A method for preparing nanocomposite fibers by coagulation of grooved hydrogel

A nanofiber and hydrogel technology, applied in the fields of fiber chemical characteristics, wet spinning, rayon manufacturing, etc., can solve the problems of complex device and low fiber preparation efficiency, saving molding time, simple and fast molding process, The effect of increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

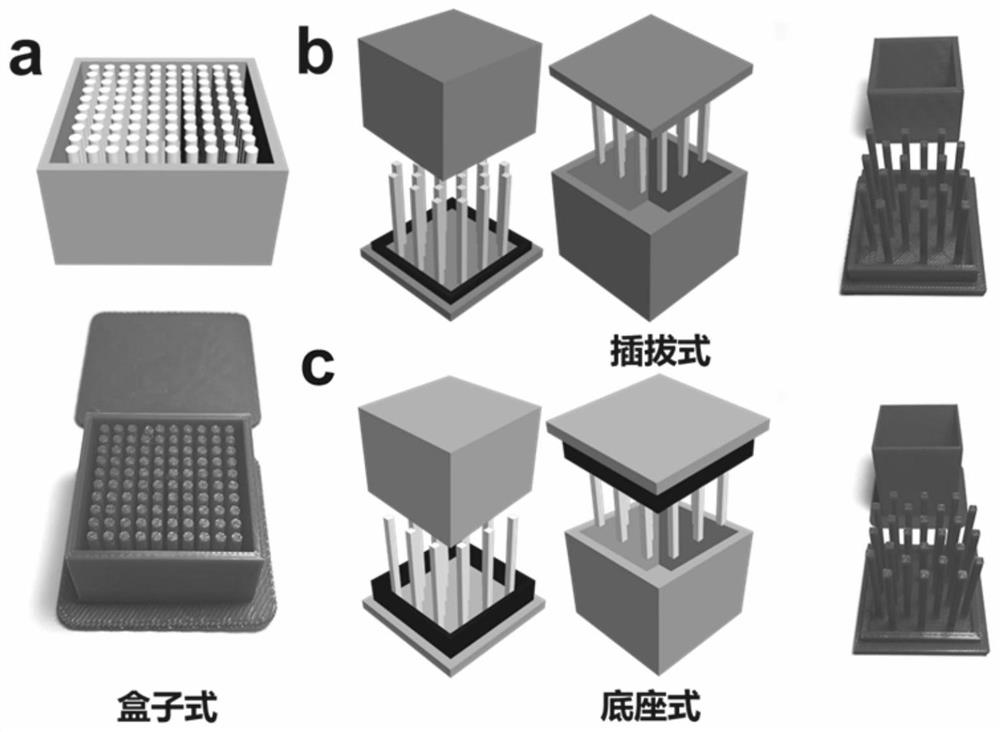

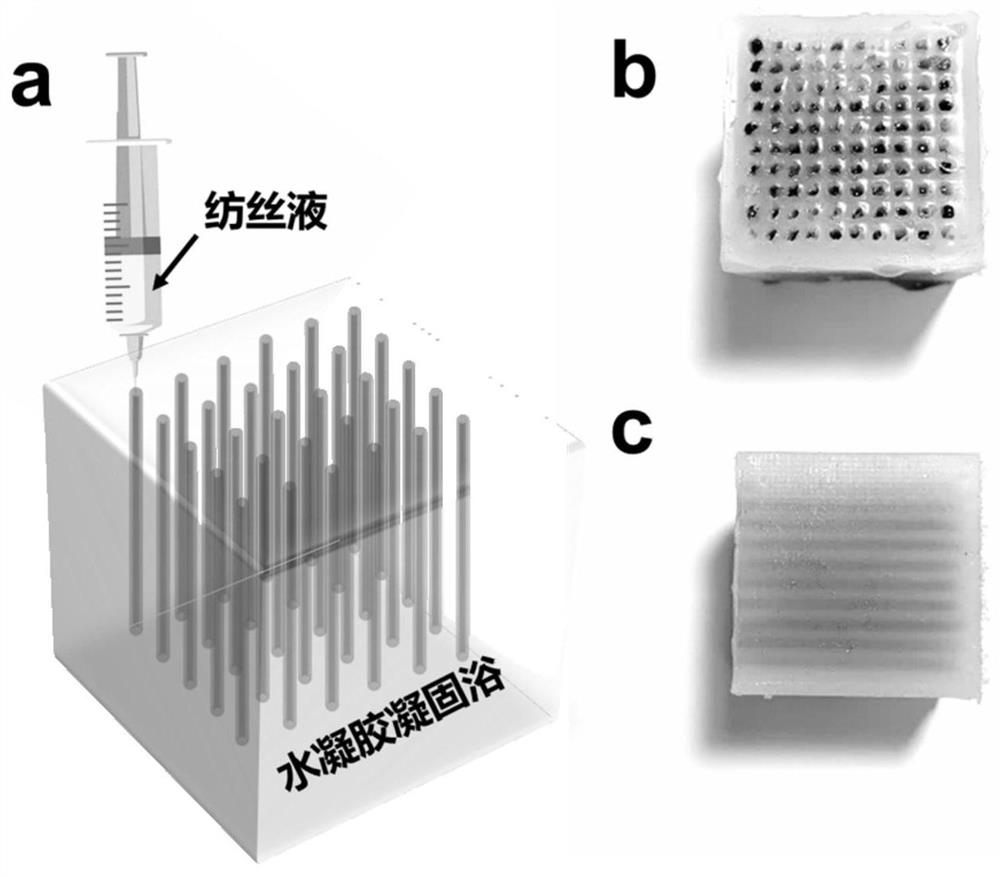

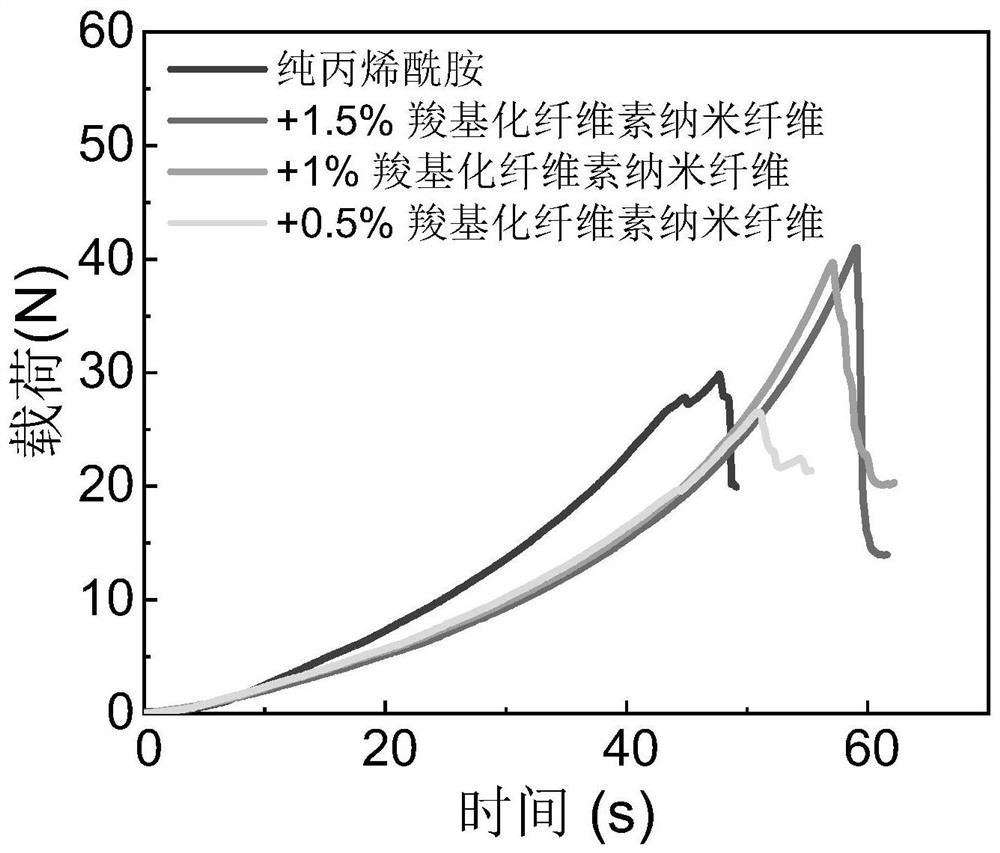

[0060] (1) At room temperature, mix 15g of acrylamide, 0.3g of ammonium persulfate, 0.3g of N,N-methylenebisacrylamide, and 0.1g of carboxylated methylcellulose in 100mL of deionized water at 250r min -1 Magnetic stirring at a rotating speed of 100°C, and after mixing evenly, 0.3 g of tetramethylethylenediamine was added. Pour the above mixed solution into the polylactic acid mold prepared by 3D printing method (plug-in type 5×5×5cm 3 ) in cross-linking curing (such as figure 1 shown). After waiting for 5 minutes, the mold was released, and the obtained flume-shaped hydrogel was rinsed with excess water to remove unreacted components to ensure