Method for preparing YAG-based multilayer composite structure transparent ceramic by Isobam gelcasting

A multi-layer composite and transparent ceramic technology, applied in the field of advanced ceramics, can solve the problems of general thermal effect control ability, high preparation cost, low transmittance, etc., and achieves small interface ion diffusion range, good overall performance, and good optical quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

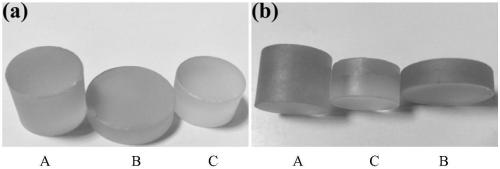

[0029] Example 1: YAG / 1at.%Nd:YAG / 2at.%Nd:YAG

[0030]The composition of pure YAG layer is shown in 0# in Table 1, the composition of 1at.% Nd:YAG layer is shown in 1# in Table 1, and the composition of 2at.% Nd:YAG is shown in 3# in Table 1.

[0031] Concrete preparation method comprises the following steps:

[0032] (1) Weigh the raw materials according to the composition in Table 1, first put the oxide raw material powder into a high-purity alumina ceramic ball mill jar, add 375g of high-purity alumina balls, and add sintering aids MgO and TEOS, Dispersant PEI and absolute ethanol were used to prepare the slurry; on a planetary ball mill at a speed of 160r / min, ball milled for 15 hours; the obtained mixed slurry A was dried at 60°C for 24 hours and then passed through a 100-mesh sieve for 3 times. The sieved powder is calcined in a muffle furnace. The calcining process is from room temperature to 700 ° C, the heating rate is 2 ° C / min, and the temperature is kept for 6 h...

Embodiment 2

[0036] Embodiment 2: YAG / 1.5at.% Nd:YAG / YAG

[0037] The composition of the pure YAG layer is shown in 0# in Table 1, and the composition of the 1.5at.% Nd:YAG layer is shown in 2# in Table 1.

[0038] Concrete preparation method comprises the following steps:

[0039] (1) Weigh the raw materials according to the composition in Table 1, first put the oxide raw material powder into a high-purity alumina ceramic ball mill jar, add 125g of high-purity alumina balls, and add sintering aids MgO and TEOS, The dispersant PEI and absolute ethanol were used to prepare slurry; on a planetary ball mill at a speed of 120r / min, ball milled for 24 hours; the obtained mixed slurry A was dried at 50°C for 48 hours and then passed through a 100-mesh sieve for 3 times. The sieved powder is placed in a muffle furnace for calcination. The calcination process is from room temperature to 900°C, the heating rate is 3°C / min, and the temperature is kept for 8 hours, and then the temperature is natura...

