A kind of editable beaded polylactic acid fiber and its preparation method and application

A polylactic acid fiber, polylactic acid technology, which is applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of immature continuous production of intelligent fibers, and achieves suitable for large-scale preparation, good mechanical properties, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

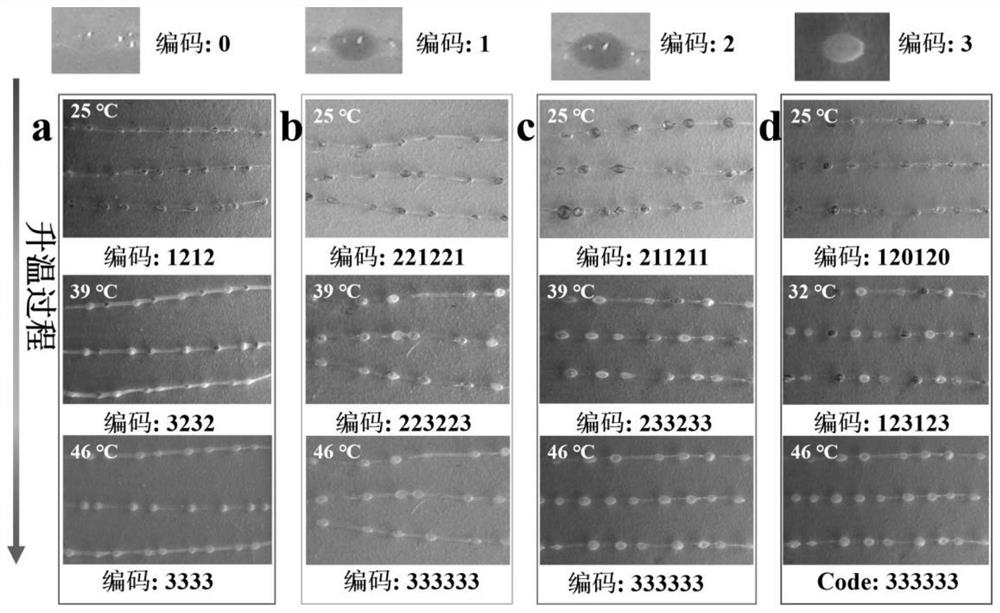

Embodiment 1

[0041] (1) 20g of polylactic acid particles are dispersed in 80g of methylene chloride solvent, 6h ultrasonic dispersion to obtain a uniform clear solution of polylactic acid, polyethylene glycol 400 liquid weighed 60mL standby. Weigh 10g 38 ℃ changed from blue to white, from green to white, the three colors red to white ink dispersion in an aqueous solution of 90g of polyvinyl alcohol 1wt%, respectively, ultrasonic dispersion 6h, giving three types of color ink dispersion was reserved.