that the flume-shaped hydrogel was fully expanded. Put the prepared fully expanded grooved hydrogel into deionized water of equal mass, then add 0.5g of calcium chloride, and soak for 5 hours at 20°C to obtain a hydrogel containing calcium chloride .

[0061] (2) Mix 0.5g SWCNTs and 10mL concentrated HNO 3 and 5mL of concentrated H...

Embodiment 2

[0069](1) At room temperature, put 17g of acrylamide, 0.4g of ammonium persulfate, 0.4g of N,N-methylenebisacrylamide, and 0.2g of carboxylated methyl cellulose in 100mL of deionized water at a speed of 300r / min. Stir, and add 0.4 g of tetramethylethylenediamine after mixing evenly. Pour the above mixed solution into the polylactic acid mold (box type 10×10×10cm) prepared by 3D printing method 3 ) in cross-linking curing (such as figure 1 shown). After waiting for 10 minutes, the mold was demoulded, and the obtained groove-shaped hydrogel was rinsed with excess water to remove unreacted components to ensure that the groove hydrogel was fully expanded. Put the prepared fully expanded grooved hydrogel into deionized water of equal mass, then add 0.75g of calcium chloride, and soak for 6 hours at 25°C to obtain a hydrogel containing calcium chloride .

[0070] (2) Mix 0.6g SWCNTs and 20mL concentrated HNO 3 , 10mL of concentrated HCl into a three-necked flask and heated at ...

Embodiment 3

[0073] (1) At room temperature, mix 19g of acrylamide, 0.5g of ammonium persulfate, 0.5g of N,N-methylenebisacrylamide, and 0.3g of carboxylated methylcellulose in 100mL of deionized water at 350r min -1 Magnetic stirring at a rotating speed of 100°C, and after mixing evenly, 0.5 g of tetramethylethylenediamine was added. Pour the above mixed solution into the polylactic acid mold prepared by 3D printing method (bottom tank type 15×15×15cm 3 ) in cross-linking curing (such as figure 1 shown). After waiting for 15 minutes, the mold was released, and the obtained groove-shaped hydrogel was rinsed with excess water to remove unreacted components to ensure that the groove hydrogel fully expanded. Put the prepared fully expanded groove hydrogel into deionized water of equal mass, then add 1g of calcium chloride, and stand and soak for 7 hours at 30°C to obtain a hydrogel containing calcium chloride.

[0074] (2) Mix 0.7g SWCNTs and 30mL concentrated HNO 3 , 15mL concentrated H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com