Preparation method of nano-hydroxyapatite/nano-hydroxyapatite gas sensing material

A nano-hydroxyapatite and gas sensing technology, which is applied in the field of nano-gas sensing materials and gas sensing, can solve the problems of long reaction time, long reaction cycle, high equipment and energy costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

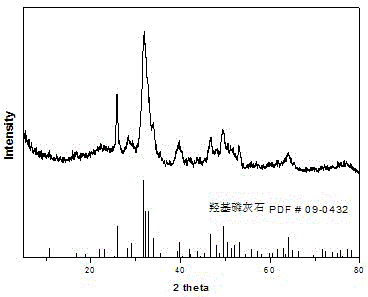

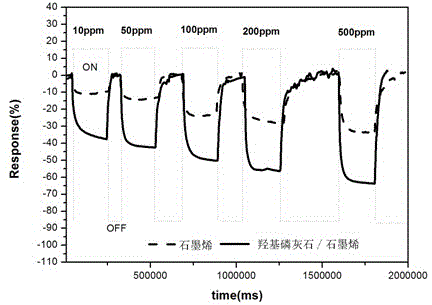

[0035] This embodiment is based on the preparation method of the gas sensor of nano-hydroxyapatite / graphene gas sensing material (refer to figure 1 ), including the following steps.

[0036] a. 0.02 g of graphene oxide was ultrasonically treated at 60 kHz for 2 h to form a well-dispersed monolithic graphene oxide suspension of 1 mg / ml. Dissolve 0.04 mg of dopamine hydrochloride in Tris-HCl solution (10 mM, pH=8.5) at a concentration of 2 mg / ml, and stir for 10 s. Then the two solutions were quickly mixed in equal volumes, magnetically stirred for 11 h, centrifuged at 12,000 rpm for 10 min, washed three times with water and twice with ethanol, and the obtained precipitate was vacuum-dried at 60°C for 12 h to obtain a powder.

[0037] b. Accurately weigh 10 mg of the hydroxylated modified graphene obtained in step a, and 60 kHz ultrasonic dispersion in pre-prepared 0.05mol / L Ca(NO 3 ) 2 4H 2 In the O solution, the concentration of graphene was controlled at 1 mg / ml, and then...

Embodiment 2

[0046] The method steps and parameters of this embodiment are basically the same as those of Embodiment 1, except that the added reducing and modifying agent is norepinephrine. The properties of the nano-hydroxyapatite / graphene gas sensing material prepared by the method steps and parameters are basically the same as those in Example 1.

Embodiment 3

[0048] The method step and parameter of present embodiment and embodiment 1 are basically the same, and difference is the Ca(OH) that calcium solution is 0.01mol / L 2 Suspension, and the phosphorus solution added dropwise is 0.006mol / L H 3 PO 4 solution. The properties of the nano-hydroxyapatite / graphene gas sensing material prepared by the method steps and parameters are basically the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com