Patents

Literature

34results about How to "Prepared for" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing YAG-based multilayer composite structure transparent ceramic by Isobam gelcasting

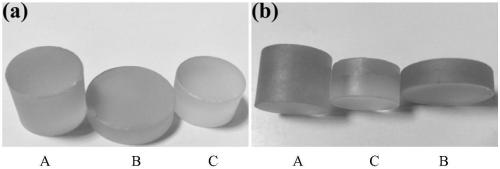

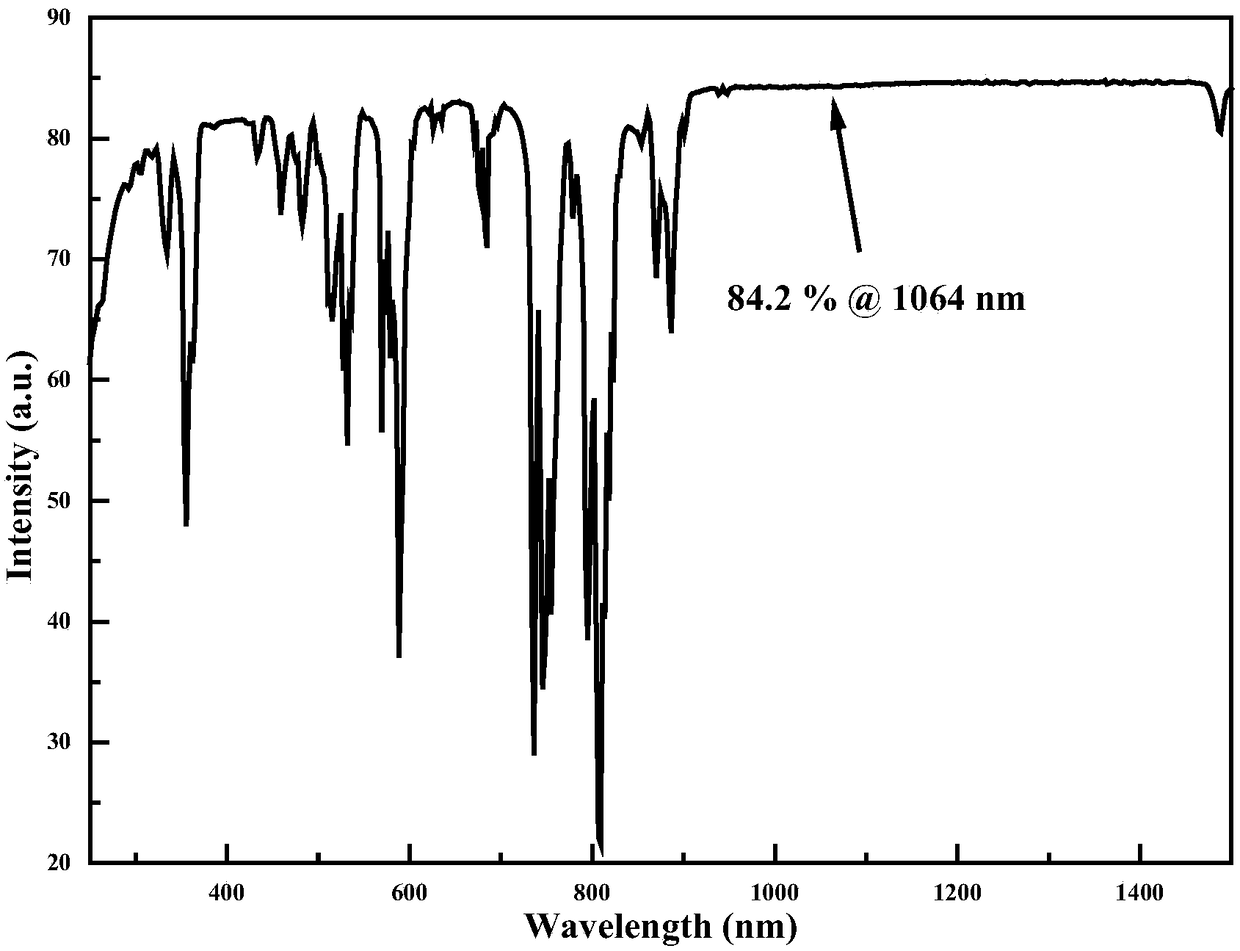

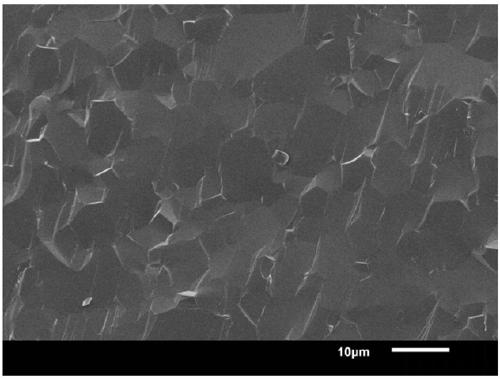

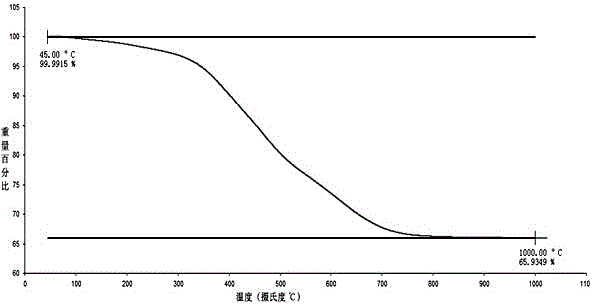

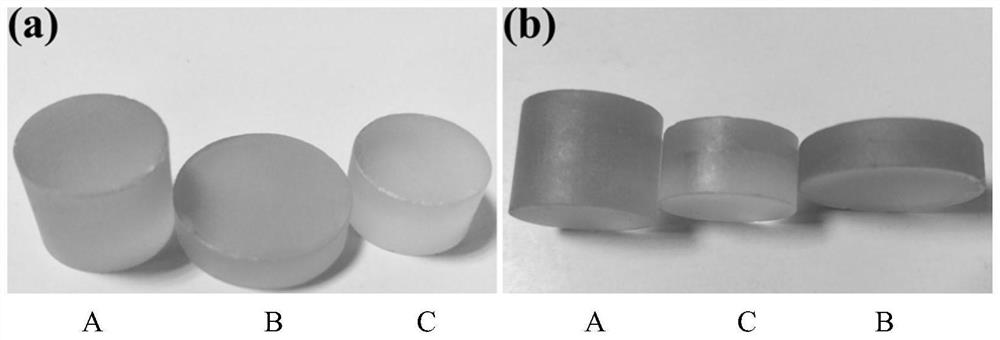

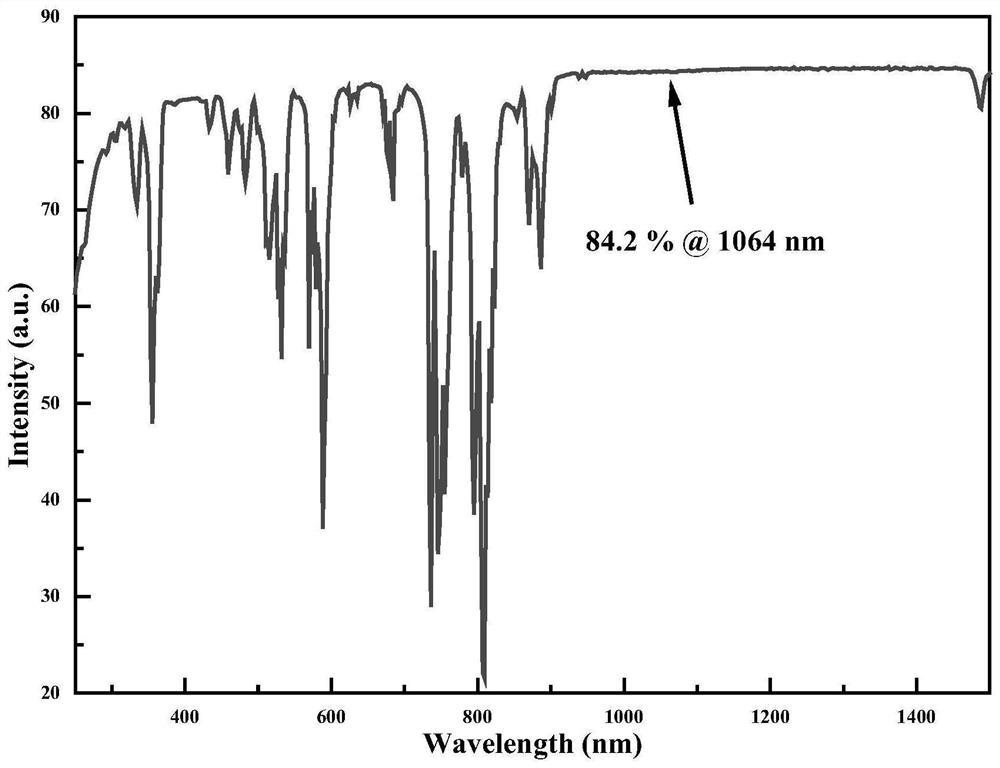

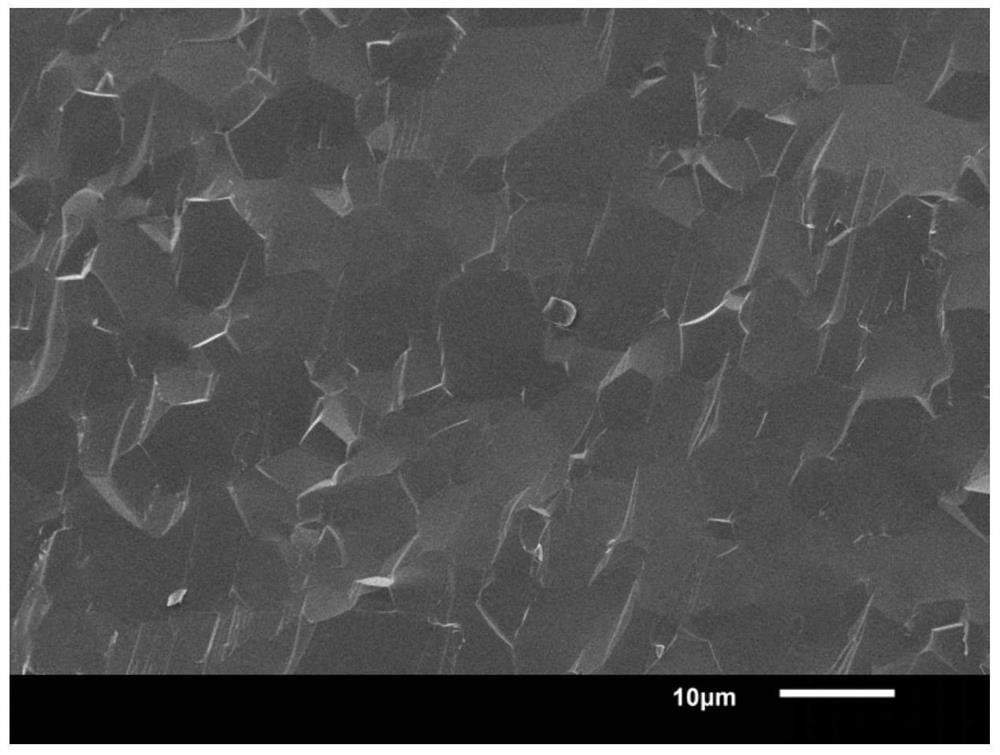

The invention discloses a method for preparing a YAG-based multilayer composite transparent ceramic by using Isobam gelcasting. The prepared multilayer ceramic satisfies a structure shown by a following formula: YAG / Re:YAG / YAG or YAG / Re: YAG / Re:YAG, wherein the YAG layer is composed of Y3A15O12, the Re:YAG layer is composed of (Y<1-x>Re<x>)<3>A<15>O<12>, x is more than or equal to 0.02 and is lessthan or equal to 0.2; Re is one of rare earth elements of cerium, praseodymium, neodymium, samarium, europium, terbium, dysprosium, holmium, erbium, thulium or ytterbium. The method comprises the steps that firstly Isobam gelcasting slurry is prepared, then the slurry is defoamed and is cast into a mold, after a first layer of the slurry gel is cured, the other layer of slurry is poured, the slurry is completely gelled, drying treatment is conducted, and the gel is discharged; biscuit after discharging the gel is vacuum sintered and annealed, and after double-sided polishing, the multilayer composite transparent ceramic is obtained. The method provided by the invention is mainly water-based slurry, green and environmentally friendly, and the obtained ceramic has the characteristics of high density, complicated structure, good optical quality, high transmittance, small interfacial ion diffusion range, and the method is very suitable for the preparation of the large size and composite YAG-based transparent ceramic material.

Owner:XUZHOU ALL TO PHOTOELECTRIC TECH CO LTD

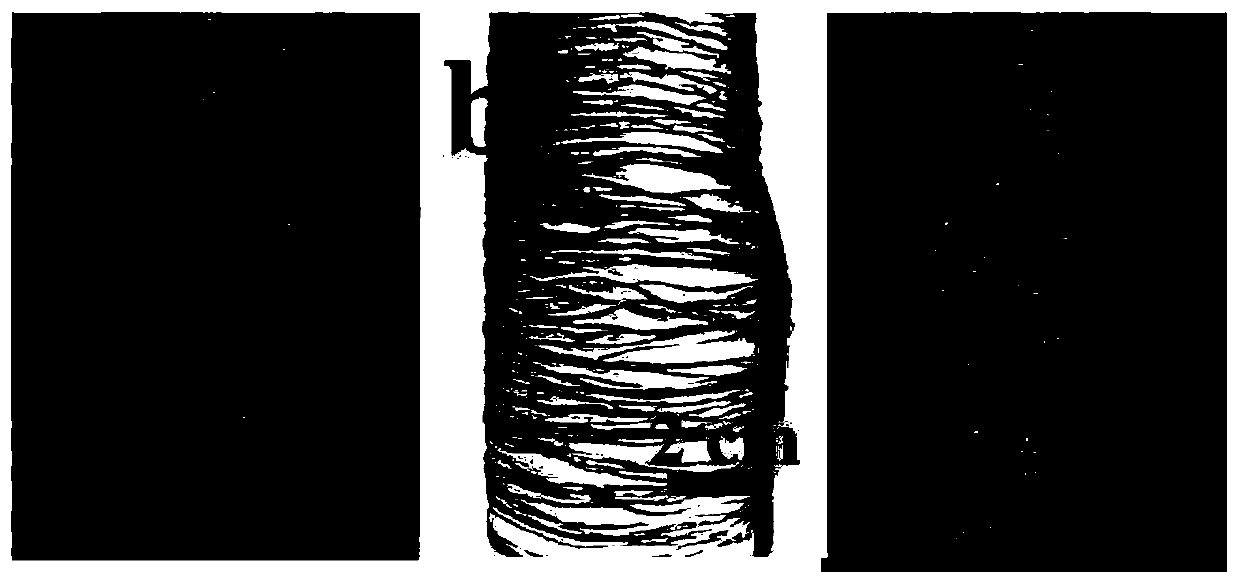

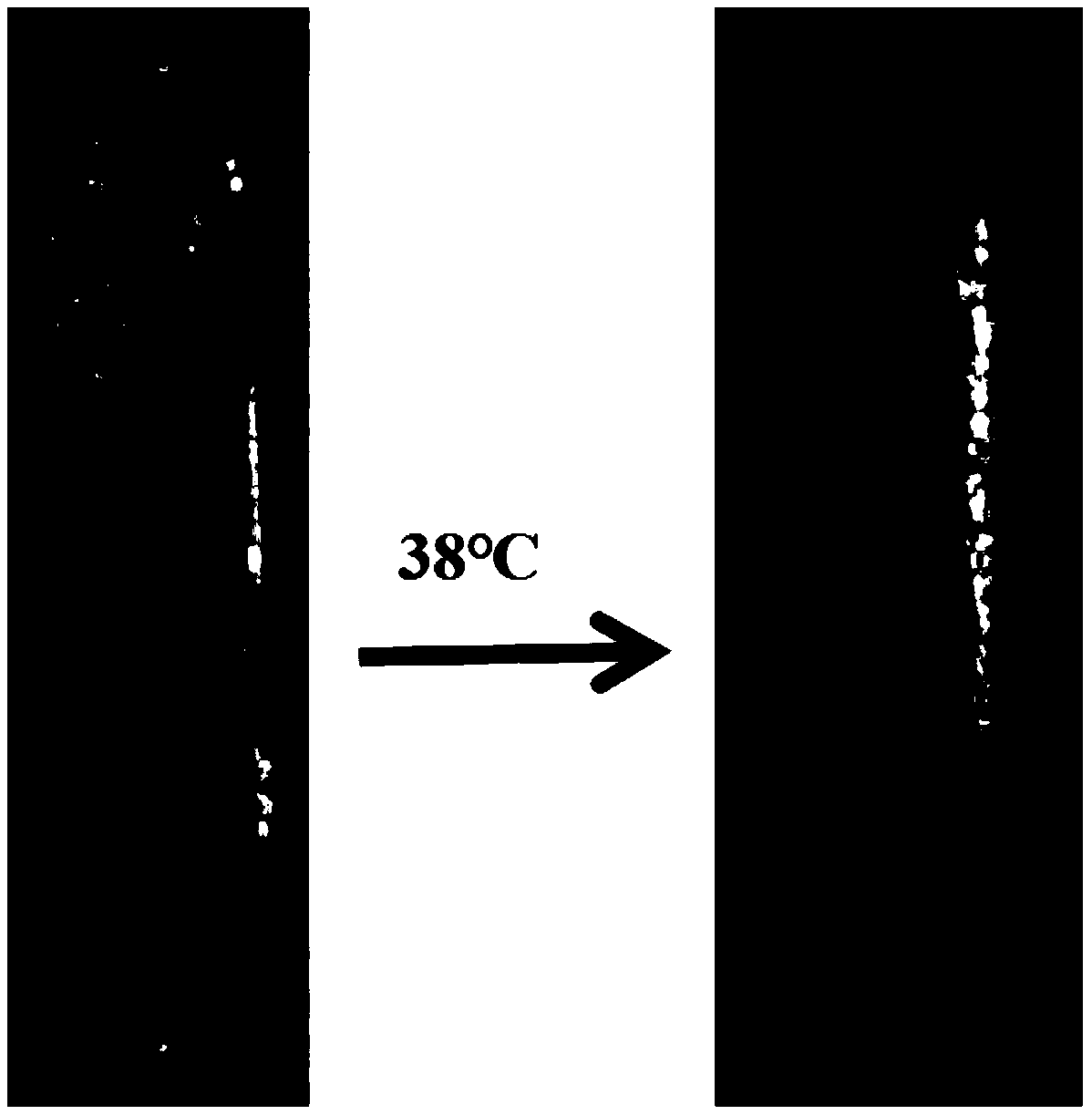

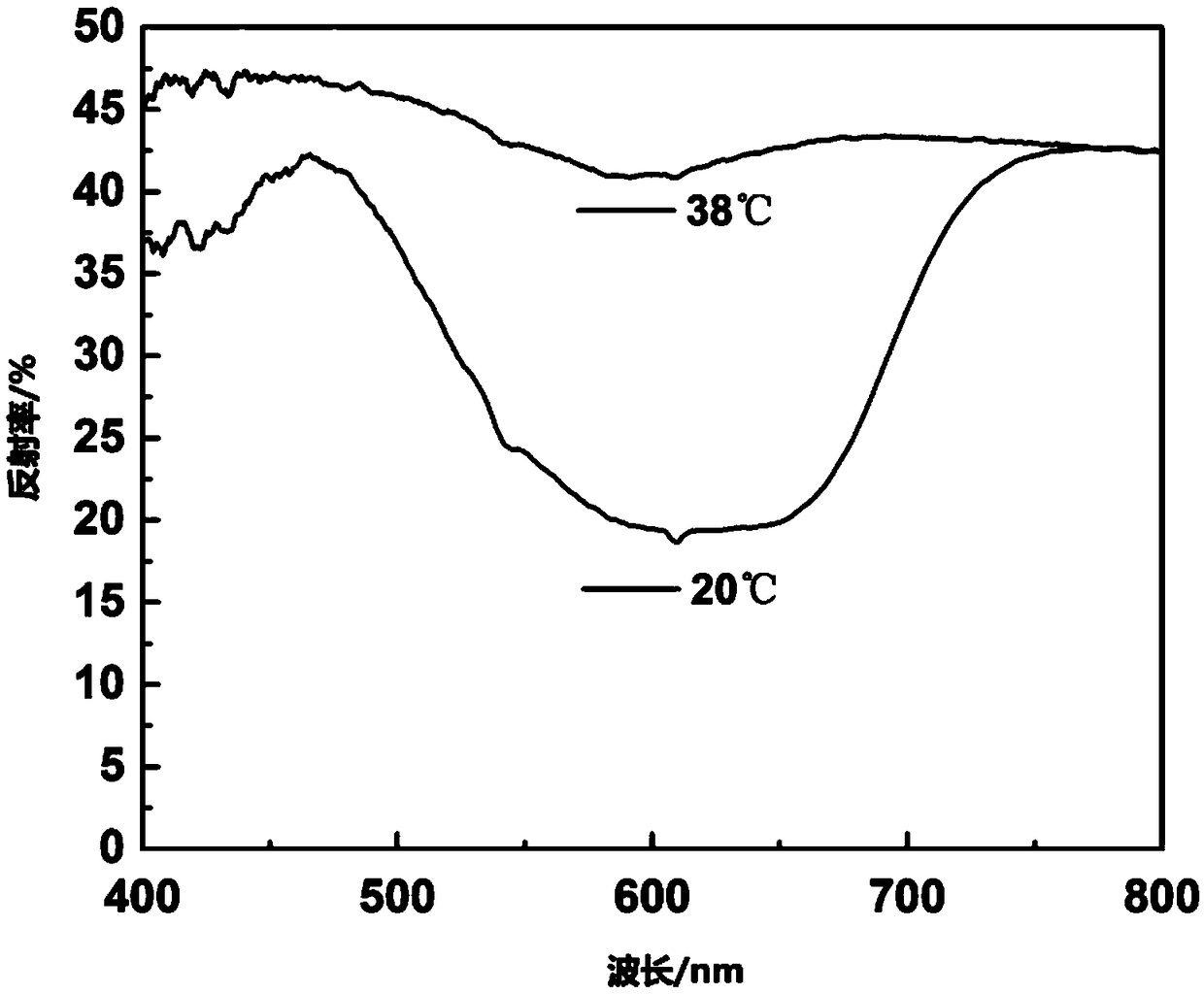

Thermochromic PLA (polylactic acid) fiber of core-shell structure as well as preparation method and application of thermochromic PLA fiber

ActiveCN110129919ASensitive to temperatureEfficient preparation methodConjugated synthetic polymer artificial filamentsArtifical filament manufactureFiberPEG 400

The invention relates to thermochromic PLA (polylactic acid) fiber of a core-shell structure as well as a preparation method and an application of the thermochromic PLA fiber. The fiber comprises a PLA shell layer and a color-changing ink and sodium alginate mixture core layer. The preparation method comprises steps as follows: a PLA solution, a color-changing ink and sodium alginate mixed solution and PEG (polyethylene glycol) 400 are put in an injector, the injector is pushed to inject three solutions into a receiving device containing PEG 400 through a microfluidic device, and collection and still standing are performed. The fiber has temperature sensitivity, a core part of one fiber can have a core-shell structure with one, two or three colors, and the fiber can be used for fluorescence labeling, the smart clothing industry and the like, and wearable underwear adopting the fiber can detect cold, fever and other symptoms of a human body.

