Preparation method of impregnating agent for high silicic acid glass fiber

A technology of glass fiber and sizing agent, which is applied in the field of preparation of sizing agent for high silicic acid glass fiber, which can solve problems such as flying silk and easy hair of glass fiber, and achieve the effect of improving textile performance and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The technical scheme adopted in the preparation method of the high silicic acid glass fiber sizing agent of the present invention is:

[0017] The sizing agent for glass fiber includes the following components in the following weight ratio:

[0018] 5500.2-0.6 parts of coupling agent, 5-15 parts of strengthening agent, 2-7 parts of film-forming agent, 0.5-1.5 parts of lubricant, 0.3-0.5 parts of defoamer, 0.01-0.07 parts of pH regulator, 0.5 parts of protective agent ~1.1 parts and 70~95 parts of deionized water;

[0019] Among them, the strengthening agent is composed of unsaturated polyester resin and water-soluble epoxy emulsion with a ratio of 7:4, the film-forming agent is starch, and the lubricant is composed of polyether polyol and oil with a ratio of 3:5 ;The defoamer is composed of polyoxyethylene polyoxypropylene pentaerythritol ether, polyoxyethylene polyoxypropanolamine ether, polyoxypropylene glyceryl ether and polyoxypropylene polyoxyethylene glyceryl eth...

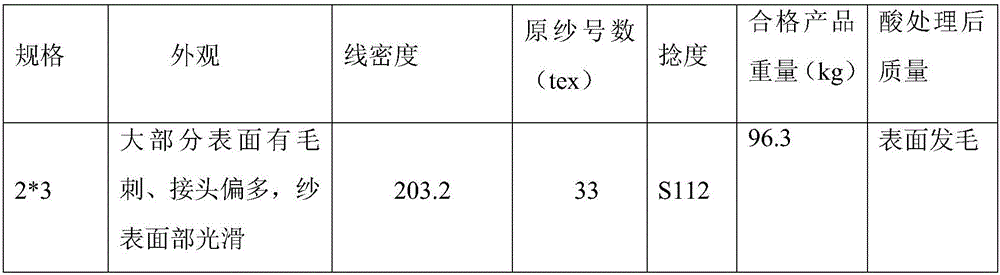

Embodiment 1

[0051] This test example is an example of adding the sizing agent produced by this scheme during the production of glass fibers:

[0052] To produce 100kg of high-silica glass fiber, the amount of raw materials required is: 125kg of high-silica glass strands, 100kg of sizing agent, wherein the sizing agent includes the following components in the following weight ratio:

[0053] 5500.2 parts of coupling agent, 9 parts of strengthening agent, 3 parts of film forming agent, 0.5 part of lubricant, 0.4 part of defoamer, 0.04 part of pH regulator, 0.7 part of protective agent and 80 parts of deionized water;

[0054] The steps for glass fiber production using the sizing produced in this embodiment are:

[0055] a, put on the shelf: put the high-silica raw silk tube produced by the above-mentioned sizing agent formula on the twisting frame according to the production process requirements, and adjust the twisting machine process parameters (twist, rotating speed, etc.);

[0056] b, de...

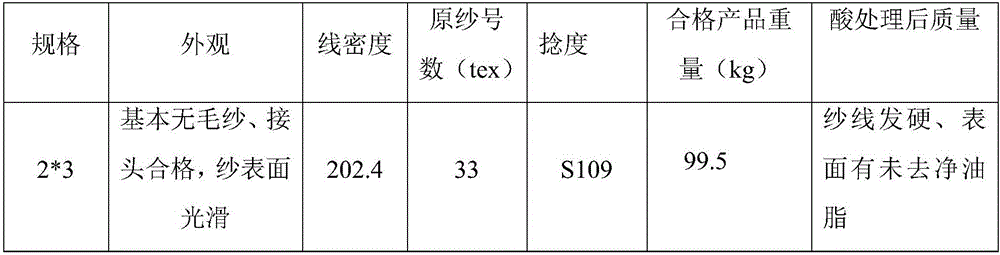

Embodiment 2

[0063] This test example is an example of adding the sizing agent produced by this scheme during the production of glass fibers:

[0064] To produce 100kg of high-silica glass fiber, the amount of raw materials required is: 125kg of high-silica glass strands, 100kg of sizing agent, wherein the sizing agent includes the following components in the following weight ratio:

[0065] 5500.4 parts of coupling agent, 5 parts of strengthening agent, 7 parts of film forming agent, 1.5 parts of lubricant, 0.5 part of defoamer, 0.01 part of pH regulator, 0.5 part of protective agent and 70 parts of deionized water;

[0066] The steps for glass fiber production using the sizing produced in this embodiment are:

[0067] a. Putting on the shelf: put the high-silica raw silk tube produced by the above sizing agent formula on the twisting frame according to the production process requirements, and adjust the twisting machine process parameters (twist, rotating speed, etc.);

[0068] b, de-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com