Potassium silicate compound finished product diatom ooze and preparation method thereof

A kind of potassium silicate and composite technology, which is applied in paints containing biocide, antifouling/underwater coatings, fireproof coatings, etc., can solve the problems of poor water resistance, film cracking, weathering, etc., and achieve excellent anti-mildew performance, good Stability, the effect of ensuring long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

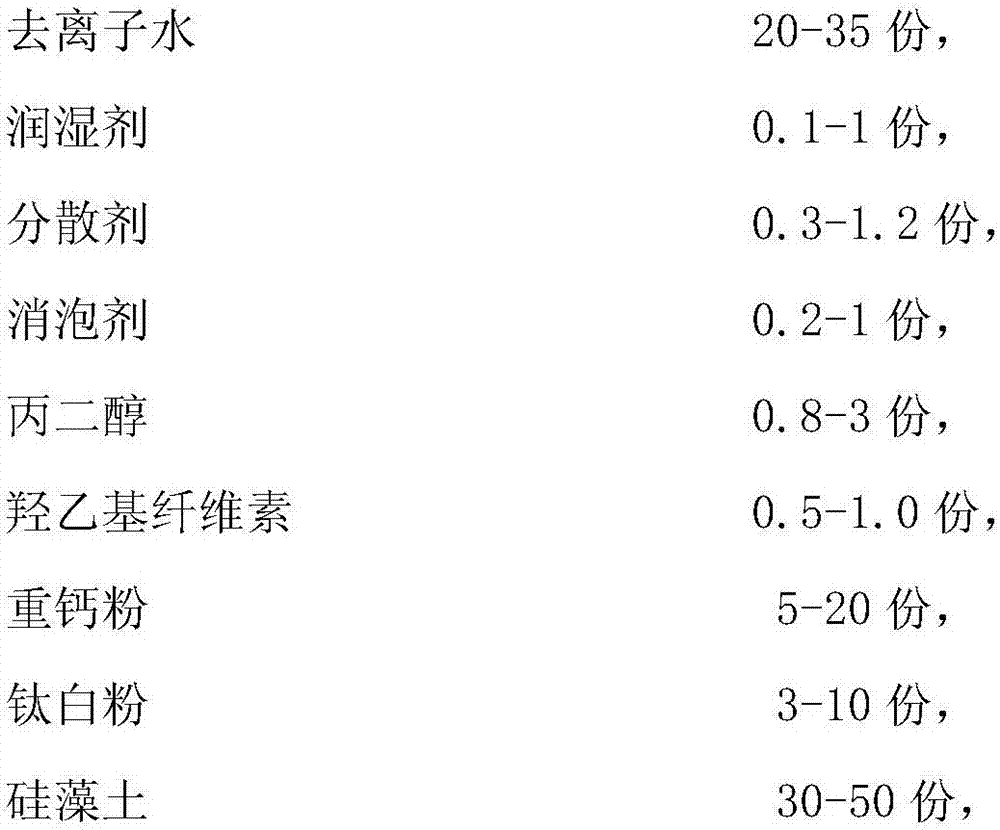

[0024] The technical solution adopted by the present invention is that a potassium silicate composite finished product diatom ooze comprises the following components in parts by weight:

[0025]

[0026]

[0027] The present invention also provides a preparation method of potassium silicate composite finished diatom ooze, comprising the following steps:

