Thermochromic PLA (polylactic acid) fiber of core-shell structure as well as preparation method and application of thermochromic PLA fiber

A polylactic acid fiber, core-shell structure technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., to achieve the effect of wide color selectivity and wide discoloration temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Disperse 25g of polylactic acid particles in 80g of dichloromethane solvent, ultrasonically disperse for 8h to obtain a uniform and clear polylactic acid solution, weigh 100mL of polyethylene glycol 400 for standby; 10g, disperse the temperature-sensitive color-changing ink in 85g deionized water, add 5g of sodium alginate to the deionized water mixed with the temperature-sensitive color-changing ink, and ultrasonically disperse for 6 hours to obtain a mixed aqueous solution of red color-changing ink and sodium alginate for use.

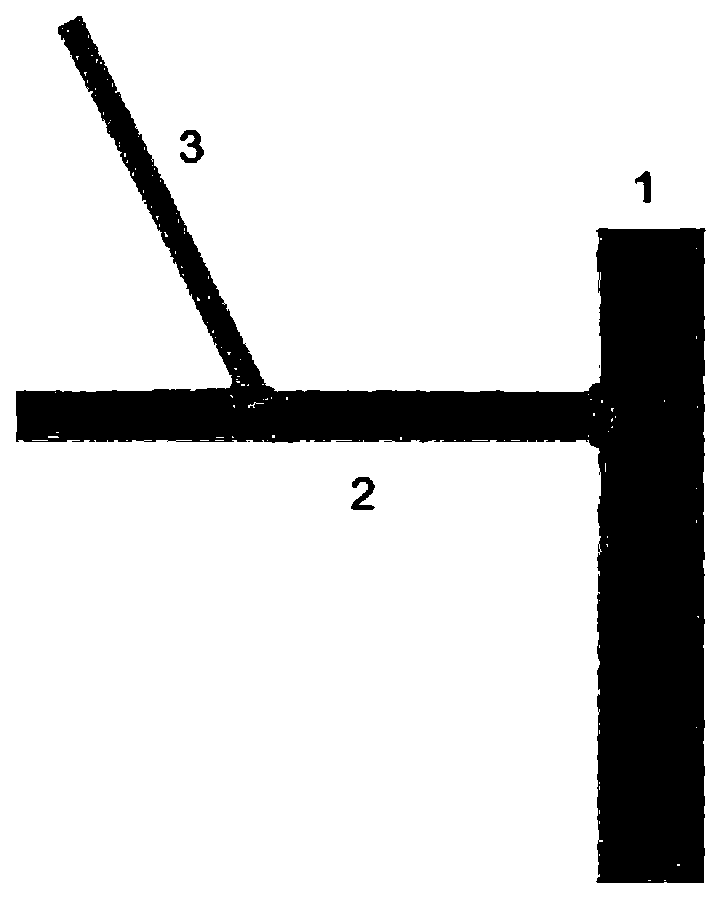

[0043] (2) The first PTFE pipe 1 is placed longitudinally, the second PTFE pipe 2 is laterally connected with the first PTFE pipe 1, and the third PTFE pipe 3 is connected with the second PTFE pipe The tubes 2 are connected longitudinally; the joints are sealed with epoxy resin glue to obtain a microfluidic device. The diameters of the first polytetrafluoroethylene pipe 1 , the second polytetrafluoroethylene pipe 2 , and the third polytetr...

Embodiment 2

[0050] (1) Disperse 20g of polylactic acid particles in 80g of dichloromethane solvent, ultrasonicate for 8h to obtain a uniform and clear polylactic acid solution, take 120mL of polyethylene glycol 400 for standby; Disperse the green thermochromic ink in 81 g of deionized water, add 6 g of sodium alginate to the deionized water mixed with the green thermochromic ink, and ultrasonically disperse for 7 hours to obtain a mixed aqueous solution of the green thermochromic ink and sodium alginate for later use.

[0051] (2) The first PTFE pipe 1 is placed longitudinally, the second PTFE pipe 2 is laterally connected with the first PTFE pipe 1, and the third PTFE pipe 3 is connected with the second PTFE pipe The tubes 2 are connected longitudinally; the joints are sealed with epoxy resin glue to obtain a microfluidic device. The diameters of the first polytetrafluoroethylene pipe 1 , the second polytetrafluoroethylene pipe 2 , and the third polytetrafluoroethylene pipe 3 are 2 mm, 1...

Embodiment 3

[0054] (1) Disperse 16g of polylactic acid particles in 80g of dichloromethane solvent, ultrasonically disperse for 8h to obtain a homogeneous and clear polylactic acid solution, and weigh 140mL of polyethylene glycol 400 for standby; 15g of ink and 7g of sodium alginate were dispersed in 78g of deionized water, and ultrasonically dispersed for 8h to obtain a mixed solution of blue color-changing ink, water and sodium alginate.

[0055] (2) The first PTFE pipe 1 is placed longitudinally, the second PTFE pipe 2 is laterally connected with the first PTFE pipe 1, and the third PTFE pipe 3 is connected with the second PTFE pipe The tubes 2 are connected longitudinally; the joints are sealed with epoxy resin glue to obtain a microfluidic device. The diameters of the first polytetrafluoroethylene pipe 1 , the second polytetrafluoroethylene pipe 2 , and the third polytetrafluoroethylene pipe 3 are 2 mm, 1 mm, and 500 μm, respectively.

[0056] (3) three kinds of solutions (dichlorom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com