Continuous preparation method of foaming material, foaming pretreatment device, and foaming device

A technology of pretreatment device and foaming material, which is applied in the fields of continuous preparation of foaming material, foaming pretreatment device and foaming device, can solve the problems of inability to realize continuous foaming, etc., and achieves low toxicity and foaming performance. Excellent, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

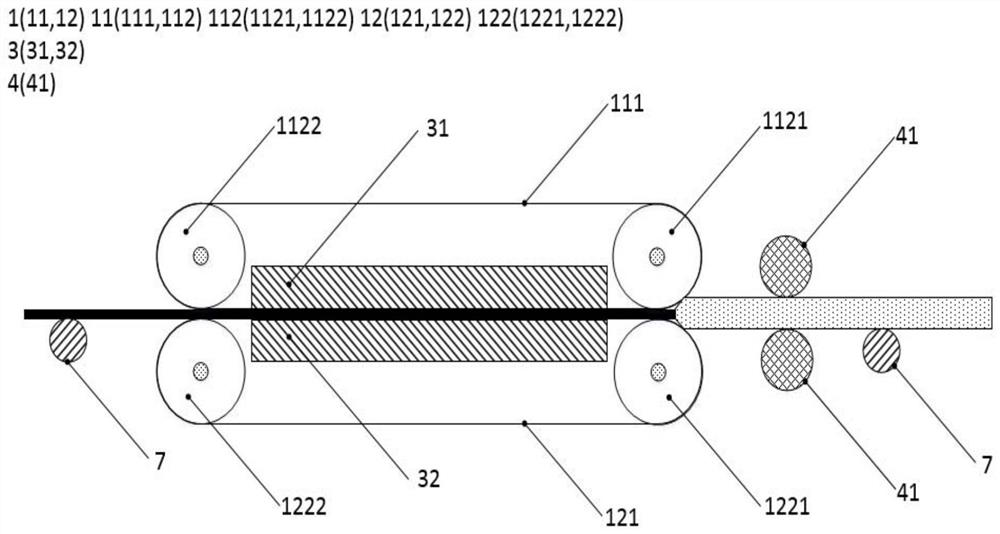

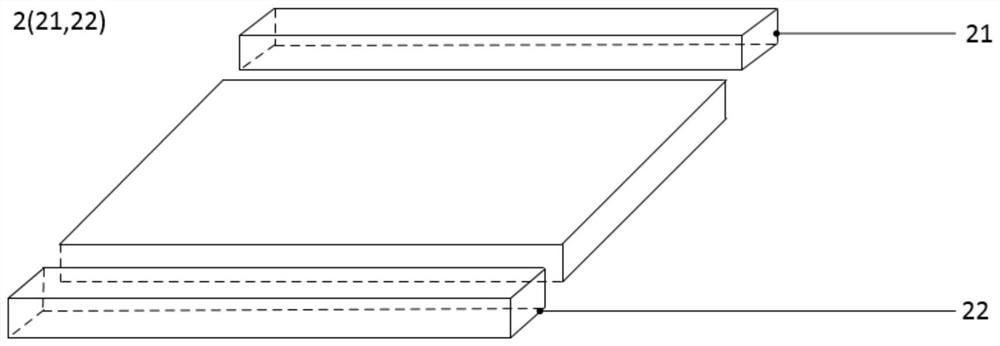

[0080] This embodiment provides a foaming pretreatment device, such as figure 1 with figure 2 As shown, it includes a transmission mechanism 1 , a limit mechanism 2 and a heating mechanism 3 . Wherein, the limiting mechanism 2 and the heating mechanism 3 are arranged inside the transmission structure.

[0081] Such as figure 1 As shown, the conveying mechanism 1 has a first conveying assembly 11 and a second conveying assembly 12 arranged oppositely, and a conveying gap for conveying the material to be foamed is reserved between the first conveying assembly 11 and the second conveying assembly 12, and the conveying mechanism 1 applying a first pressure to the material to be foamed in a vertical direction perpendicular to its transport direction. Wherein, the first conveying assembly 11 includes a first conveying press belt 111 and a first driving roller 112, and the first driving roller 112 includes first driving rollers arranged at required intervals along the conveying d...

