Thermo-sensitive and degradable micro hydrogel as well as preparation method and application thereof

A temperature-sensitive, micro-water technology, which is used in medical preparations, pharmaceutical sciences, prostheses, etc. with non-active ingredients, and can solve problems such as non-biodegradable properties, limited application scope, and life hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

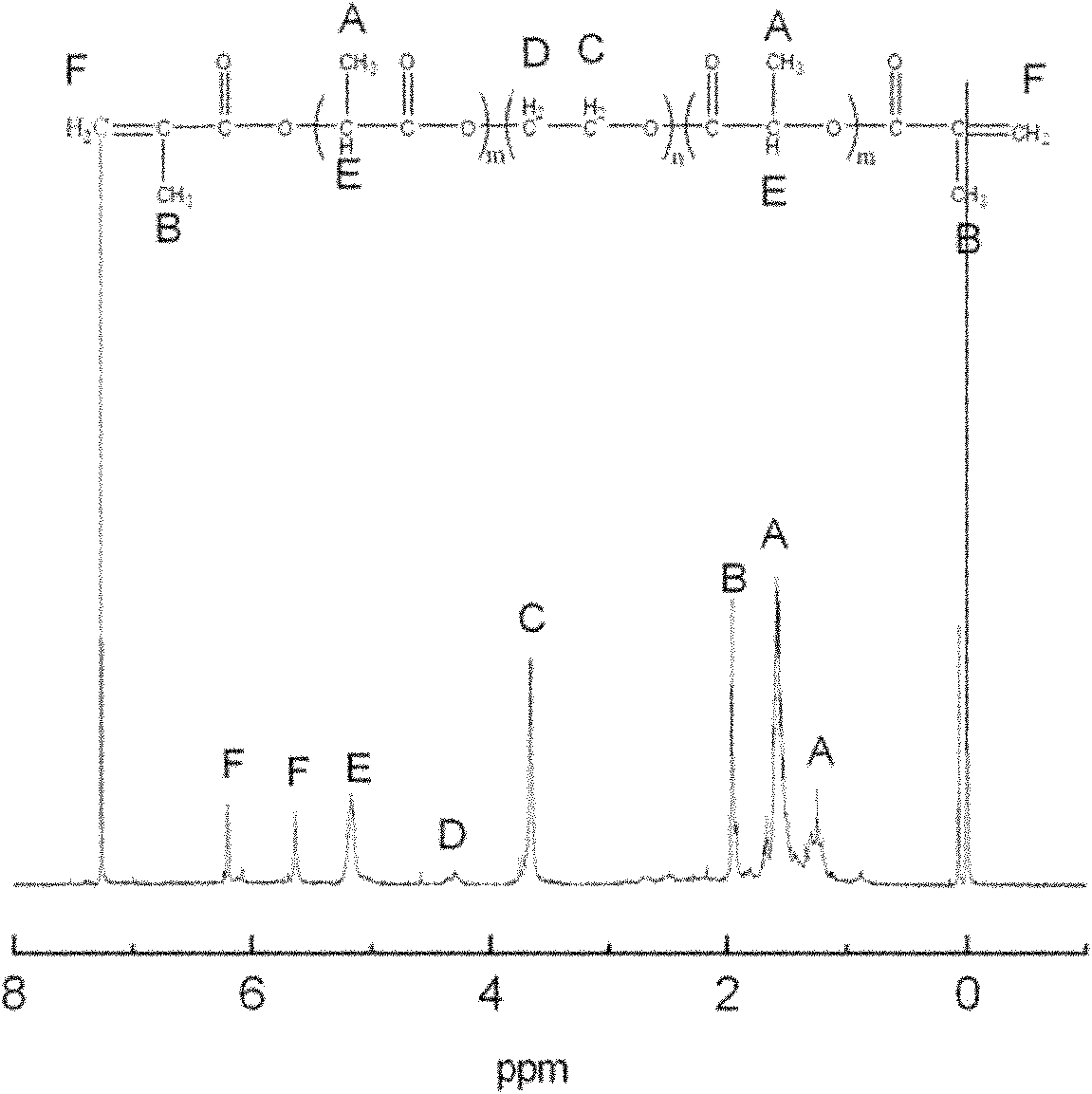

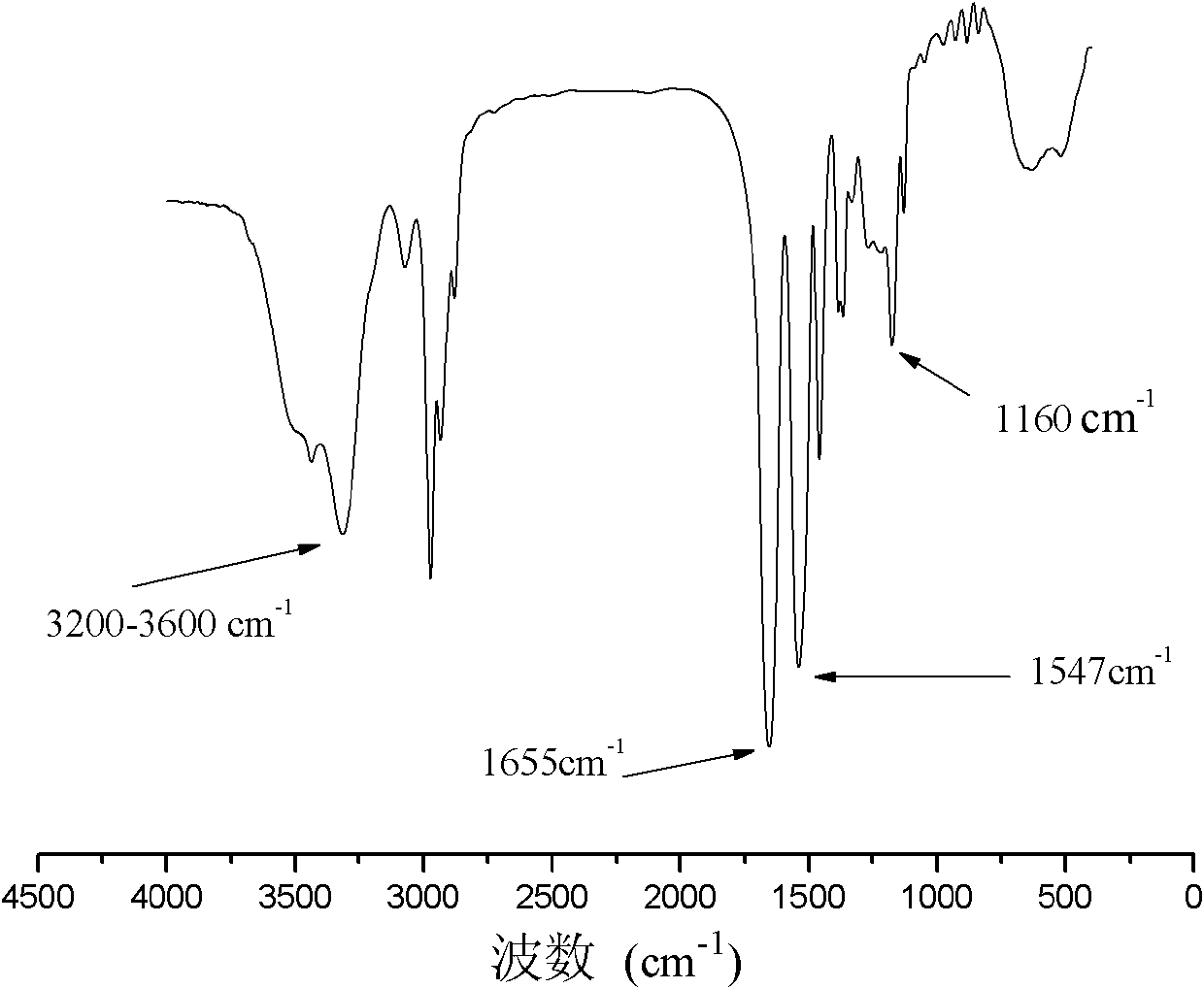

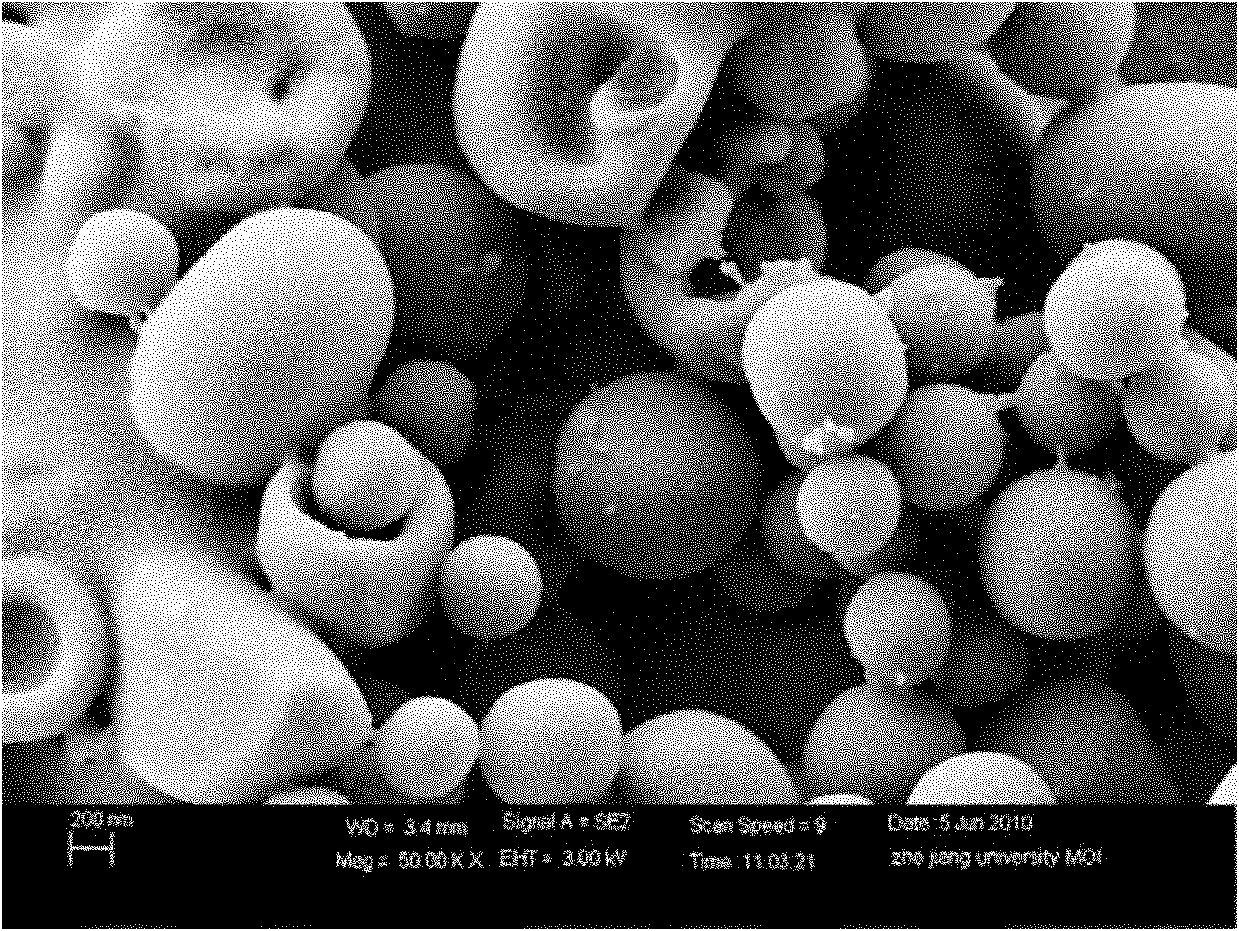

[0054] Put a stirring magnet into a 100ml three-neck flask, vacuumize, bake with an alcohol lamp to remove water, fill with nitrogen, and repeat three times. Add 7.5g of polyethylene glycol (number average molecular weight: 1000) and 4.32g of L-lactide to the three-necked flask under nitrogen protection, heat to melt, add 0.1ml of stannous octoate dropwise under stirring, and vacuumize , the temperature of the oil bath was raised to 130° C. for 24 hours. After the product was cooled to room temperature, the product was dissolved with as little chloroform as possible, and precipitated in a large amount of n-hexane to obtain a yellow-brown oily viscous