Embodiment 3

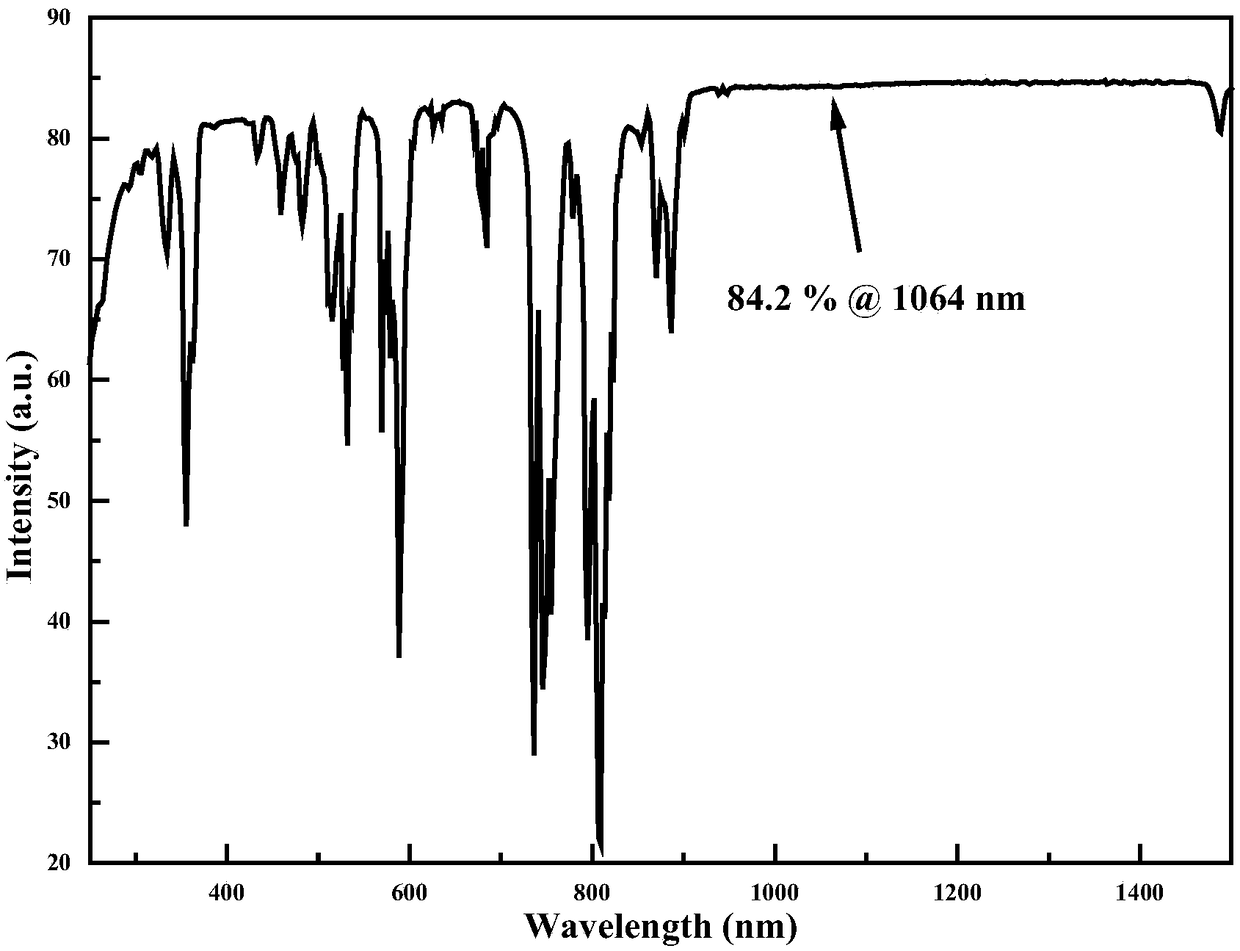

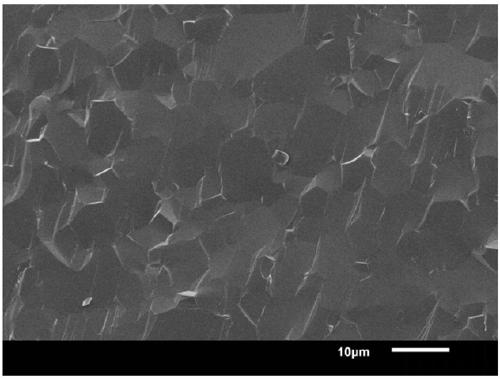

[0042] Embodiment 3: YAG / 2at.% Nd:YAG / YAG

[0043] The pure YAG layer composition is shown in 0# in Table 1, and 2at.% Nd:YAG is shown in 3# in Table 1.

[0044] Concrete preparation method comprises the following steps:

[0045] (1) Weigh the raw materials according to the composition in Table 1, first put the oxide raw material powder into a high-purity alumina ceramic ball mill jar, add 250g of high-purity alumina balls, and add sintering aids MgO and TEOS, The dispersant PEI and absolute ethanol were used to prepare the slurry; on a planetary ball mill at a speed of 150r / min, ball milled for 20 hours; the obtained mixed slurry A was dried at 55°C for 36 hours and passed through a 200-mesh sieve for 3 times. The sieved powder is placed in a muffle furnace for calcination. The calcination process is from room temperature to 800°C, the heating rate is 2°C / min, the temperature is kept for 7 hours, and then the temperature is naturally lowered to 50°C. The obtained powder is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com