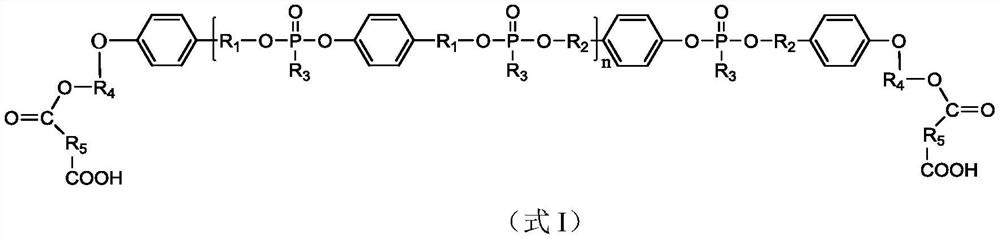

Phosphorus-containing flame retardant nylon and its preparation method and application

A technology of flame retardant nylon and flame retardant is applied in the field of phosphorus-containing flame retardant nylon and its preparation, and achieves the effects of excellent application prospects, little impact on mechanical properties, and lasting flame retardant effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

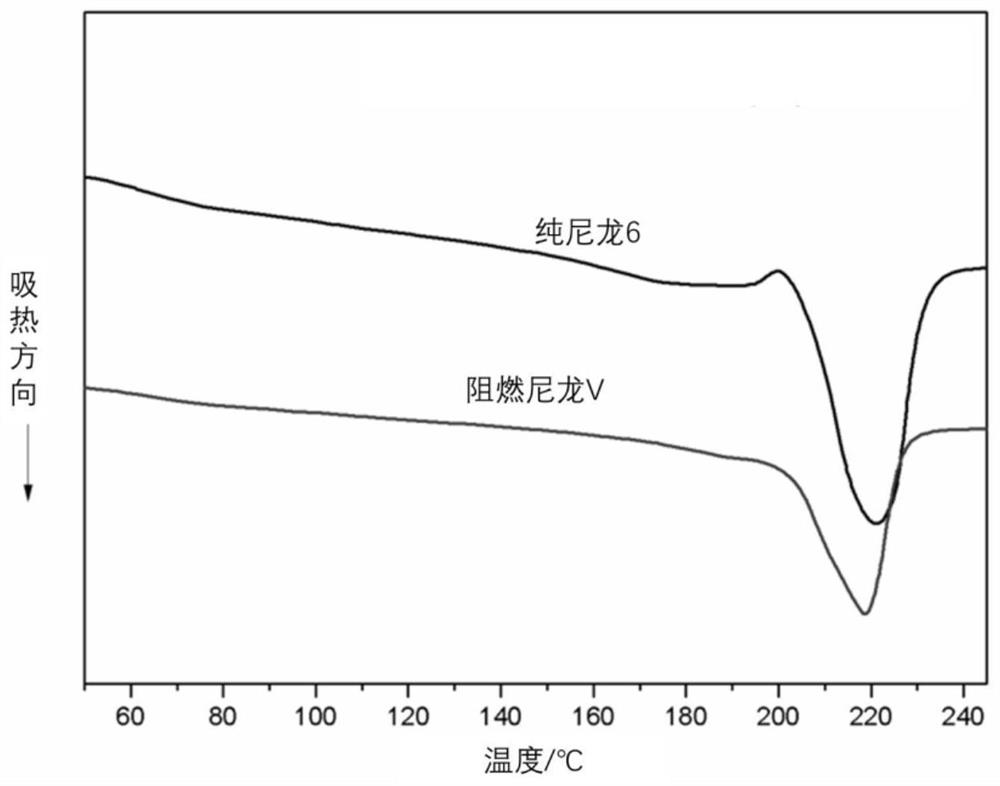

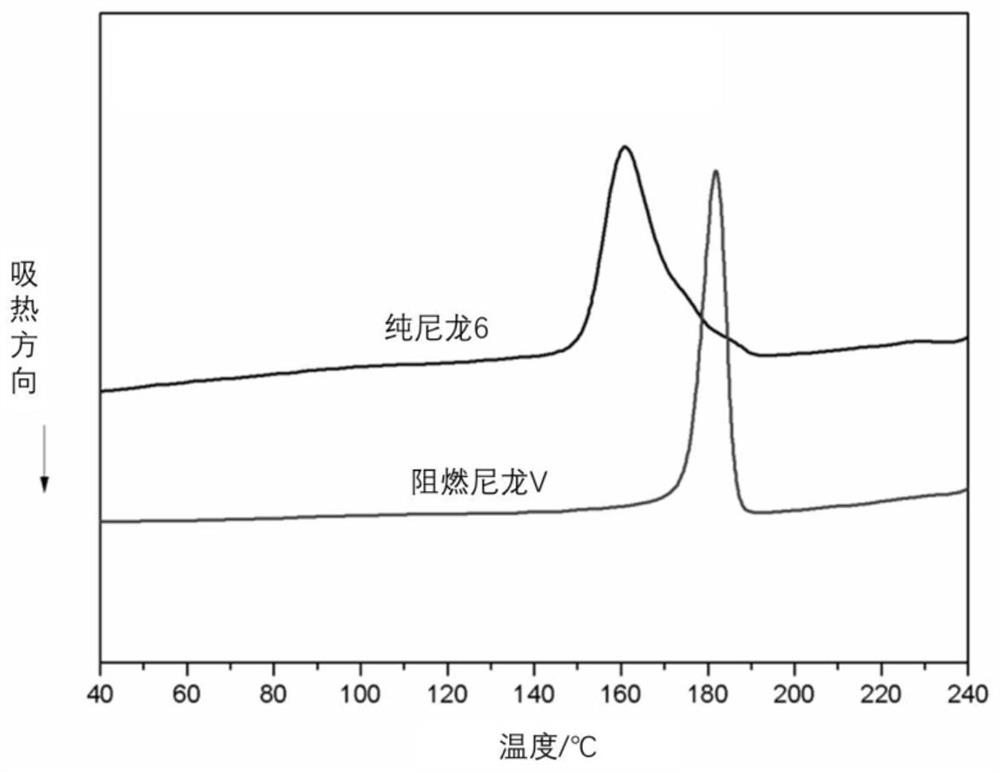

[0068] Example 1: Flame Retardant Nylon I

[0069] 1880g of solid caprolactam was taken, melted at 130°C, 120g of polyphosphonate (Nofia OL1001 from FRX Polymer Company) was added, and after it was fully dissolved, the material was put into a 5L autoclave, and 60g of deionized water was added. Replace the air in the kettle with nitrogen, turn on stirring, heat up to 250 °C, keep the pressure in the kettle at 0.5 MPa, open the ring for 3 hours, and then release the pressure and pass nitrogen for 5 hours. , finally vacuumed for 0.5h, left to discharge, cast tape, cut into pellets, extracted with deionized water at 90°C for 12h, and vacuum dried at 80°C for 12h to obtain flame retardant nylon 6 slices.

Embodiment 2

[0070] Example 2: Flame Retardant Nylon II

