Finished-product-shaped inorganic environment-friendly diatom mud and preparation method thereof

An environmentally friendly, diatom mud technology, applied in the field of environmentally friendly materials, can solve the problems of difficulty in meeting the high requirements of brilliant colors and visual perception, inability to carry out on-site construction and color matching, and few color options, so as to achieve convenient construction and development. Good tank condition, effective adsorption and decomposition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

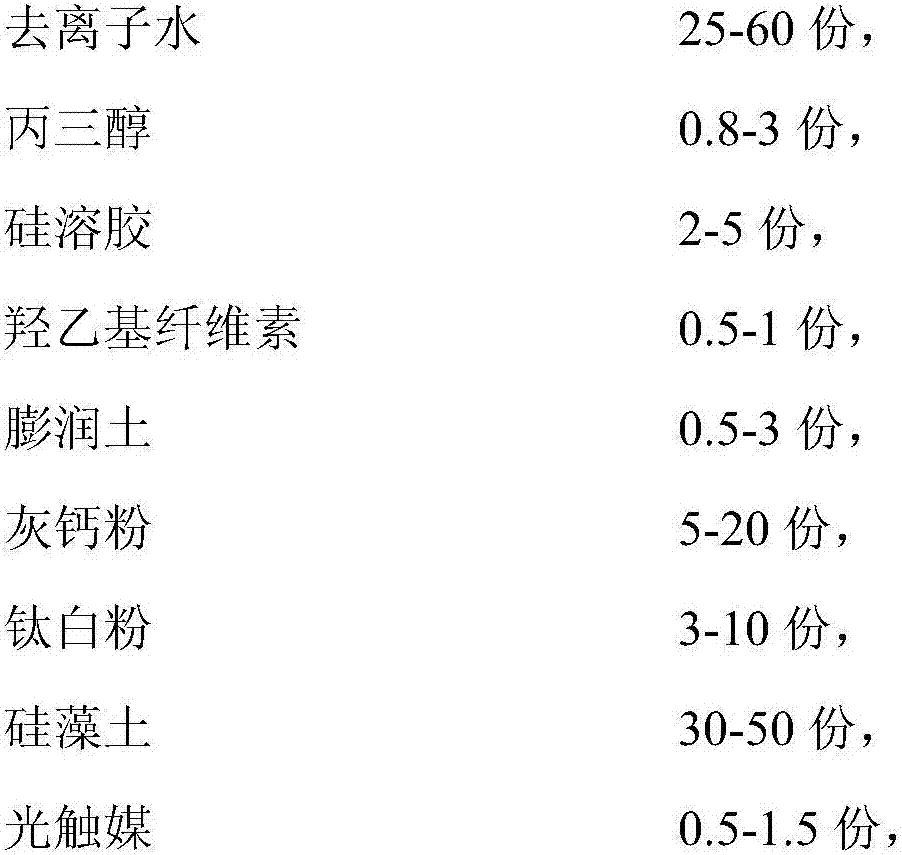

[0026] A finished inorganic environment-friendly diatom ooze, comprising the following components in parts by weight:

[0027]

[0028] Wherein, when preparing the finished shape inorganic environment-friendly diatom ooze, first 10 parts of deionized water, 10 parts of ash calcium powder and 0.5 part of ash calcium powder stabilizer are made into modified ash calcium powder for prepulping, and then mixed with remaining other The components are mixed to prepare a finished inorganic environment-friendly diatom mud.

[0029] The method for preparing the finished shape inorganic environment-friendly diatom ooze comprises the following steps:

[0030] 1) Add 10 parts of deionized water and 0.5 parts of ash calcium powder stabilizer to a dispersion container with stirring, and stir evenly at a speed of 250r / min; then add 10 parts of ash calcium powder and continue stirring for 20 minutes to make the ash calcium powder The powder is fully dispersed, and the processed modified ash...

