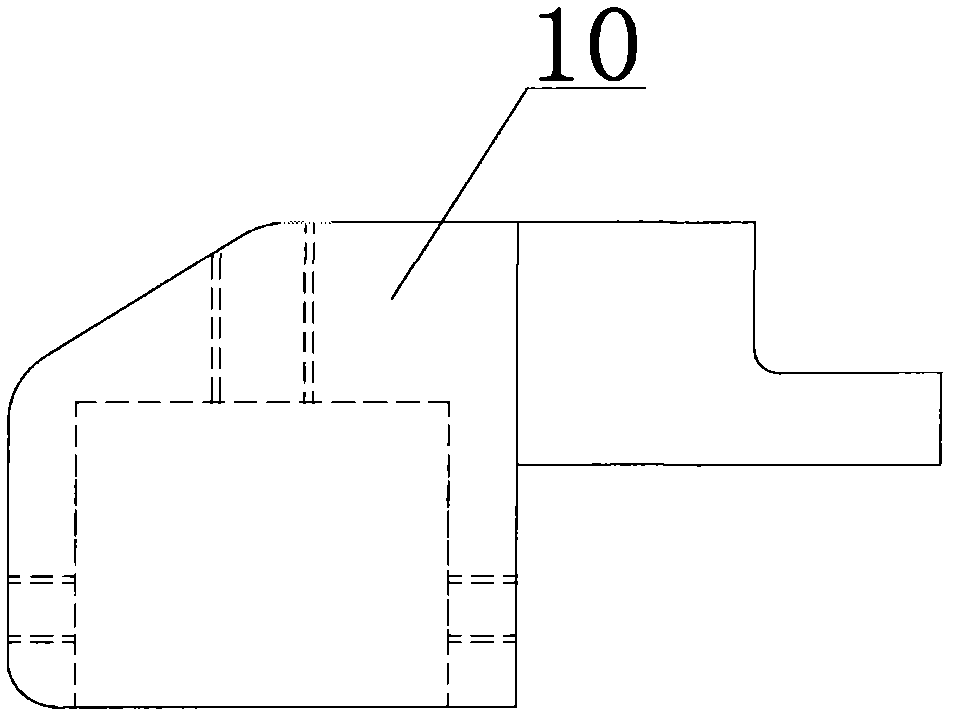

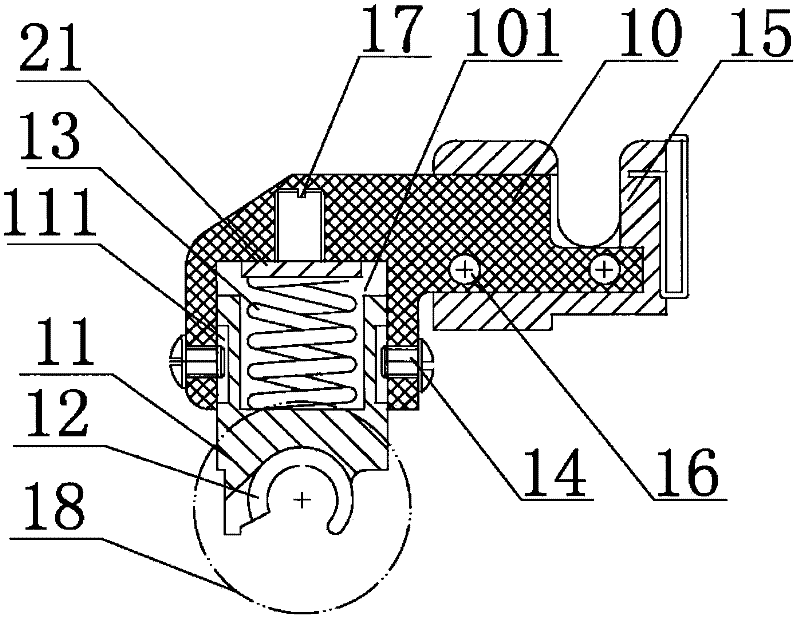

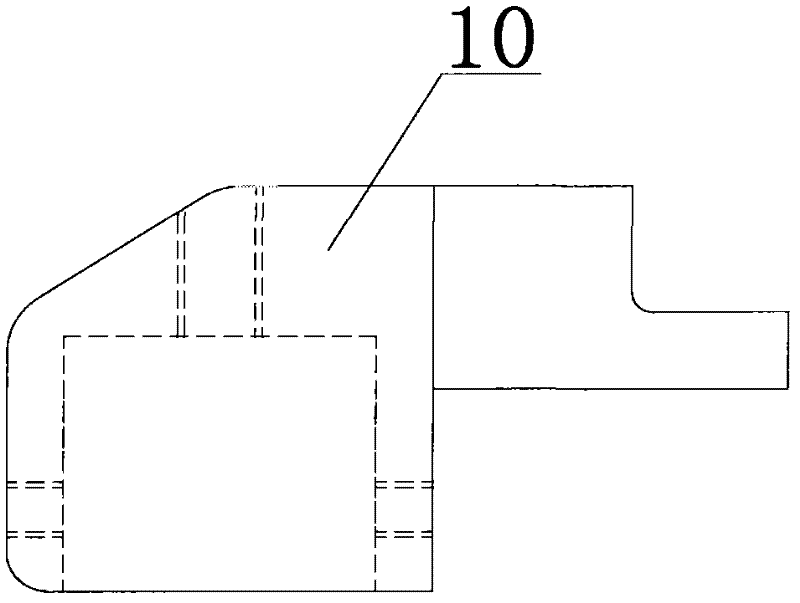

Adjusting installing structure of guiding roller claw in compact spinning cradle

The invention discloses an adjusting installing structure of a guiding roller claw in compact spinning cradle. The adjusting installing structure comprises a cradle seat, which is hinged with a handle and a rocker arm; the lower side of the rocker arm is provided with a front pressing component, a middle pressing component and a rear pressing component; lower ends of the three pressing componentsare provided with corresponding roller claws; a guiding pressing seat is installed at the front end of the rocker arm through a distance adjusting device; the guiding pressing seat is provided with an installing cavity, which is provided with a guiding roller seat inside; the lower end of the guiding roller seat is provided with the guiding roller claw; a spring is disposed between the guiding roller seat and the top of installing cavity; and a limiting device is disposed between the guiding roller seat and the guiding pressing seat. The adjusting installing structure of the guiding roller claw in the compact spinning cradle enables the distance between the guiding roller and a front roller to be adjusted according to requirements of technology, thereby improving spinning effect of compact spinning. The adjusting installing structure is applicable to various cradles of compact spinning in thread spinners.

Owner:ZHANGJIAGANG GUANGDA TEXTILE MACHINERY

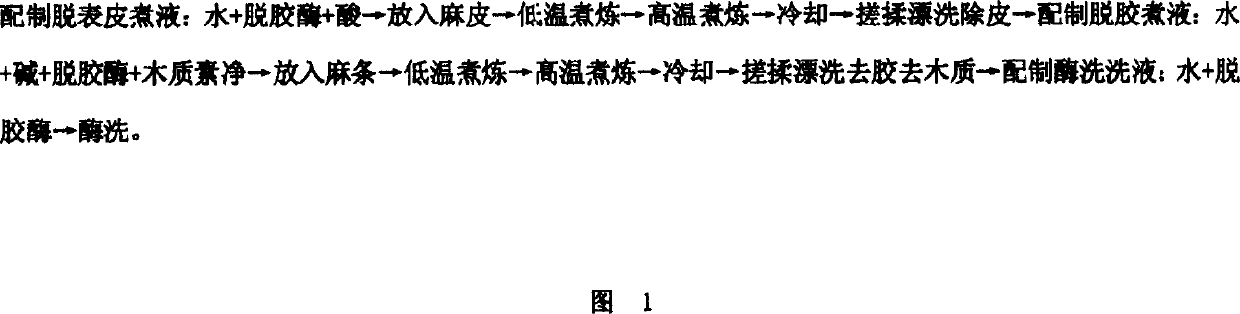

Peeling and degumming process for hemp plants

InactiveCN1274901CReduce lossesSave scraping laborBiochemical fibre treatmentVegetal fibresFiberHemp plant