Owner:DONGHUA UNIV

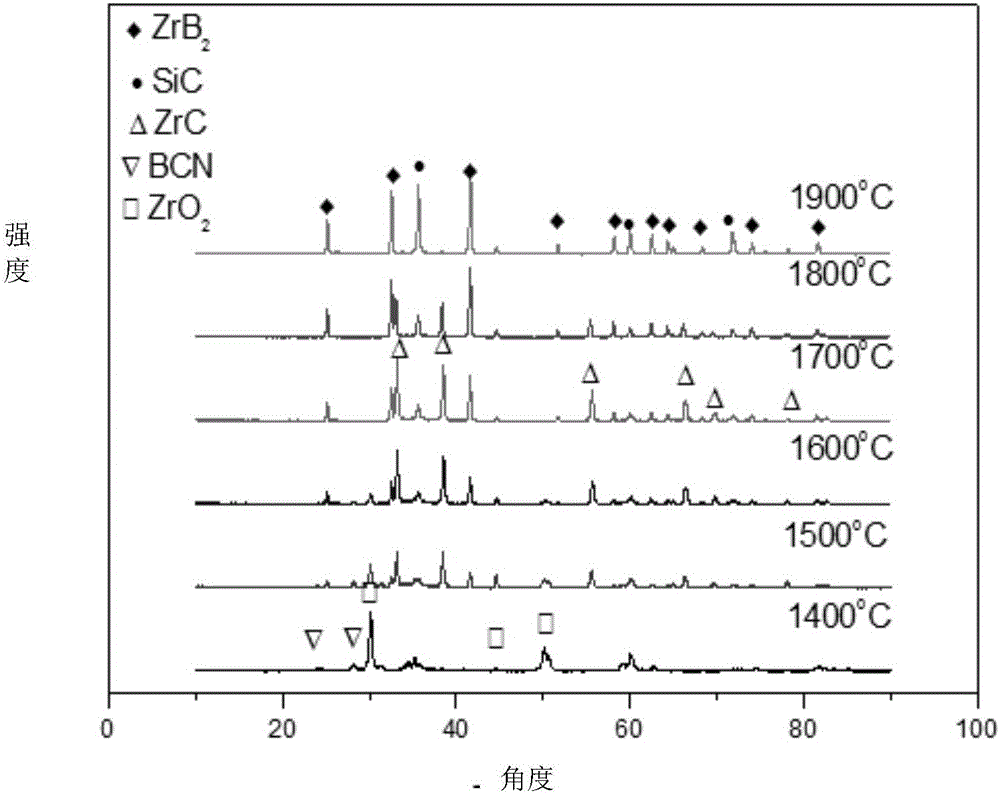

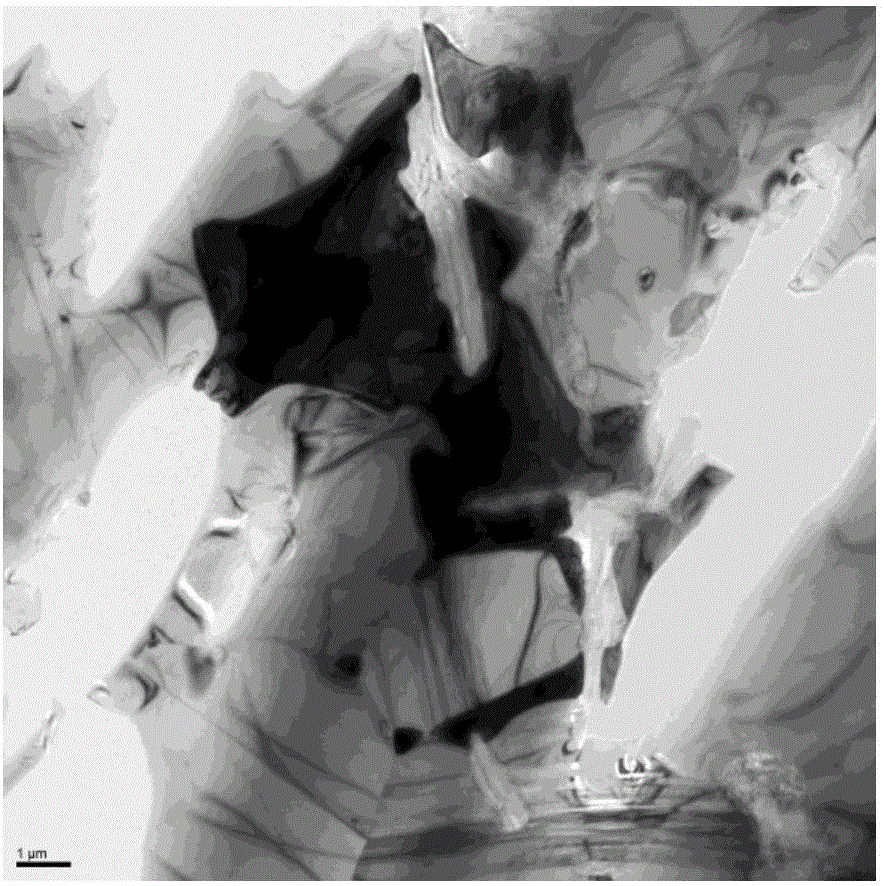

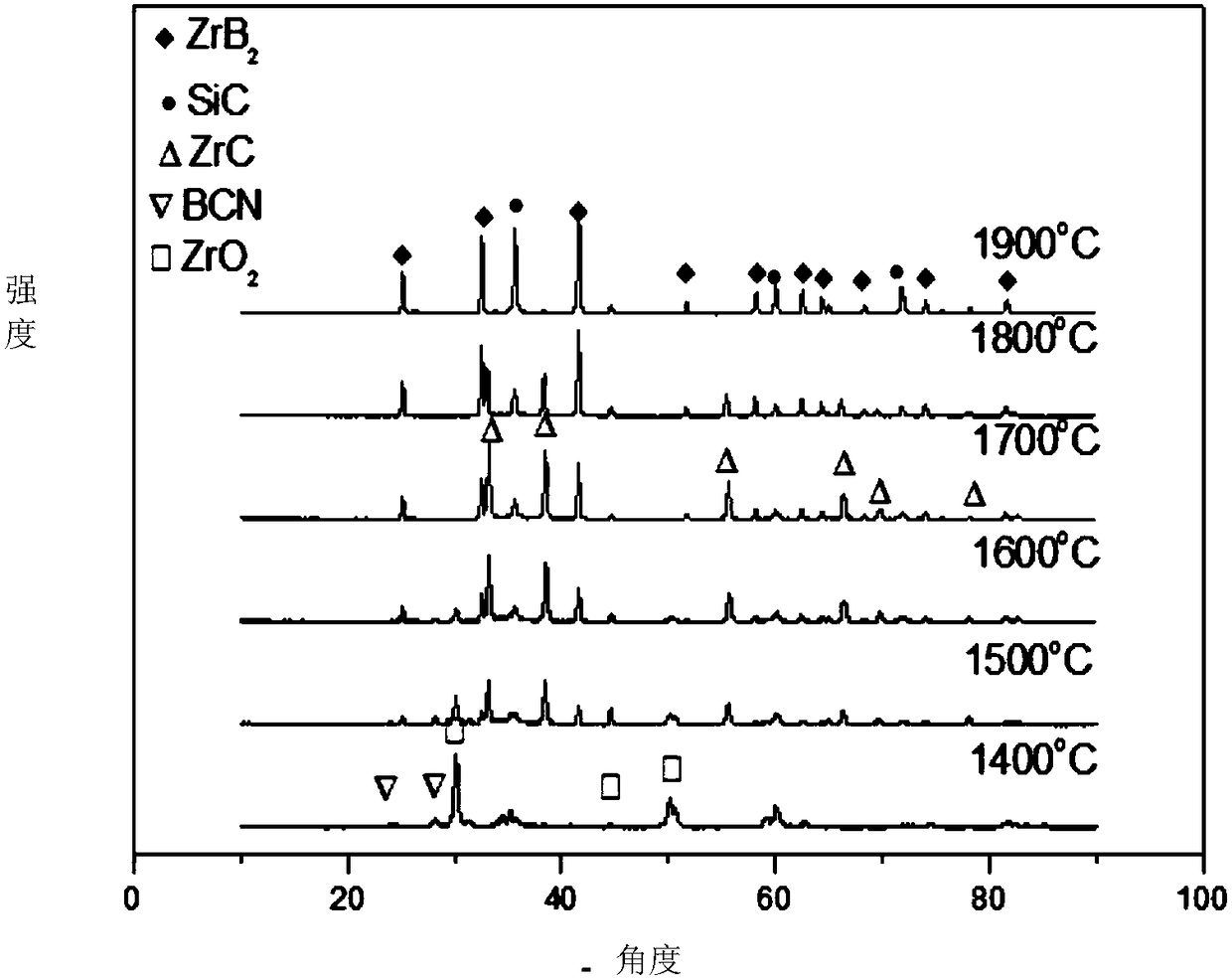

Silicon-boron-carbon-nitrogen-zirconium ceramic composite material and preparation method thereof

ActiveCN105948748ARaw materials are cheap and easy to getSimple processCeramic compositeHexagonal boron nitride

The invention discloses a silicon-boron-carbon-nitrogen-zirconium ceramic composite material and a preparation method thereof. A sol-gel liquid adopts zirconium n-propoxide, acetylacetone and anhydrous ethanol as raw materials. Zirconium n-propoxide is the precursor of zirconium oxide, and can be subjected to a gel reaction with acetylacetone, while ethanol is a solvent. Silicon powder, graphite and hexagonal boron nitride are the raw materials for silicon-boron-carbon-nitrogen ceramic composite powder. The preparation method comprises the following steps: zirconium n-propoxide and acetylacetone are subjected to magnetic stirring for 48h in an anhydrous ethanol solution, such that a gel solution is formed; the silicon-boron-carbon-nitrogen ceramic composite powder is mixed with the solution according to a certain ratio; magnetic stirring is carried out for 48h, and the obtained material is dried; cracking is carried out for 3h under a temperature of 550 DEG C in a tubular furnace, such that a silicon-boron-carbon-nitrogen-zirconium oxide ceramic composite material is obtained. The powder is subjected to pressurized sintering under a temperature of 2000 DEG C in discharge plasma, such that in-situ reaction sintering is carried out. The silicon-boron-carbon-nitrogen-zirconium ceramic composite material synthesized with the method provided by the invention has the advantages of high interfacial bonding strength and good comprehensive performance. The material is especially suitable to be used for manufacturing aerospace heat-proof core components.

Owner:HARBIN INST OF TECH

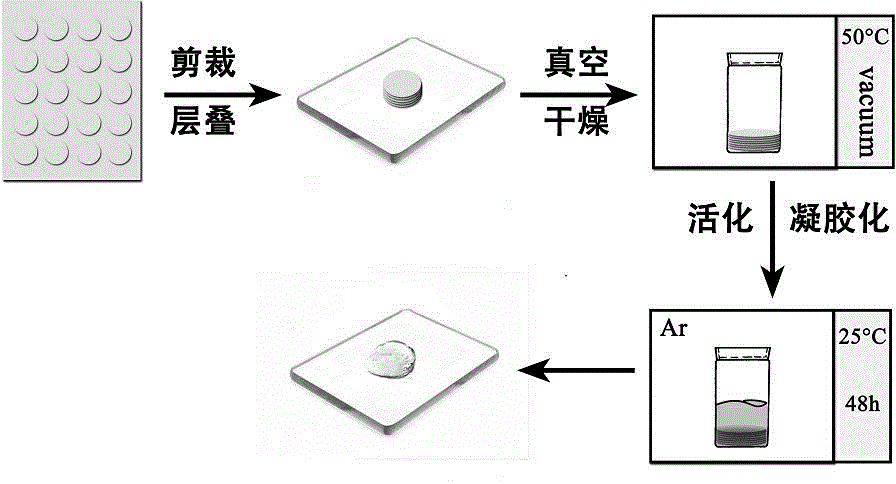

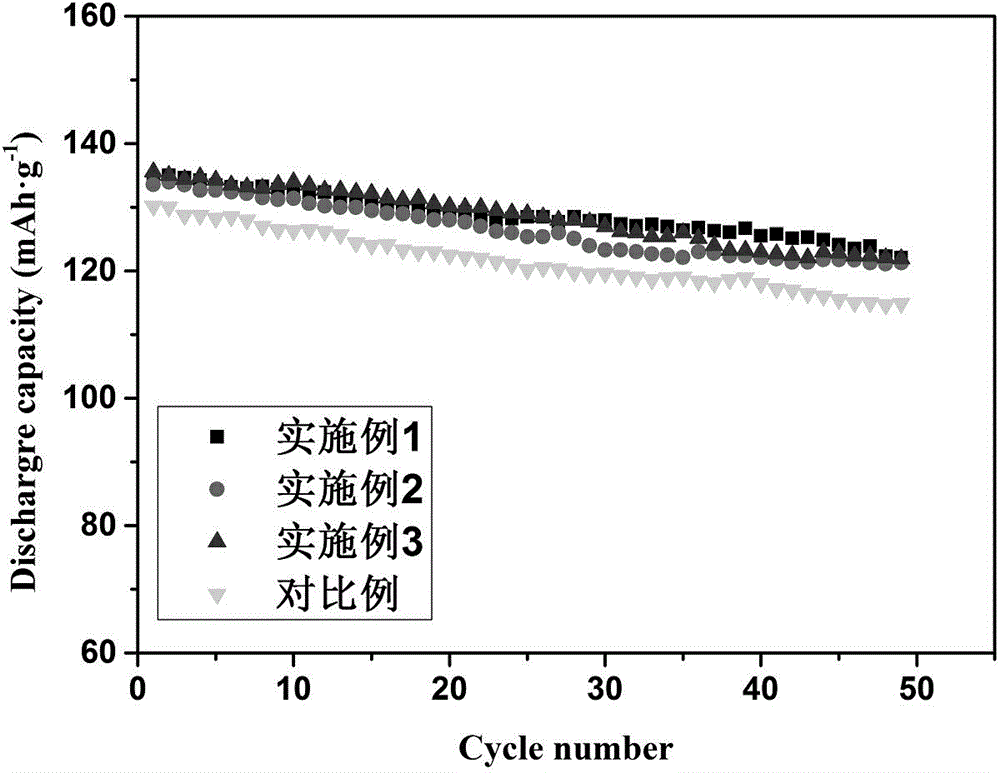

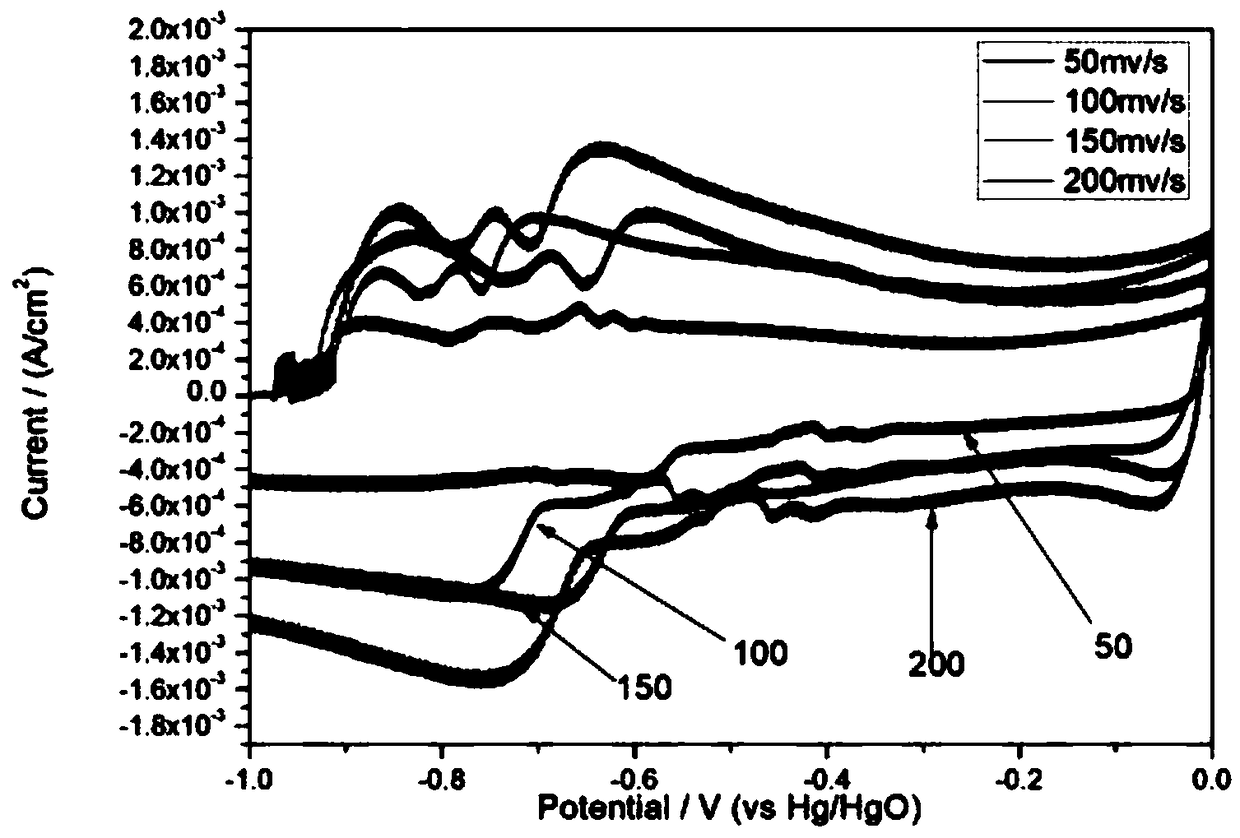

Core/shell structure fiber film-based gel polymer electrolyte and preparation method thereof

InactiveCN104577198AGood compatibilityThe preparation process is simpleSecondary cellsConjugated synthetic polymer artificial filamentsPolymer gelGlovebox

The invention relates to a polymer electrolyte, especially relates to a micropore polymer electrolyte skeletal material prepared by a coaxial electrospinning technology and a method for preparing a gel polymer electrolyte from the skeletal material, and belongs to the field of polymer lithium ion batteries. The preparation method comprises the following steps of 1, preparing core and shell layer electrostatic spinning solutions, 2, preparing a core / shell structure nanometer fiber film by a coaxial electrospinning technology, 3, drying and cutting the nanometer fiber film, and carrying out lamination to obtain a polymer gel electrolyte skeleton, and 4, putting the skeleton into an electrolyte in a glove box and carrying out activation and gelation. The electrolyte skeleton has ultra-strong electrolyte adsorptivity and retentivity. The prepared gel polymer electrolyte has high ion conductivity, a stable electrochemical window, good charging and discharging performances and good interface compatibility with a lithium electrode, satisfies common button cell assembling requirements and can be used for preparation of a secondary lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

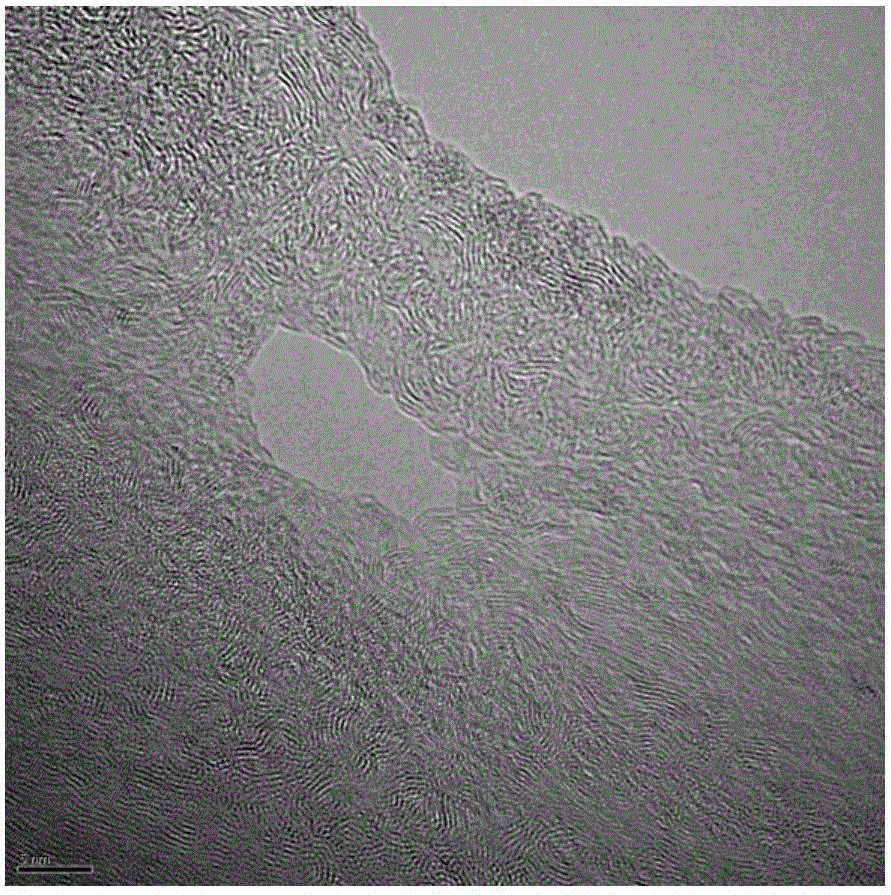

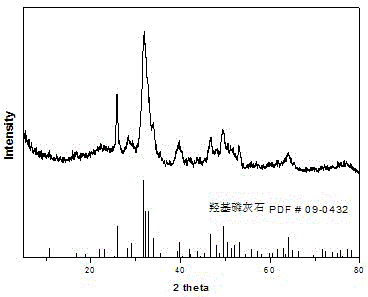

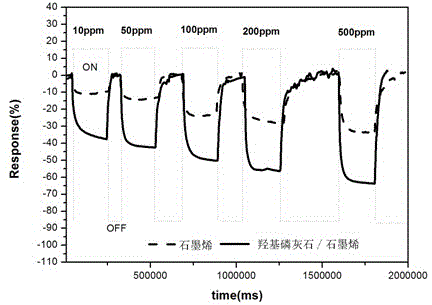

Preparation method of nano-hydroxyapatite/nano-hydroxyapatite gas sensing material

ActiveCN103950922AImprove Sensing PerformancePrepared forCarbon compoundsMaterial resistanceApatiteSlurry

The invention relates to a preparation method of a nano-hydroxyapatite / nano-hydroxyapatite gas sensing material. The preparation method comprises the following steps: first, preparing a graphene oxide dispersion liquid by an ultrasonic method; preparing hydroxylated modified graphene through reduction and modification of a mussel foot fibronectin analogue; in-situ reducing nucleation and growth of nucleation by a chemical precipitation method; and centrifugalizing, washing and drying to obtain the nano-hydroxyapatite / nano-hydroxyapatite gas sensing material. A gas sensor element can be prepared by the following steps: preparing the obtained gas sensing material with a binder to slurry; coating the slurry on a base body with an electrode; and then, sintering and welding for 3 hours at 300 DEG C under a nitrogen protective atmosphere.

