Comprehensive warp lubricating device

A lubricating device and warp yarn technology, which is applied in the field of yarn lubricating devices in the textile field, can solve problems such as broken yarns affecting work efficiency and product quality, low work efficiency, and long moving paths, so as to improve line toughness and textile performance, Prevents sticking and facilitates cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

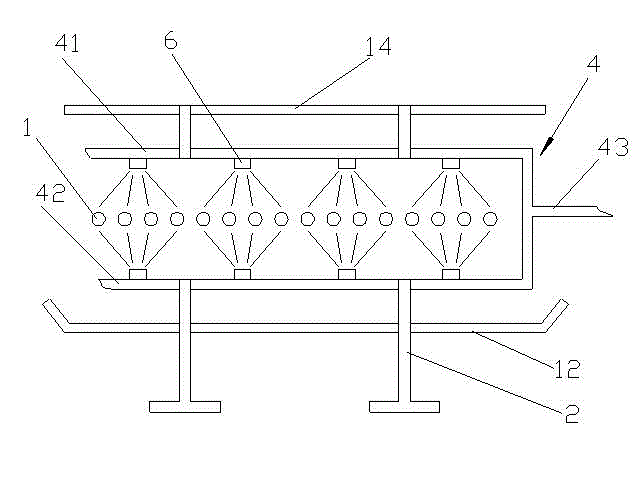

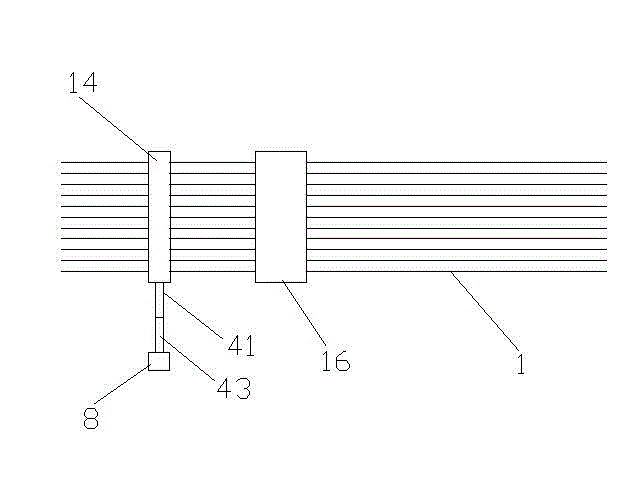

[0015] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0016] Such as Figure 1-2 As shown, a kind of overall lubricating device of warp thread of the present invention comprises the support 2 that extends longitudinally, is located at the oil delivery pipe 4 that extends transversely on support 2 and is located at a plurality of oil injection nozzles 6 on the oil delivery pipe 4, oil delivery pipe 4 and oil supply device 8 connected. The oil delivery pipe 4 includes an upper oil delivery pipe 41 , a lower oil delivery pipe 42 , and a main oil delivery pipe 43 whose extending directions are parallel to each other. The upper oil delivery pipe 41 and the lower oil delivery pipe 42 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com