The invention relates to a peeling and degumming process for hemp plants, comprising: peeling off the hurds from the stalk, peeling the hurds by acid enzyme and removing the woodiness by alkali enzyme and lignin. The method abolishes the procedure of mechanically peeling off hurds so as to avoid the fiber loss during peeling off hurds and improve the 15% of yield. Meanwhile, the degumming process needs less water, degumming time, low acid and alkali concentration in the boiling liquid. The boiling liquid can be recycled.

Owner:徐奎元

Adjusting installing structure of guiding roller claw in compact spinning cradle

The invention discloses an adjusting installing structure of a guiding roller claw in compact spinning cradle. The adjusting installing structure comprises a cradle seat, which is hinged with a handle and a rocker arm; the lower side of the rocker arm is provided with a front pressing component, a middle pressing component and a rear pressing component; lower ends of the three pressing componentsare provided with corresponding roller claws; a guiding pressing seat is installed at the front end of the rocker arm through a distance adjusting device; the guiding pressing seat is provided with an installing cavity, which is provided with a guiding roller seat inside; the lower end of the guiding roller seat is provided with the guiding roller claw; a spring is disposed between the guiding roller seat and the top of installing cavity; and a limiting device is disposed between the guiding roller seat and the guiding pressing seat. The adjusting installing structure of the guiding roller claw in the compact spinning cradle enables the distance between the guiding roller and a front roller to be adjusted according to requirements of technology, thereby improving spinning effect of compact spinning. The adjusting installing structure is applicable to various cradles of compact spinning in thread spinners.