Owner:CENT SOUTH UNIV

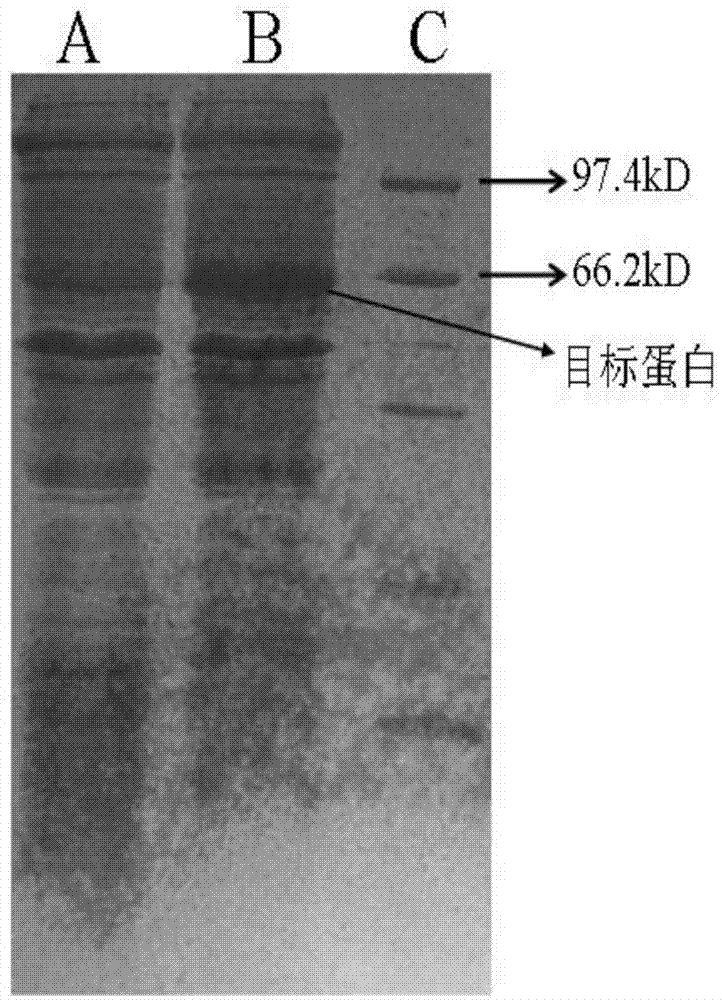

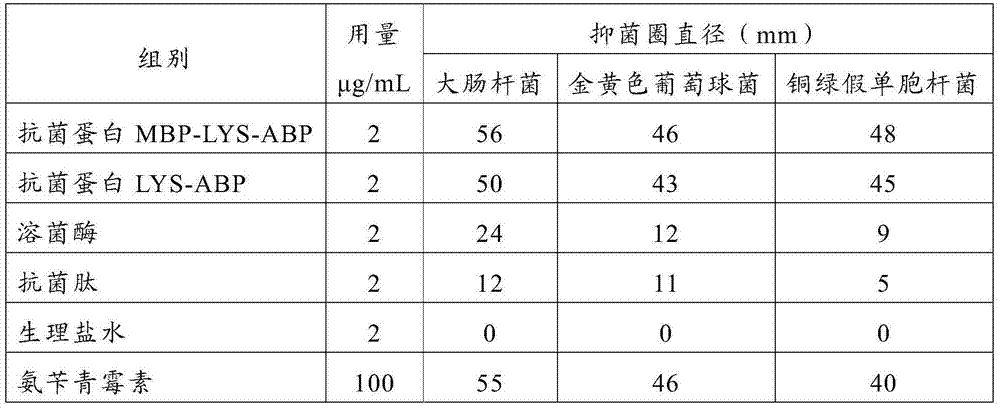

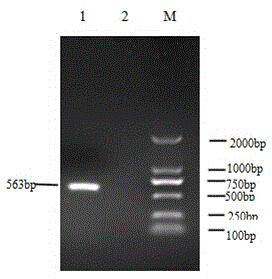

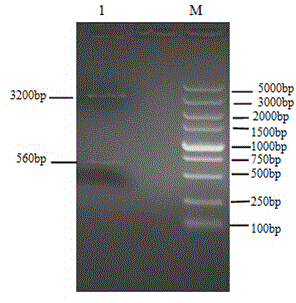

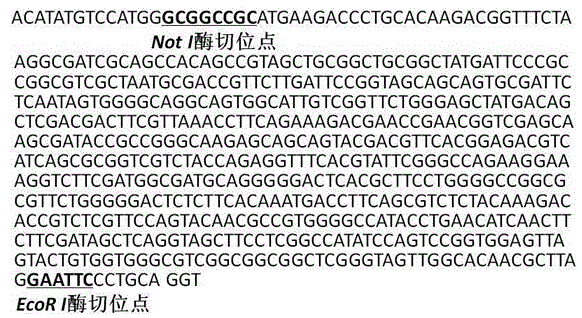

Antibacterial proteins

ActiveCN104761621ANon-irritatingGood antibacterial effectPeptide preparation methodsDepsipeptidesLysobacter soliEnzyme digestion

The invention belongs to the field of biochemistry, and discloses an antibacterial protein LYS-ABP and an antibacterial protein MBP-LYS-ABP having an LYS-ABP protein N terminal added with MBP, and preparation methods thereof, wherein the antibacterial protein LYS-ABP and the antibacterial protein MBP-LYS-ABP have no stimulation to human bodies and have good antibacterial effect. The antibacterial protein LYS-ABP and the antibacterial protein MBP-LYS-ABP have no stimulation to the human bodies and have good antibacterial effect, the antibacterial effect is better than single muramidases and antibacterial peptide proteins, and the biological activity stability is good. The antibacterial protein MBP-LYS-ABP is obtained by in-vitro recombinant expression, and is easy to prepare and relatively low in cost; and the antibacterial protein MBP-LYS-ABP has high soluble expression yield and is suitable for large-scale preparation. The antibacterial protein LYS-ABP is obtained by enzyme digestion of a recombinant expression-prepared MBP-LYS-ABP fusion protein with thrombin, and is easy to prepare and relatively low in cost.

Owner:CHANGCHUN XINYUERAN SCI & TECH CO LTD

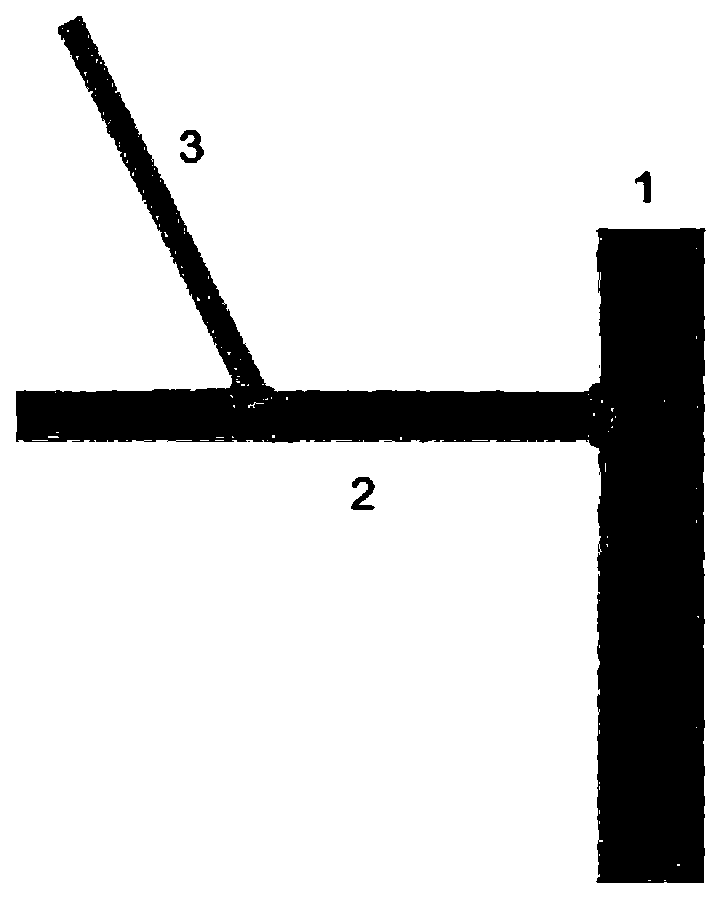

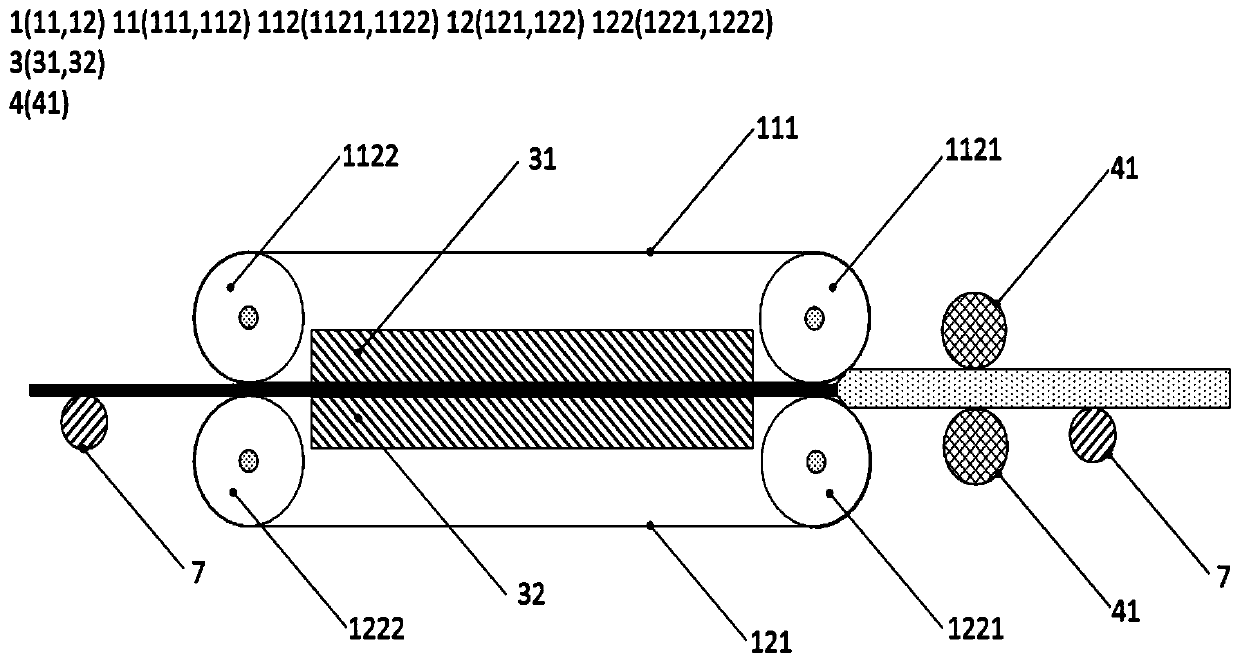

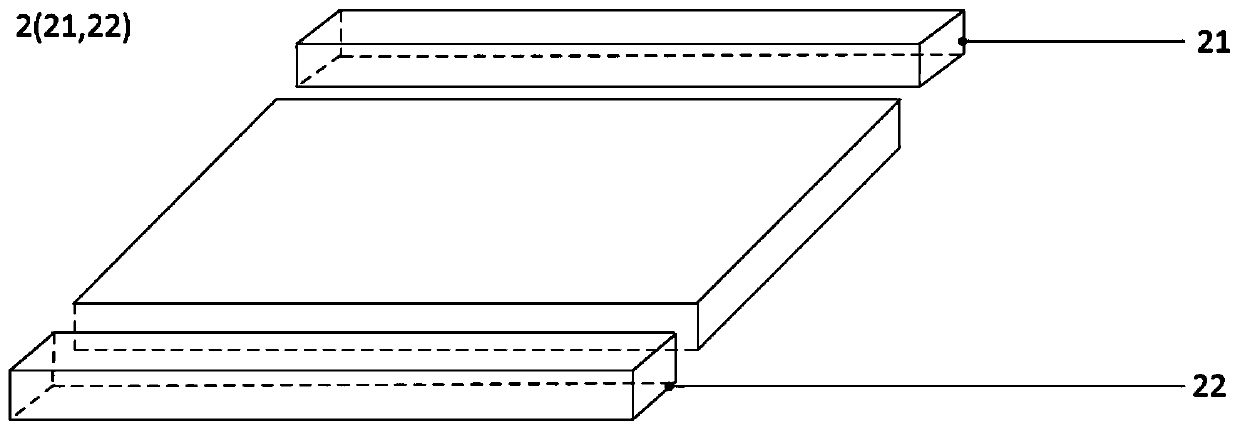

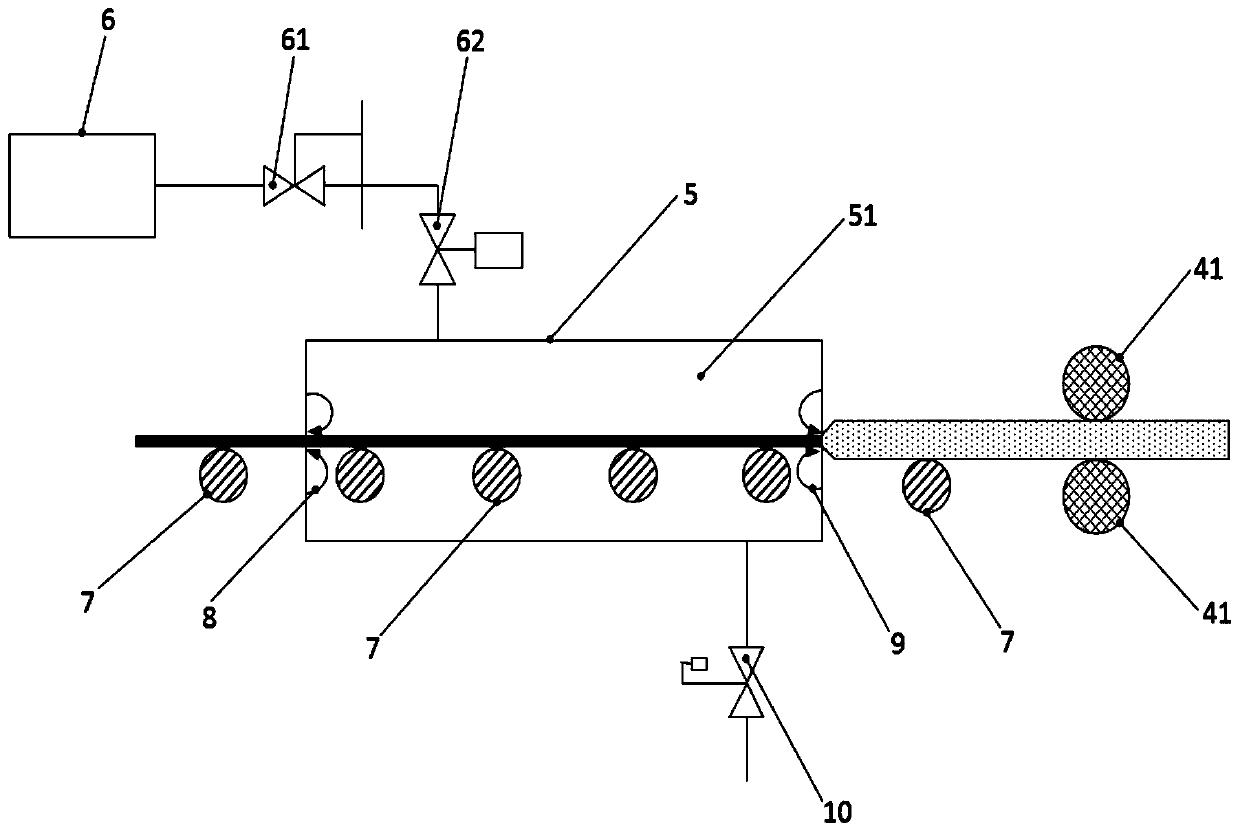

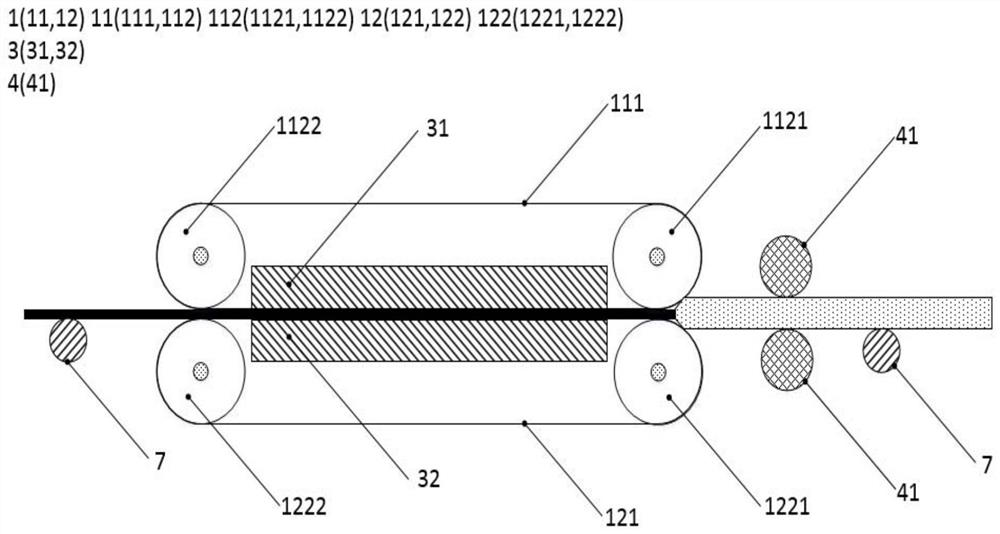

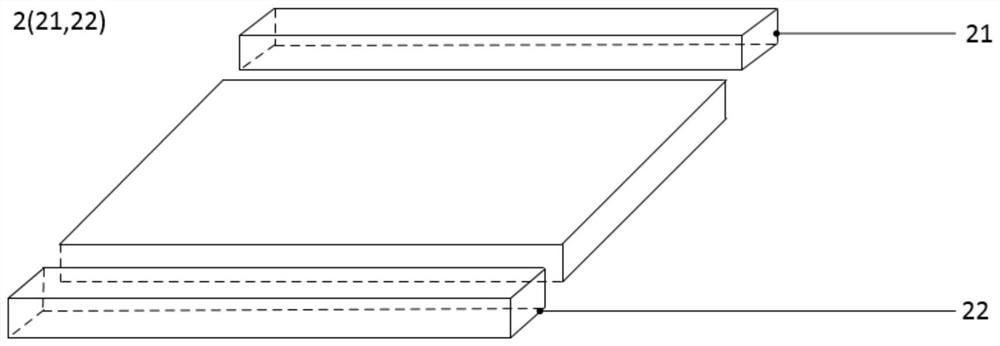

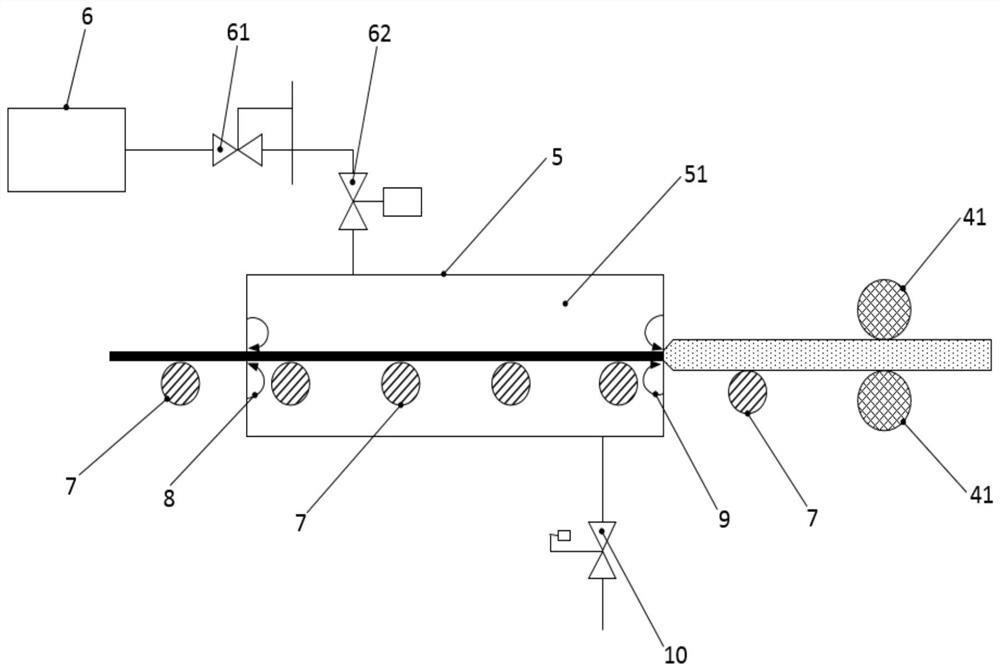

Continuous preparation method of foam material, foaming pretreatment device and foaming device

The invention discloses a continuous preparation method of a foam material. A foaming agent filling process, a heating process and a foaming process are carried out on a material to be foamed in a first reaction area, a second reaction area and a third reaction area correspondingly. First pressure is exerted on the material to be foamed in the second reaction area, bubbles in the material to be foamed do not grow during heating, and expanding foaming of the material during uneven heating is avoided. Through conveying to the third reaction area from the first reaction area, continuous preparation of the foam material can be achieved. The invention discloses a foaming pretreatment device applying the method. In the conveying process, the material to be foamed is evenly heated to a foaming temperature under the condition that the internal bubbles do not grow, instant foaming is carried out after the material to be foamed leaves the foaming pretreatment device, and the foam material has uniform and controllable hole diameters and foaming ratios. The invention discloses a foaming device. The foaming device comprises the foaming pretreatment device. The foaming device is suitable for continuously preparing the foam material with uniform bubble hole diameters and large thicknesses in a solid foaming process.

