Shuttle air draft guide rail of shuttle loom

A technology for air-floating guide rails and shuttle looms, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of unstable power consumption, affecting work progress, waste of resources, etc., so as to improve the textile effect and reduce the waste of resources. , Improve the effect of work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

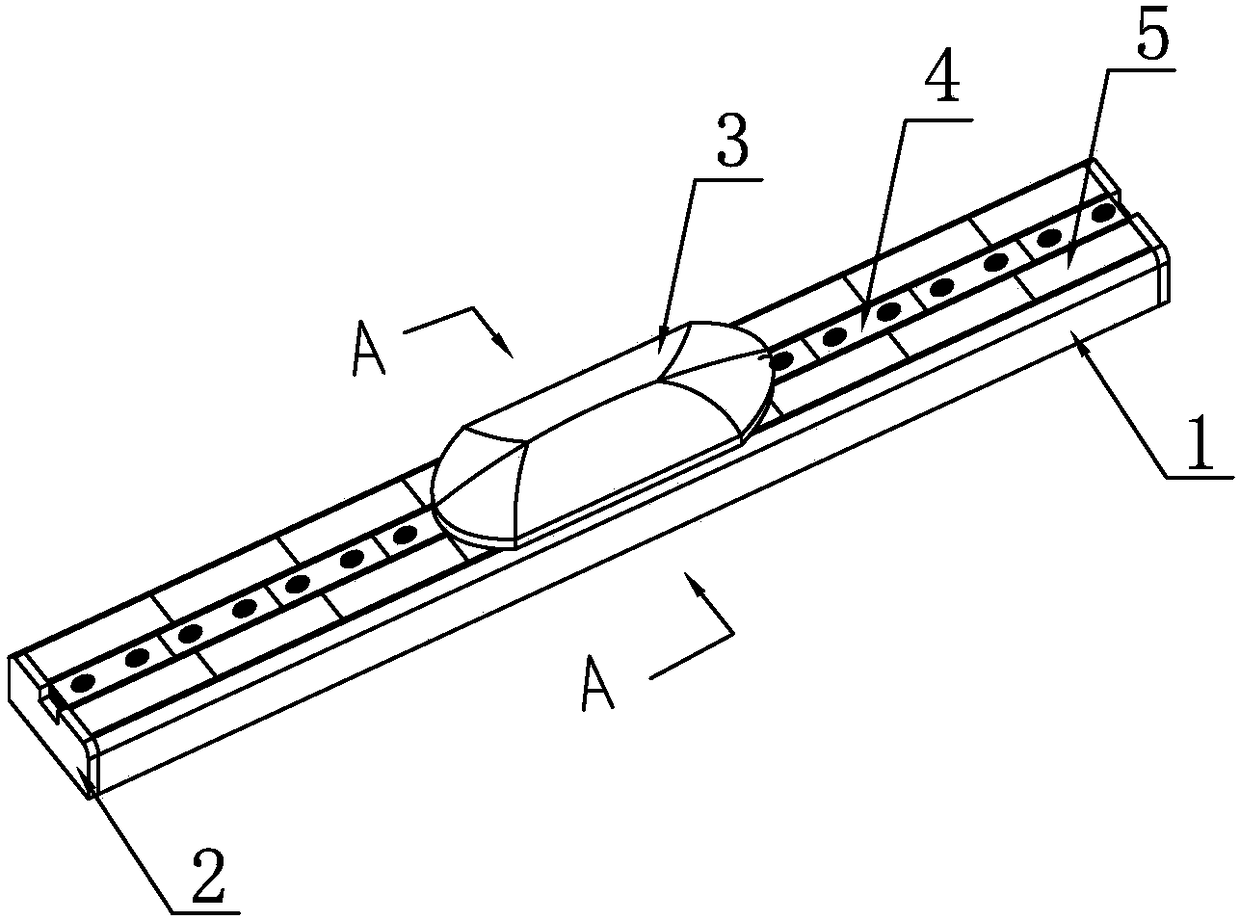

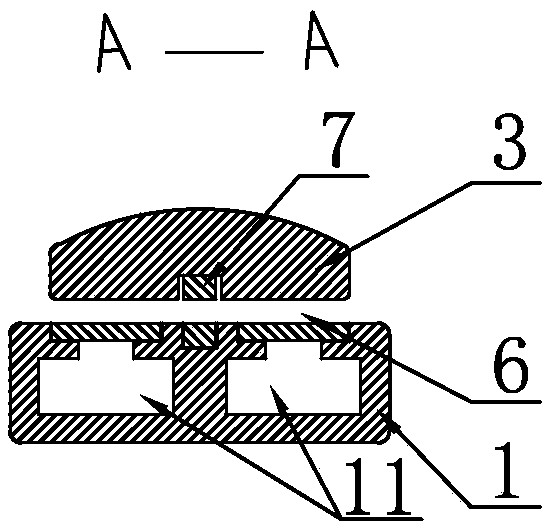

[0029] For the shuttle air-floating guide rail of a shuttle loom provided in Embodiment 1 of the present invention, please refer to figure 1 As shown, it includes an air-floating guide rail 1 and a shuttle 3 suspended above the air-floating guide rail 1. The top extension direction of the air-floating guide rail 1 is provided with a number of first permanent magnets 4 and is arranged on the first permanent magnet. Some porous ceramics 5 on both sides of the magnet 4, and some of the porous ceramics 5 on both sides are symmetrical to each other with the first permanent magnet 4 as the axis of symmetry; please refer to figure 2 As shown, there are two compressed air flow grooves 11 inside the air flotation guide rail 1, and the two compressed air flow grooves 11 communicate with the plurality of porous ceramics 5 on both sides respectively; the compressed air flow grooves 11 are externally connected to Air compressor; the two ends of the air-floating guide rail 1 are respective...

Embodiment 2

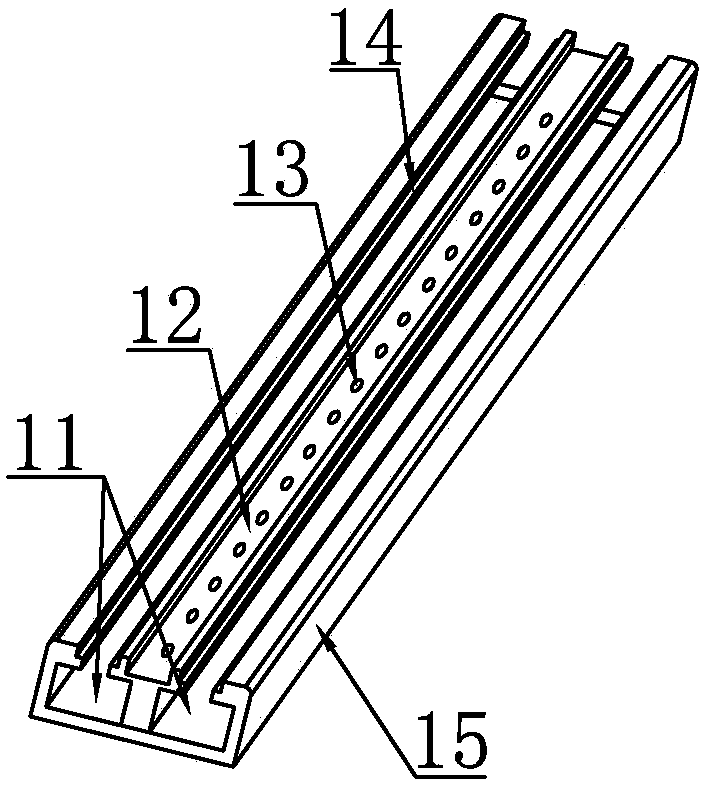