Owner:ZHANGJIAGANG GUANGDA TEXTILE MACHINERY

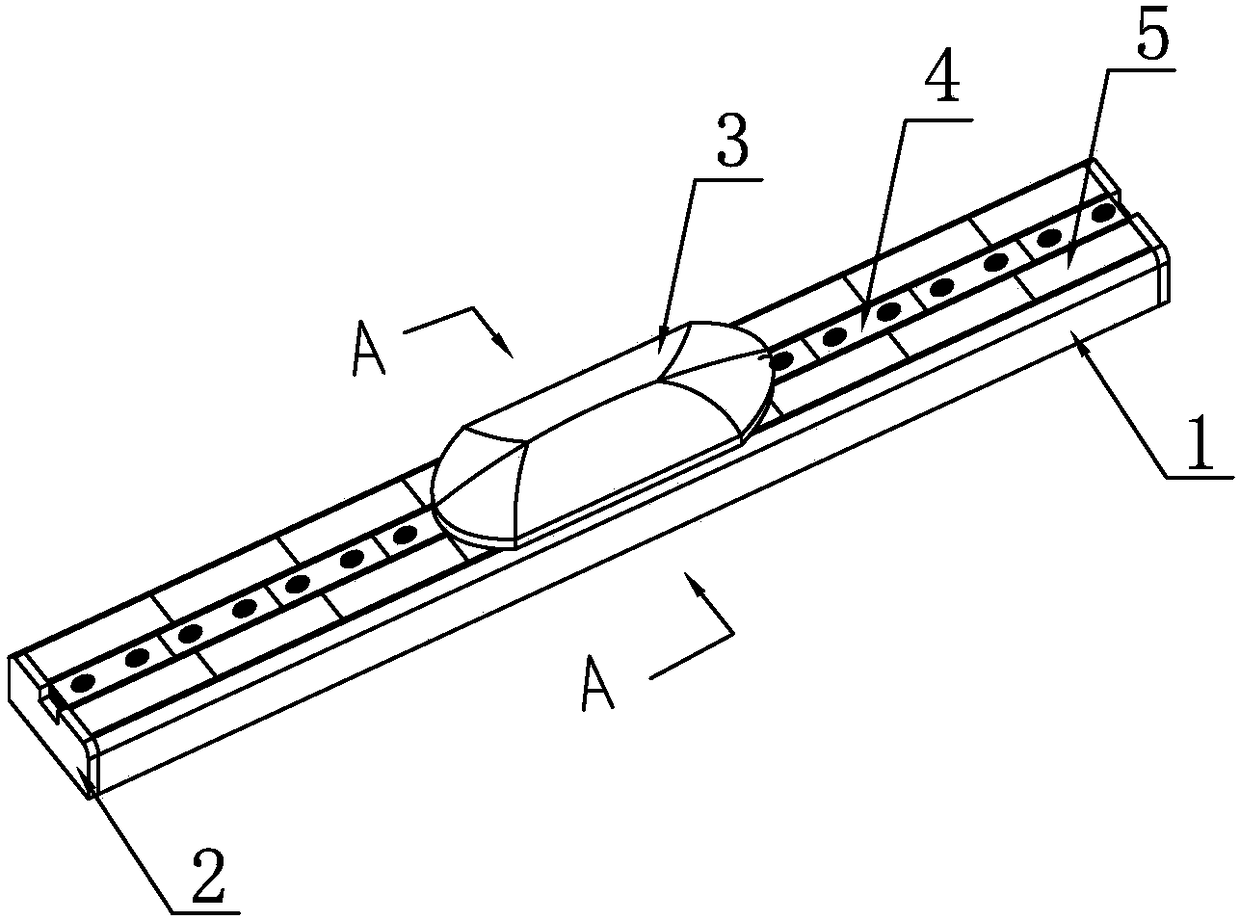

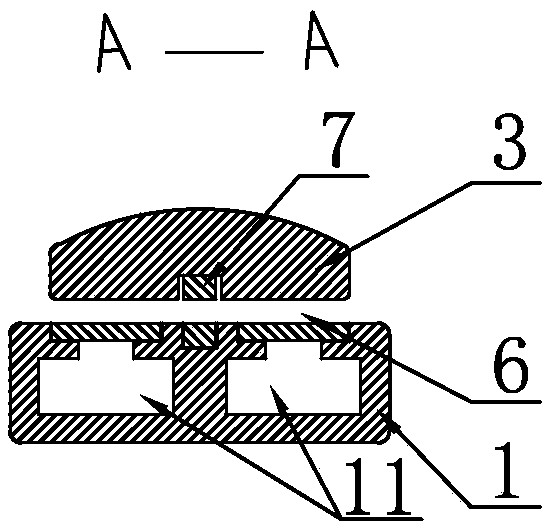

Shuttle air draft guide rail of shuttle loom

The invention discloses a shuttle air draft guide rail of a shuttle loom, comprising an air draft guide rail and a shuttle suspended above the air draft guide rail, wherein a plurality of first permanent magnets and a plurality of porous ceramics arranged at two sides of the first permanent magnets are arranged at the top of the air draft guide rail along a length direction, and the plurality of porous ceramics at two sides are symmetric by taking the first permanent magnets as axis of symmetry; two compressed air flowing channels are formed in the air draft guide rail, the two compressed airflowing channels are respectively communicated with the plurality of porous ceramics at two sides; air compressors are connected to the outside of the compressed air flowing channels; plugs are respectively connected to two ends of the air draft guide rail; second permanent magnets mutually attracting with the first permanent magnets are connected to the bottom of the shuttle and air draft gaps exist between the air draft guide rail and the shuttle.