Embodiment 2

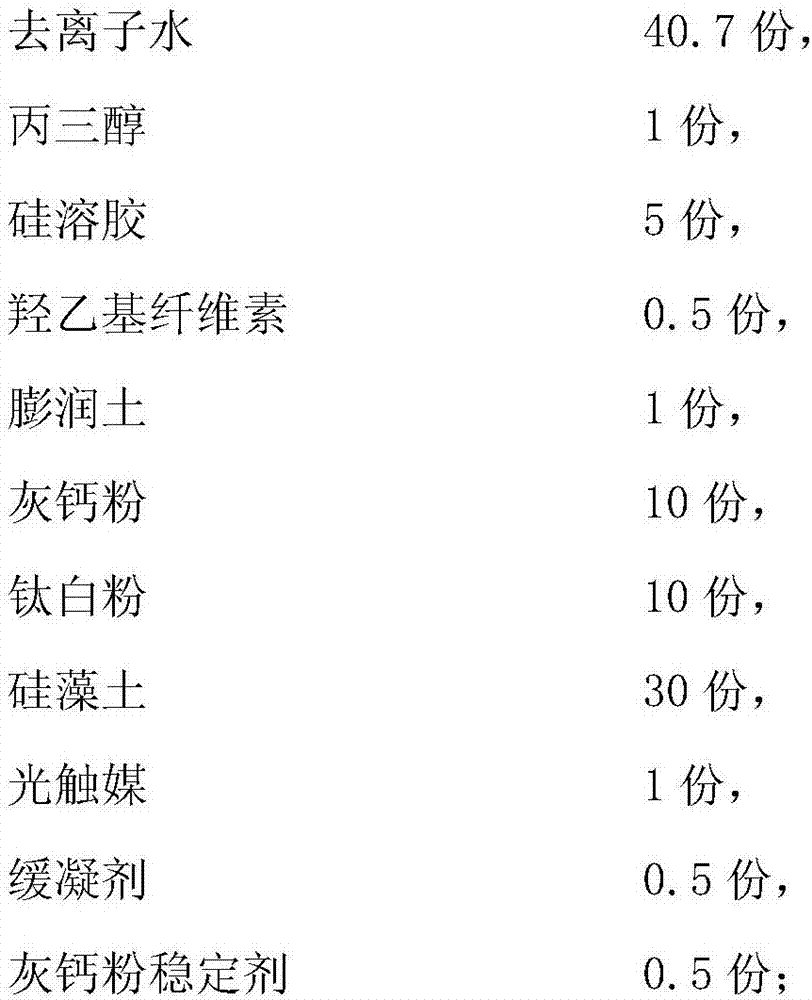

[0033] A finished inorganic environment-friendly diatom ooze, comprising the following components in parts by weight:

[0034]

[0035] Wherein, when preparing the finished inorganic environment-friendly diatom ooze, first 5 parts of deionized water, 5 parts of ash calcium powder and 0.5 part of ash calcium powder stabilizer are made into modified ash calcium powder pre-pulp, and then mixed with remaining other The components are mixed to prepare a finished inorganic environment-friendly diatom mud.

[0036] The method for preparing the finished shape inorganic environment-friendly diatom ooze comprises the following steps:

[0037] 1) Add 5 parts of deionized water and 0.5 parts of ash calcium powder stabilizer in a stirring dispersion container, and stir evenly at a speed of 300r / min; then add 5 parts of ash calcium powder, and continue stirring for 30 minutes to make the ash calcium powder The powder is fully dispersed, and the processed modified ash-calcium powder pre-...

Embodiment 3

[0040] A finished inorganic environment-friendly diatom ooze, comprising the following components in parts by weight:

[0041]

[0042] Wherein, when preparing the finished inorganic environment-friendly diatom ooze, first 6 parts of deionized water, 6 parts of ash calcium powder and 0.5 part of ash calcium powder stabilizer are made into modified ash calcium powder pre-slurry, and then mixed with remaining other diatom mud. The components are mixed to prepare a finished inorganic environment-friendly diatom mud.

[0043] The method for preparing the finished shape inorganic environment-friendly diatom ooze comprises the following steps:

[0044] 1) Add 6 parts of deionized water and 0.5 part of ash calcium powder stabilizer in a stirring dispersion container, and stir evenly at a speed of 350r / min; then add 6 parts of ash calcium powder, and continue stirring for 30 minutes to make the ash calcium powder The powder is fully dispersed, and the processed modified ash-calciu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com