A kind of preparation method of polyborosilazane with high softening point

A technology of polyborosilazane and high softening point, which is applied in the field of preparation of SiBNC ceramic precursors, can solve the problems of low ceramic yield and achieve the effects of high batch stability, simple process and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

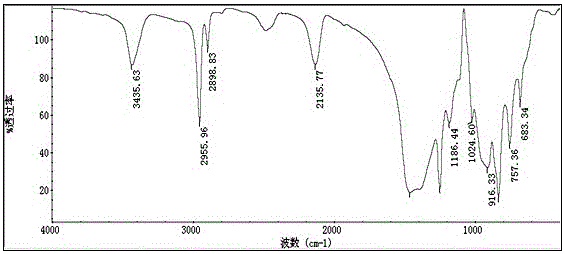

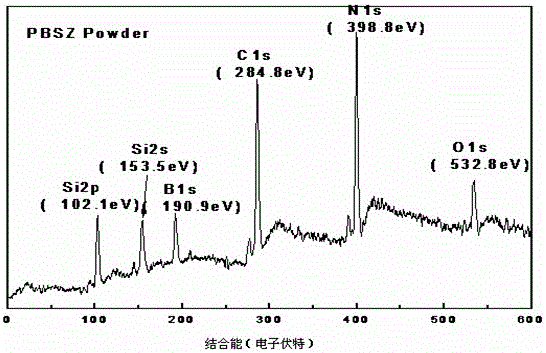

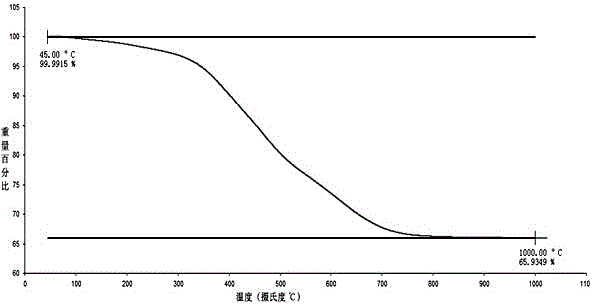

Image

Examples

Embodiment 1

[0024] This embodiment includes the following steps:

[0025] (1) Replace nitrogen in the reaction kettle with stirring, temperature measuring, feeding, ventilating, discharging and distillation devices;

[0026] (2) Weigh trichlorosilane, B, B'-dimethylborazine: heptamethyldisilazane molar ratio of 1:0.5:6 Methylborazine, heptamethyldisilazane;

[0027] (3) First add trichlorosilane, B, B'-dimethylborazine to the reactor respectively, and cool the reactor to minus 5°C; then add heptamethyldisilazane at 0.01 liter / min Speed into the reaction kettle, keep stirring;

[0028] (4) After the feeding is completed, heat the reactor to 300°C, and distill at this temperature for 16 hours under atmospheric pressure;

[0029] (5) After the distillation at atmospheric pressure, lower the temperature of the reactor by 50°C, and distill under reduced pressure at this temperature for 1 hour (vacuum degree 0.5kPa), and cool to room temperature to obtain 95g of high softening point polybo...

Embodiment 2

[0035] This embodiment includes the following steps:

[0036] (1) Replace nitrogen in the reaction kettle with stirring, temperature measuring, feeding, ventilating, discharging and distillation devices;

[0037] (2) Weigh trichlorosilane, B, B'-dimethylborazine: heptamethyldisilazane molar ratio of 1:1:6 Methylborazine, heptamethyldisilazane;

[0038] (3) Add trichlorosilane and B, B'-dimethylborazine to the reaction kettle respectively, and cool the reaction kettle to -55°C below zero; then add heptamethyldisilazane at 0.05 liter / Add the reaction kettle at a speed of 1 minute and keep stirring;

[0039] (4) After the feeding is completed, heat the reactor to 250°C, and distill at atmospheric pressure for 25 hours at this temperature;

[0040] (5) After the distillation at atmospheric pressure, lower the temperature of the reactor by 60°C, and distill under reduced pressure at this temperature for 0.3 hours (vacuum degree 0.1kPa), and cool to room temperature to obtain 11...

Embodiment 3

[0043] This embodiment includes the following steps:

[0044] (1) Replace nitrogen in the reaction kettle with stirring, temperature measuring, feeding, ventilating, discharging and distillation devices;

[0045](2) Weigh methylvinylchlorosilane according to the molar ratio of methylvinylchlorosilane: B, B'-diethylborazine: heptamethyldisilazane: 1:1.5:8 Silane, B, B'-diethylborazine, heptamethyldisilazane;

[0046] (3) Add methylvinylchlorosilane and B, B'-diethylborazine to the reactor respectively, and cool the reactor to minus 35°C; then add heptamethyldisilazane at 0.1 The speed of liters / minute is added in the reactor, keep stirring;

[0047] (4) After the feeding is completed, heat the reactor to 300°C, and distill at this temperature for 8 hours under atmospheric pressure;

[0048] (5) After the distillation at atmospheric pressure, lower the temperature of the reactor by 45°C, conduct vacuum distillation for 1 hour (vacuum degree 2kPa), and cool to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com