Owner:王广和 +1

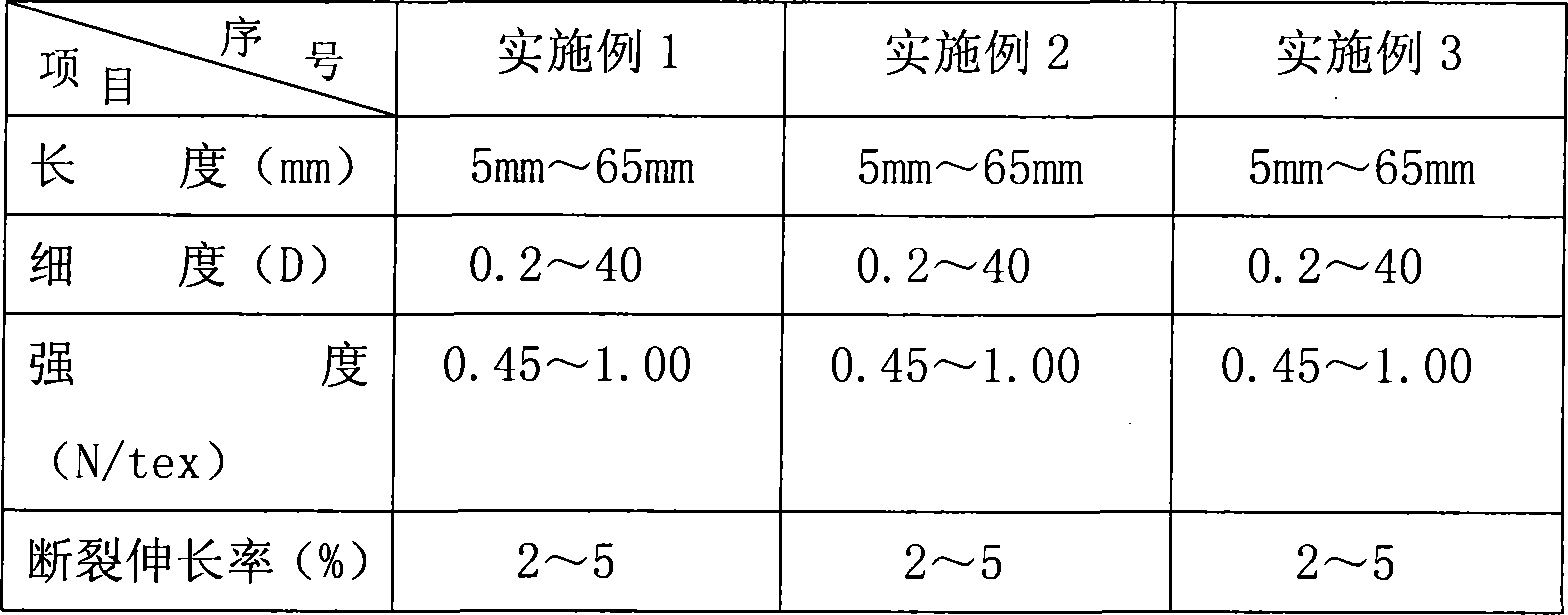

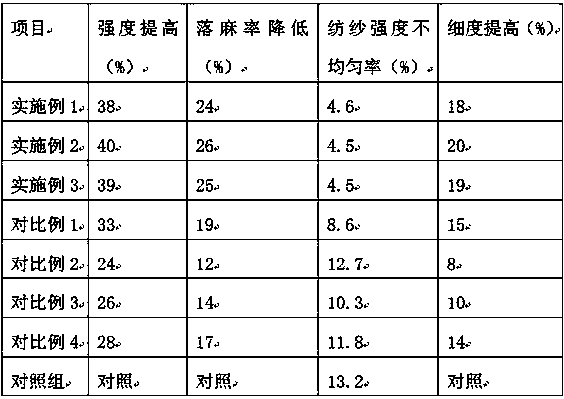

Processing method for improving quality of jute fibers

ActiveCN108978201AQuality improvementHigh strengthVegetal fibresPotassium acetateMaterials processing

The invention relates to the technical field of textile material processing and producing, and discloses a processing method for improving the quality of jute fibers. According to the method, the jutefibers are subjected to modification treatment, firstly, the jute fibers subjected to rinsing treatment are placed in a potassium acetate-ethanol mixed solvent to be dispersed, then a fiber modifieris added, various performances of the modified jute fibers can be changed, curing treatment is further carried out, so that the performance is stabilized, carding is facilitated, the strength, the fineness, the length and the textile performance of the final prepared jute fibers are remarkably improved, and therefore the market prospect and the economic value of the jute fibers are remarkably improved, the practical significance in deepening the research on the performance characteristics of the jute fibers and expanding the range of high-quality raw materials of textiles can be achieved, andthe method is worthy of popularization and use.

