Brake band woven by blend-spinning fiber

A technology of blended fibers and brake bands, which is applied in textiles, brake parts, textiles and papermaking, etc., can solve the problems of failure to meet the use requirements, unreasonable use of resin, rough production process, etc., and achieve shortened curing time, anti- High tensile strength, tight and reasonable overall weaving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

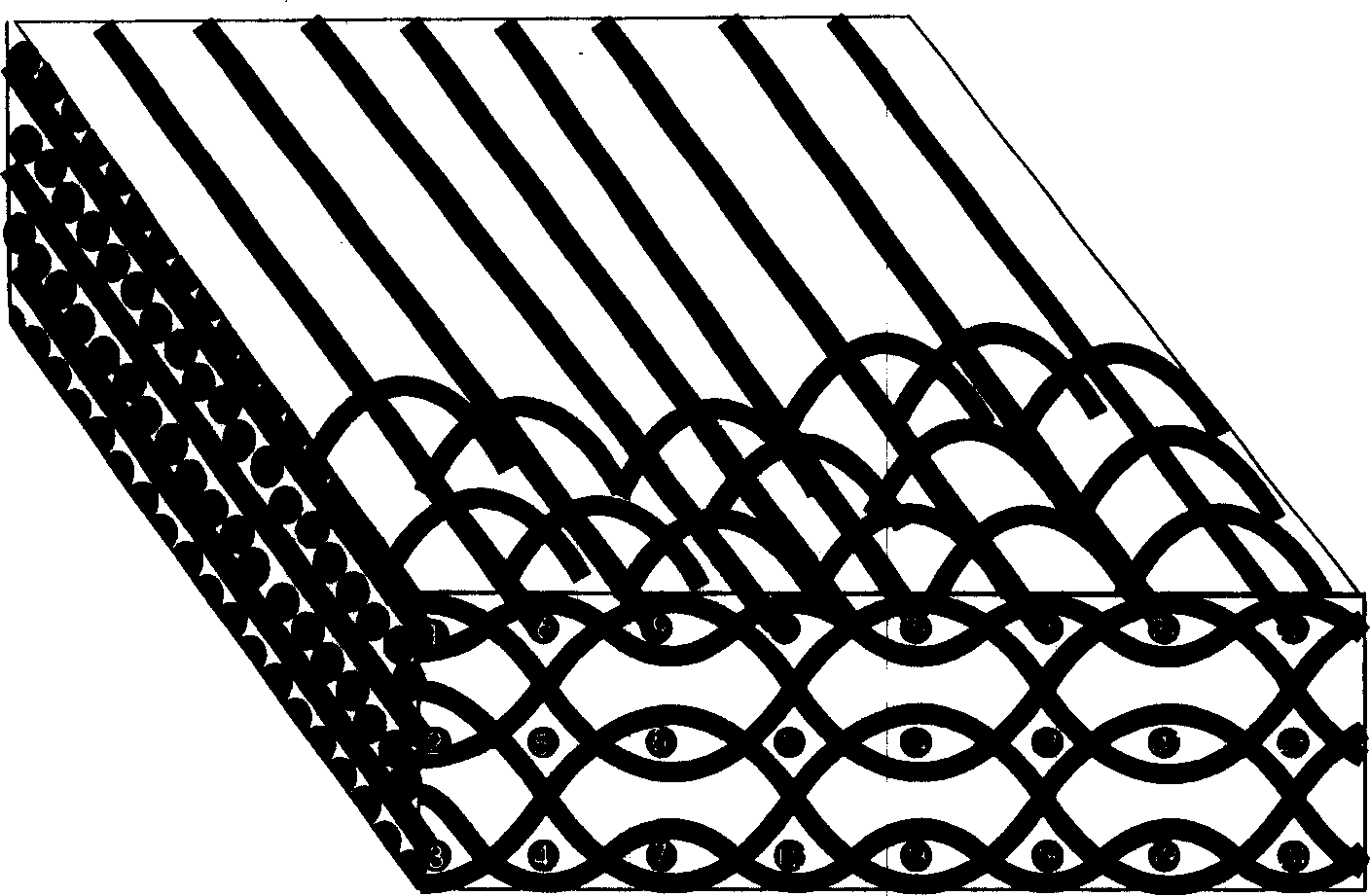

[0032] The specific embodiment of the present invention is provided, which adopts a plurality of blended fiber core-spun single yarn twisted strands wrapped with a metal wire in the center, and is braided by automatic machinery to form an integral multi-layer fabric blank belt, wherein the acrylic fiber used for the blended fiber , Aramid fiber, and glass fiber are spinnable short fibers, and the molecular formula of the acrylic fiber used is: The molecular formula of aramid fiber is: The glass fiber composition is: SiO 2 、AL 2 o 3 , CaO, MgO, Na 2 O, etc., the metal wire is a brass wire with a diameter of 0.08-0.12mm.

