Temperature-sensitive hollow polylactic acid color changing microsphere as well as preparation method and application thereof

A technology of polylactic acid microspheres and polylactic acid, which is applied in the preparation of microspheres, microcapsule preparations, etc., achieves the effects of high stability, wide color selectivity, and wide discoloration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

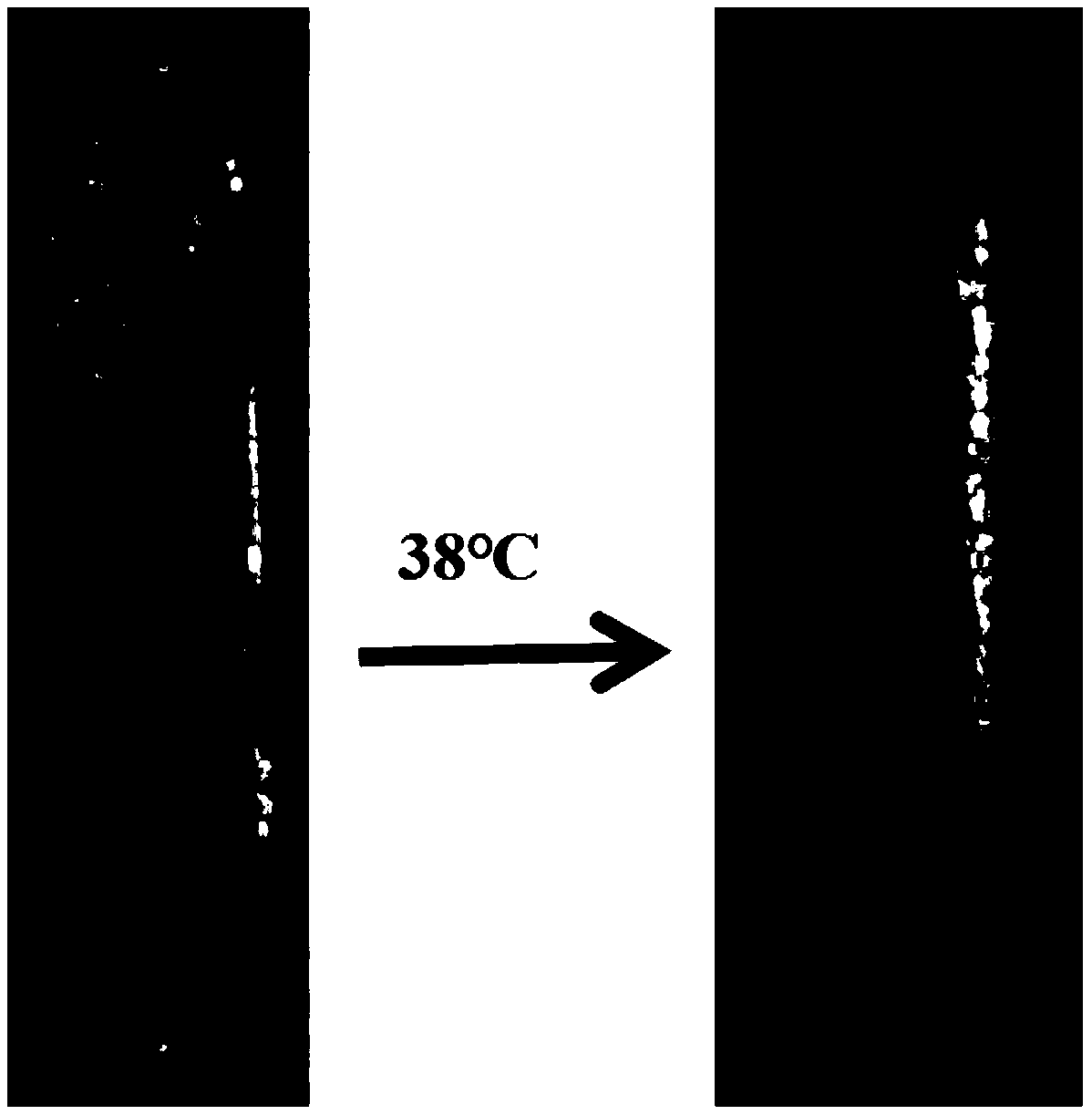