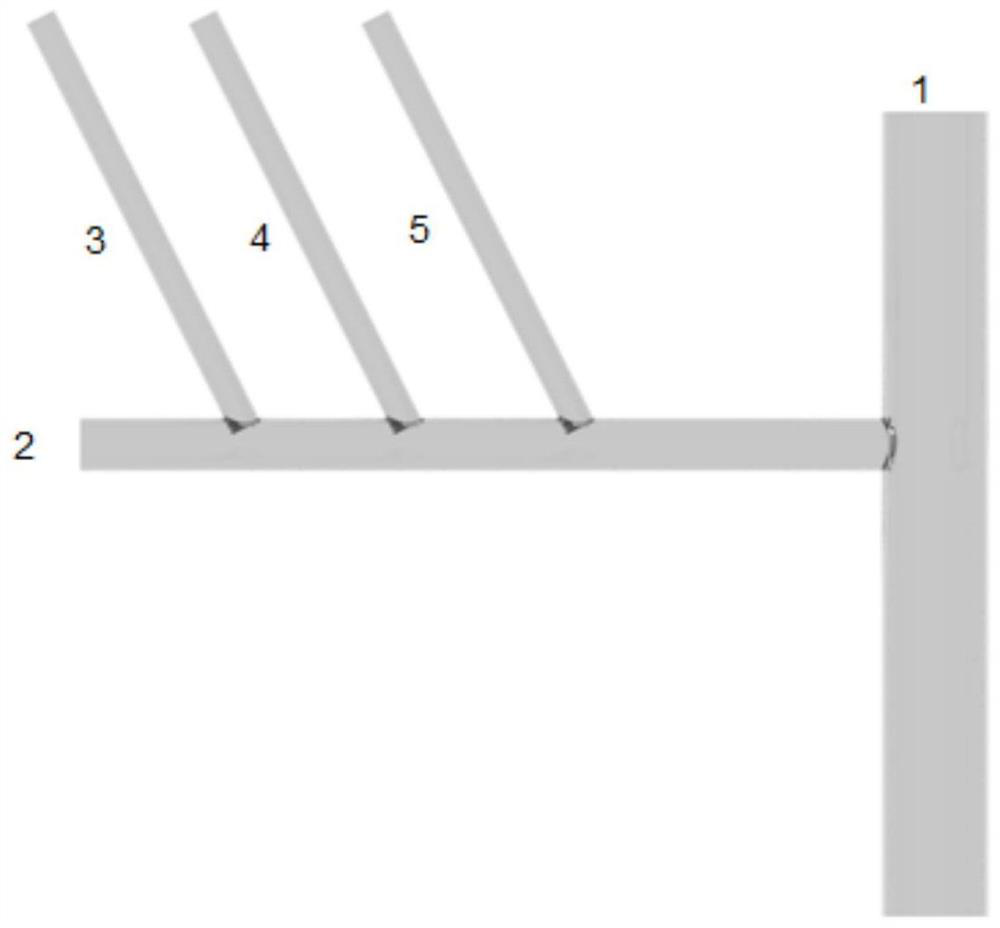

[0042] (2) using a Teflon tube microfluidic structures spinning apparatus, all the tubes are made of polytetrafluoroethylene Henkel Decker AB glue connection, the PTFE tube longitudinally disposed first, second PTFE vinyl tube 2 and the first transverse tube connected to PTFE, PTFE tube 3 the third, fourth polytetrafluoroethylene tube 4, sequentially fifth PTFE tube 5 and the second PTFE tube 2 longitudinally connected. Polyethylene glycol 400 is injected from a first PTFE tube 1, a polylactic ac...

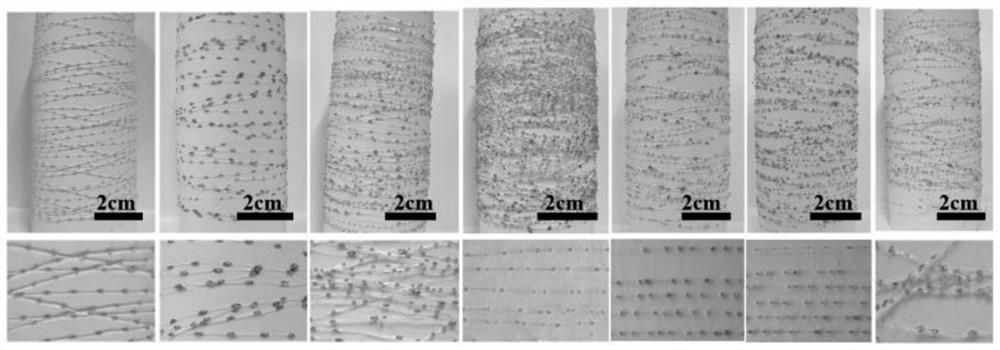

Embodiment 2

[0048] (1) 20g of polylactic acid particles are dispersed in 80g of methylene chloride solvent, 6h ultrasonic dispersion to obtain a uniform clear solution of polylactic acid, polyethylene glycol 400 liquid weighed 50mL standby. Weigh 11g 38 ℃ changed from blue to white, from green to white, the ink of three colors red to white are dispersed in 88g of an aqueous solution of 1wt% polyvinyl alcohol, ultrasonic dispersion 5h, to obtain three kinds of color ink dispersion was reserved.

[0049] (2) using a Teflon tube microfluidic structures spinning apparatus, device structures same as in Example 1, Step (1) corresponding to the five kinds of solution are also the same as in Example 1 PTFE tube implantation.

[0050] (3) The step (1) of Five solutions were charged five syringes, the syringe mounted in a microfluidic propulsion pump, syringe, and the step (2) tight connection microfluidic device, to adjust each injector advance rate: V 聚乳酸 = 25μL / min; rate of each color ink propulsi...

Embodiment 3

[0052] (1) 20g of polylactic acid particles are dispersed in 80g of methylene chloride solvent, 6h ultrasonic dispersion to obtain a uniform clear solution of polylactic acid, polyethylene glycol 400 liquid weighed 60mL standby. Weigh 12g 38 ℃ changed from blue to white, from green to white, the three colors red to white ink dispersion in an aqueous solution of 97g of polyvinyl alcohol 1wt%, respectively, ultrasonic dispersion 4h, to give three kinds of color ink dispersion was reserved.

[0053] (2) using a Teflon tube microfluidic structures spinning apparatus, device structures same as in Example 1, Step (1) corresponding to the five kinds of solution are also the same as in Example 1 PTFE tube implantation.

[0054] (3) The step (1) of Five solutions were charged five syringes, the syringe mounted in a microfluidic propulsion pump, syringe, and the step (2) tight connection microfluidic device, to adjust each injector advance rate: V 聚乳酸 = 25μL / min; rate of each color ink pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com