Yarn inlet and guiding device for textile machine

A textile machine and wire technology, which is applied to the field of wire feed wire devices for textile machines, can solve problems such as poor wire effect and yarn breakage, and achieve the effect of improving textile effect and preventing wire breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

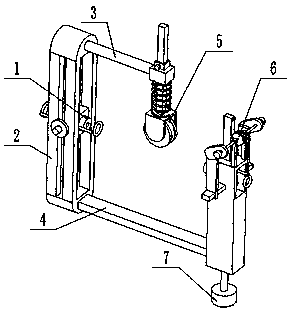

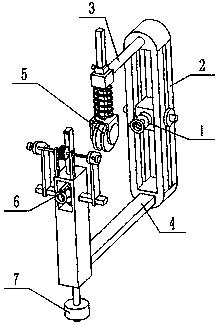

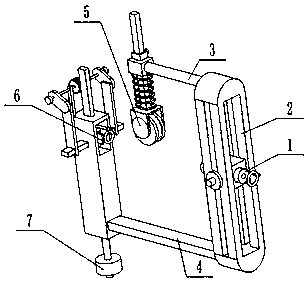

[0030] Such as Figure 1-12 As shown, an incoming wire device for a textile machine includes a wire conduit mechanism 1, a mounting frame 2, a cylindrical connecting rod 3, a rectangular connecting rod 4, a guide wheel mechanism 5, a cleaning brush assembly 6 and a dust collection pipe assembly 7, The front and rear sides of the mounting bracket 2 are provided with through rectangular slots 2-1, There is a rectangular slot on the left side and the right side of the mounting frame 2 2-2, rectangular slot 2-1 and two rectangular slots 2-2 are connected; the wire conduit mechanism 1 is connected to the rectangular slot of the mounting frame 2 2-1 and two rectangular slots 2-2 inside; the upper end of the rear side of the mounting frame 2 is fixedly connected to the cylindrical connecting rod 3, and the rear end of the cylindrical connecting rod 3 is fixedly connected to the guide wheel mechanism 5; the lower end of the rear side of the mounting frame 2 is fixedly connect...

specific Embodiment approach 2

[0031] Such as Figure 1-12 As shown, the wire conduit mechanism 1 includes a rectangular guide slider 1-1, an externally threaded wire conduit 1-2, a front wire loop 1-3, a rear wire loop 1-4, a cylindrical slide rod 1-5 and a positioning ring 1-6; the rectangular guide slider 1-1 is matched and connected in the rectangular groove 2-1; the middle of the rectangular guide slider 1-1 is provided with an internally threaded through hole, and the inner side of the internally threaded through hole is threaded to connect the externally threaded conduit 1-2; the rectangular guide slider 1-1 The left end and the right end of each are fixedly connected with a cylindrical sliding rod 1-5, and the two cylindrical sliding rods 1-5 are respectively slidingly fitted and connected in two rectangular slots On the inner side of 2-2, the outer ends of the two cylindrical slide rods 1-5 are respectively threaded to a positioning ring 1-6, and the two positioning rings 1-6 are attached to the...

specific Embodiment approach 3

[0032] Such as Figure 1-12 As shown, the guide wheel mechanism 5 includes a fixed sliding sleeve 5-1, a movable sliding sleeve 5-2, a rectangular slide bar 5-3, a guide wheel body 5-4, a wheel seat 5-5, a compression spring 5-6 and Positioning bolt 5-7; the front end of the fixed sliding sleeve 5-1 is fixedly connected to the rear end of the cylindrical connecting rod 3; the rectangular sliding rod 5-3 is slidingly fitted and connected to the fixed sliding sleeve 5-1; the rectangular sliding The upper end of the rod 5-3 is slidably fitted to connect the movable sliding sleeve 5-2, and the movable sliding sleeve 5-2 is threaded to connect the positioning bolt 5-7, and the positioning bolt 5-7 is against the rectangular sliding rod 5-3; The lower end of the slide bar 5-3 is connected to the wheel seat 5-5 by screws; the guide wheel body 5-4 is connected to the inner lower end of the wheel seat 5-5 through rotation of the rotating shaft; the upper sleeve of the rectangular slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com