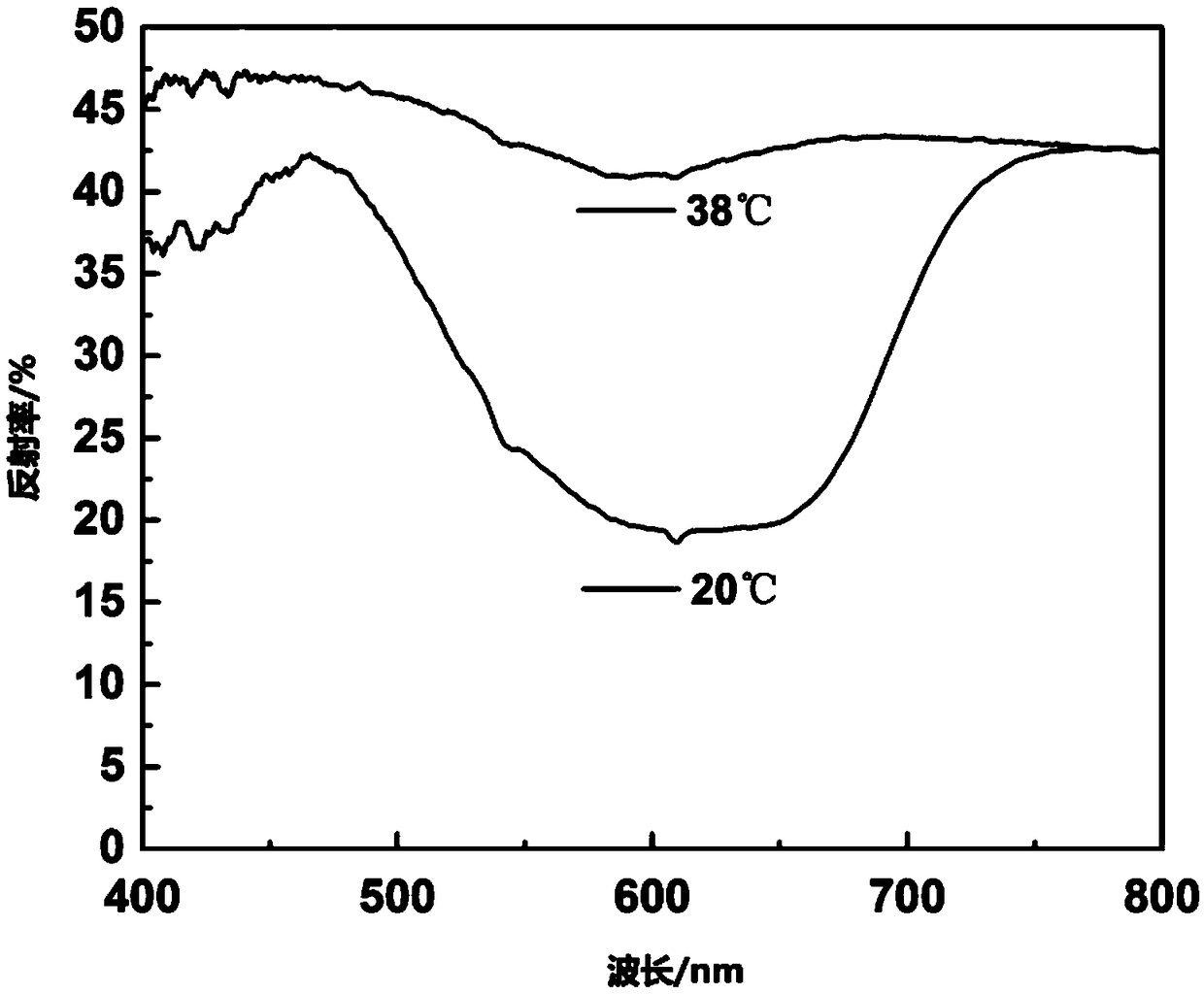

[0034] (1) Disperse 3g of polylactic acid particles in 97g of dichloromethane solution, obtain a uniform and clear polylactic acid solution after ultrasonic dispersion for 6 hours, weigh 1g of polyvinyl alcohol and dissolve it in 99g of deionized water, heat and stir at 90°C for 6 hours stand-by. Weigh 1g of ink that turns from blue to white at 38°C and disperse it in 99g of deionized water, ultrasonically disperse for 6 hours and set aside.