Owner:SHINCELL NEW MATERIAL CO LTD

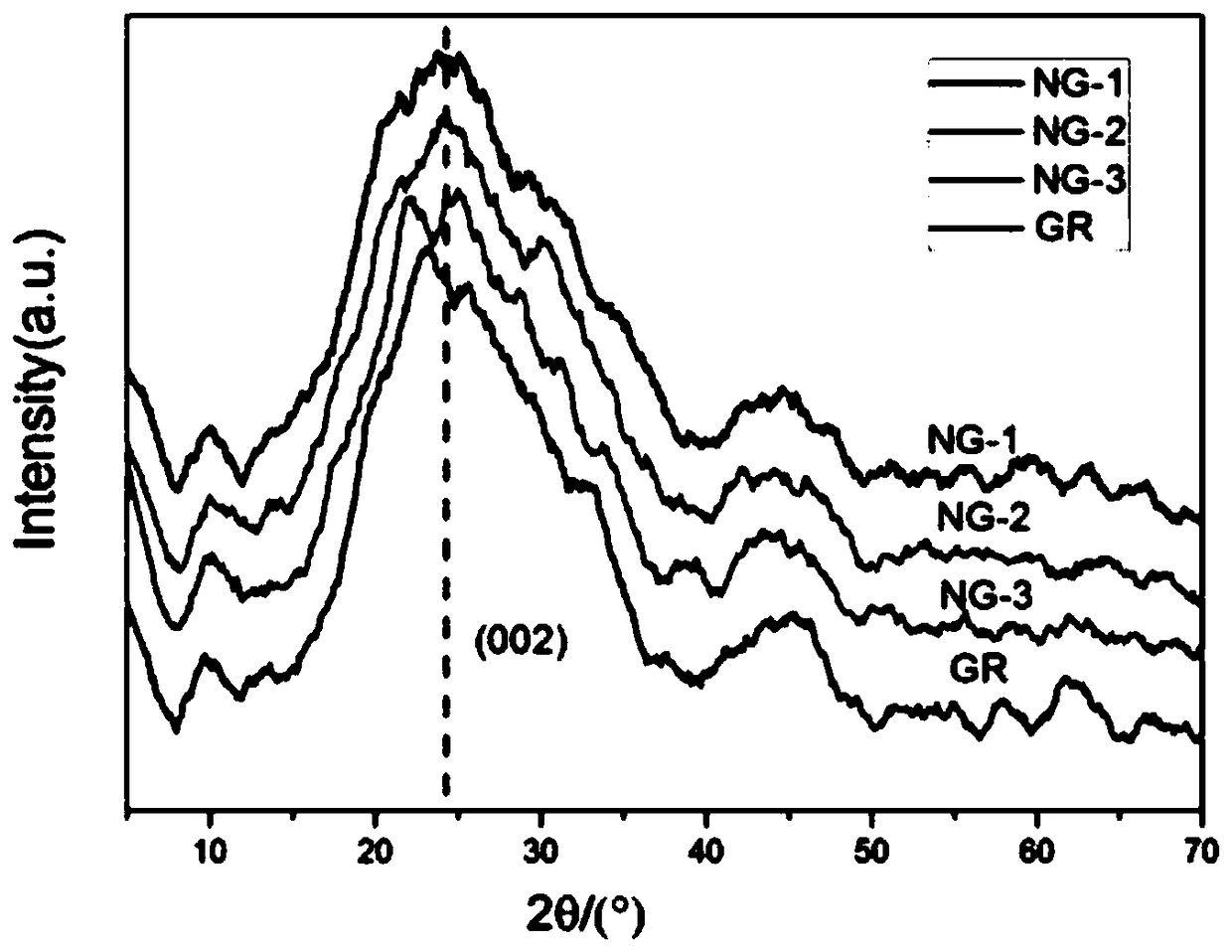

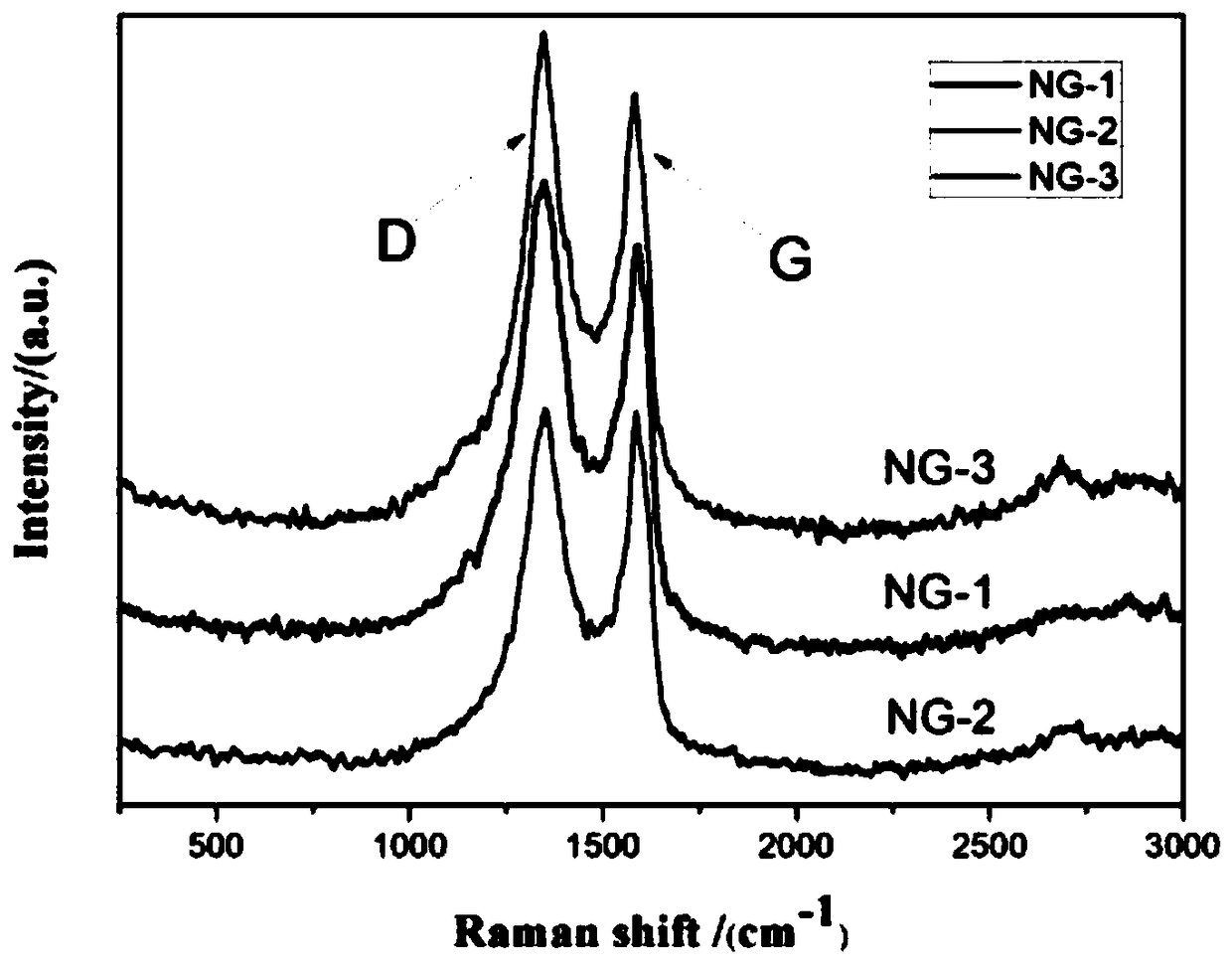

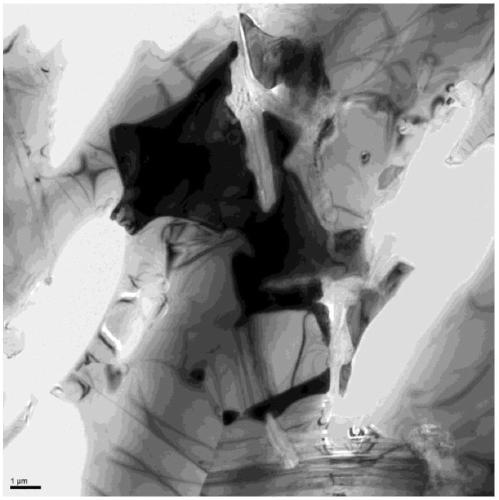

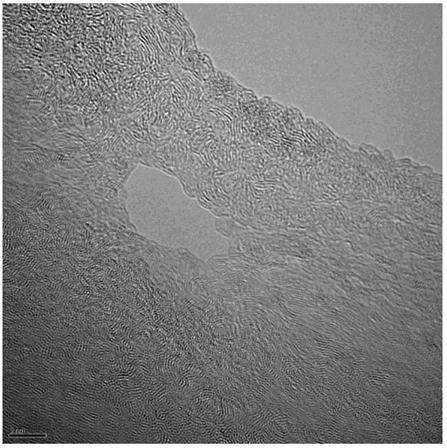

Nitrogen-doped grapheme and preparation method

The invention discloses nitrogen-doped grapheme and a preparation method. The method comprises the following steps: preparing graphene oxide; adding deionized water to graphene oxide, carrying out ultrasound treatment and centrifugation to obtain a graphene oxide dispersion, adding urea I into the graphene oxide dispersion, carrying out ultrasound treatment, and then placing in a reaction kettle to obtain nitrogen-doped grapheme I, wherein the reaction temperature is 160 DEG C and the reaction time lasts for 3 hours; adding melamine to absolute ethyl alcohol to obtain a mixture, mixing the mixture with the graphene oxide dispersion, then placing in a high pressure reaction kettle to obtain nitrogen-doped grapheme II, wherein the reaction temperature is 180 DEG C and the reaction time lastsfor 8 hours; mixing the graphene oxide dispersion, calcium chloride and oxalic acid powder in an ultrasound treatment manner, dissolving thioacetamide in deionized water, mixing the two in the ultrasound treatment manner to obtain a mixture, vibrating the mixture in the ultrasound treatment manner for 1 hour, and heating by an electromagnetic furnace to obtain nitrogen-doped grapheme III, whereinthe reaction temperature is 80 DEG C and the reaction time lasts for 6 hours. The nitrogen-doped graphene prepared according to the preparation method provided in the invention has the advantages that the quality is relatively high, defects are reduced, and the comprehensive performance of the nitrogen-doped graphite is improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

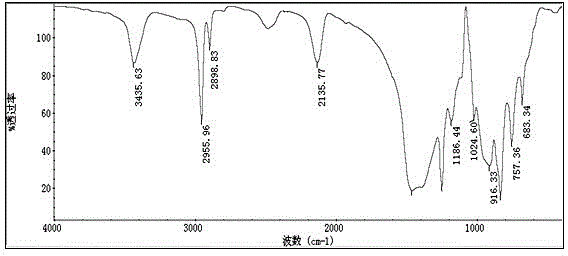

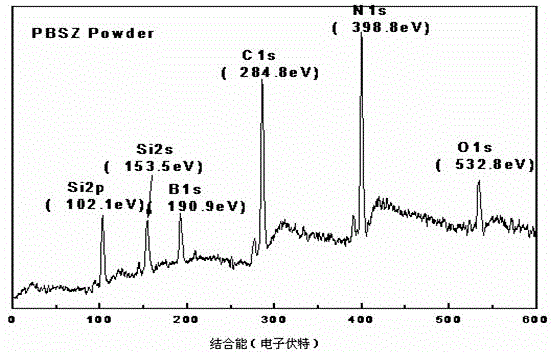

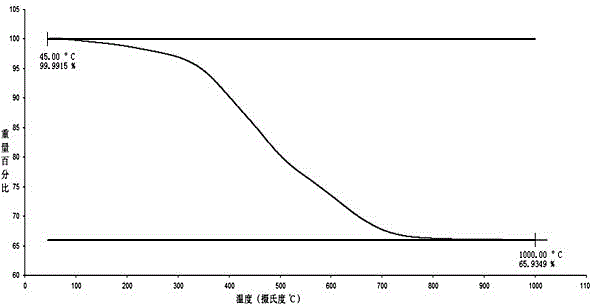

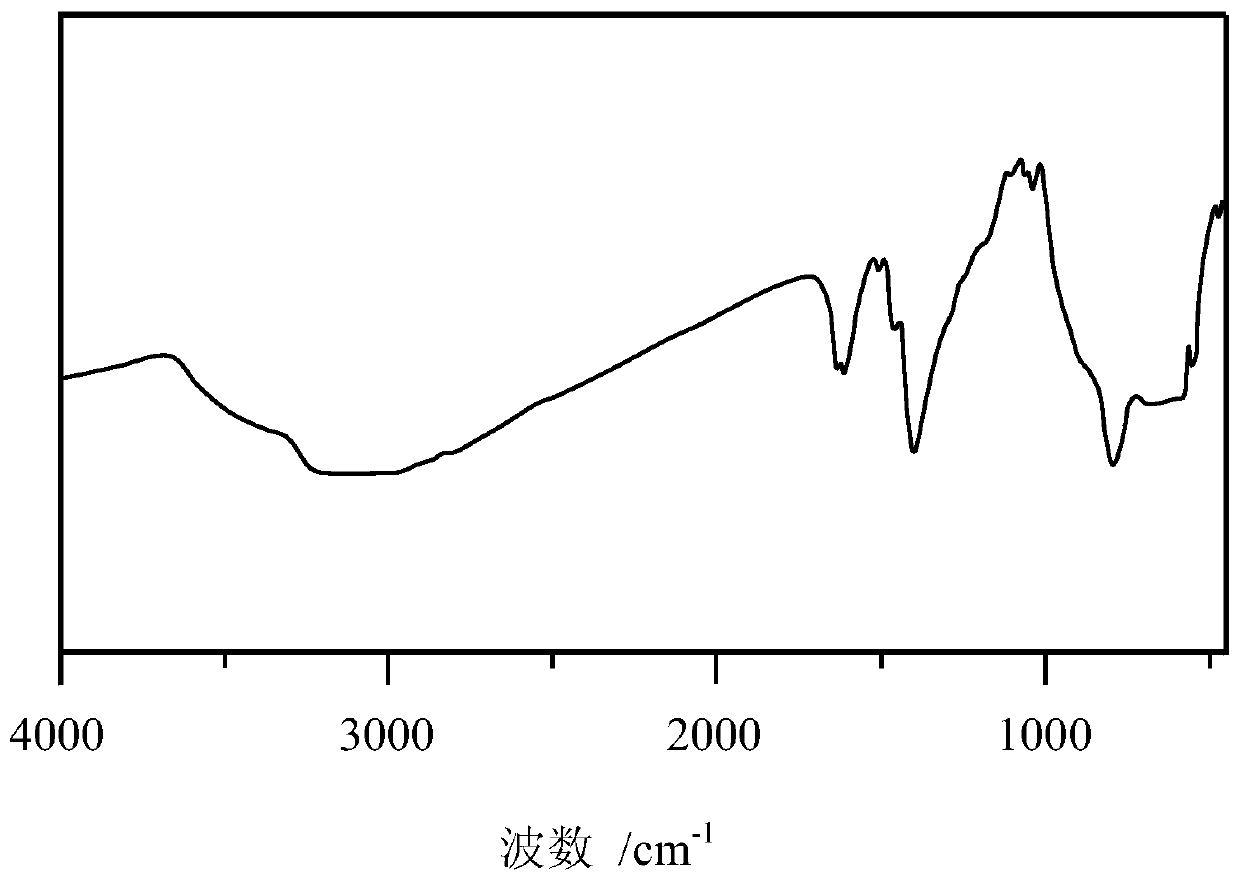

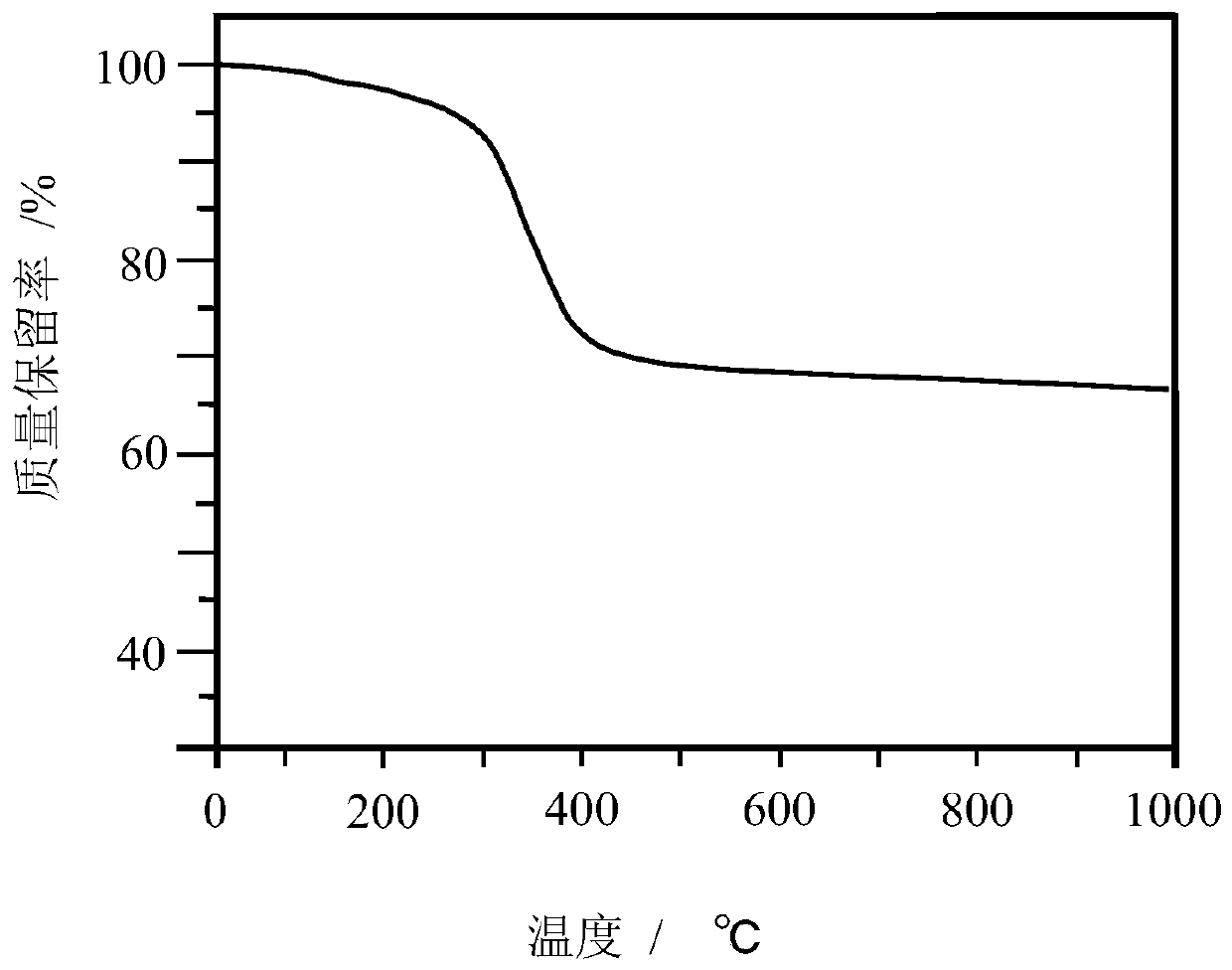

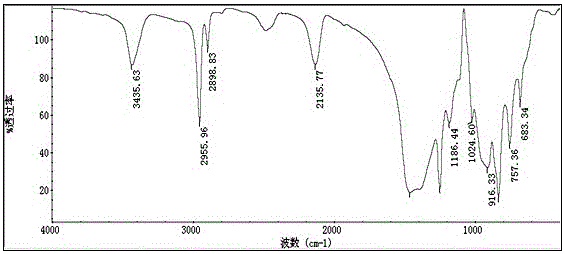

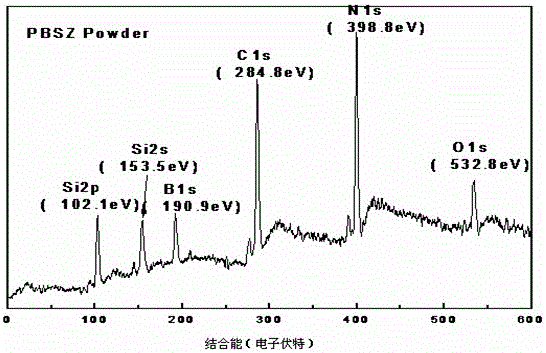

Preparation method for high softening point polyborosilazane

The invention discloses a preparation method for high softening point polyborosilazane, which comprises the following steps: (1) a reaction still provided with a stirring device, a temperature measurement device, a charging device, a ventilation device, a discharging device, and a distillation device is used for replacement of nitrogen; (2)chlorosilane, dialkyl group borazine and heptamethyldisilazane are weighed according to the molar ratio of 1:(0.5-3):(6-12); (3) chlorosilane, dialkyl group borazine and heptamethyldisilazane are added into the reaction still, and the reaction still is cooled to 5-55 below zero DEG C; the heptamethyldisilazane is added into a reactor at the speed of 0.01-0.2L / min and is stirred; (4) after the charging is completed, the reactor is heated to reach 250-350 DEG C and is distilled for 6-48 hours under the normal pressure; (5) after the distillation under the normal pressure is completed, the temperature of the reactor is reduced by 10-60 DEG C and is subjected to reduced pressure distillation for 0.3-3 hours. The softening point of polyborosilazane is synthesized by the method is greater than 180 DEG C, the ceramic yield is more than 60 percent, and high performance ceramic fiber and ceramic matrix can be prepared.