Owner:HEFEI SHENGDA GARMENT ACCESSORIES CO LTD

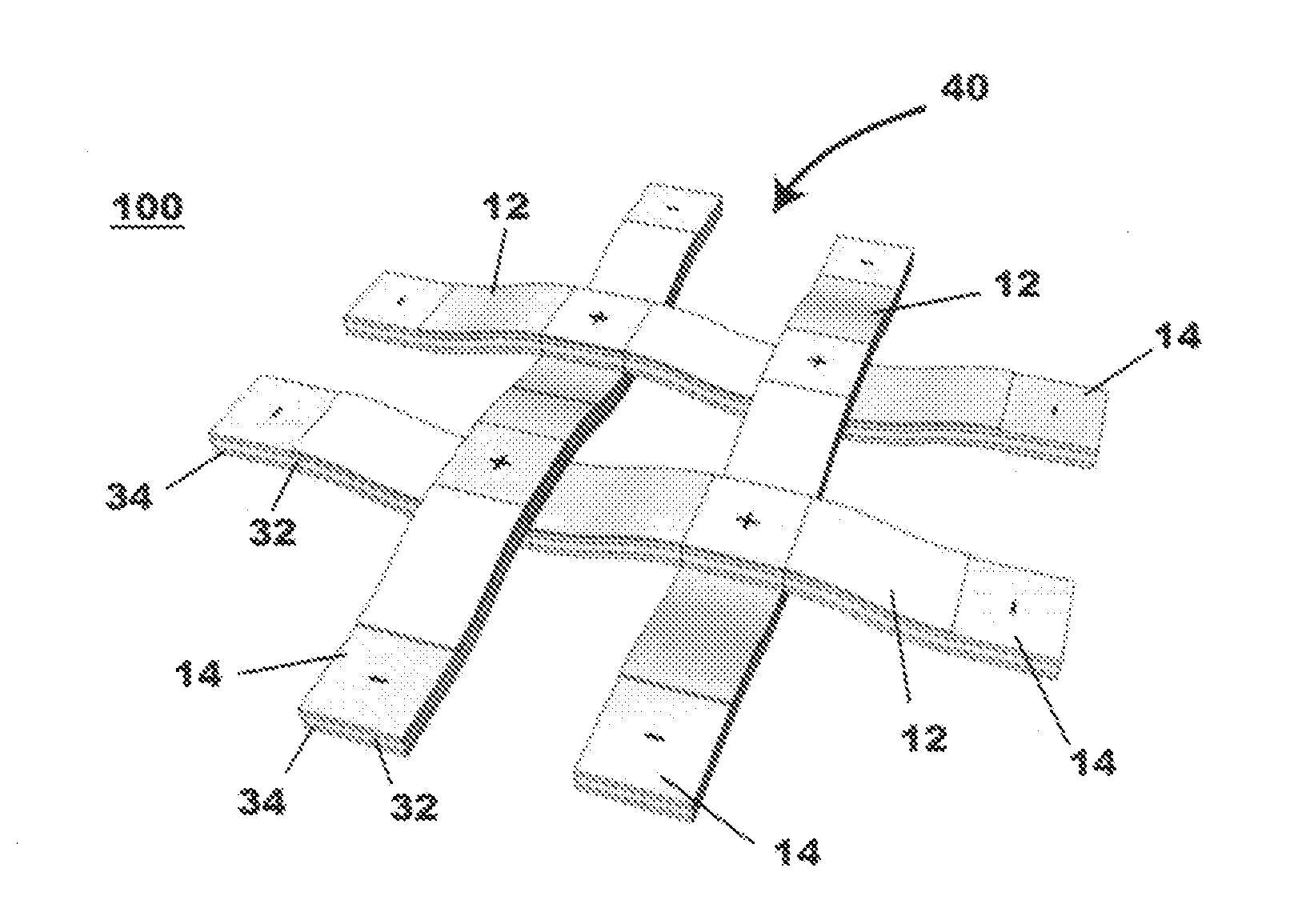

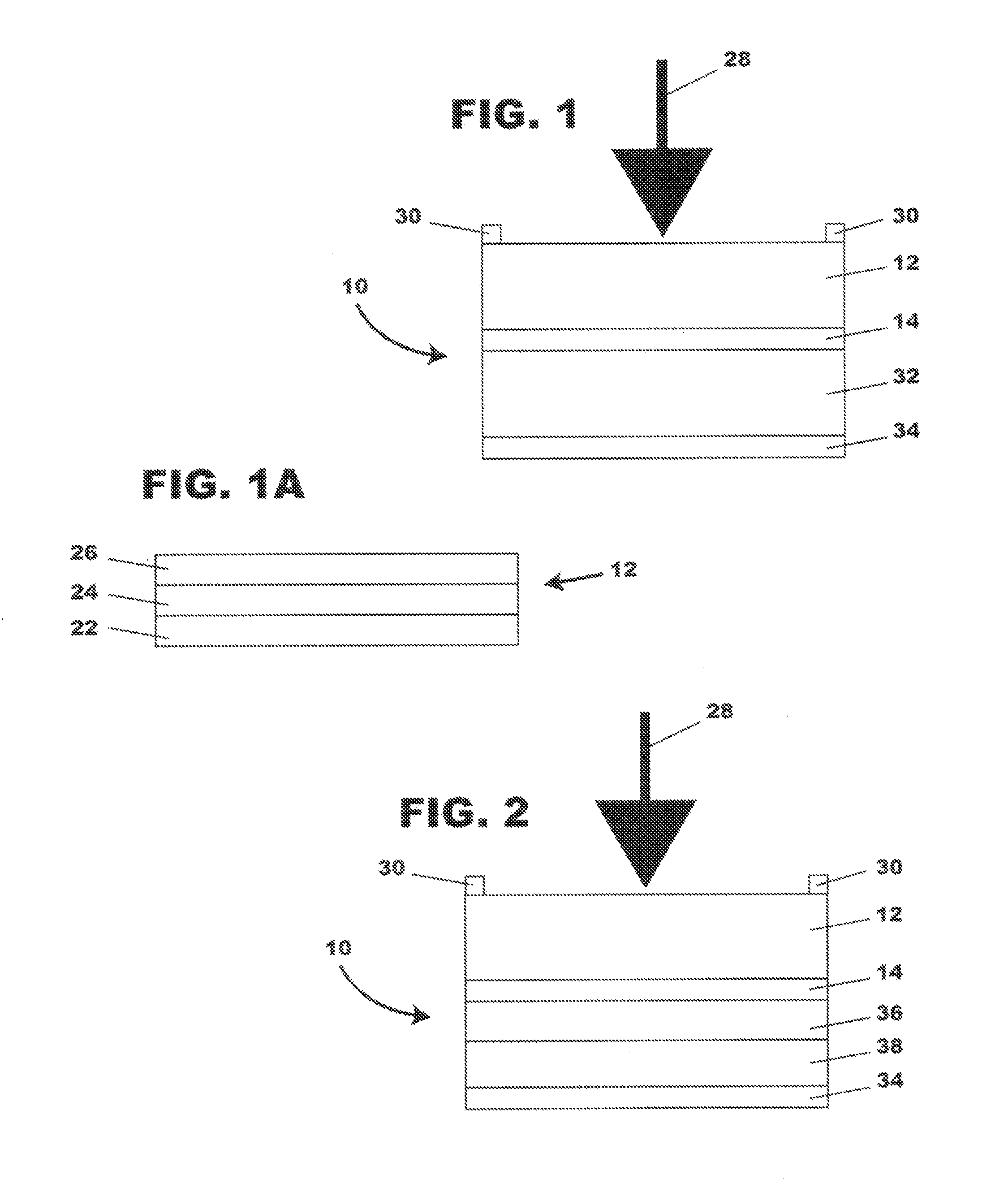

Photovoltaic textiles

ActiveUS9419236B2Improve textile performanceEasy to manufactureSolid-state devicesPhotovoltaicsPhotovoltaicsTextile

