Phosphorus-containing copolymerized nylon as well as preparation method and application thereof

A technology for nylon and flame-retardant nylon, which is applied in the field of phosphorus-containing copolymerized nylon and its preparation, and achieves the effects of little influence on mechanical properties, easy process, and excellent application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1: flame retardant nylon I

[0088] Get 10g phosphonate-carbonate copolymer (FRX Polymer Noifa OL5000), 0.5g three (2.4-di-tert-butylphenyl) (Beijing extremely easy Chemical Co., Ltd., 168), 89g nylon 6 (Baling Petrochemical, BL2340 ) after blending evenly, then add 0.5g aliphatic epoxy (Jiangsu Taitel New Material Technology Co., Ltd., ERL4221) and mix evenly for the second time, melt and blend in the mixing chamber of the torque rheometer respectively, and the rotor is Sigma type, the temperature was set at 230°C, the rotor speed was set at 50rpm, and 40g was added each time. After the torque was balanced, the melt-mixing was continued for 6 minutes, and samples were collected to obtain flame-retardant nylon I.

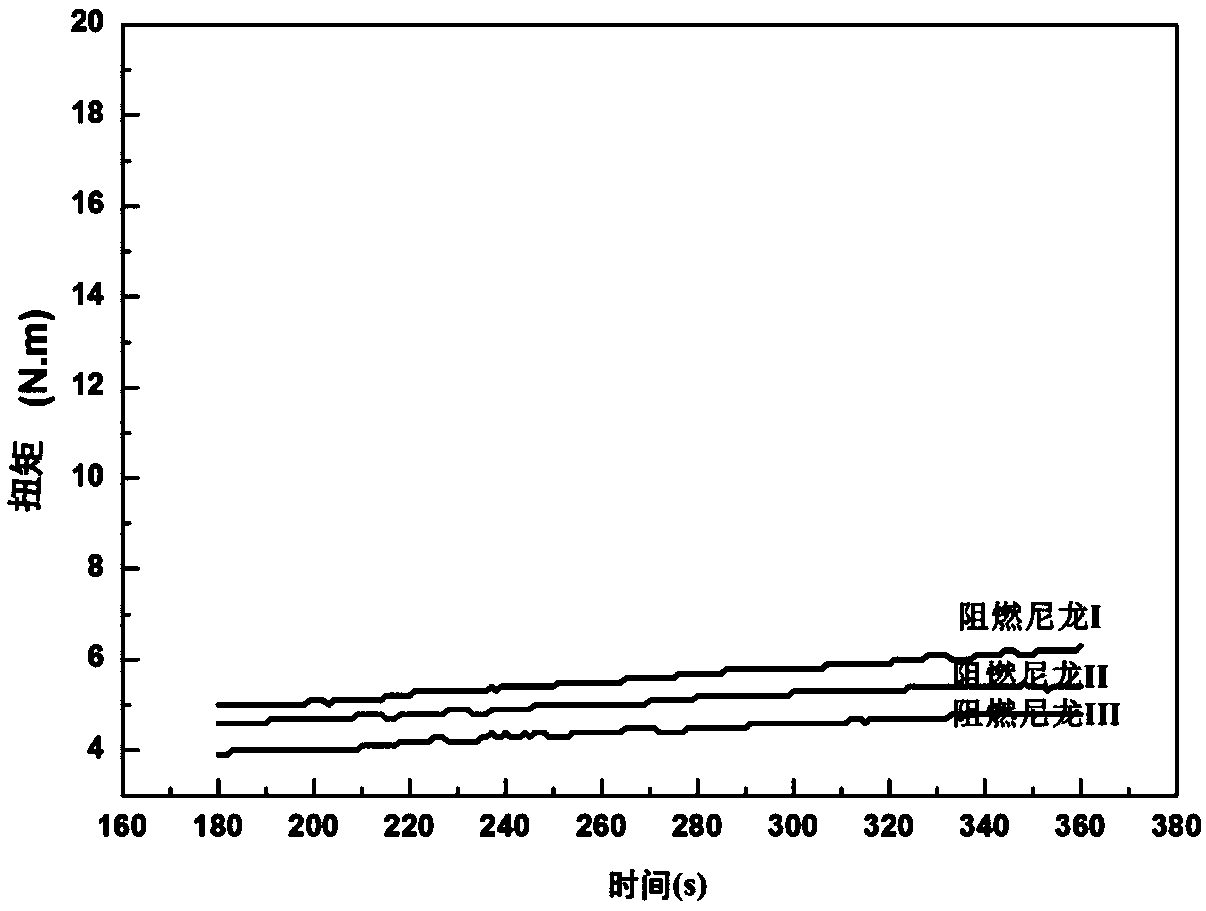

[0089] The curve and data of torque with time such as figure 1 As shown in the middle curve (a), with the introduction of difunctional aliphatic epoxy, the viscosity of the system obviously increases gradually with time, indicating that it has ach...

Embodiment 2

[0090] Example Two: Flame Retardant Nylon II

[0091] Get 13g phosphonate-carbonate copolymer (FRX Polymer Noifa OL5000), 0.5g three (2.4-di-tert-butylphenyl) (Beijing extremely easy chemical industry Co., Ltd., 168), 86g nylon 6 (Baling petrochemical, BL2340 ) after blending evenly, then add 0.5g aliphatic epoxy (Jiangsu Taitel New Material Technology Co., Ltd., ERL4221) and mix evenly for the second time. Melt and blend the formulations in the mixing chamber of the torque rheometer, the rotor is Sigma type, the temperature is set at 230°C, the rotor speed is set at 50rpm, 40g is added each time, and the blending is continued for 6 minutes after the torque is balanced. Collect samples to obtain flame retardant nylon II.

[0092] Save the torque curve and data over time such as figure 1 As shown in the middle curve (b), with the introduction of difunctional aliphatic epoxy, the viscosity of the system obviously increases gradually with time, indicating that it has achieved t...

Embodiment 3

[0093] Example Three: Flame Retardant Nylon III

[0094] Get 16g phosphonate-carbonate copolymer (FRX Polymer Noifa OL5000), 0.5g three (2.4-di-tert-butylphenyl) (Beijing extremely easy Chemical Co., Ltd., 168), 89g nylon 6 (Baling Petrochemical, BL2340 ) after blending evenly, then add 0.5g aliphatic epoxy (Jiangsu Taitel New Material Technology Co., Ltd., ERL4221) and mix evenly for the second time. Melt and blend the formulations in the mixing chamber of the torque rheometer, the rotor is Sigma type, the temperature is set at 230°C, the rotor speed is set at 50rpm, 40g is added each time, and the blending is continued for 6 minutes after the torque is balanced. Samples were collected to obtain flame retardant nylon III.

[0095] Save the torque curve and data over time such as figure 1 As shown in the middle curve (c), with the introduction of difunctional aliphatic epoxy, the viscosity of the system obviously increases gradually with time, indicating that it has achieved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com