Silicon-boron-carbon-nitrogen-zirconium ceramic composite material and preparation method thereof

A ceramic composite material, silicon boron carbon nitride zirconium technology, applied in the field of silicon boron carbon nitride based ceramic composite material and its preparation, can solve the problems of damage, easy to produce defects, limited application scope and the like, achieve simple process and short preparation period , the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples.

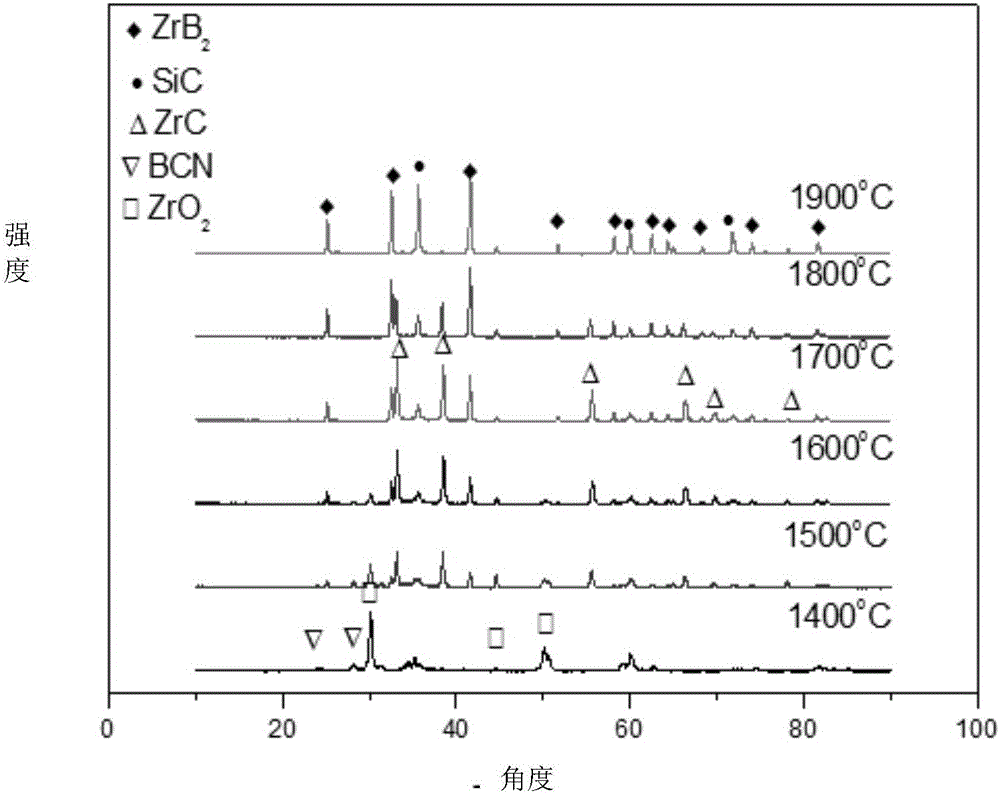

[0017] A silicon-boron-carbon-nitrogen-zirconium ceramic composite material involved in this embodiment is made of zirconium n-propoxide, acetylacetone, absolute ethanol, boron nitride powder, silicon powder and graphite powder, the zirconium n-propoxide, The molar ratio between acetylacetone and absolute ethanol is 1:2:10, and the molar ratio of boron nitride powder, silicon powder and graphite powder is 2:1:3.

[0018] A preparation method of silicon boron carbon nitrogen zirconium ceramic composite material,

[0019] Step 1. Mix zirconium n-propoxide, acetylacetone and absolute ethanol to prepare a sol solution and stir it magnetically; the molar ratio of zirconium n-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com