A kind of warm mix agent, SBS/SBR modified warm mix asphalt mixture and preparation method

A technology of warm mix asphalt and warm mix agent, which is applied in the direction of climate change adaptation, etc., can solve the problem that it is difficult to meet the performance requirements of warm mix asphalt mixture, the performance of asphalt mixture is high and low temperature is reduced, and it is difficult to ensure the performance requirements of asphalt mixture, etc. problems, to achieve the effect of improving water damage resistance, poor high temperature performance, and reducing harmful gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

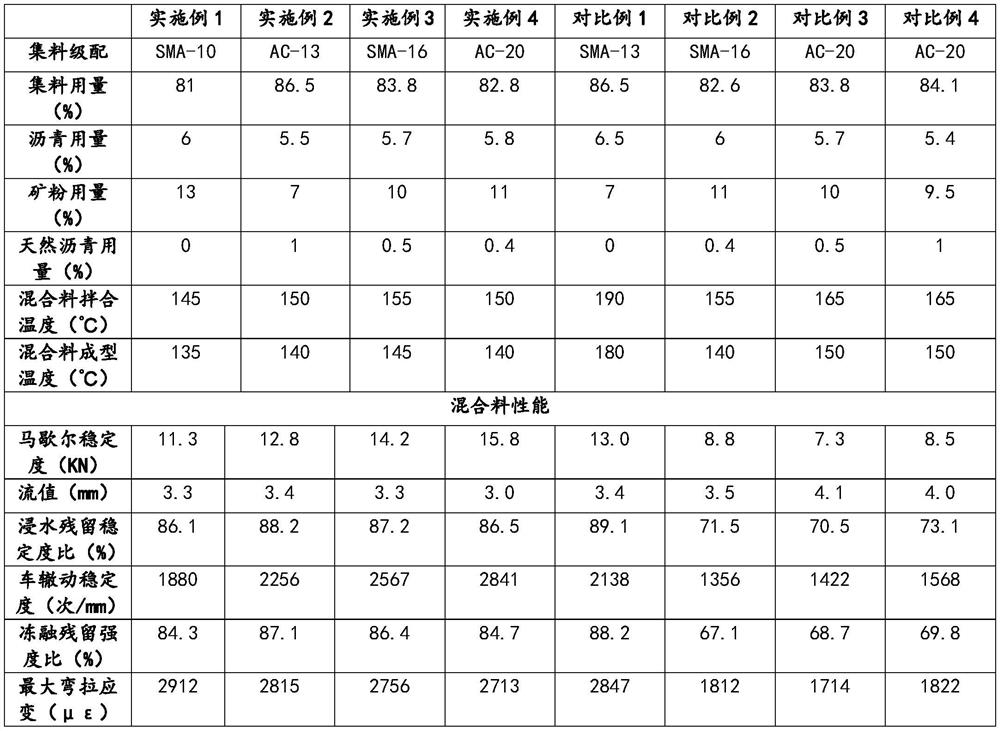

Examples

Embodiment 1

[0036] Preparation of warm mixing agent: Take 94% of aromatic oil, 4% of slaked lime and 2% of quaternary ammonium surfactant according to mass percentage, heat the aromatic oil to 80-130°C, and then add slaked lime and quaternary ammonium The salt surfactant is added to the aromatic oil, and stirred for 5-15 minutes to obtain a warm mixing agent.

[0037] Preparation of SBS modified warm mix asphalt: according to mass percentage, take 86% of 110# base asphalt, 4% of SBS modifier, and 10% of warm mix agent respectively; heat 110# base asphalt to a temperature of 130~ 150°C, then add SBS modifier to 110# base asphalt, shear and stir for 30 to 60 minutes to obtain SBS modified asphalt; finally add the aforementioned warm mix agent to SBS modified asphalt, and continue to shear and stir for 5 ~10 minutes to obtain SBS modified warm mix asphalt.

[0038] Preparation of SBS modified warm mix asphalt mixture: the aggregate is prepared into SMA-10 aggregate, and according to the mas...

Embodiment 2

[0040] Preparation of warm mixing agent: Take 86% aromatic oil, 8% slaked lime and 6% quaternary ammonium salt surfactant according to mass percentage, heat the aromatic oil to 80-130°C, and then mix slaked lime and quaternary ammonium The salt surfactant is added to the aromatic oil, and stirred for 5-15 minutes to obtain a warm mixing agent.

[0041]Preparation of SBR modified warm mix asphalt: according to the mass percentage, take 92% of 130# base asphalt, 2% of SBR modifier, and 6% of warm mix agent; heat 130# base asphalt to a temperature of 130~ 150°C, then add SBR modifier to 130# base asphalt, shear and stir for 30 to 60 minutes to obtain SBR modified asphalt; finally add the aforementioned warm mix agent to SBR modified asphalt, and continue to shear and stir for 5 ~10 minutes to obtain SBR modified warm mix asphalt.

[0042] Preparation of SBR modified warm-mix asphalt mixture: the aggregate is prepared into AC-13 aggregate, and 86.5% of aggregate, 5.5% of SBR modi...

Embodiment 3

[0044] Preparation of warm mixing agent: Take 90% of aromatic oil, 6% of slaked lime and 4% of quaternary ammonium surfactant according to mass percentage, heat the aromatic oil to 80-130°C, and then add slaked lime and quaternary ammonium The salt surfactant is added to the aromatic oil, and stirred for 5-15 minutes to obtain a warm mixing agent.

[0045] Preparation of SBS modified warm mix asphalt: according to mass percentage, take 89% of 110# base asphalt, 3% of SBS modifier, and 8% of warm mix agent respectively; heat 110# base asphalt to a temperature of 130~ 150°C, then add SBS modifier to 110# base asphalt, shear and stir for 30 to 60 minutes to obtain SBS modified asphalt; finally add the aforementioned warm mix agent to SBS modified asphalt, and continue to shear and stir for 5 ~10 minutes to obtain SBS modified warm mix asphalt.

[0046] Preparation of SBS modified warm mix asphalt mixture: the aggregate is prepared into SMA-16 aggregate, and 83.8% of aggregate, 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com