Owner:NAT UNIV OF DEFENSE TECH

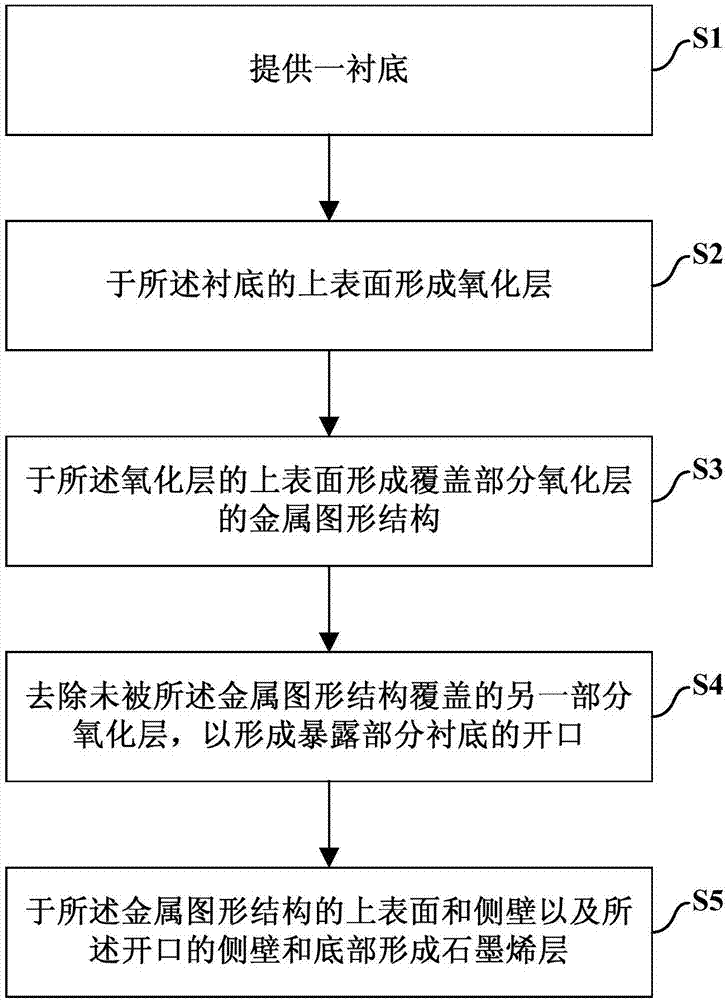

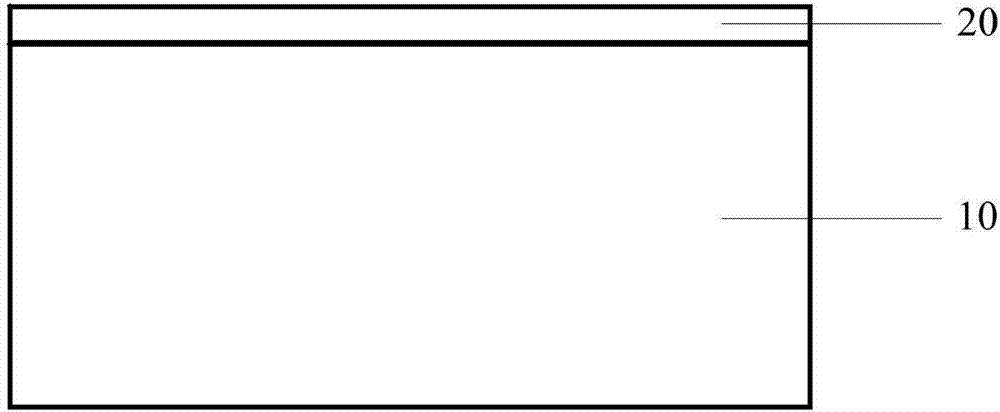

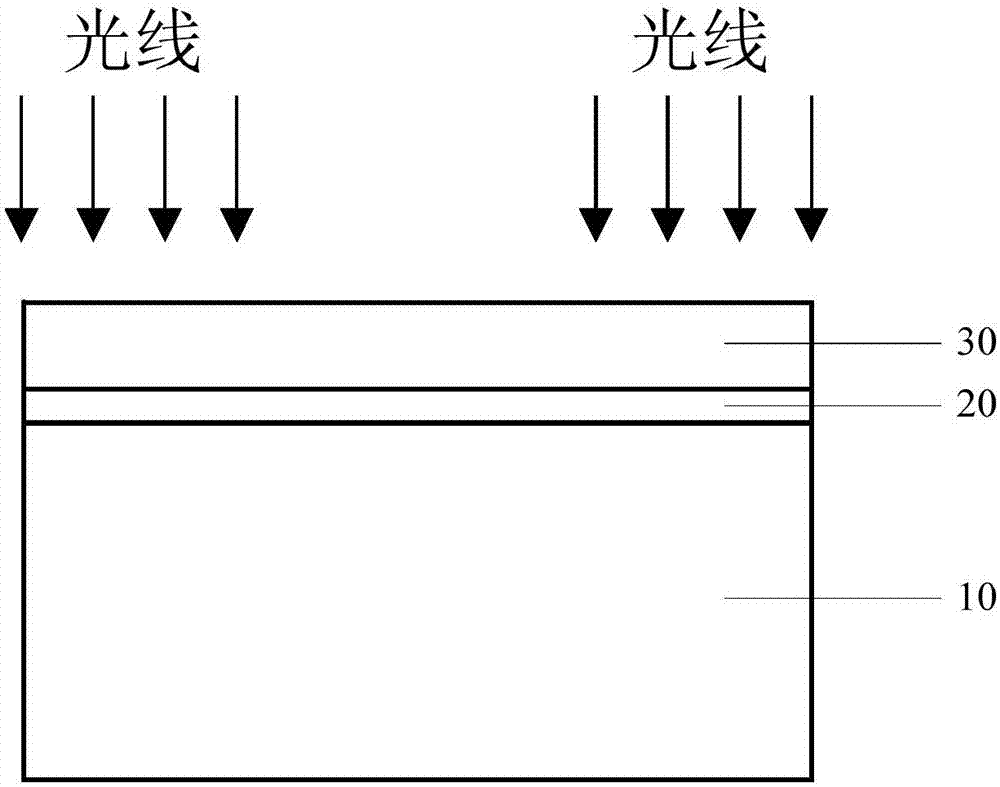

Preparation method of graphene gas sensor

The invention provides a graphene gas sensor and a preparation method thereof. The preparation method of the graphene gas sensor at least comprises the steps of providing a substrate; forming an oxidation layer on the upper surface of the substrate; forming a metal graphical structure covering part of oxidation layer on the upper surface of the oxidation layer; removing the other part of oxidation layer which is not covered by the metal graphical structure so as to form an opening exposing part of substrate; forming graphene layers on the upper surface and the side wall of the metal graphical structure and the side wall and the bottom part of the opening, wherein the graphene layers are contacted with the part of substrate exposed by the opening, so that a schottky barrier is realized. According to the graphene gas sensor and the preparation method thereof provided by the invention, by combining an existing graphic technique process, the problems of pollution and damage of a graphene thin film during a craft process are ingeniously solved. According to the graphene gas sensor provided by the invention, not only are the sensitivity and the stability greatly improved, but also the cost is reduced, and the batch production and the preparation efficiency of such devices are realized favorably.

Owner:上海新克信息技术咨询有限公司

Temperature-sensitive hollow polylactic acid color changing microsphere as well as preparation method and application thereof

InactiveCN109331752AWide color selectionColor change temperature wideMicroballoon preparationMicrocapsule preparationPolylactic acidPolyvinyl alcohol

The invention relates to a temperature-sensitive hollow polylactic acid color changing microsphere as well as a preparation method and application thereof. The microsphere comprises polylactic acid, color changing ink and polyvinyl alcohol. The preparation method comprises the following steps of preparation of polylactic acid solution, preparation of color changing ink suspension, preparation of polyvinyl alcohol solution and preparation of the polylactic acid microsphere. The preparation method has the advantages of being high efficiency, feasible and suitable for the preparation of large-scale monodisperse functional hollow microspheres.

Owner:DONGHUA UNIV

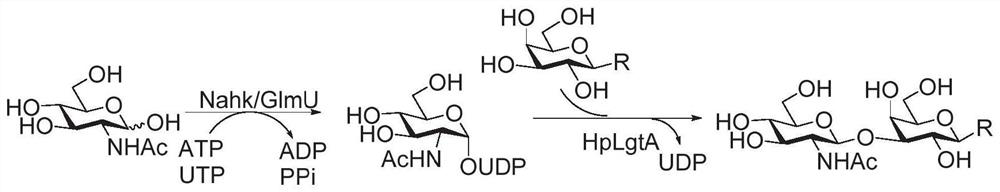

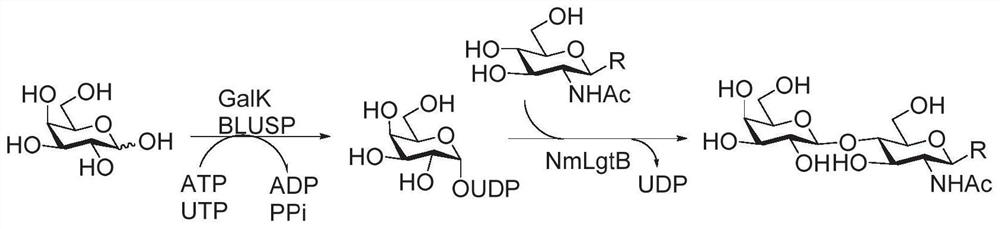

Fluorine label and preparation method thereof, and method for synthesizing oligosaccharide chain by adopting assisted enzymic method

ActiveCN112940058AHigh modular assembly efficiencyEfficient preparationSugar derivativesOligosaccharidesReceptorCombinatorial chemistry

The invention relates to a fluorine label and a preparation method thereof, and a method for synthesizing an oligosaccharide chain by adopting an assisted enzyme method. The structural formula of the fluorine label is G-R(I) as shown in the formula I. G represents monosaccharide or oligosaccharide; and R is one of the following formulas II and III, wherein R1 is one of C6H13 and C8H17. When G represents lactose and R represents a C8F17 difluoro chain, the formula II is shown in the specification. The fluorine label has the advantages of being easy to remove and recycle. The glycosyl receptor is used for synthesizing various different oligosaccharide chains, so that the oligosaccharide chain with a determined structure is quickly and efficiently synthesized.