Embodiment 2

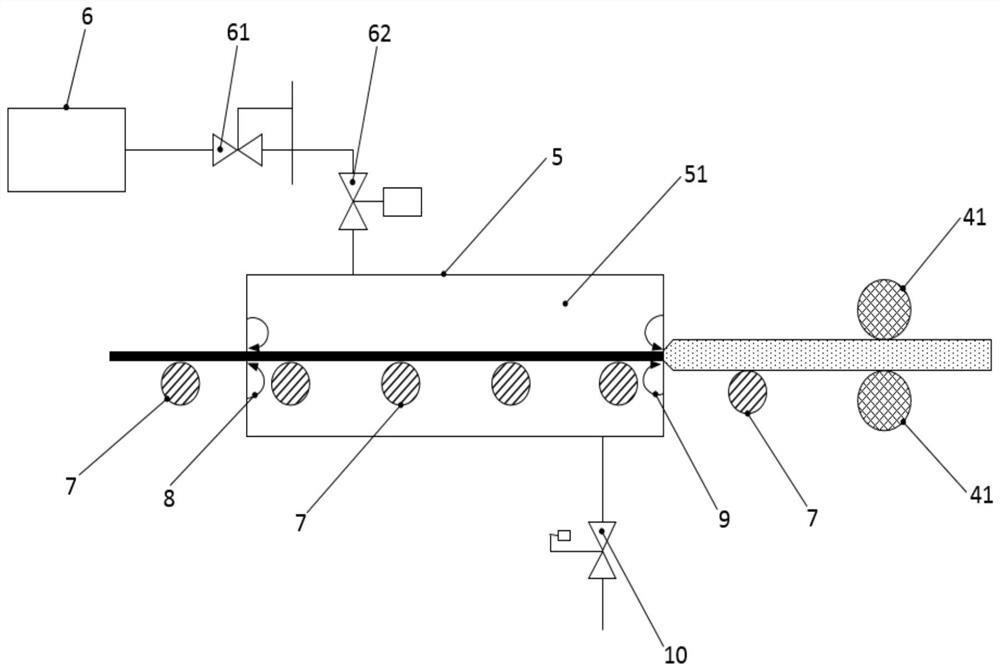

[0090] This embodiment provides a foaming pretreatment device, such as image 3 As shown, a required number of support members 7, foam boxes 5 and steam generators 6 are included. Wherein, the foaming box 5 has a foaming inner cavity 51 , and the support member 7 is disposed in the foaming inner cavity 51 of the foaming box 5 .

[0091] Such as image 3 As shown, the steam generator 6 communicates with the foaming box 5 through pipelines, and steam with required temperature and pressure is generated in the steam generator 6, and the steam is transported to the foaming inner chamber 51 of the foaming box 5 through the pipelines. A pressure valve 61 and an intake valve 62 are sequentially arranged on the pipeline connecting the steam generator 6 and the foaming tank 5, and the pressure of the steam delivered from the steam generator 6 to the foaming tank 5 is further adjusted through the pressure valve 61 , the delivery of steam to the foaming tank 5 is controlled by the intak...

Embodiment 3

[0099] This embodiment provides a foaming device, including any foaming pretreatment device provided in Embodiment 1 or Embodiment 2.

[0100] The foaming device also includes an autoclave connected to the foaming pretreatment device, and the autoclave provides a second pressure and a dissolution temperature for dissolving the physical foaming agent in the material to be foamed. Dissolve the physical foaming agent in the material to be foamed in the autoclave to form a homogeneous system, and the material to be foamed filled with the physical foaming agent is transported to the foaming pretreatment device. was heated to the foaming temperature. The material to be foamed cannot be expanded and foamed during the process of being heated by the foaming pretreatment device, so that the material to be foamed is uniformly heated to the foaming temperature without foaming. After the foaming material is conveyed away from the foaming pretreatment device, it is foamed instantly at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com