Adjusting installing structure of guiding roller claw in compact spinning cradle

A technology of cot claws and installation structure, which is applied in the field of cradles, can solve the problems affecting the spinning effect of compact spinning, and cannot adjust the installation distance between the guide cot roller and the front cot roller as required, and achieve the effect of improving the weaving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail.

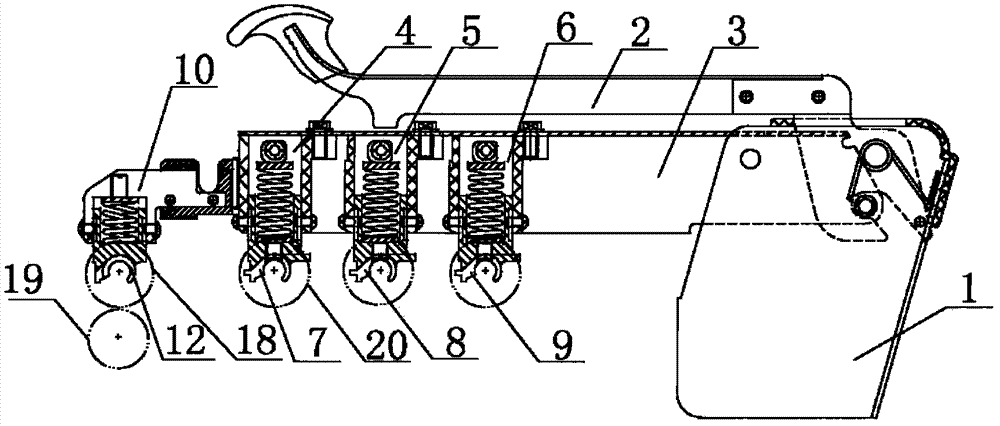

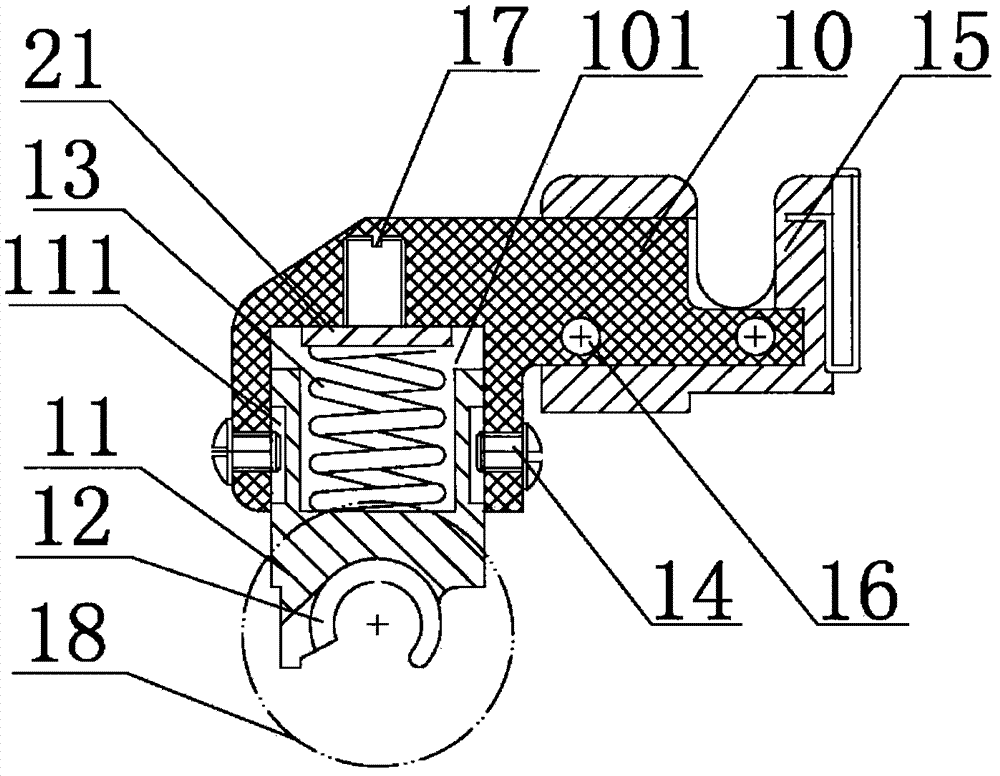

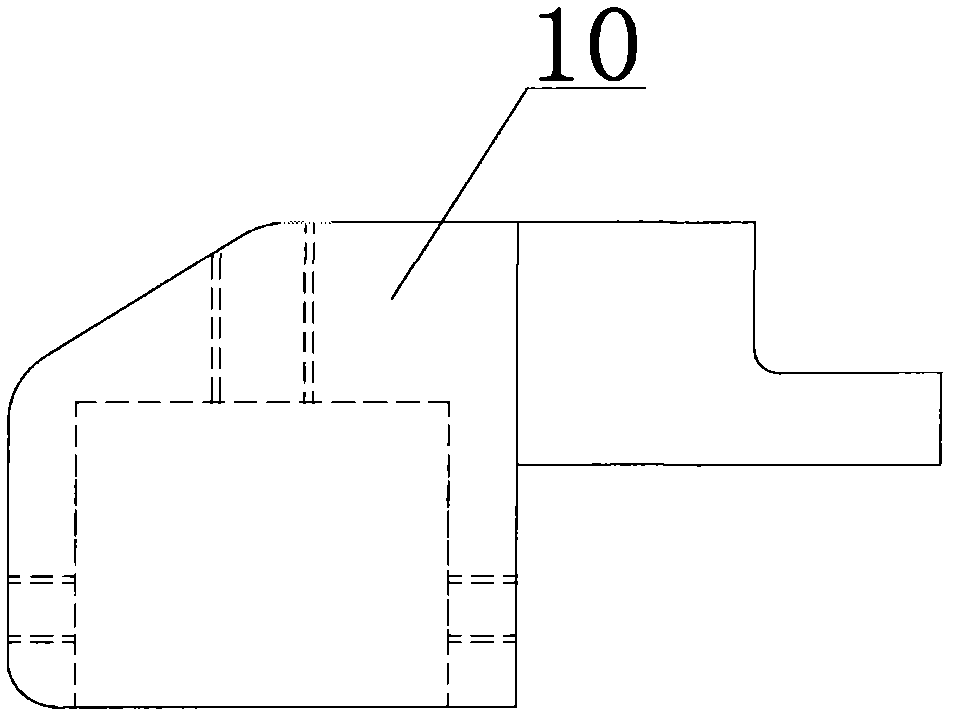

[0016] Such as Figure 1 ~ Figure 4 As shown, the adjustment and installation structure of the guide roller claws in the compact spinning cradle includes: the cradle seat 1, the handle 2 and the rocker arm 3 are hinged on the cradle seat 1, and the lower side of the rocker arm 3 is equipped with a front pressure Component 4, middle pressurization component 5 and rear pressurization component 6, the lower end of the front pressurization component 4 is equipped with the front top roller claw 7, the lower end of the middle pressurization component 5 is equipped with the middle top roller claw 8, and the rear pressurization component 6 The lower end is equipped with a rear roller claw 9, and a guide pressure seat 10 is also arranged at the front end of the rocker arm 3. The guide pressure seat 10 is installed on the front end of the rocker arm 3 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com