Owner:SHANDONG UNIV

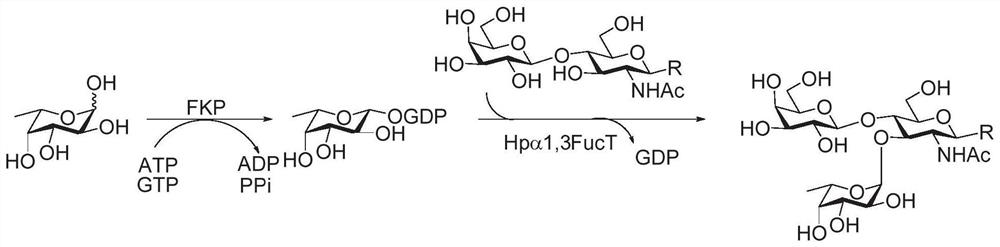

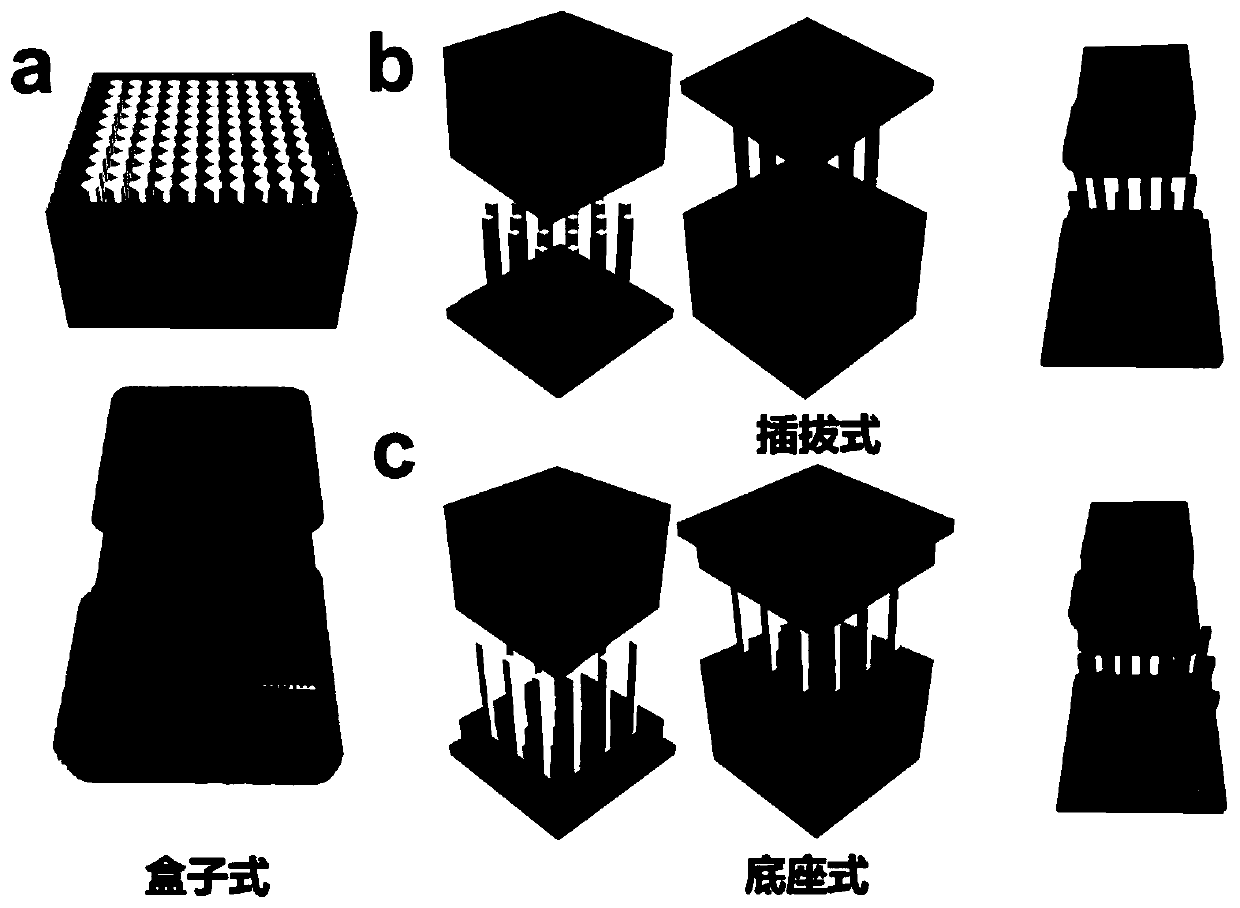

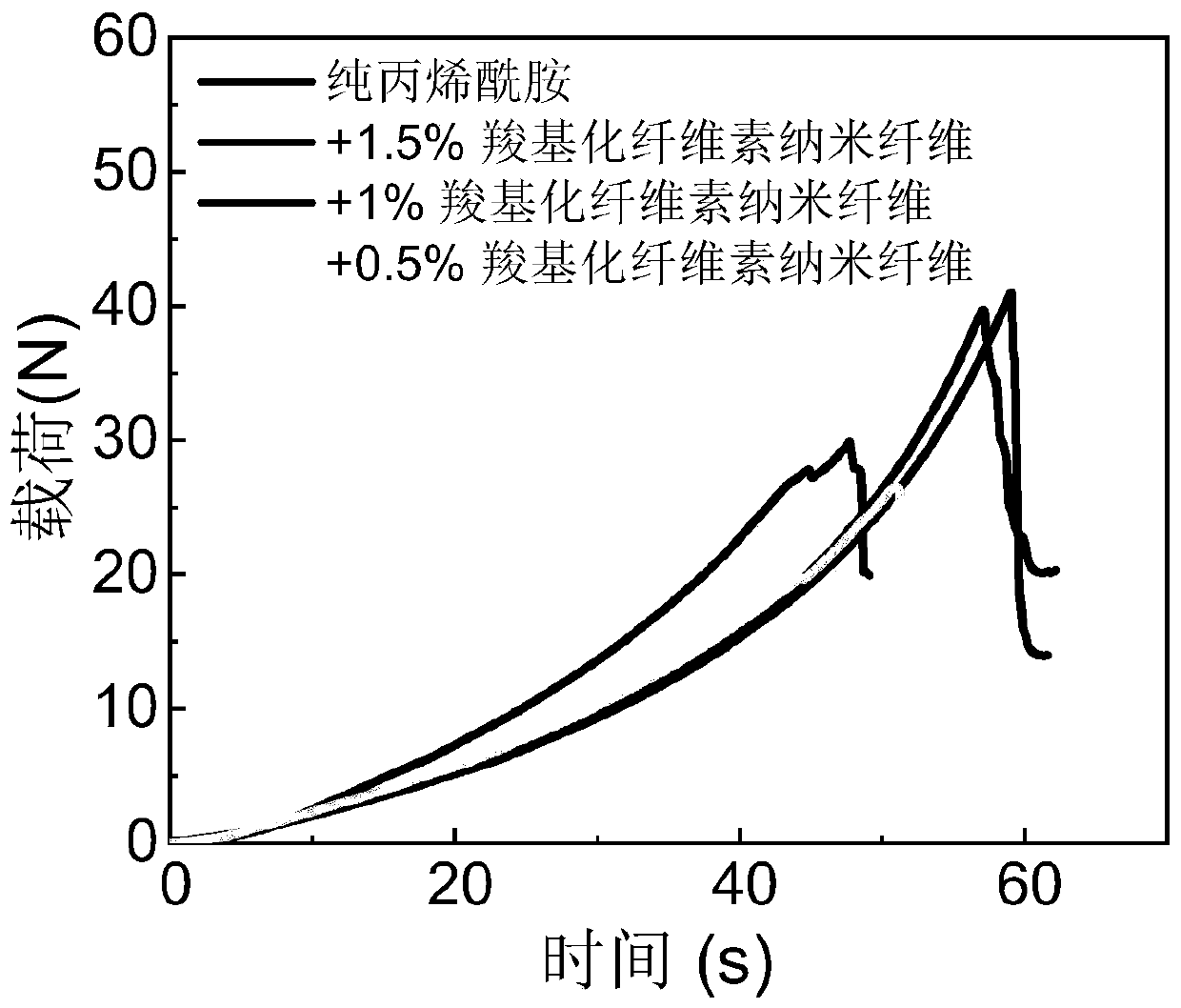

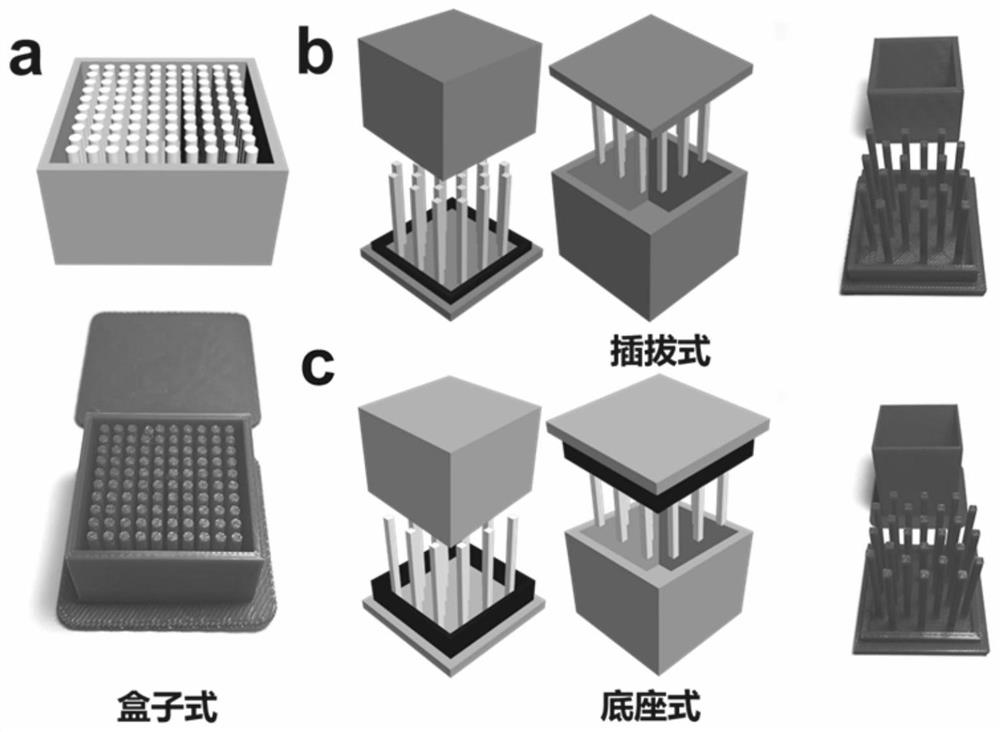

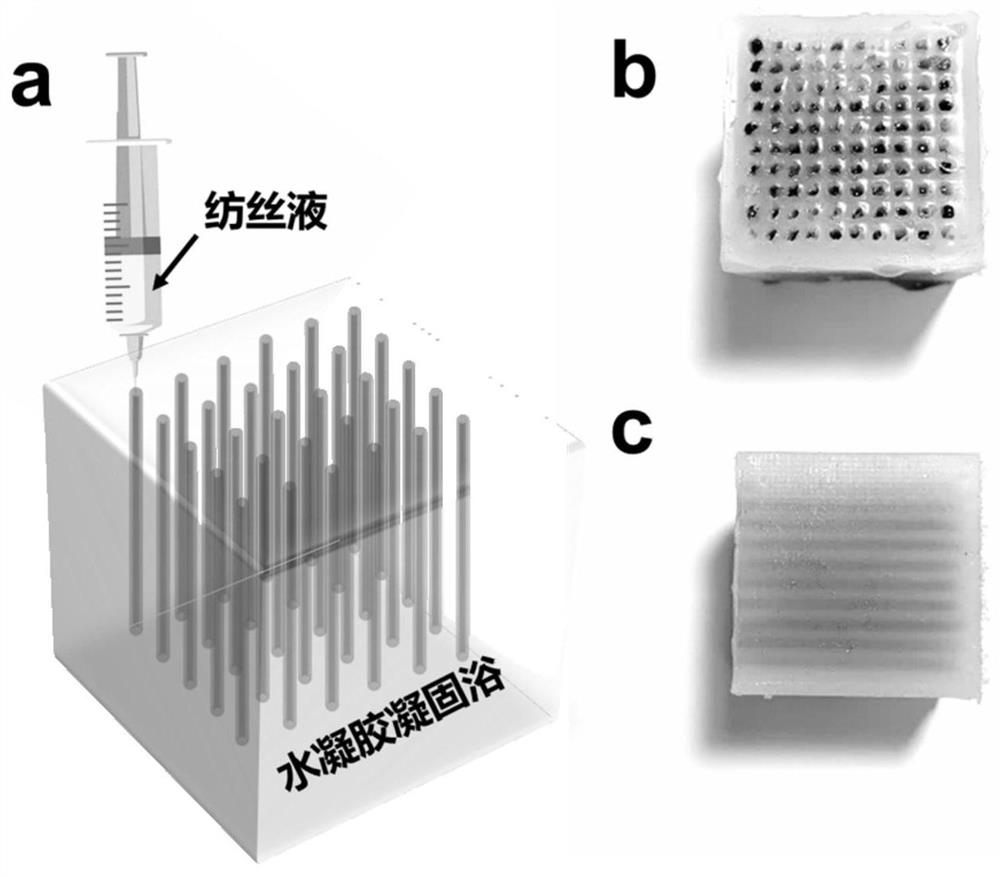

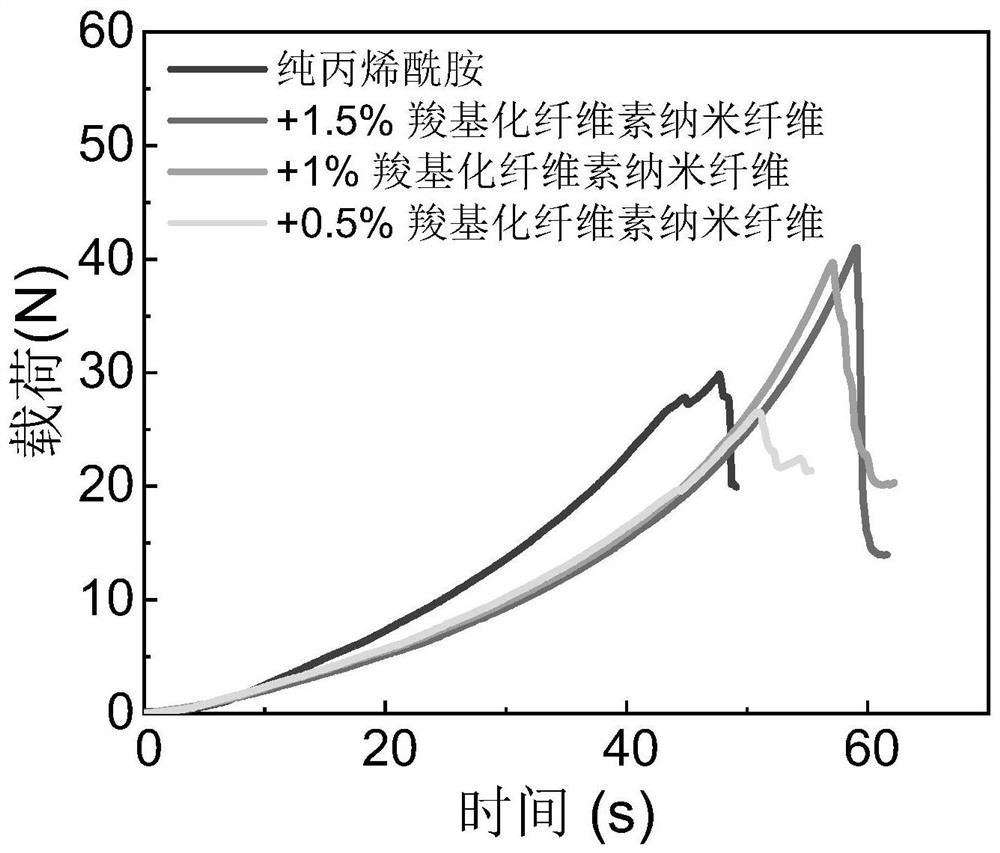

Method for preparing nanocomposite fiber by using grooved-type water gel

ActiveCN111286814ASimple moldingShorten molding timeAdditive manufacturing apparatusAlginate artificial filamentsFiberPolymer science

The invention relates to a method for preparing a nanocomposite fiber by using grooved-type water gel. The composite fiber is obtained by adopting grooved-type water gel prepared through a 3D printingmethod as a coagulation bath and combining a microfluidic method in wet spinning. The method for preparing the nanocomposite fiber is novel and simple; and a plurality of nanocomposite fibers with high strength and good weaving property employing sodium alginate (SA) as a matrix can be prepared and can be applied to intelligent clothing industry and the like. By using the water gel as the coagulation bath, the fiber preparation efficiency of traditional wet spinning is improved and the service life of the coagulation bath can be prolonged.

Owner:DONGHUA UNIV

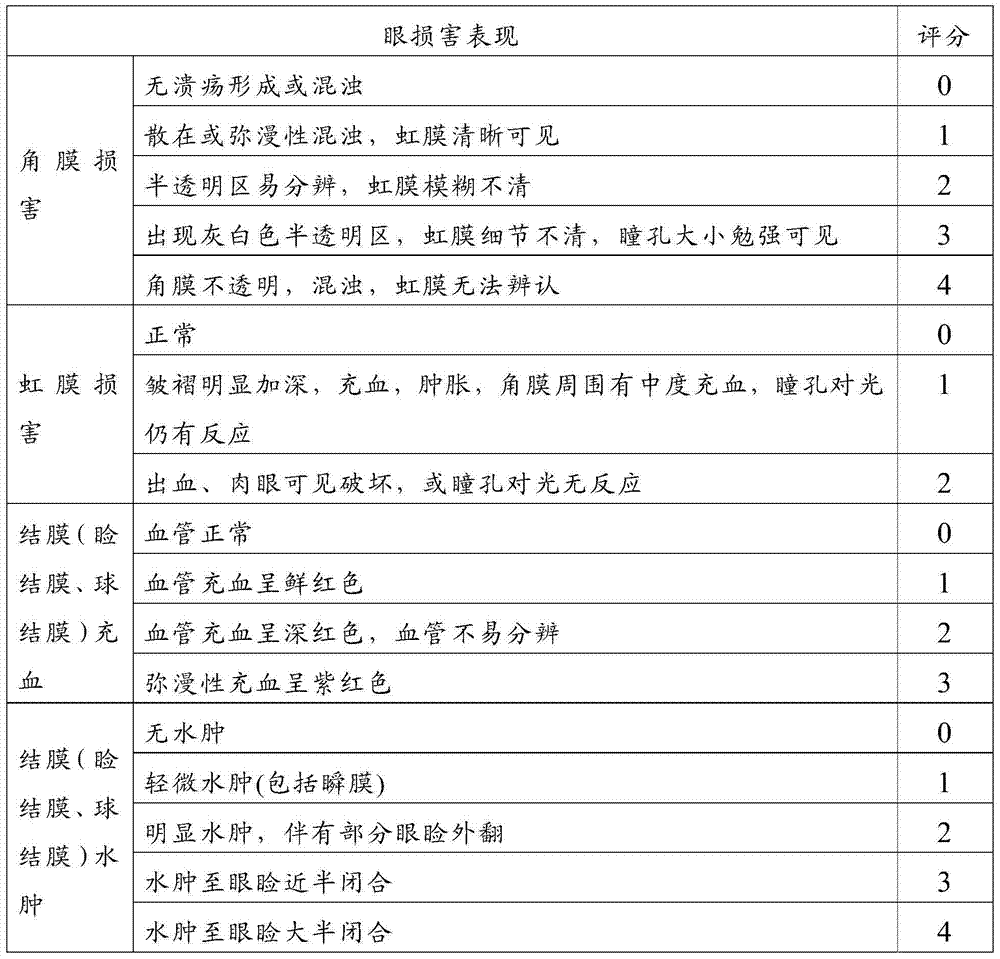

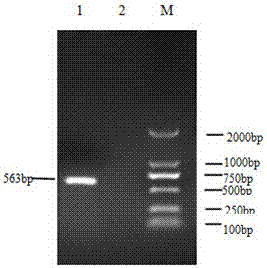

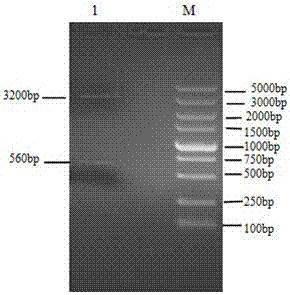

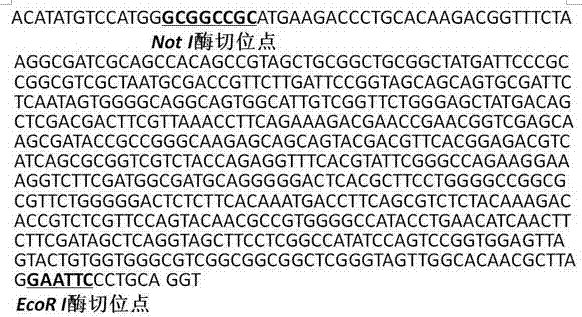

Application of rhodococcus equi virulence gene VapA recombinant protein

ActiveCN104888208AImproving immunogenicityPrepared forAntibacterial agentsBacterial antigen ingredientsImmunogenicityTGE VACCINE

The invention belongs to the biotechnical field, and particularly discloses an application of a rhodococcus equi virulence gene VapA recombinant protein to preparing a preparation for treating or detecting rhodococcus equi. The application is characterized in that the rhodococcus equi virulence gene VapA recombinant protein is MBP-VapA with an MBP label, wherein an amino acid sequence of the recombinant protein is as shown in SEQ ID NO: 1; the obtained recombinant protein almost exists in a soluble expression form. The recombinant protein has good immunogenicity, and is suitable for developing biotechnical products such as hyper-immune serum antibodies for clinical treatment, vaccines, clinical diagnosis reagents and the like.

Owner:SOUTH CHINA AGRI UNIV

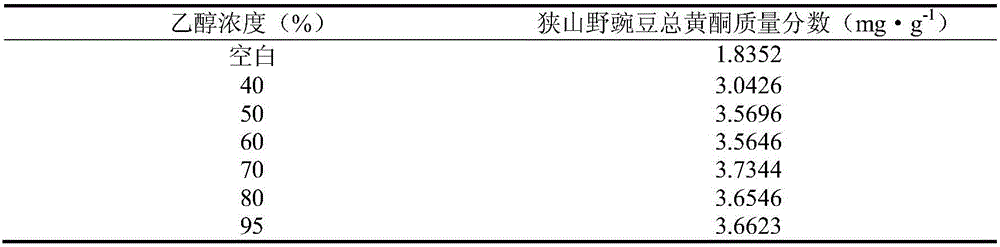

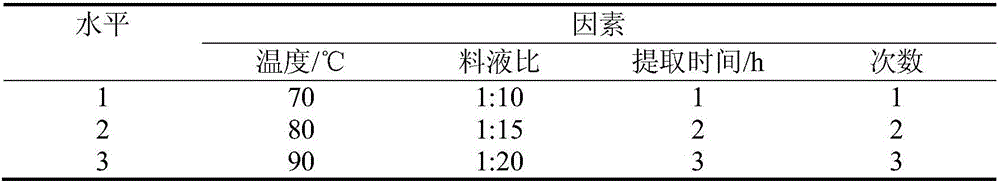

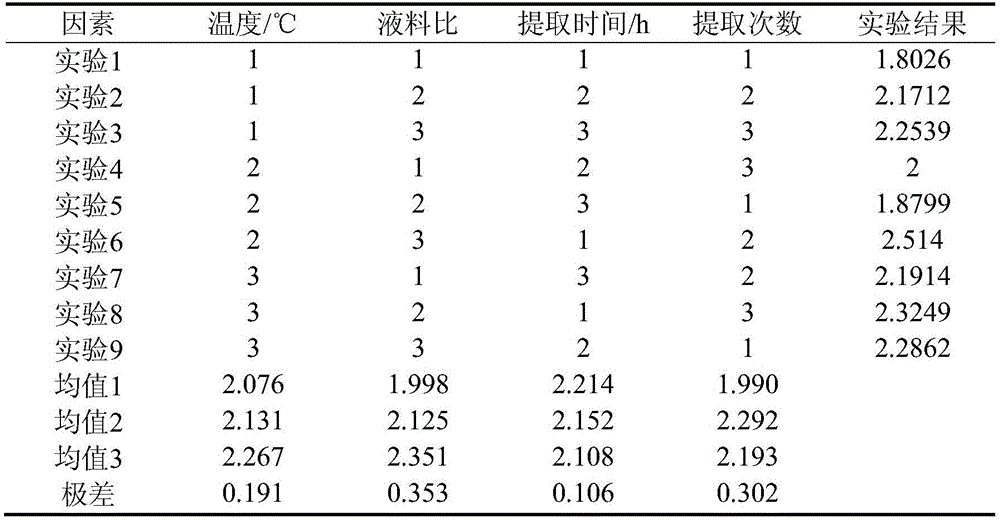

Preparation method for total flavonoids in V.amoena Fisch.var.angusta Freyn.

ActiveCN105998154AImprove physical stabilityHigh adsorption selectivityAntipyreticAnalgesicsDesorptionElution

The invention relates to a preparation method for total flavonoids in V.amoena Fisch.var.angusta Freyn.. According to the technical scheme, V.amoena Fisch.var.angusta Freyn. medicinal material powder is taken and extracted at 70-90 DEG C with a 40-95% ethanol water solution as the solvent in the liquid-material ratio of 1:(10-20), and extraction liquor is obtained; an adsorption column filled with weak polarity-medium polarity macroporous adsorption resin is selected, the total flavonoid loading concentration is 0.21-3.18 mg / mL, the pH is regulated to be 1-8, samples are loaded on the adsorption column, the loading volume is 4-6 times the resin column bed volume, the adsorption flow velocity is regulated to be 2-6 mL / min for dynamic adsorption, elution is carried out with a 30-95% ethanol water solution at the flow velocity of 2-6 mL / min, and elution liquor is collected. According to the macroporous adsorption resin preparation method for total flavonoids, the yield of total flavonoids is high, desorption conditions are mild, the service cycle is long, regeneration is easy and convenient, the extraction ratio is high, and the cost is low; the preparation method is suitable for popularization and application in industrial production.

