Method for preparing (Y1-xYbx)AG transparent ceramic from monodisperse spherical Y2O3 and Al2O3 powder

A transparent ceramic, monodisperse technology, applied in the field of materials, can solve the problems that restrict the development of YAG transparent ceramics, high activation energy between molecules, and difficult to mix uniformly, and achieve the effects of being conducive to sintering, easy to promote, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

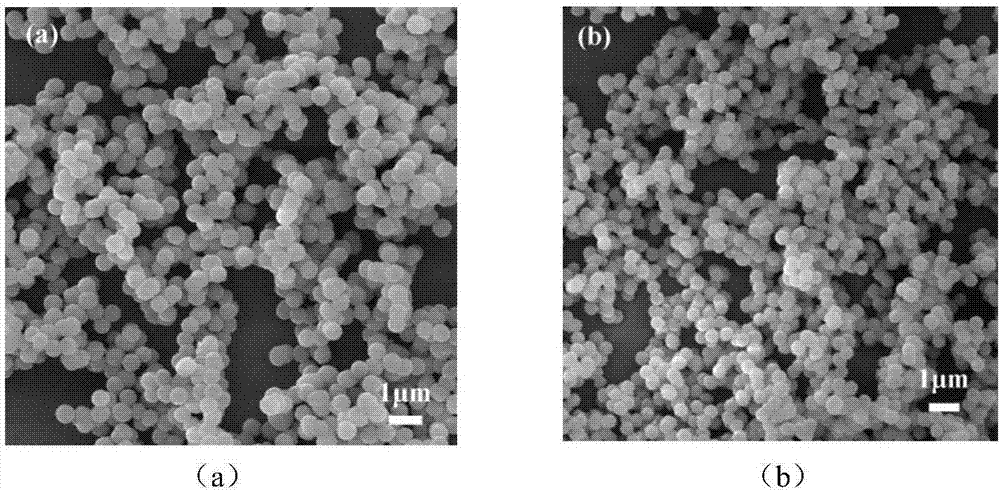

[0021] Step 1, preparing monodisperse spherical Y 2 o 3 powder

[0022] Monodisperse spherical Y 2 o 3 The preparation of the powder adopts the homogeneous precipitation method. First set Y 2 o 3 powder dissolved in an appropriate amount of hot concentrated HNO 3 get Y(NO 3 ) 3 solution, prepared as a 500mL mixed solution, in which Y(NO 3 ) 3 Concentration 0.15M and CO(NH 2 ) 2 The concentration was 0.5M, and stirred evenly, the mixed solution was heated to 90°C and kept for 2h. After the end, the precipitate was cooled, centrifuged, washed with deionized water and absolute ethanol, and dried in an oven at 80°C for 24 hours to obtain a white and soft Y2 o 3 Precursor powder. The precursor was ground, sieved, and then calcined in a muffle furnace at 900°C to obtain Y 2 o 3 Powder.

[0023] Step 2, preparing monodisperse spherical Al 2 o 3 powder

[0024] First prepare Al(NO 3 ) 3 solution, prepared as a 500mL mixed solution, in which Al(NO 3 ) 3 The conc...

Embodiment 2

[0028] Step 1, preparing monodisperse spherical Y 2 o 3 Powder

[0029] Monodisperse spherical Y 2 o 3 The preparation of the powder adopts the homogeneous precipitation method; first, prepare a mixed solution of 0.5L, wherein Y(NO 3 ) 3 The concentration is 0.1M and CO(NH 2 ) 2 The concentration is 0.2M, and stir evenly, heat the mixed solution to 80°C, and keep it warm for 2h; after the end, the precipitate is cooled, centrifuged, washed with deionized water and absolute ethanol, and dried in an oven at 80°C for 24h to obtain white Fluffy Y 2 o 3 Precursor powder; the precursor is ground, sieved, and then calcined in a muffle furnace at 900°C to obtain Y 2 o 3 Powder.

[0030] Step 2, preparing monodisperse spherical Al 2 o 3 powder

[0031] Al(NO 3 ) 3 solution, prepare a mixed solution of 0.5L, in which Al(NO 3 ) 3 The concentration is 0.002M, (NH 4 ) 2 SO 4 The concentration is 0.002M and CO(NH 2 ) 2 The concentration is 0.05M, and stir evenly, heat...

Embodiment 3

[0035] Step 1, preparing monodisperse spherical Y 2 o 3 powder

[0036] Monodisperse spherical Y 2 o 3 The preparation of the powder adopts the homogeneous precipitation method; firstly, the mixed solution is prepared, wherein Y(NO 3 ) 3 The concentration is 0.2M and CO(NH 2 ) 2 The concentration is 0.7M, and stir evenly, heat the mixed solution to 80-100°C, and keep it warm for 2h; after the end, the precipitate is cooled, centrifuged, washed with deionized water and absolute ethanol, and dried in an oven at 80°C for 24h get white fluffy y 2 o 3 Precursor powder; the precursor is ground, sieved, and then calcined in a muffle furnace at 900°C to obtain Y 2 o 3 Powder.

[0037] Step 2, preparing monodisperse spherical Al 2 o 3 Powder

[0038] Al(NO 3 ) 3 solution, prepared as a mixed solution, in which Al(NO 3 ) 3 Concentration of 0.01M, (NH 4 ) 2 SO 4 The concentration is 0.008M and CO(NH 2 ) 2 The concentration is 0.15M, and stir evenly, heat the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com