[0071] 1840g of solid caprolactam was taken, melted at 130°C, 160g of polyphosphonate (Nofia OL1001 from FRX Polymer Company) was added, and after it was fully dissolved, the material was put into a 5L autoclave, and 60g of deionized water was added. Replace the air in the kettle with nitrogen, turn on stirring, heat up to 250 °C, keep the pressure in the kettle at 0.5 MPa, open the ring for 3 hours, and then release the pressure and pass nitrogen for 5 hours. , finally vacuumed for 0.5h, left to discharge, cast tape, cut into pellets, extracted with deionized water at 90°C for 12h, and vacuum dried at 80°C for 12h to obtain flame retardant nylon 6 slices.

Embodiment 3

[0072] Example 3: Flame Retardant Nylon III

[0073] 1800g of solid caprolactam was taken, melted at 130°C, 200g of polyphosphonate (Nofia OL1001 from FRX Polymer Company) was added, and after it was fully dissolved, the material was put into a 5L autoclave, and 60g of deionized water was added. Replace the air in the kettle with nitrogen, turn on stirring, heat up to 250 °C, keep the pressure in the kettle at 0.5 MPa, open the ring for 3 hours, and then release the pressure and pass nitrogen for 5 hours. , finally vacuumed for 0.5h, left to discharge, cast tape, cut into pellets, extracted with deionized water at 90°C for 12h, and vacuum dried at 80°C for 12h to obtain flame retardant nylon 6 slices.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com