Owner:LIAONING UNIVERSITY

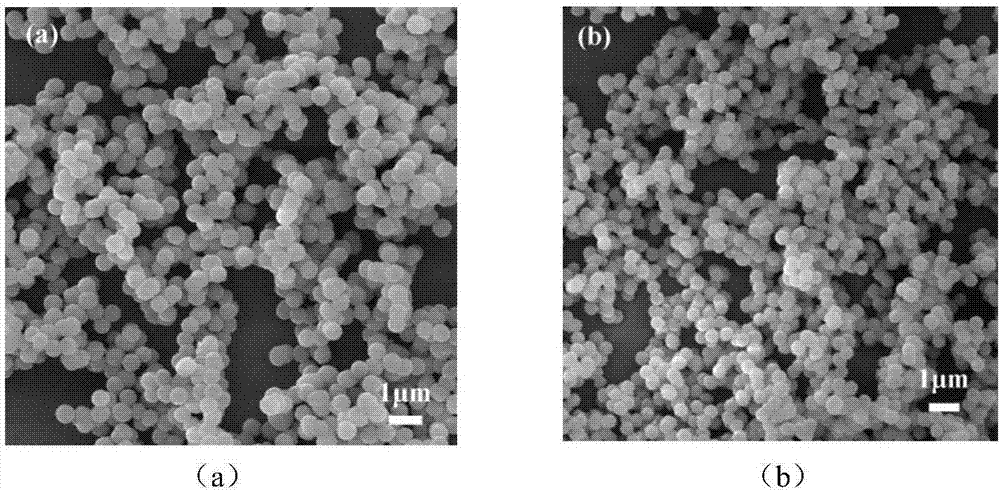

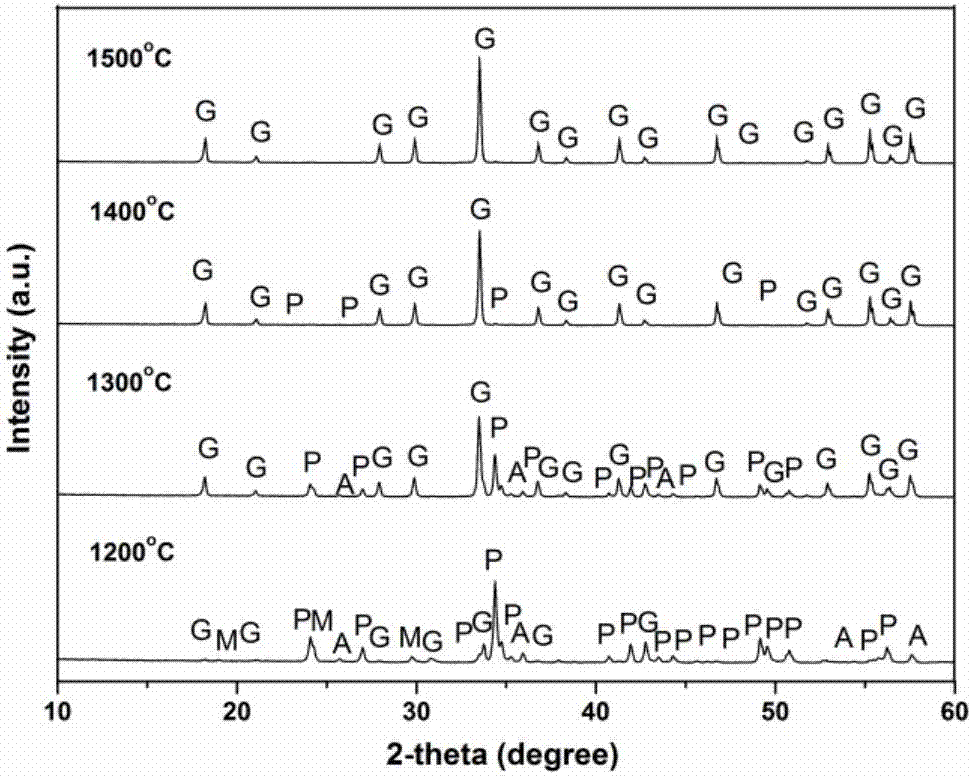

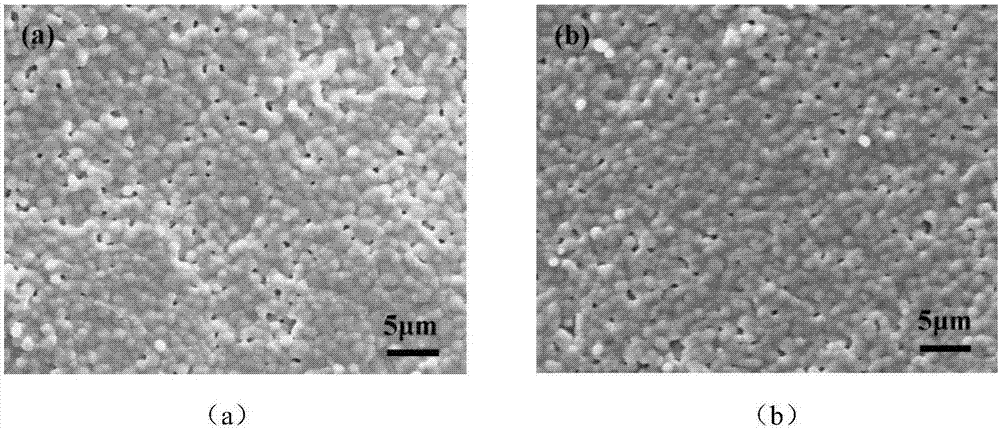

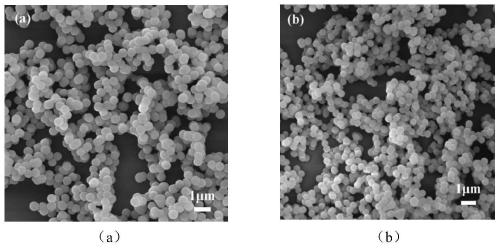

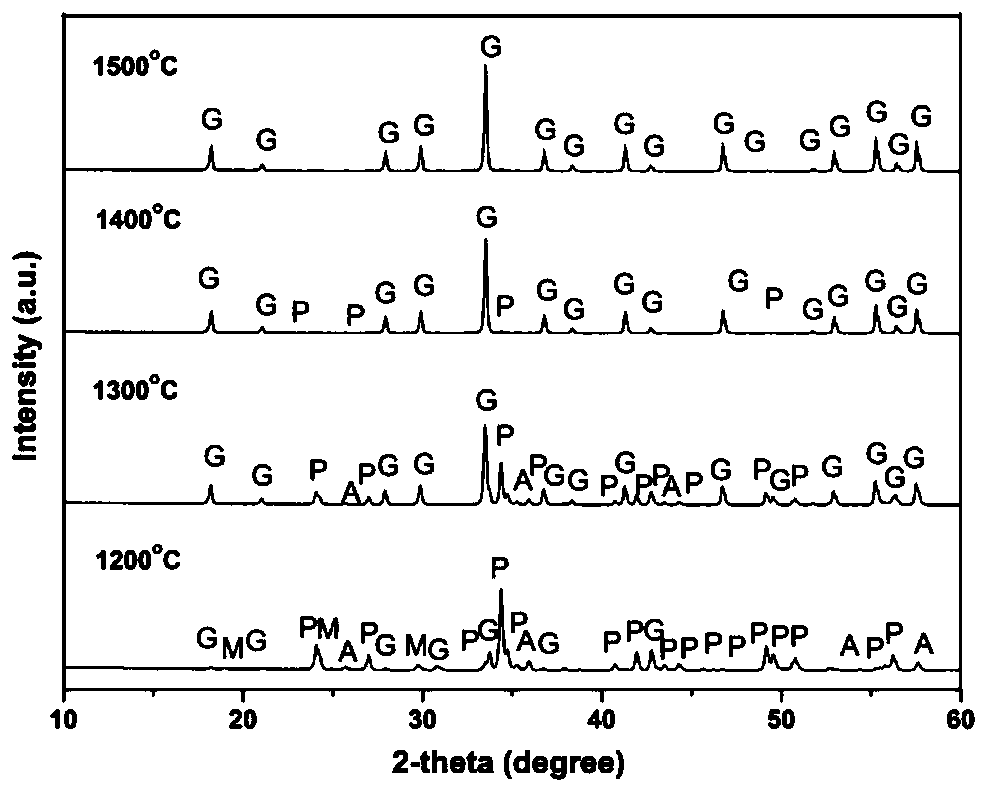

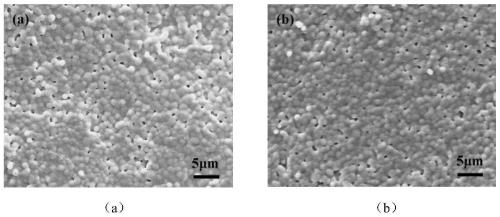

Method for preparing (Y1-xYbx)AG transparent ceramic from monodisperse spherical Y2O3 and Al2O3 powder

The invention belongs to the technical field of materials and provides a method for preparing (Y1-xYbx)AG transparent ceramic from monodisperse spherical Y2O3 and Al2O3 powder. According to the methodprovided by the invention, monodisperse spherical Al2O3 powder is prepared by adopting a homogeneous co-precipitation method; the monodisperse spherical Al2O3 powder, prepared monodisperse sphericalY2O3 powder and nano Yb2O3 powder are mixed to obtain a raw material; a solid-phase reaction method, a pressing and molding technology and a vacuum sintering technology are used for treating the raw material to prepare Yb:YAG transparent ceramic. The prepared Y2O3 powder and the prepared spherical Al2O3 powder have uniform grains and good dispersity; a preparation technology is simple; when the powder is molded, a blank has high density and is easily sintered to prepare laser transparent ceramic; the method provided by the invention has the advantages of simple reaction conditions, small environment pollution, easiness for popularization and the like.

Owner:NORTHEASTERN UNIV

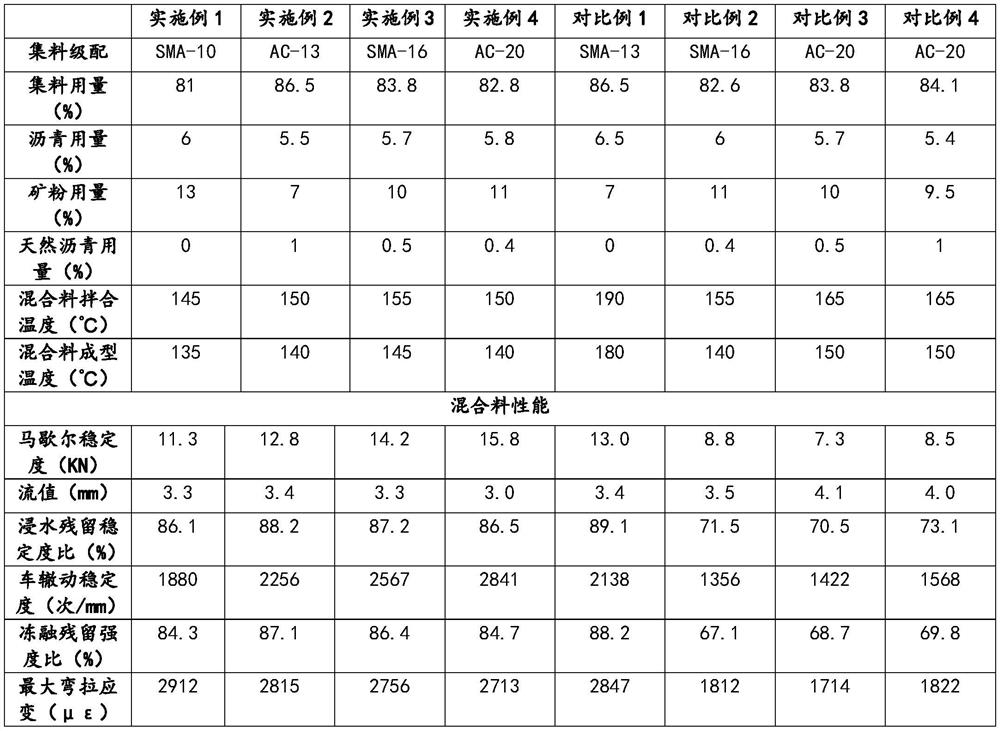

A kind of warm mix agent, SBS/SBR modified warm mix asphalt mixture and preparation method

ActiveCN110171937BPoor resolutionEmission reductionClimate change adaptationPhysical chemistryEngineering

Owner:山东高速路用新材料技术有限公司 +1

A kind of silicon boron carbon nitrogen zirconium ceramic composite material and preparation method thereof

ActiveCN105948748BRaw materials are cheap and easy to getSimple processZirconium hydrideCeramic composite

The invention discloses a silicon-boron-carbon-nitrogen-zirconium ceramic composite material and a preparation method thereof. A sol-gel liquid adopts zirconium n-propoxide, acetylacetone and anhydrous ethanol as raw materials. Zirconium n-propoxide is the precursor of zirconium oxide, and can be subjected to a gel reaction with acetylacetone, while ethanol is a solvent. Silicon powder, graphite and hexagonal boron nitride are the raw materials for silicon-boron-carbon-nitrogen ceramic composite powder. The preparation method comprises the following steps: zirconium n-propoxide and acetylacetone are subjected to magnetic stirring for 48h in an anhydrous ethanol solution, such that a gel solution is formed; the silicon-boron-carbon-nitrogen ceramic composite powder is mixed with the solution according to a certain ratio; magnetic stirring is carried out for 48h, and the obtained material is dried; cracking is carried out for 3h under a temperature of 550 DEG C in a tubular furnace, such that a silicon-boron-carbon-nitrogen-zirconium oxide ceramic composite material is obtained. The powder is subjected to pressurized sintering under a temperature of 2000 DEG C in discharge plasma, such that in-situ reaction sintering is carried out. The silicon-boron-carbon-nitrogen-zirconium ceramic composite material synthesized with the method provided by the invention has the advantages of high interfacial bonding strength and good comprehensive performance. The material is especially suitable to be used for manufacturing aerospace heat-proof core components.

Owner:HARBIN INST OF TECH

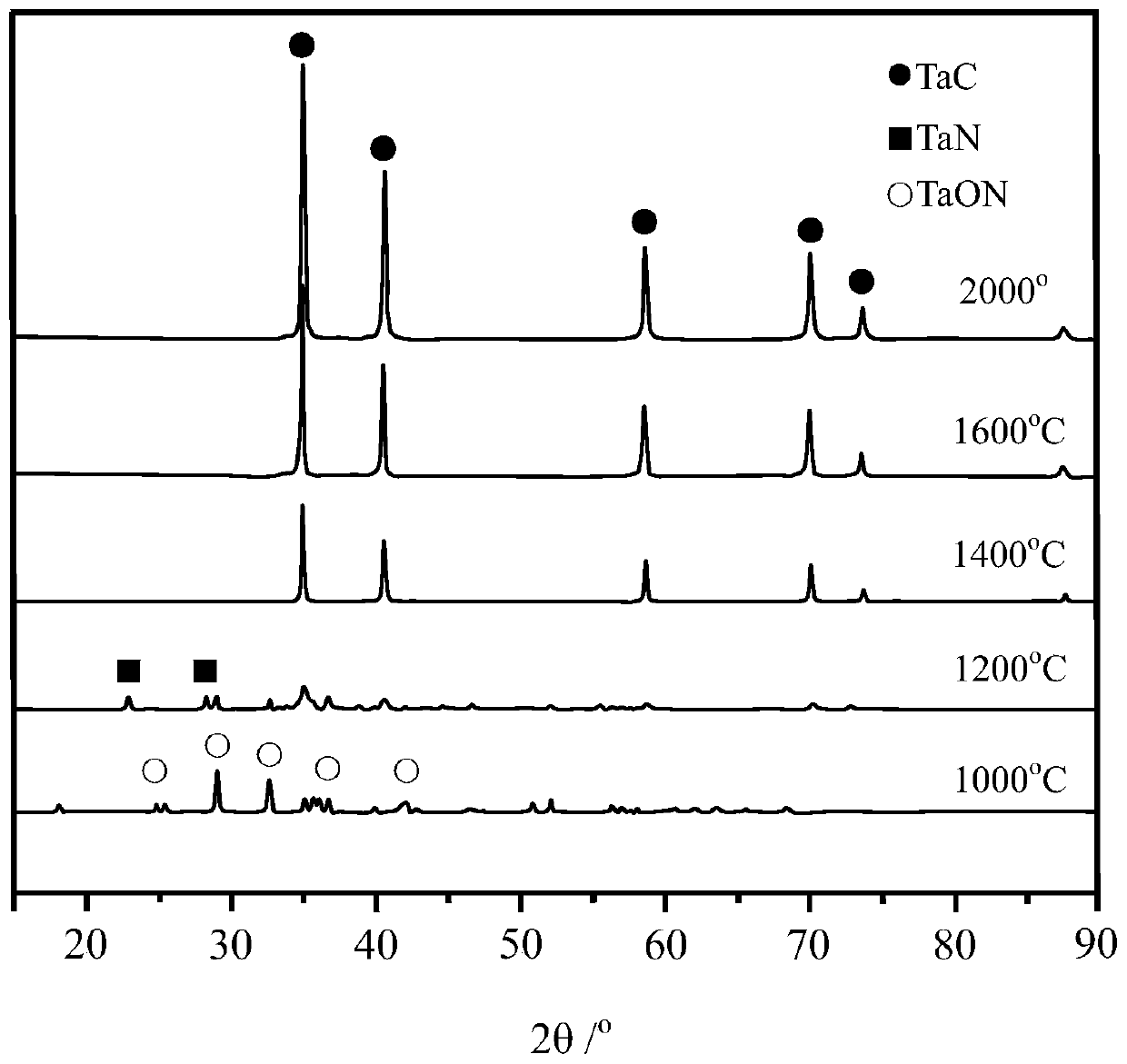

Preparation method of tantalum carbide ceramic precursor

Owner:NAT UNIV OF DEFENSE TECH

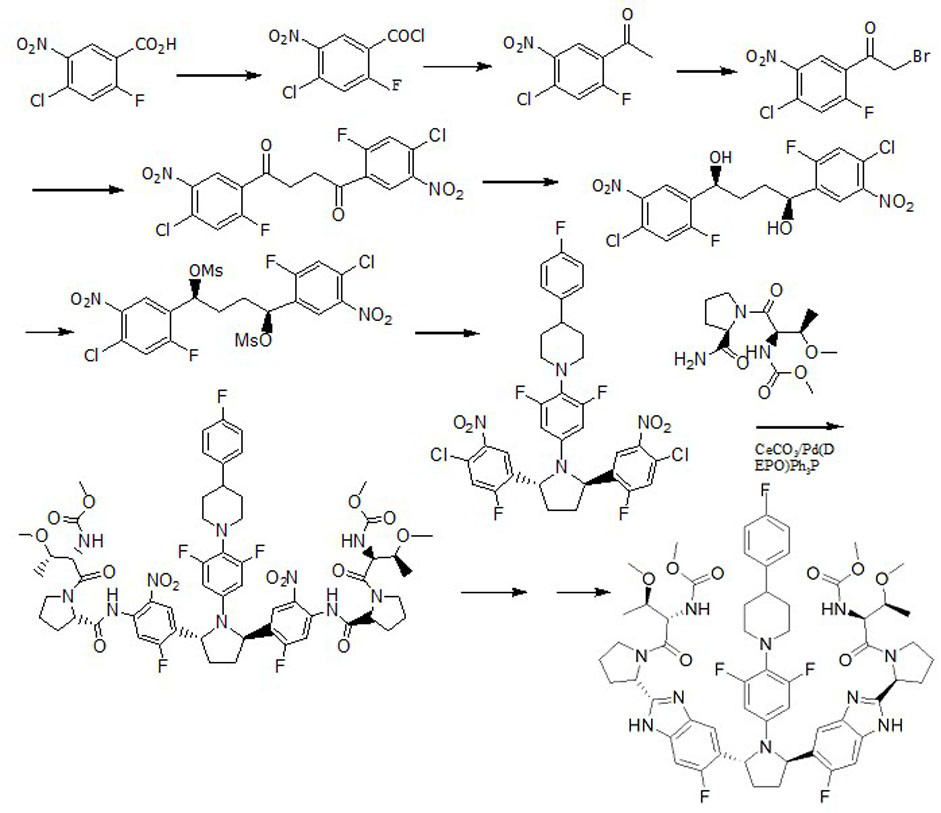

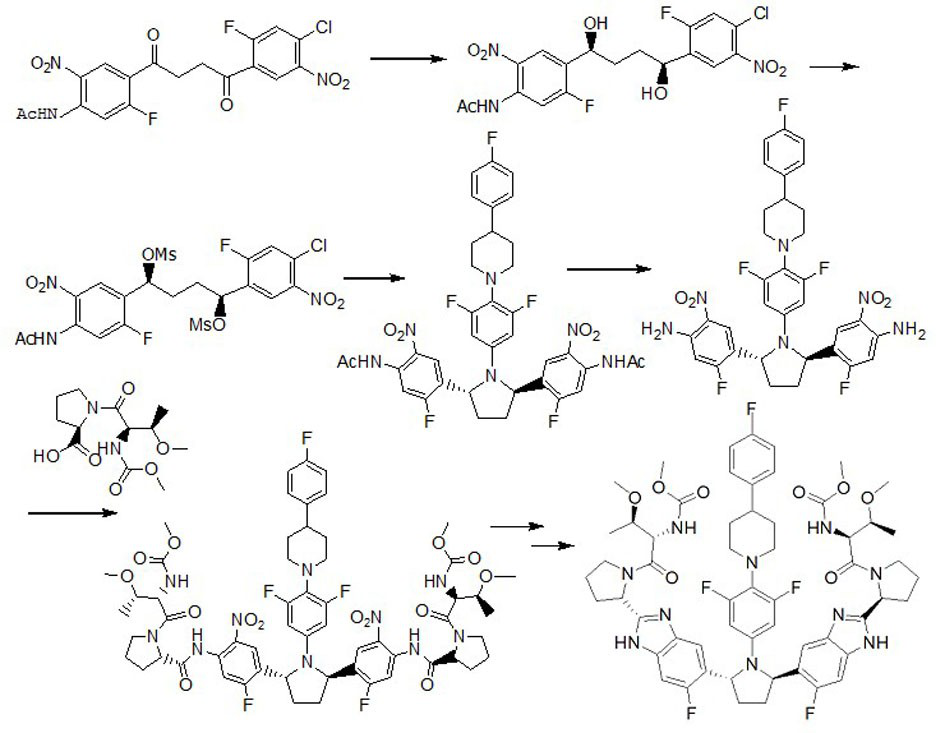

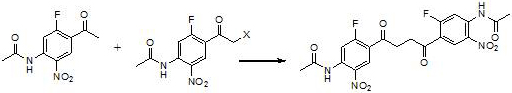

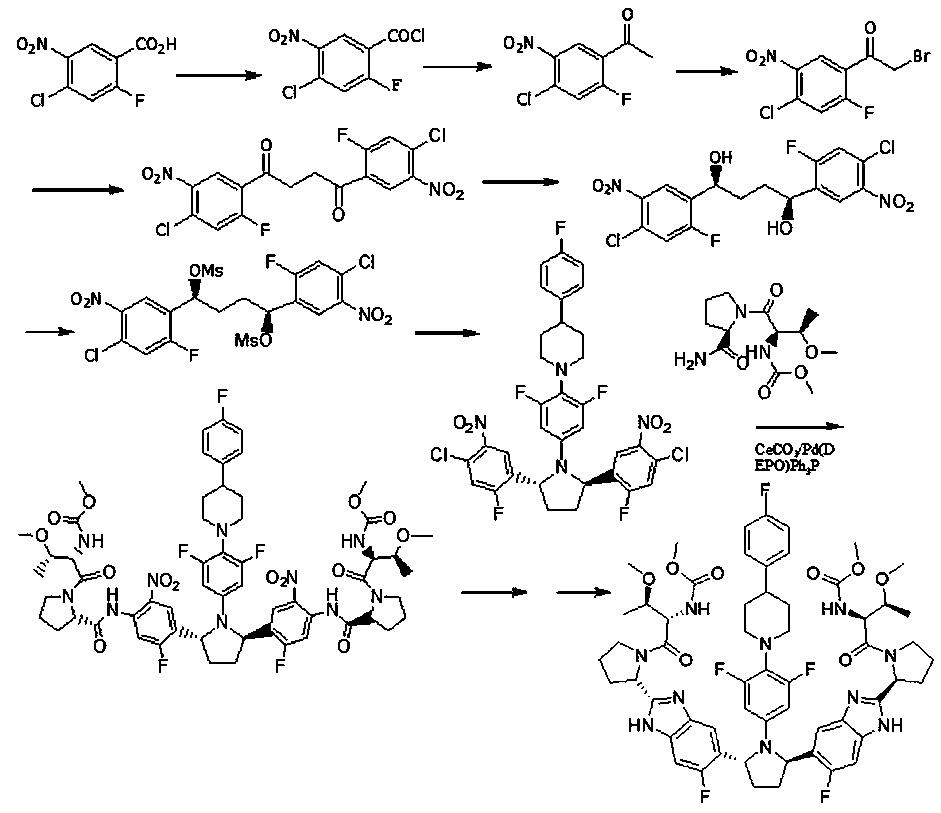

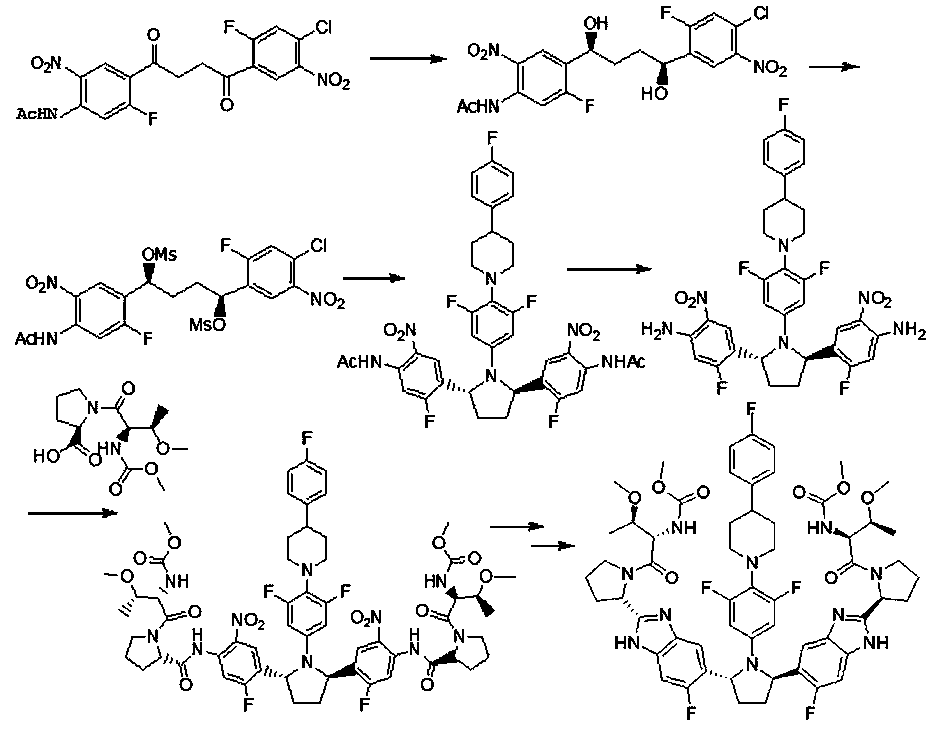

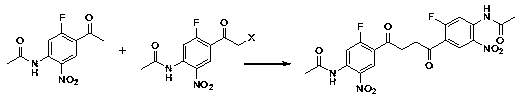

A kind of preparation method of hepatitis drug intermediate

ActiveCN111072513BRaw materials are easy to getLow reaction conditionsOrganic compound preparationCarboxylic acid amides preparationNitrationAcyl group

The invention discloses a preparation method of a hepatitis drug intermediate, which is characterized in that m-fluoroaniline is used as a starting material, and after acetylated amino protection, Friedel-Crafts acylation reaction, nitration reaction, bromination reaction, and finally coupling to obtain 1,4‑bis‑[(4‑acetamido‑2‑fluoro‑5‑nitro)phenyl]butane‑1,4‑dione. The present invention has easy-to-obtain raw materials, low requirements on reaction conditions, few side reactions, and high yield. 1,4-bis-[(4-acetamido-2-fluoro-5-nitro)phenyl]butane-1,4 -Diketones can be used as pharmaceutical intermediates for the preparation of pirentasvir.