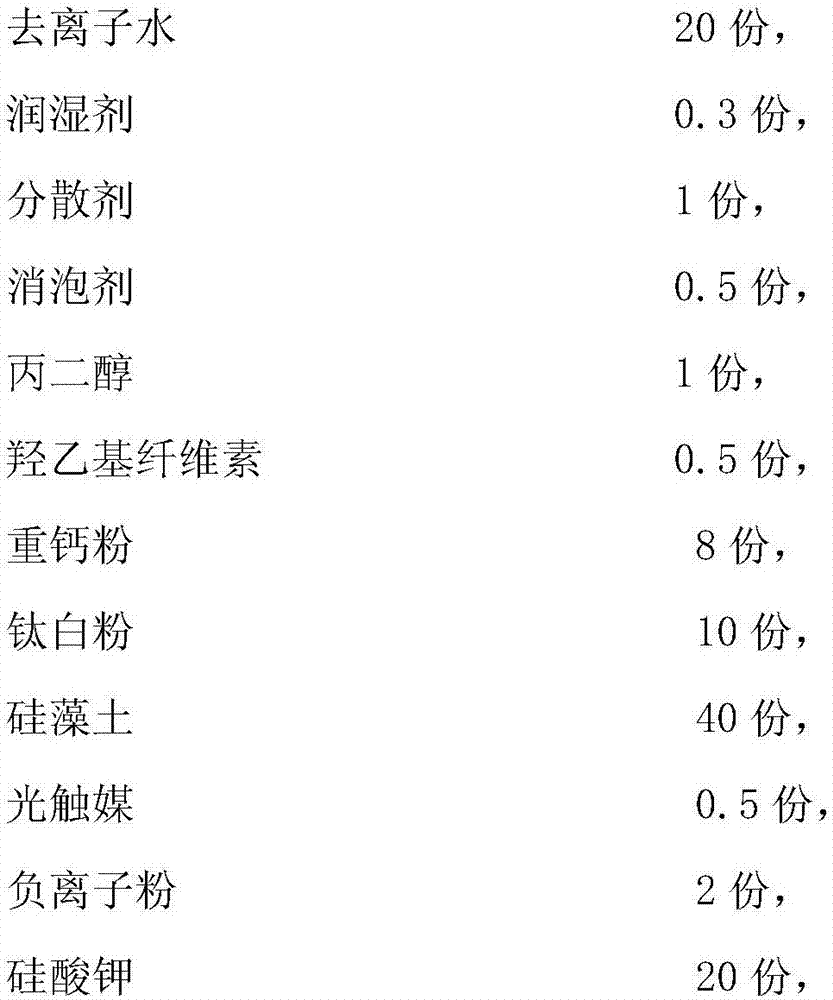

[0028] 1) Put 20 parts of deionized water into the reactor, and put in 0.3 parts of wetting agent, 1 part of dispersant, 0.2 parts of defoamer, 1 part of propylene glycol, and 0.5 parts of hydroxyethyl cellulose in sequence under stirring at a speed of 250r / min , dispersed for 15 minutes;

[0029] 2) Adjust the reaction kettle to a stirring speed of 1300r / min, add 8 parts of heavy calcium powder, 10 parts of titanium dioxide, 40 parts of diatomaceous earth, 0.5 parts of photocatalyst, and 2 parts of negative ion powder, and stir and disperse for 20 minutes;

[0030] 3) Adjust the reaction kettle to stir at a speed of 7...

Embodiment 2

[0032] The technical solution adopted by the present invention is that a potassium silicate composite finished product diatom ooze comprises the following components in parts by weight:

[0033]

[0034] The preparation method of potassium silicate composite type finished product diatom ooze comprises the following steps:

[0035] 1) Put 25 parts of deionized water into the reactor, and put in 0.3 parts of wetting agent, 1.2 parts of dispersing agent, 0.3 parts of defoamer, 0.8 parts of propylene glycol, and 0.8 parts of hydroxyethyl cellulose in sequence under stirring at a speed of 300r / min , dispersed for 20 minutes;

[0036] 2) Adjust the reaction kettle to a stirring speed of 1500r / min, add 5 parts of heavy calcium powder, 8 parts of titanium dioxide, 30 parts of diatomaceous earth, 1 part of photocatalyst, and 3 parts of negative ion powder, and stir and disperse for 20 minutes;

[0037] 3) Adjust the reactor to stir at a speed of 800r / min, add 18 parts of potassium ...

Embodiment 3

[0039] The technical solution adopted by the present invention is that a potassium silicate composite finished product diatom ooze comprises the following components in parts by weight:

[0040]

[0041] The preparation method of potassium silicate composite type finished product diatom ooze comprises the following steps:

[0042] 1) Put 30 parts of deionized water into the reactor, and then put in 0.2 parts of wetting agent, 0.8 parts of dispersant, 0.3 parts of defoamer, 1.2 parts of propylene glycol, and 0.6 parts of hydroxyethyl cellulose under stirring at a speed of 350r / min , dispersed for 15 minutes;

[0043] 2) Adjust the reaction kettle to a stirring speed of 1600r / min, add 6 parts of heavy calcium powder, 6 parts of titanium dioxide, 50 parts of diatomaceous earth, 1.5 parts of photocatalyst, and 2 parts of negative ion powder, and stir and disperse for 25 minutes;

[0044] 3) Adjust the reactor to stir at a speed of 900r / min, add 20 parts of potassium silicate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com