[0032] The shuttle air-floating guide rail of a shuttle loom provided in Embodiment 2 of the present invention is basically the same as Embodiment 1, the difference is that please refer to image 3 As shown, the air bearing guide rail 1 includes a guide rail base 15; the guide rail base 15 is a cuboid, and the middle part of the top end of the guide rail base 15 is provided with a first magnet placement groove 12 in the extension direction, and the first magnet is placed The two ends of the groove 12 communicate with the outside world. The bottom of the first magnet placement groove 12 is provided with a number of first threaded blind holes 13; There are two symmetrical ceramic placement grooves 14 , the two ends of the ceramic placement grooves 14 communicate with the outside world; the ceramic placement grooves 14 communicate with the compressed air flow groove 11 .

[0033] Furthermore, for a better connection of the permanent magnets to the rail base and the shuttle, see ...

Embodiment 3

[0035] The shuttle air-floating guide rail of a shuttle loom provided in Embodiment 3 of the present invention is basically the same as Embodiment 2, the difference is that please refer to Figure 6 As shown, in order to achieve a better suspension effect of the shuttle, the plug 2 is a cuboid plate; the top of the plug 2 has a gap 22, and the width of the gap 22 is the same as the width of the first permanent magnet 4 ; Two second through holes 21 are arranged horizontally side by side on the plug 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com