A tape structure and related circuit configurations for textile systems to establish electrical characteristics of textiles. The textiles incorporate charge carrying components, such as photovoltaic components, in contact with conductive layers in a single tape structure to improve electrical properties without compromising physical characteristics of the textiles. The textiles include photovoltaic tapes, each having an optically transparent layer, a photovoltaic layer, a first electrically conducting layer, a second electrically conducting layer and an insulating substrate located between the first electrically conducting layer and the second electrically conducting layer.

Owner:PARENT DONALD G

Photovoltaic textiles

ActiveUS10014484B2Improve textile performanceEasy to manufactureSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerEngineering

A solar textile formed of a weave of a first tape structure and a second tape structure. In one embodiment, the ratio of the number of the first tape structure to the second tape structure is three to one. The first tape structure includes a photovoltaic (PV) conversion layer and an electrically conductive substrate. The second tape structure includes a PV conversion layer, a first electrically conductive layer, a non-conducting insulation layer and a second electrically conductive layer. The first tape structure and the second tape structure are in contact with one another so that the electrically conductive substrate of the first tape structure is in contact with the PV conversion layer of the second tape structure.

Owner:PARENT DONALD G

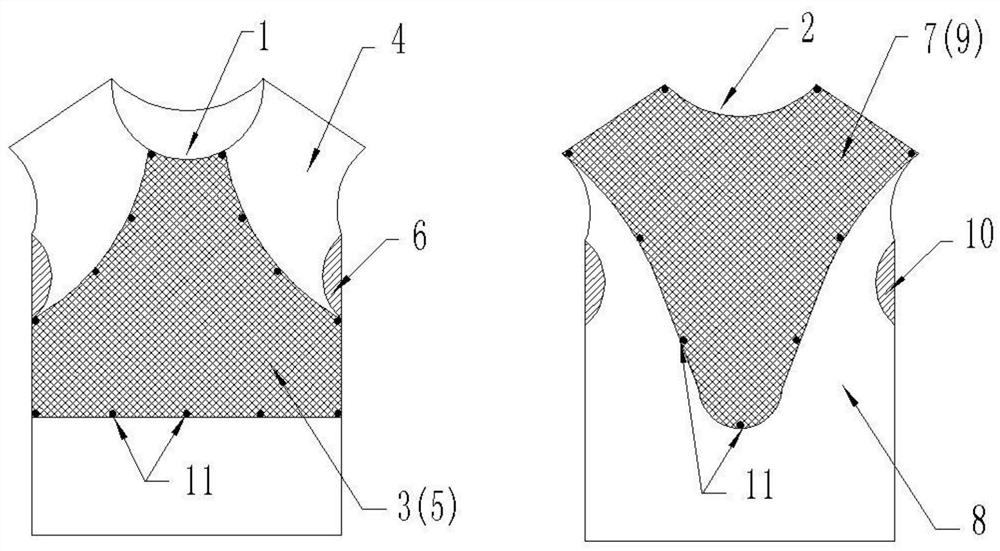

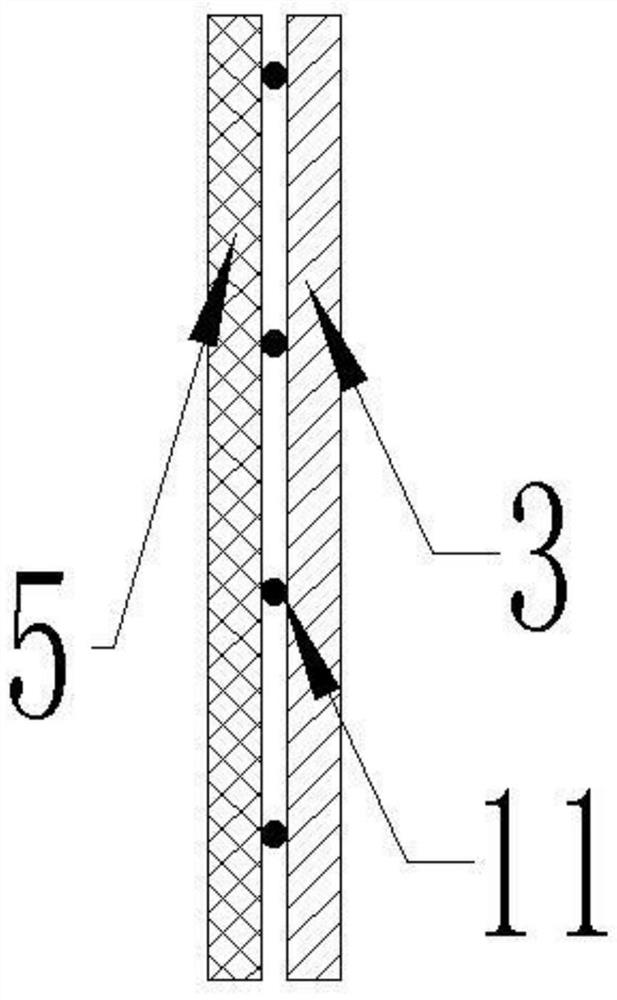

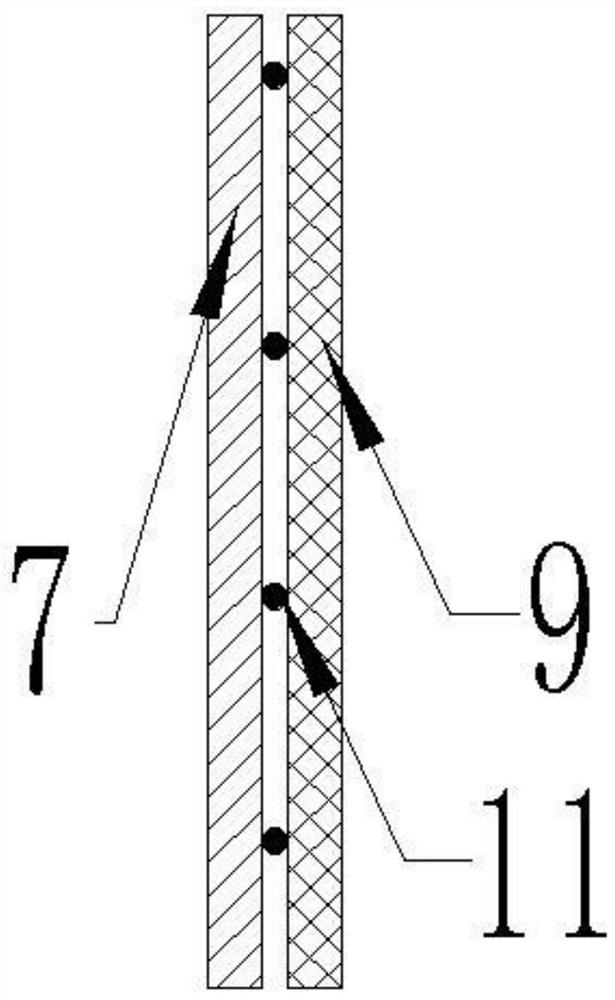

Firefighter underwear

PendingCN112121319AEffective perspirationImprove wearing comfortChemical protectionHeat protectionPerspirationEngineering

