A method for preparing paper-based materials from full chlorine-free bleached chemical pulp of softwood kraft mixed kraft pulp

A technology of kraft pulp and mixed pulp, applied in pulp beating method, chemical/chemical mechanical pulp, special paper, etc. high smoothness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

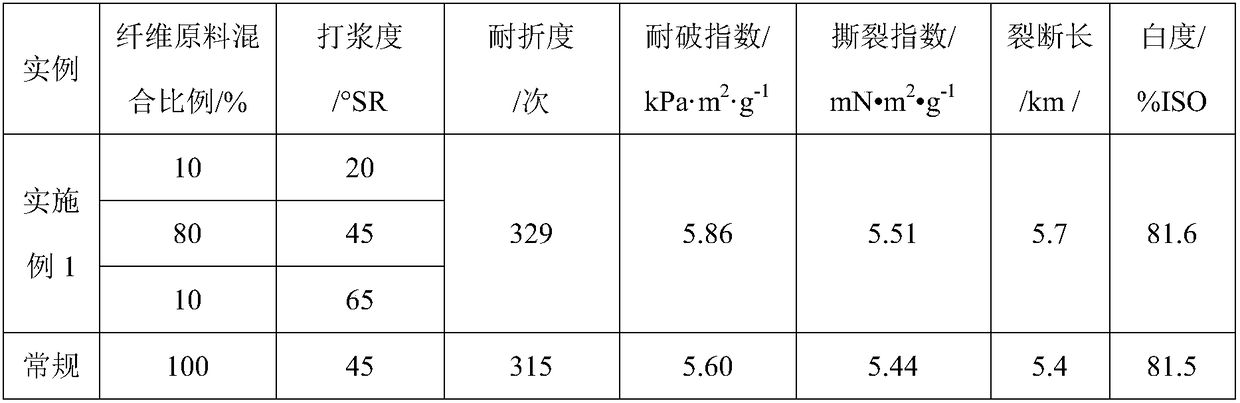

Embodiment 1

[0040] A method for preparing a paper-based material from needle-leaf mixed kraft full chlorine-free bleached chemical pulp. This embodiment prepares a heat-sensitive raw paper paper-based material.

[0041] Proceed as follows:

[0042] (1) The high-performance chlorine-free bleached chemical pulp obtained by the patent ZL201210405720.7 "a process for fully chlorine-free bleaching of coniferous and broadleaf mixed kraft chemical pulp", softwood kraft chemical pulp and hardwood kraft chemical pulp The ratio of the pulp is 1:1, the pulp whiteness is 82.2% ISO, take three parts of the pulp according to 100g·t -1 Add the LPK-CR1 (L1) beating enzyme of Lvweikang Co., Ltd. to the amount of dry pulp for mixing treatment, and then use the PFI mill for precise refining, so that the beating degrees of the pulp are 20°SR, 45°SR, and 65°SR respectively. .

[0043] The bleaching process specifically includes the following steps:

[0044] 1. Mix the cooked softwood kraft pulp with a kapp...

