A kind of silver-loaded nano-titanium dioxide bactericidal anti-mildew diatom mud and preparation method thereof

A nano-titanium dioxide and diatom mud technology, applied in the field of diatom mud coatings, can solve the problems of reduced utilization rate of nano-materials, difficult to achieve bactericidal effect, small color selection range, etc., to improve uniformity, improve indoor air purification efficiency, The effect of improving the surface sterilization and mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

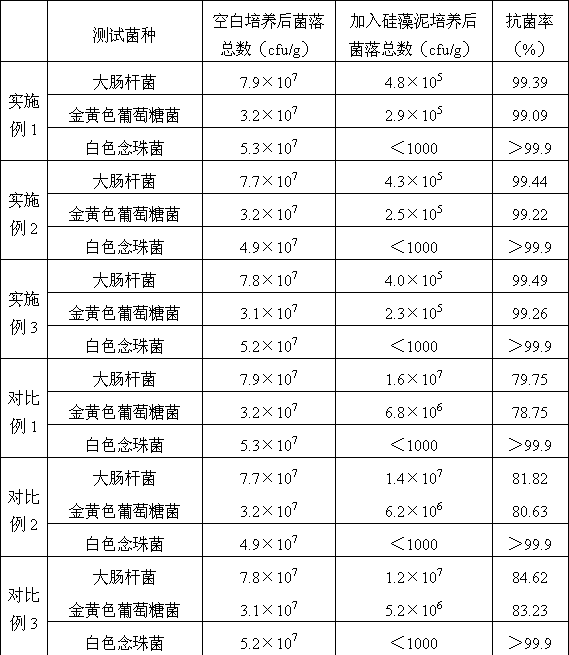

Examples

Embodiment 1

[0030] Add 17.5wt% deionized water to the reactor, add 0.2wt% dispersant, 0.1wt% wetting agent, 0.2wt% defoamer, 1wt% hydroxyethyl cellulose in sequence at 300 rpm, and disperse for 10 minutes , add 1wt% silver-loaded nano-titanium dioxide at a speed of 1500 rpm, and disperse at a high speed for 30 minutes until the fineness is below 50 μm to obtain a silver-loaded nano-titanium dioxide pre-pulp;

[0031] Add 22.3wt% deionized water to the reactor, add 1wt% glycerin, 2wt% nano-silica solution, 0.6wt% hydroxyethyl cellulose, and 0.3wt% bentonite in sequence at 300 rpm, and disperse for 15 minutes Finally, adjust the rotating speed to 1500 rpm, add 20wt% silver-loaded nano-titanium dioxide prefabricated slurry, 8wt% titanium dioxide, 15wt% 800 mesh ash calcium, 30wt% diatomite, 0.5wt% retarder, 0.3wt% ash Calcium stabilizer, stir and disperse evenly to get the finished product.

Embodiment 2

[0033] Add 19.4wt% deionized water to the reactor, add 0.2wt% dispersant, 0.1wt% wetting agent, 0.2wt% defoamer, 0.8wt% hydroxyethyl cellulose in sequence at 300 rpm, and disperse After 10 minutes, adjust the rotation speed to 1500 rpm and add 1.5wt% silver-loaded nano-titanium dioxide, and disperse at a high speed for 30 minutes until the fineness is below 50 μm to obtain a silver-loaded nano-titanium dioxide pre-pulp;

[0034] 29.7wt% deionized water was added to the reaction kettle, and 0.8wt% glycerol, 2.5wt% nano-silica solution, 0.3wt% hydroxyethyl cellulose, and 0.6wt% bentonite were added successively at 300 rpm. After dispersing for 15 minutes, adjust the speed to 1500 rpm, add 22.2wt% silver-loaded nano-titanium dioxide prefabricated slurry, 3wt% titanium dioxide, 12wt% 800 mesh ash calcium, 28wt% diatomaceous earth, 0.6wt% retarder, 0.3 Wt% ash calcium stabilizer, stir and disperse evenly to get the finished product.

Embodiment 3

[0036] Add 21.9wt% deionized water to the reactor, add 0.2wt% dispersant, 0.1wt% wetting agent, 0.2wt% defoamer, 0.6wt% hydroxyethyl cellulose in sequence at 300 rpm, and disperse After 10 minutes, adjust the rotation speed to 1500 rpm and add 2wt% silver-loaded nano-titanium dioxide, and disperse at a high speed for 30 minutes until the fineness is below 50 μm to obtain a silver-loaded nano-titanium dioxide pre-pulp;

[0037] Add 22wt% deionized water to the reaction kettle, add 1.2wt% glycerin, 3wt% nano-silica solution, 0.5wt% hydroxyethyl cellulose, 0.5wt% bentonite in sequence at 300 rpm, and disperse for 15 minutes Finally, adjust the rotating speed to 1500 rpm, add 25wt% silver-loaded nano-titanium dioxide prefabricated slurry, 5wt% titanium dioxide, 10wt% 800 mesh ash calcium, 32wt% diatomite, 0.5wt% retarder, 0.3wt% ash Calcium stabilizer, stir and disperse evenly to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com