The invention discloses a firefighter underwear. The firefighter underwear comprises an underwear front piece and an underwear rear piece which are connected by sewing, wherein the underwear front piece comprises first fabric with high sweat-absorbent ability, first fabric with low sweat-absorbent ability and first protective fabric; the underwear rear piece comprises second fabric with high sweat-absorbent ability, second low fabric with low sweat-absorbent ability and second protective fabric; both the first fabric with high sweat-absorbent ability and second fabric with high sweat-absorbentability consist of aramid fibers wound with bamboo fabrics; both the first fabric with low sweat-absorbent ability and second fabric with low sweat-absorbent ability consist of aramid fibers wound with polypropylene fabric; and both the first protective fabric and the second protective fabric consist of aramid fibers. The firefight underwear uses hot-humid comfortable fabric in an area at which afirefighter is liable to perspire, and improves wearing comfort. A protective area is set in an important area of a human body, protective fabric is fixedly connected onto the firefighter underwear locally in a spaced mode to increase a gap between a protective material and firefighter underwear, so that air convection is convenient, and perspiration is facilitated.

Owner:泰安市丽源工贸有限公司

Phosphorus-containing flame retardant nylon and its preparation method and application

ActiveCN111087612BNo dropletImprove mechanical propertiesAdditive manufacturing apparatusFlame-proof filament manufactureFiberPolymer science

The invention provides a phosphorus-containing flame-retardant nylon, a preparation method and application thereof, namely, a macromolecular phosphine-containing component is introduced into the nylon polymerization process to maximize the compatibility of the system and reduce the blending modification. It can significantly improve the flame retardancy and spinnability of nylon, and this method is simple in process, easy to produce on a large scale, and more suitable for applications in the field of spinning-fiber, wire and cable, and 3D printing.

Owner:JIANGSU HAIYANG CHEM FIBERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com