Owner:SUZHOU JINGYE MEDICINE & CHEM

A monodisperse spherical y 2 o 3 and al 2 o 3 Powder preparation (y 1-x yb x )ag transparent ceramic method

The invention belongs to the field of material technology and provides a monodisperse spherical Y 2 O 3 and Al 2 O 3 Powder preparation (Y 1‑x yb x )AG transparent ceramic method. Monodisperse spherical Al was prepared by homogeneous co-precipitation method 2 O 3 powder, prepared with monodisperse spherical Y 2 O 3 Powder and nano Yb 2 O 3 Mix as raw materials, and use solid-state reaction method, press molding and vacuum sintering technology to prepare Yb:YAG transparent ceramics. Prepared spherical Y 2 O 3 and spherical Al 2 O 3 The powder particles are uniform, the dispersion is good, the preparation process is simple, and the density of the green body is high when the powder is formed, which is beneficial to sintering and is suitable for preparing laser transparent ceramics; the method of the present invention has simple reaction conditions, low environmental pollution, and is easy to promote, etc. advantage.

Owner:NORTHEASTERN UNIV LIAONING

Continuous preparation method of foaming material, foaming pretreatment device, and foaming device

ActiveCN110027157BRealize continuous preparationFacilitate continuous preparationFoaming agentReaction zone

The invention discloses a continuous preparation method of a foaming material. In the first reaction zone, the second reaction zone and the third reaction zone, the foaming agent filling, heating and foaming processes are respectively carried out in the first reaction zone, the second reaction zone and the third reaction zone. The first pressure is applied to the material to be foamed in the area, so that the internal bubbles of the material to be foamed will not grow when heated, and the expansion and foaming of the material when heated unevenly is avoided. The continuous preparation of the foaming material can be realized through the transmission from the first reaction zone to the third reaction zone. The invention discloses a foaming pretreatment device implementing the above method. During the transmission process, the material to be foamed is uniformly heated to the foaming temperature under the condition that internal bubbles do not grow, and foams instantly after leaving the foaming pretreatment device. The foam material has uniform and controllable cell diameter and expansion ratio. The invention discloses a foaming device, comprising the above-mentioned foaming pretreatment device, which is suitable for continuously preparing foaming materials with uniform cell diameter and large thickness in the solid state foaming process.

Owner:SHINCELL NEW MATERIAL CO LTD

A kind of preparation method of polyborosilazane with high softening point

The invention discloses a preparation method for high softening point polyborosilazane, which comprises the following steps: (1) a reaction still provided with a stirring device, a temperature measurement device, a charging device, a ventilation device, a discharging device, and a distillation device is used for replacement of nitrogen; (2)chlorosilane, dialkyl group borazine and heptamethyldisilazane are weighed according to the molar ratio of 1:(0.5-3):(6-12); (3) chlorosilane, dialkyl group borazine and heptamethyldisilazane are added into the reaction still, and the reaction still is cooled to 5-55 below zero DEG C; the heptamethyldisilazane is added into a reactor at the speed of 0.01-0.2L / min and is stirred; (4) after the charging is completed, the reactor is heated to reach 250-350 DEG C and is distilled for 6-48 hours under the normal pressure; (5) after the distillation under the normal pressure is completed, the temperature of the reactor is reduced by 10-60 DEG C and is subjected to reduced pressure distillation for 0.3-3 hours. The softening point of polyborosilazane is synthesized by the method is greater than 180 DEG C, the ceramic yield is more than 60 percent, and high performance ceramic fiber and ceramic matrix can be prepared.

Owner:NAT UNIV OF DEFENSE TECH

A method for preparing YAG-based multilayer composite structure transparent ceramics by using isobam gel injection molding

Owner:XUZHOU ALL TO PHOTOELECTRIC TECH CO LTD

Preparation method of hepatitis drug intermediate

ActiveCN111072513ARaw materials are easy to getLow reaction conditionsOrganic compound preparationCarboxylic acid amides preparationNitrationAcyl group

The invention discloses a preparation method of a hepatitis drug intermediate, which is characterized in that m-fluoroaniline is used as an initial raw material, and subjected to acetylation amino protection, a Friedel-Crafts acylation reaction, a nitration reaction and a bromination reaction, and finally coupling is performed to obtain 1,4-bis-[(4-acetamido-2-fluoro-5-nitro)phenyl]butane-1,4-dione. According to the method, the raw materials are easy to obtain, the reaction condition requirements are low, side reactions are few, the yield is high, and the 1,4-bis-[(4-acetamido-2-fluoro-5-nitro)phenyl]butane-1,4-dione can be used as a drug intermediate for preparing pibrentasvir.

Owner:SUZHOU JINGYE MEDICINE & CHEM

Chloronitrobenzene preparation method

InactiveCN104311423AWith environmental economic characteristicsImprove atomic efficiencyNitro compound preparationNitro compoundChlorobenzene

The invention belongs to the technical field of fine chemical industry, and mainly relates to a method for preparation of a nitrocompound by use of nitrogen tetroxide / ozone as a nitrating agent; the method comprises the following steps: reaction raw material chlorobenzene, a solvent and a solid catalyst are added into a reactor; ozone and nitrogen tetroxide are introduced for reaction for 7-10h in the 0.011.5MPa and at 50 to 100 DEG C. After the reaction, the temperature is cooled to room temperature, oxygen is introduced into the reaction mixture until nitrogen oxides completely escape from the reactor, and the catalyst is filtered out. The filtrate is washed to neutral with sodium carbonate solution, an organic phase is washed, and vacuum rotary evaporation and concentration is performed.

Owner:王晓伟

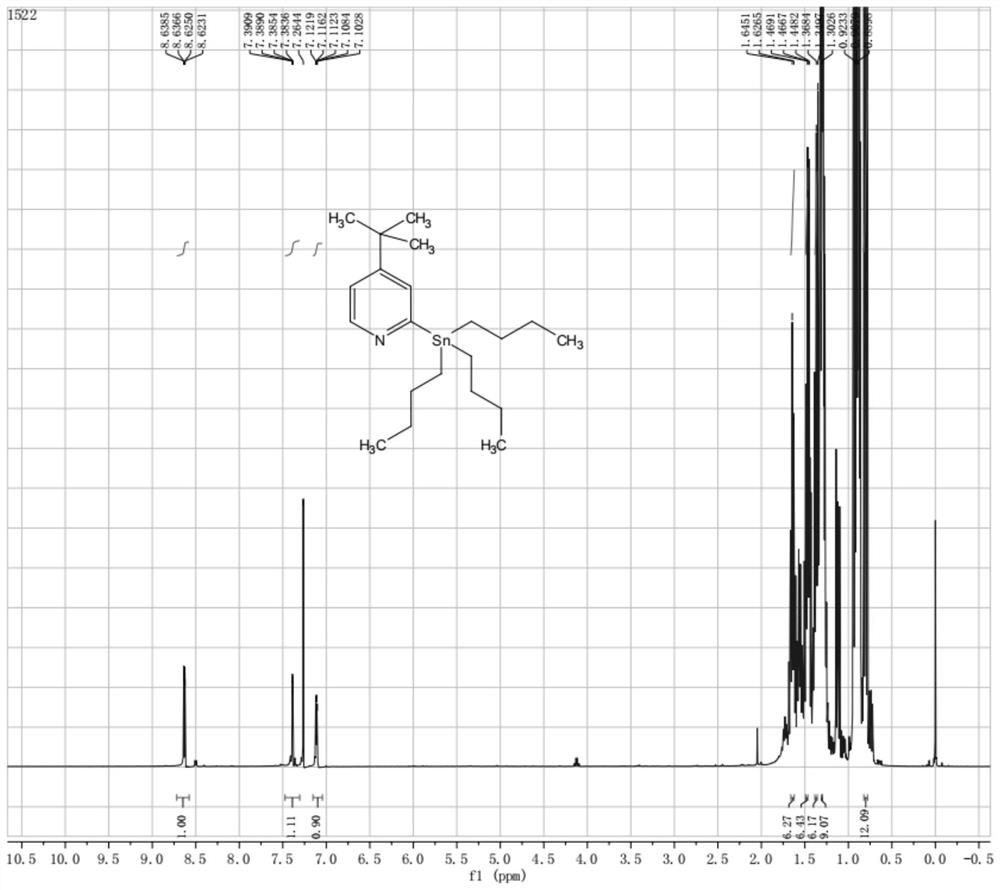

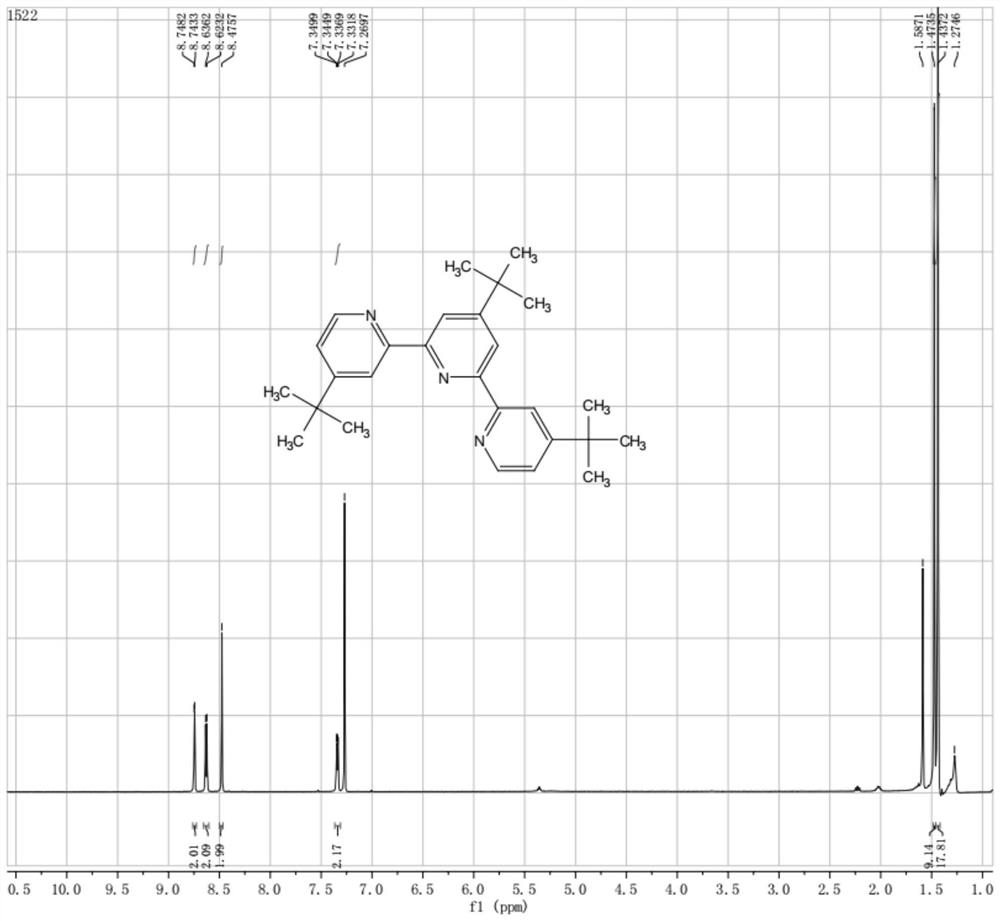

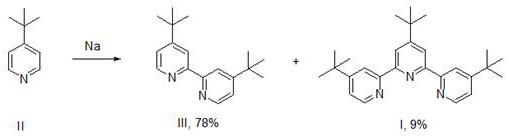

Preparation method of 4,4',4''-tritert-butyl-2,2':6',2''-terpyridine

InactiveCN111646932AEasy to separate and purifyEfficient preparationOrganic chemistryPolymer sciencePtru catalyst

The invention relates to a preparation method of 4,4',4''-tritert-butyl-2,2':6',2''-terpyridine, which comprises the following steps: dissolving an additive in a solvent, and carrying out a reaction with 4-tert-butylpyridine and a tin reagent under strong alkali conditions to obtain 4-tert-butyl-2-tributyltin alkyl pyridine; then carrying out a coupling reaction with 4-tert-butyl-2,6-dichloropyridine under the effect of a catalyst to obtain 4,4',4''-tritert-butyl-2,2':6',2''-terpyridine. Beginning from the raw material 4-tert-butylpyridine, the product 4,4',4''-tritert-butyl-2,2':6',2''-terpyridine is prepared through two reaction steps. The method is simple in product separation and purification and is suitable for large-scale production.

Owner:南京合巨药业有限公司

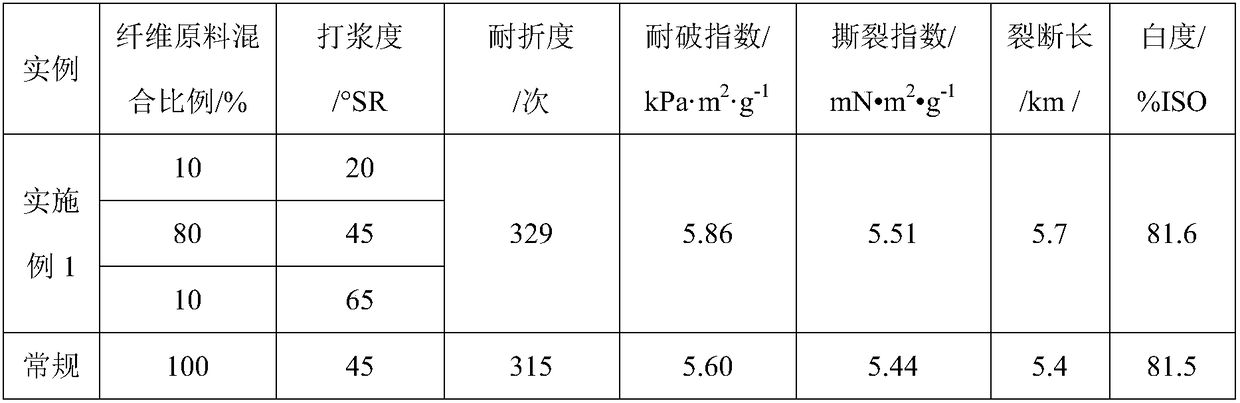

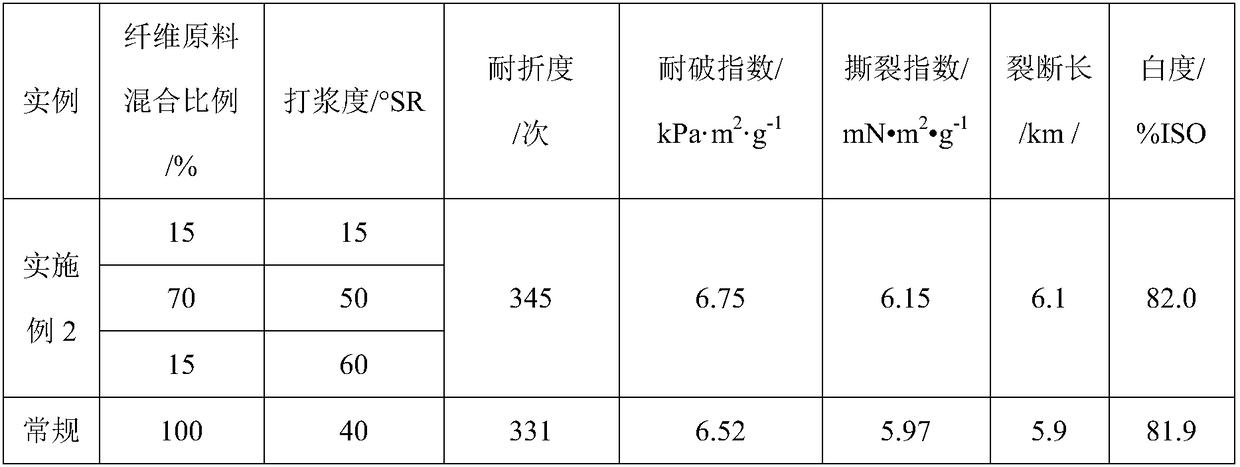

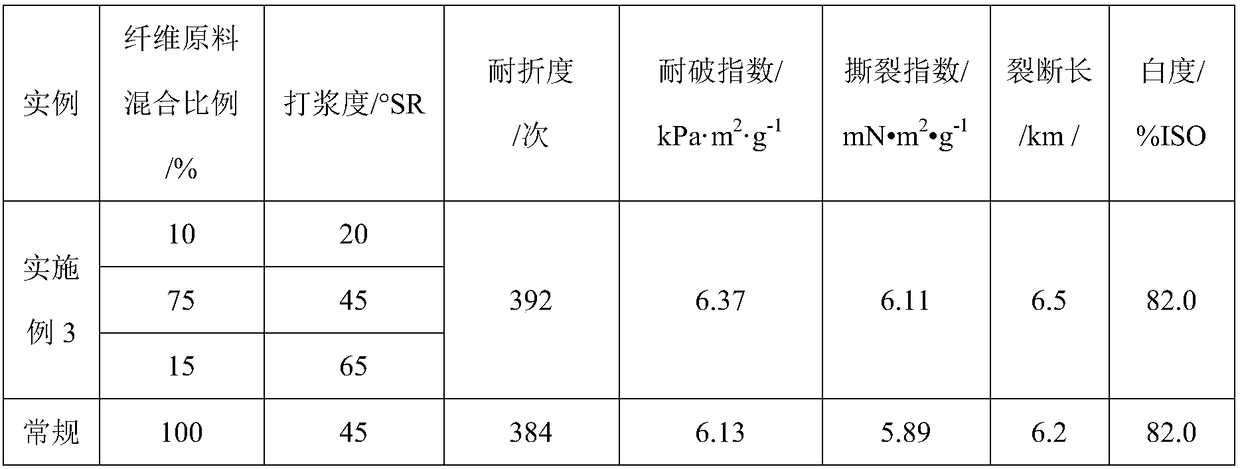

A method for preparing paper-based materials from full chlorine-free bleached chemical pulp of softwood kraft mixed kraft pulp

ActiveCN106758487BGood filterabilityHigh strengthSpecial paperPulp beating methodsPaper basedPulp fibre

The invention discloses a method for preparing a paper base material through a needle broad-leaved mixed sulfate pulp total-chlorine-free bleaching chemical pulp. The method comprises the following steps of (1) using a needle broad-leaved mixed pulp obtained by bleaching through a biochemical method as a paper pulp raw material, dividing the paper pulp raw material into three parts, and respectively pulp-beating, wherein the pulp-beating degree of the first paper pulp ranges from 15 to 25 degrees SR, the pulp-beating degree of the second paper pulp ranges from 45 to 55 degrees SR, and the pulp-beating degree of the third paper pulp ranges from 60 to 75 degrees SR; (2) mixing the three paper pulps prepared in the step (1) according to a certain proportion so as to obtain a mixed pulp, and enabling the mass ratio of the first paper pulp, the second paper pulp and the third paper pulp in the mixed pulp to be 10 to 30:65 to 85:10 to 20; (3) mixing moulding or compression moulding the mixed pulp obtained the step (2) so as to obtain the paper base material. According to the method provided by the invention, a gradient pulp-beating method is adopted, and paper pulp fibers with different pulp-beating degrees are mixed, so that the paper base material can be ensured to have a favorable drainage property during a preparation process, and the prepared paper base material has higher strength.

Owner:QILU UNIV OF TECH

Application of recombinant protein of pathogenic gene vapa of Rhodococcus equi

ActiveCN104888208BImproving immunogenicityPrepared forAntibacterial agentsBacterial antigen ingredientsRhodococcus equiImmunogenicity

Owner:SOUTH CHINA AGRI UNIV

A method for preparing nanocomposite fibers by coagulation of grooved hydrogel

ActiveCN111286814BHigh tensile strengthSimple moldingAdditive manufacturing apparatusAlginate artificial filamentsFiberPolymer science

The invention relates to a method for preparing nanocomposite fibers by coagulation of groove-shaped hydrogels. The composite fibers are as follows: the groove-shaped hydrogels prepared by 3D printing methods are used as coagulation baths, combined with the microstructures in wet spinning Obtained by flow control method. The method for preparing nanocomposite fibers in the present invention is novel and convenient, and can prepare various nanocomposite fibers with high strength and good weaving performance using sodium alginate (SA) as a matrix, and can be used in the smart clothing industry and the like. Using hydrogel as a coagulation bath not only improves the efficiency of traditional wet spinning to prepare fibers, but also prolongs the service life of the coagulation bath.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com