liquid. Pour off the upper layer of n-hexane, then dissolve it with a small amount of chloroform, precipitate a large amount of n-hexane, centrifuge and filter the precipitate for three times, and then dry the precipitate.

[0055] Dissolve the dried product in a 100ml three-necked flask with 40ml of refluxed tetrahydrofuran, con...

Embodiment 2

[0062]Put a stirring magnet into a 100ml three-neck flask, vacuumize, bake with an alcohol lamp to remove water, fill with nitrogen, and repeat three times. Add 11.25g of polyethylene glycol (number average molecular weight 1500) and 4.32g of L-lactide to the three-necked flask under nitrogen protection, heat and make it melt, add dropwise 0.1ml of stannous octoate under stirring, vacuumize, The temperature of the oil bath was raised to 130° C. for 24 hours. After the product was cooled to room temperature, the product was dissolved with as little chloroform as possible, and precipitated in a large amount of n-hexane to obtain a yellow-brown oily viscous liquid. Pour off the upper layer of n-hexane, then dissolve it with a small amount of chloroform, precipitate a large amount of n-hexane, centrifuge and filter the precipitate for three times, and then dry the precipitate.

[0063] Dissolve the dried product in a 100ml three-necked flask with 40ml of refluxed tetrahydrofuran,...

Embodiment 3

[0067] Put a stirring magnet into a 100ml three-neck flask, vacuumize, bake with an alcohol lamp to remove water, fill with nitrogen, and repeat three times. Add 15g of polyethylene glycol (number average molecular weight 2000) and 4.32g of L-lactide to the three-necked flask under the protection of nitrogen, heat to make it melt, add 0.1ml of stannous octoate dropwise under stirring, vacuumize, oil The bath was heated to 130°C for 24 hours. After the product was cooled to room temperature, the product was dissolved with as little chloroform as possible, and precipitated in a large amount of n-hexane to obtain a yellow-brown oily viscous liquid. Pour off the upper layer of n-hexane, then dissolve it with a small amount of chloroform, precipitate a large amount of n-hexane, centrifuge and filter the precipitate for three times, and then dry the precipitate.

[0068] Dissolve the dried product in a 100ml three-necked flask with 40ml of refluxed tetrahydrofuran, connect it to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com