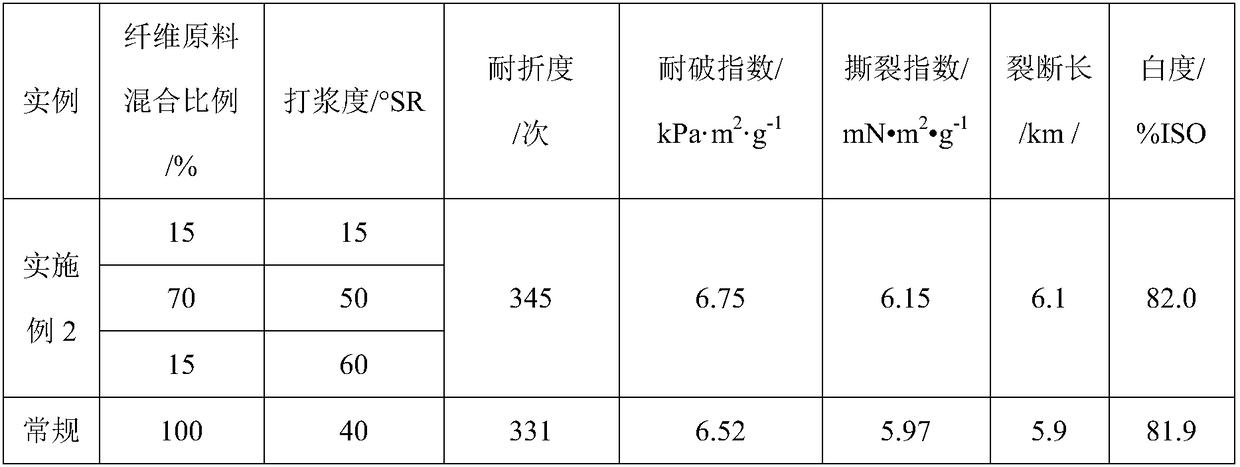

Embodiment 2

[0061] Example 2 A method for preparing a paper-based material from needlewood mixed kraft full chlorine-free bleached chemical pulp. This embodiment prepares a heat-sensitive base paper paper-based material.

[0062] Proceed as follows:

[0063] (1) The high-performance chlorine-free bleached chemical pulp obtained by the patent ZL201210405720.7 "a process for fully chlorine-free bleaching of coniferous and broadleaf mixed kraft chemical pulp", softwood kraft chemical pulp and hardwood kraft chemical pulp The pulp ratio is 3:1, the pulp brightness is 82.5%ISO, and three parts of the pulp are refined by PFI mill, so that the beating degrees of the pulp are 15°SR, 50°SR, and 60°SR respectively.

[0064] The bleaching process specifically includes the following steps:

[0065] 1. Mix the cooked softwood kraft pulp with a kappa number of 16-23 and the hardwood kraft pulp with a kappa number of 16-22 at a mass ratio of 3:1, wash and mix evenly , put the needle-wood mixed pulp in...

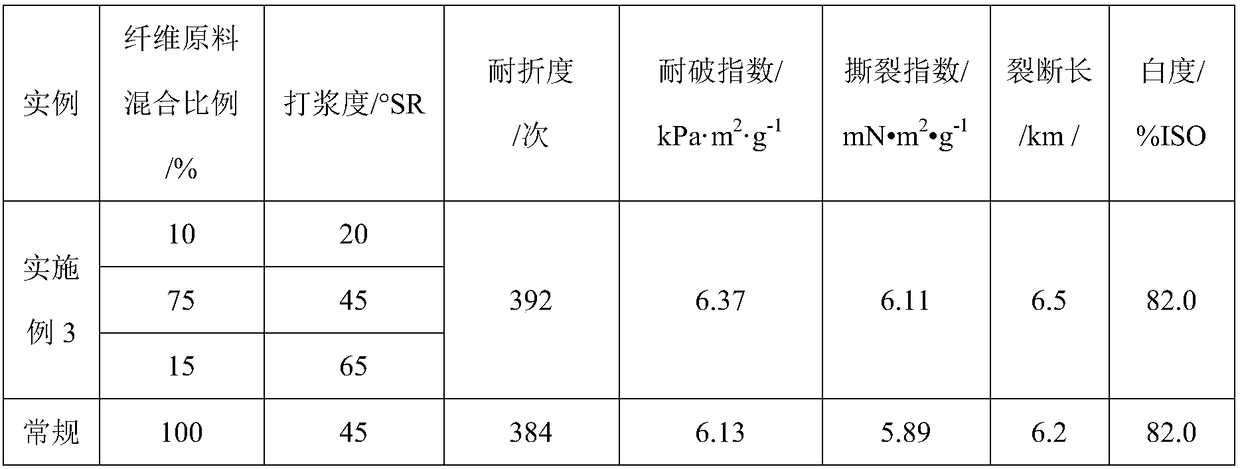

Embodiment 3

[0083] A method for preparing a paper-based material from mixed kraft full chlorine-free bleached chemical pulp, this embodiment prepares a transfer printing paper-based material.

[0084] Proceed as follows:

[0085] (1) The high-performance chlorine-free bleached chemical pulp obtained by the patent ZL201210405720.7 "a process for fully chlorine-free bleaching of coniferous and broadleaf mixed kraft chemical pulp", softwood kraft chemical pulp and hardwood kraft chemical pulp The pulp ratio is 1:1, the pulp brightness is 82.3%ISO, and three parts of the pulp are refined by PFI mill, so that the beating degrees of the pulp are 20°SR, 45°SR, and 65°SR respectively.

[0086] The bleaching process specifically includes the following steps:

[0087] 1. Mix the cooked softwood kraft pulp with a kappa number of 16-23 and the hardwood kraft pulp with a kappa number of 16-22 at a mass ratio of 1:1, wash and mix evenly , put the needle-wood mixed pulp into a polyethylene plastic bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com