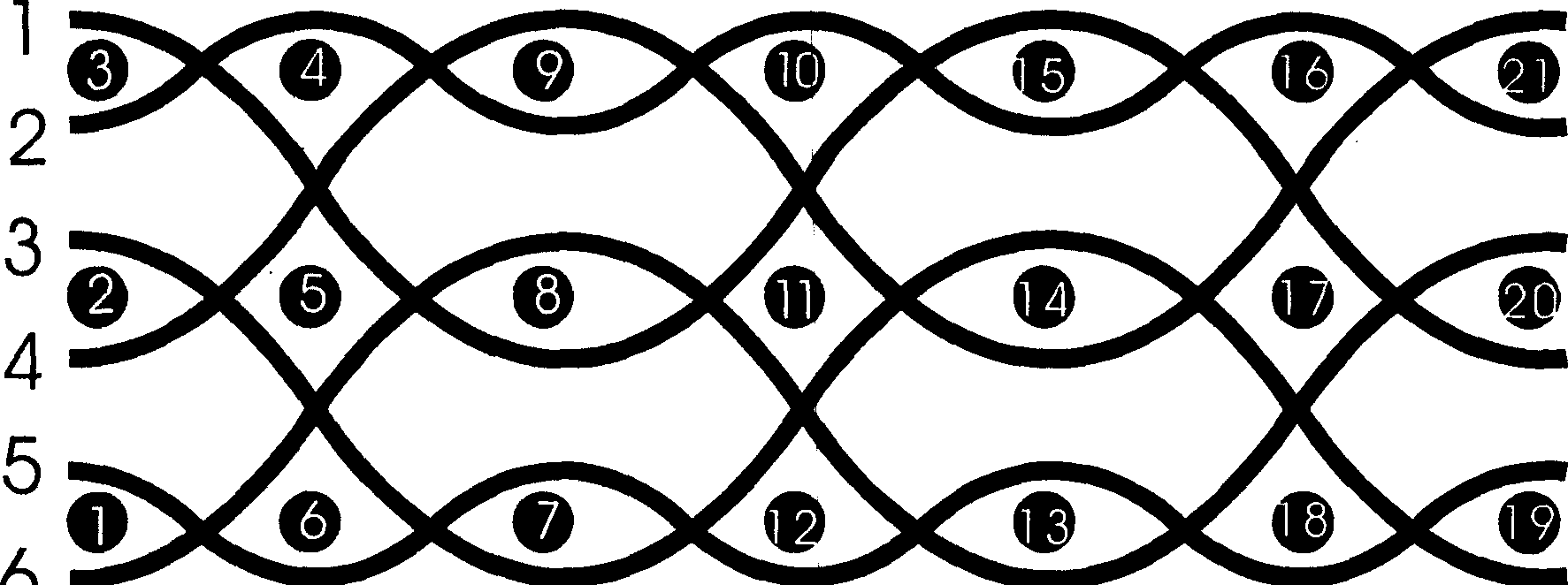

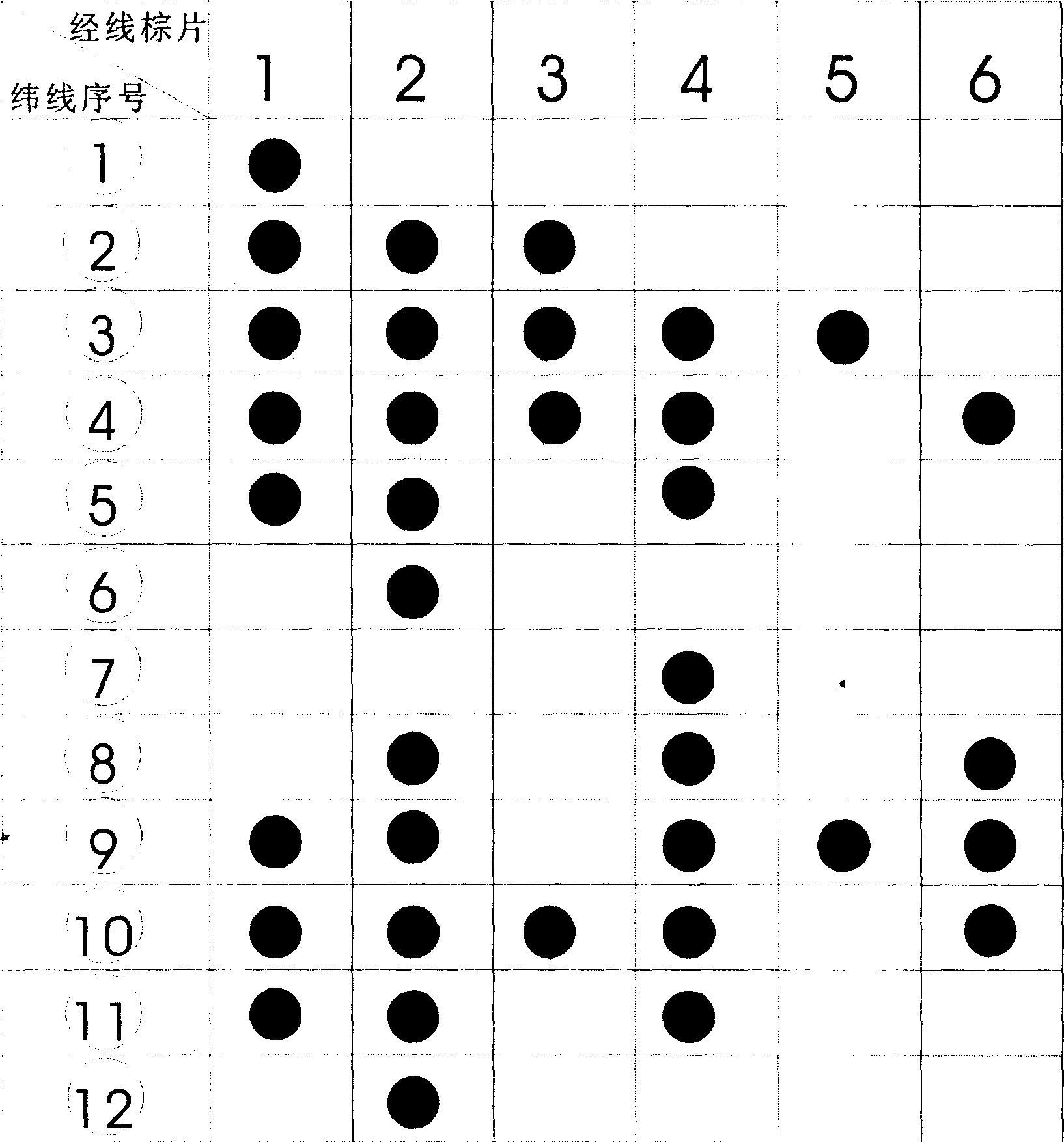

[0033] see Figure 1 ~ Figure 3 , introducing a fabric weaving method for an integral multi-layer braided blank tape, taking the integral three-layer braided blank tape as an example: the integral three-layer braided blank tape is formed by interweaving weft threads ①~ with warp threads 1~6;

[0034] The processing process flow of the present inventio...

Embodiment 2-5

[0037] The specific embodiment of the present invention is to use a plurality of blended fiber core-spun yarns with a metal wire wrapped in the center to twist the ply yarn, and weave an integral multi-layer fabric blank belt through automatic machinery, wherein the acrylic fiber used for the blended fiber, aromatic Lun fiber and glass fiber are spinnable short fibers, and the molecular formula of the acrylic fiber used is: The molecular formula of aramid fiber is: The glass fiber composition is: SiO 2 、AL 2 o 3 , CaO, MgO, Na 2 O etc., metal wire is the embodiment 2 aluminum alloy wire of diameter 0.08-0.2mm or embodiment 3 brass wire or embodiment 4 red copper wire or embodiment 5 iron wire.

[0038] Example 2 see Figure 4 ~ Figure 6 , introducing another fabric weaving method for the overall three-layer braided blank belt; refer to Figure 4 ~ Figure 6 , Weaving in a similar manner Embodiment 3: four layers, Embodiment 4: five layers, Embodiment 5: six layers, Embod...

Embodiment 8

[0042] see Figure 1 ~ Figure 3 , introducing a fabric weaving method for integral multi-layer braided blank tape, taking the integral three-layer braided blank tape as an example: the overall three-layer braided blank tape is formed by interweaving weft threads ①~ with warp threads 1~6, and its processing technology The process is: acrylic fiber, aramid fiber, glass fiber, mixed with spinnable friction material fiber and carbon fiber - spinning with existing technology - making aluminum alloy wire core-spun single yarn - adding multiple core-spun single yarns Twisted and twisted into strands—automatically woven into an integral multi-layer fabric blank—impregnated in thermoplastic phenolic resin, taken out after being soaked—naturally air-dried—grinding surface with existing technology—with existing technology at 180 Heating and curing under the condition of ℃—the finished product of blended fiber braided brake belt (implementing GB11834-2000 standard).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com