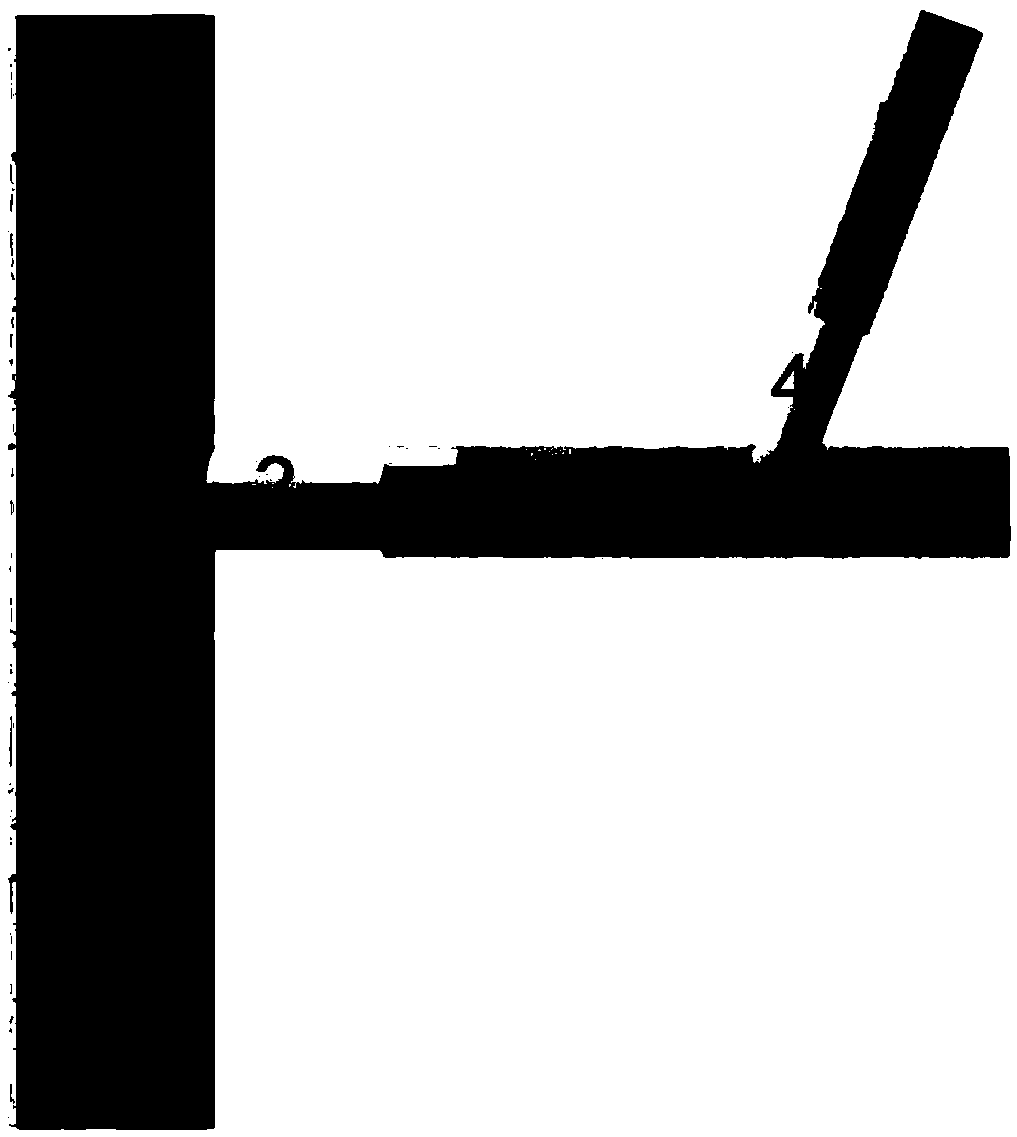

[0035] (2) Place the first polytetrafluoroethylene tube (1) vertically, the second polytetrafluoroethylene tube (3) is connected horizontally with the first polytetrafluoroethylene tube (1) through the first glass capillary tube (2), the second The three polytetrafluoroethylene tubes (5) are longitudinally connected to the second polytetrafluoroethylene tube (3) through the second glass capillary tube (4); all the polytetrafluoroethylene tubes and glass capillary tubes are connected with Henkel Baide AB glue Get a microfluidic device. ...

Embodiment 2

[0042] (1) Disperse 5g of polylactic acid particles in 95g of dichloromethane solution, obtain a uniform and clear polylactic acid solution after ultrasonic dispersion for 3 hours, weigh 3g of polyvinyl alcohol and dissolve it in 97g of deionized water, heat and stir at 95°C for 5 hours stand-by. Weigh 2g of ink that turns from blue to white at 38°C and disperse it in 98g of deionized water, ultrasonically disperse for 5 hours and set aside.

[0043] (2) Place the first polytetrafluoroethylene tube (1) vertically, the second polytetrafluoroethylene tube (3) is connected horizontally with the first polytetrafluoroethylene tube (1) through the first glass capillary tube (2), the second The three polytetrafluoroethylene tubes (5) are longitudinally connected to the second polytetrafluoroethylene tube (3) through the second glass capillary tube (4); all the polytetrafluoroethylene tubes and glass capillary tubes are connected with Henkel Baide AB glue Get a microfluidic device. ...

Embodiment 3

[0046] (1) Disperse 7g of polylactic acid particles in 93g of dichloromethane solution, obtain a uniform and clear polylactic acid solution after ultrasonic dispersion for 7 hours, weigh 3g of polyvinyl alcohol and dissolve it in 97g of deionized water, heat and stir at 94°C for 4 hours stand-by. Weigh 3g of ink that turns from blue to white at 38°C and disperse it in 97g of deionized water, ultrasonically disperse for 4 hours and set aside.

[0047] (2) Place the first polytetrafluoroethylene tube (1) vertically, the second polytetrafluoroethylene tube (3) is connected horizontally with the first polytetrafluoroethylene tube (1) through the first glass capillary tube (2), the second The three polytetrafluoroethylene tubes (5) are longitudinally connected to the second polytetrafluoroethylene tube (3) through the second glass capillary tube (4); all the polytetrafluoroethylene tubes and glass capillary tubes are connected with Henkel Baide AB glue Get a microfluidic device. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com